High-flexural-fatigue-life aviation sidewall rubber as well as preparation method and application thereof

A technology of fatigue life and sidewall rubber, applied in the field of rubber, can solve the problems of low strength, poor processability of butadiene rubber, solar radiation aging resistance, etc., achieve high constant tensile stress, high flex fatigue life, and extend sidewall The effect of glue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

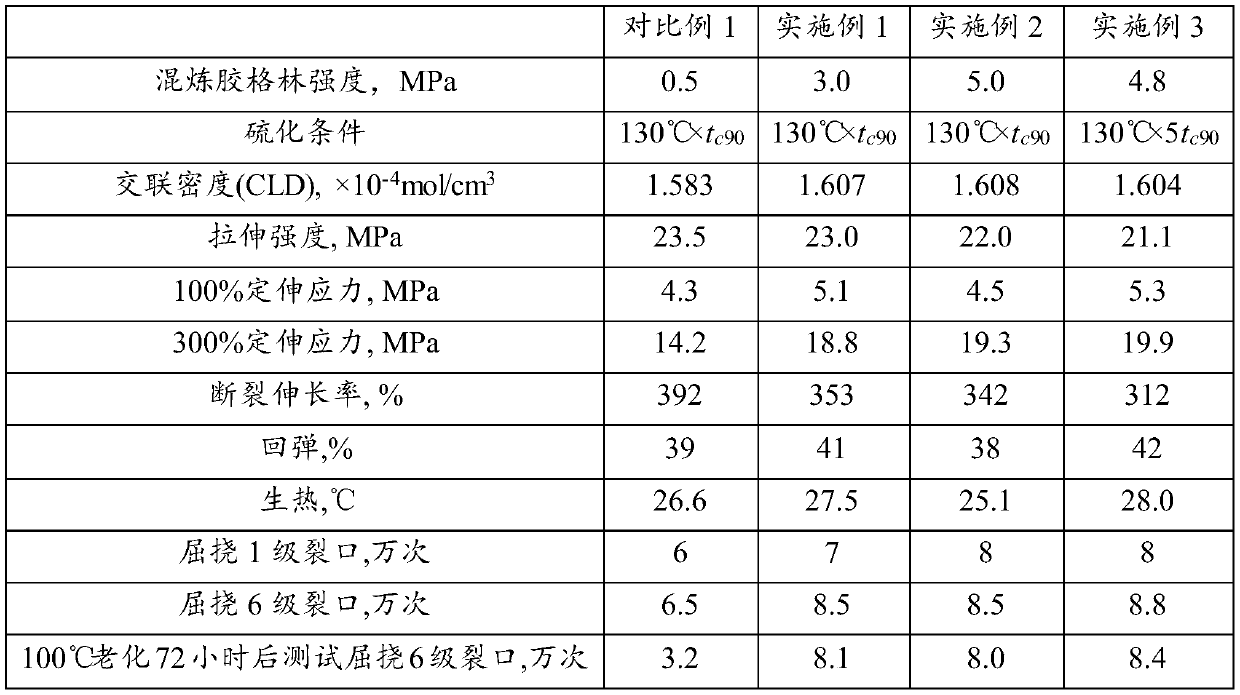

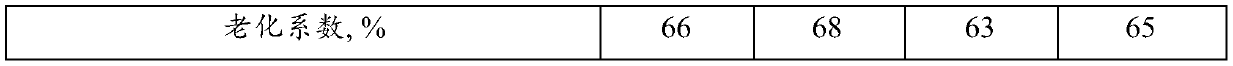

Embodiment 1

[0075] 10 parts of trans-1,4-butadiene-isoprene copolymer rubber TBIR; 80 parts of natural rubber NR; 10 parts of butadiene rubber BR; 60 parts of carbon black N234; 10 parts of white carbon black; silane coupling agent Si69 8 parts; 5 parts of zinc oxide; 2.5 parts of stearic acid; 6 parts of plasticizer environmental aromatic oil; 2 parts of antioxidant RD; 3 parts of antioxidant 4020; anti-scorch agent N-cyclohexylthiophthaloyl 0.2 parts of amine; 1.8 parts of insoluble sulfur; 2 parts of accelerator CZ; 1 part of anti-reversion agent SVA-2.

[0076] Natural rubber (NR), grade SCR WF, ML3+4100℃=95.0, Jinshui Processing Plant of China Haijiao Group; butadiene rubber (BR), grade BR 9000, ML3+4100℃=42.0, Sinopec Qilu Branch; trans -1,4-butadiene-isoprene copolymer rubber (TBIR), butadiene content is 19.8mol%, trans-1,4-structure content>95mol%, Mooney viscosity ML3+4100℃=60.5 , weight average molecular weight 540,000g / mol, molecular weight distribution index 3.09, Shandong Hu...

Embodiment 2

[0092] Same as Example 1, except that the number of BR copies is 0, and the number of TBIR copies is 20. The obtained mechanical properties are listed in Table 1.

Embodiment 3

[0094] Same as Example 1, except that the vulcanization time is 5 times of the positive vulcanization time of the vulcanization characteristic test at 130°C. The obtained mechanical properties are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com