Patents

Literature

34results about How to "Will not affect the process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

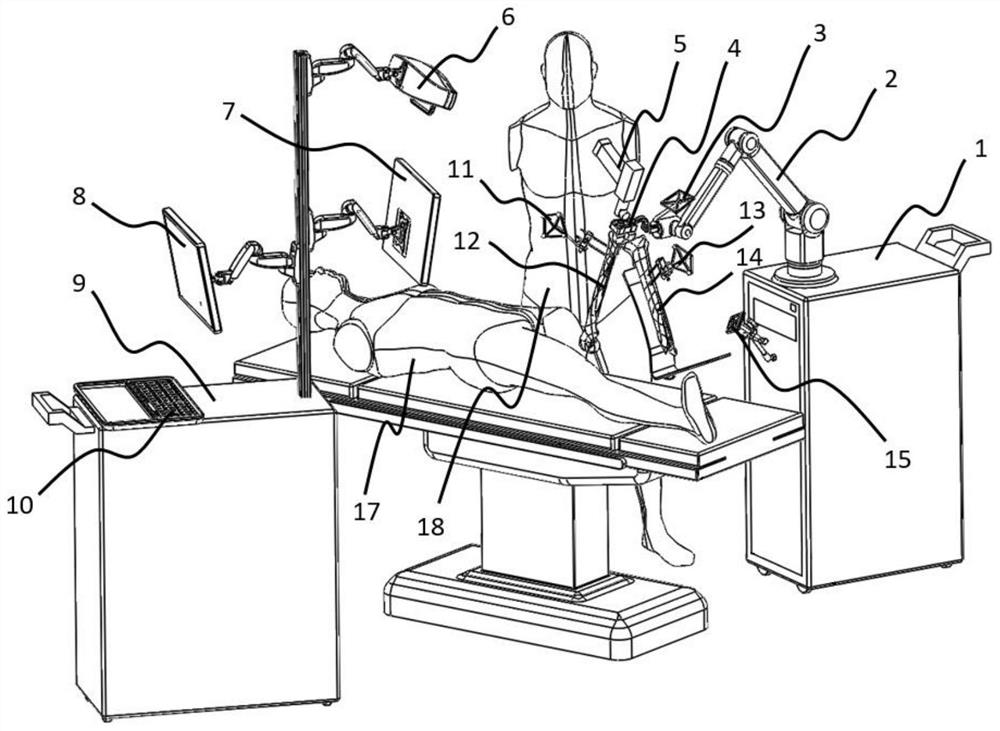

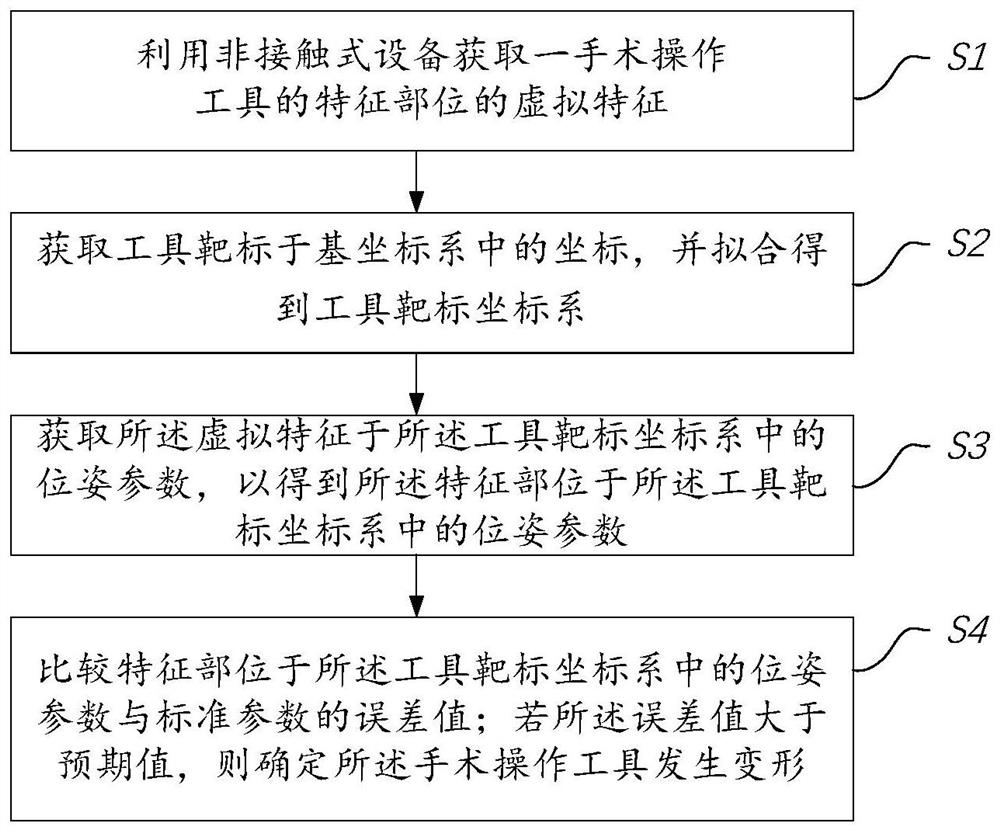

