Pre-vulcanized tread rubber for retreaded tire and manufacturing process of pre-vulcanized tread rubber

A technology for precured tires and retreaded tires, which is applied to special tires, tire parts, transportation and packaging, etc. It can solve the problems affecting the overall quality of retreaded tires and the decline in carcass performance, so as to avoid the decline in rubber performance and aging resistance Performance improvement and the effect of improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

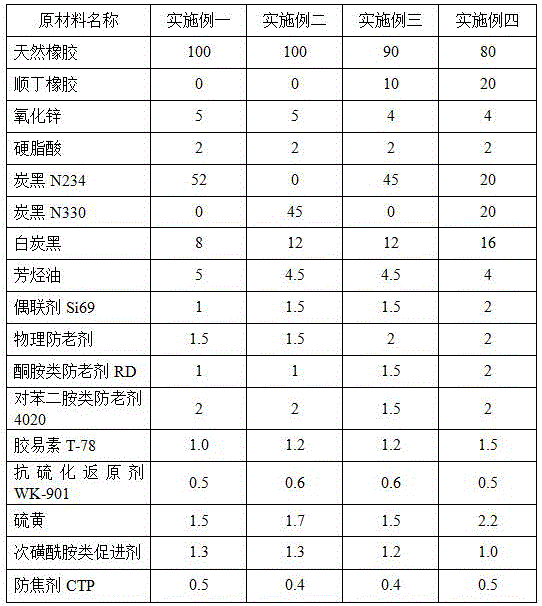

[0026] The prevulcanized tread rubber for retreading tires of the present invention is formulated by weight ratio from the following raw materials;

[0027]

[0028] The preparation process of the above-mentioned embodiments is the same. Firstly, the rubber is masticated, and then the rubber after mastication is mixed with other raw materials according to the weight ratio to make a mixed rubber through an internal mixer, and the mixed rubber is extruded through an extruder with a A film of a certain size is then vulcanized on a flat vulcanizer to obtain pre-vulcanized tread rubber.

[0029] The prevulcanized tread rubber of the present invention has the characteristics of excellent physical and mechanical properties, wear resistance, flex fatigue resistance, aging resistance, and vulcanization reversion resistance after testing. The best performance test data is as follows:

[0030] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com