Test device for flexible life of coiled tubing

A testing device and bending fatigue technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as unpredictable bending fatigue life of coiled tubing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

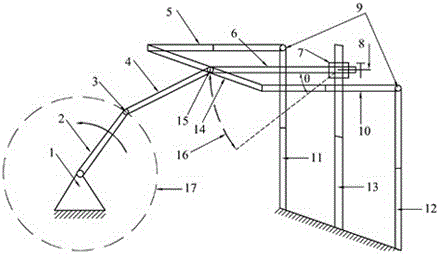

[0012] Implementation example, based on the test device of a kind of coiled tubing bending fatigue life proposed by the present invention, mainly adopts the following test steps:

[0013] (1) The coiled tubing 6 is fixed on the third support 13 by the clamp 7, the first hydraulic push rod 5, the second hydraulic push rod 10 and the beam 14;

[0014] (2) adopting the first hydraulic push rod 5, the second hydraulic push rod 10 and the beam 14 to apply a certain tensile load to the coiled tubing 6;

[0015] (3) Apply a certain internal pressure to the coiled tubing 6 through the air inlet 8;

[0016] (4) Start the motor, let the crank 2 drive the coiled tubing 6 to reciprocate along the swing track 16, and record the number of reciprocating motions of the coiled tubing 6 until micro-cracks appear on the surface of the coiled tubing 6 (judging that the coiled tubing 6 has a bending fatigue failure Criterion), stop motor, thereby obtain the fatigue life of coiled tubing 6;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com