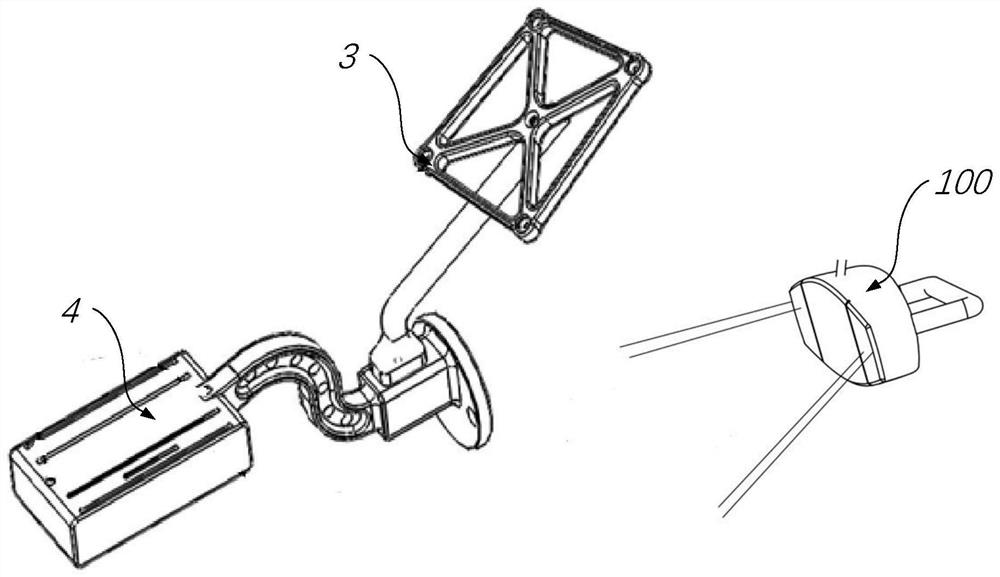

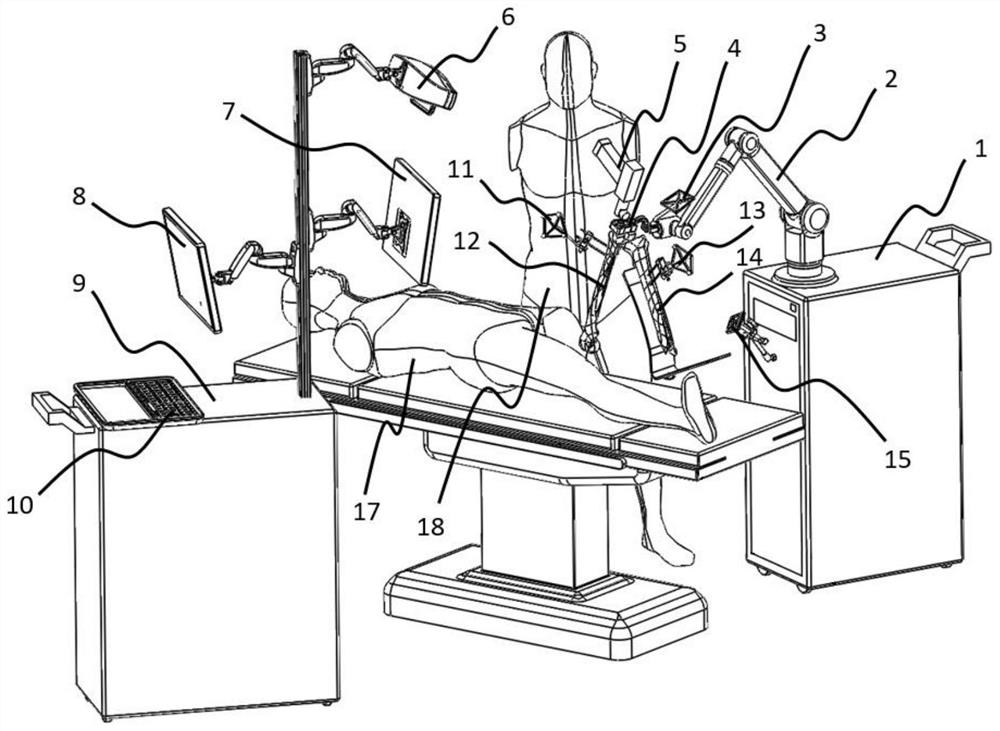

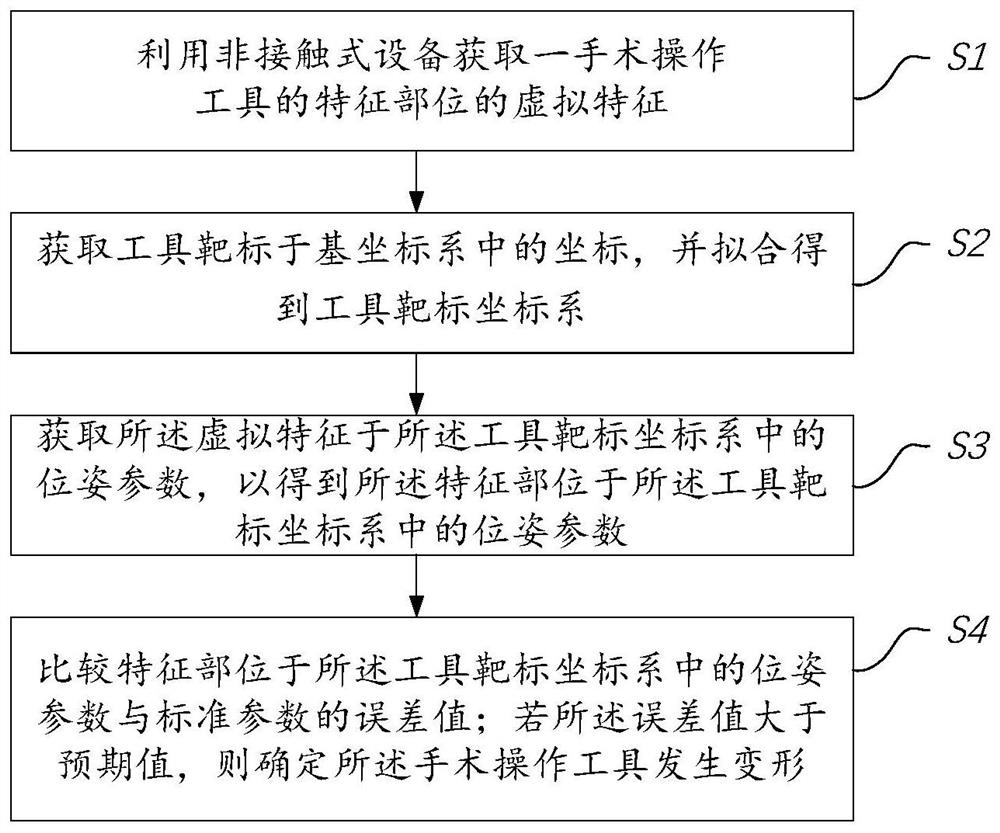

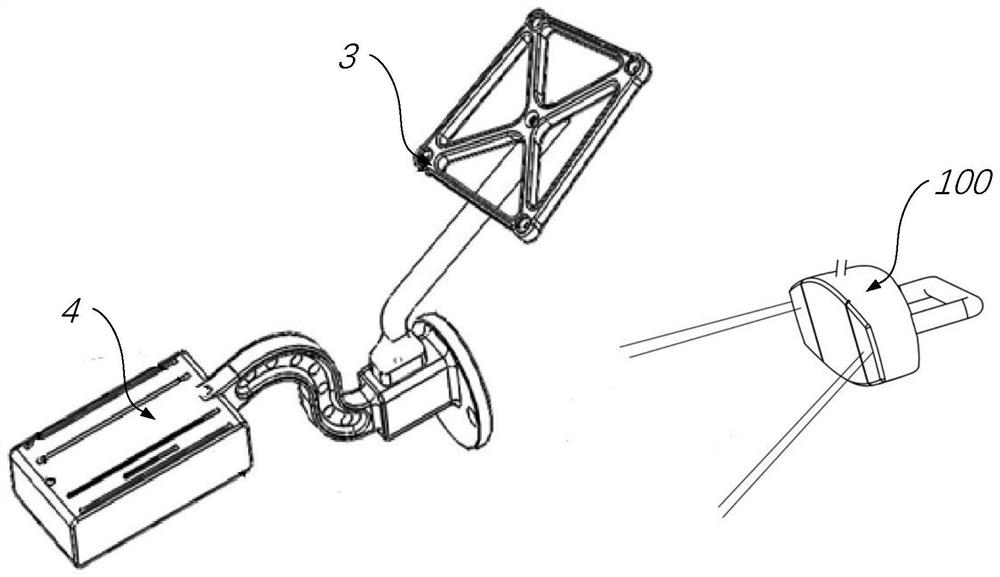

Verification method and verification system for surgical operation tool

ActiveCN112190332AReduce the risk of infectionWill not affect the processSurgical navigation systemsComputer-aided planning/modellingSurgical operationSurgical Manipulation

The invention provides a verification method and verification system for a surgical operation tool. The verification method comprises the following steps of: acquiring virtual characteristics of a characteristic part of the surgical operation tool by using non-contact equipment; acquiring coordinates of a tool target in a base coordinate system, and fitting to obtain a tool target coordinate system; acquiring a pose parameter of the virtual characteristic in the tool target coordinate system to obtain a pose parameter of the characteristic part in the tool target coordinate system; comparing an error value between the pose parameter of the characteristic part in the tool target coordinate system and a standard parameter; and, if the error value is greater than the expected value, determining that the surgical operation tool deforms. Due to the configuration, the disinfection step is omitted; the infection risk in the operation is reduced; the operation process is not influenced; the device is free of extra abrasion to the surgical operation tool, good in universality and capable of adapting to various surgical operation tools of different forms; and the non-contact equipment of thedevice cannot be adjusted.

Owner:SUZHOU MICROPORT ORTHOBOT CO LTD

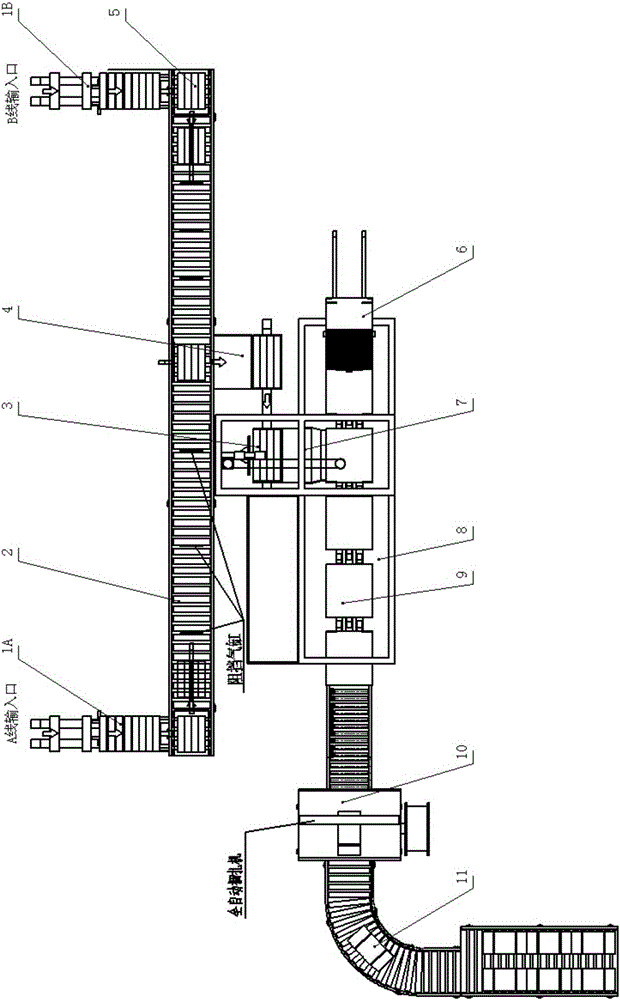

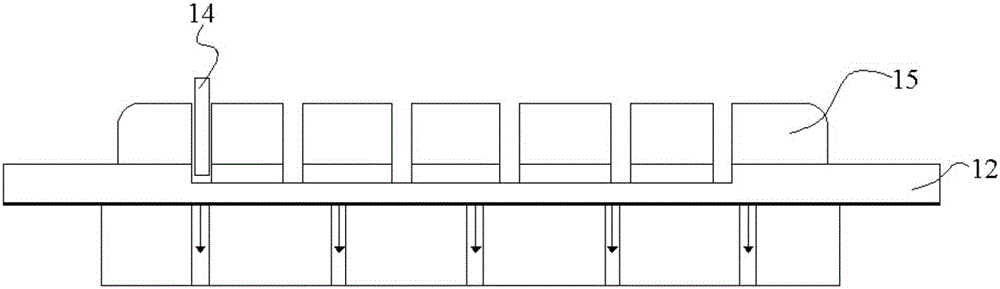

Integrated full-automatic boxing system

ActiveCN105292585AAutomate operationSave human effortWrapper twisting/gatheringPackaging machinesMachine partsEngineering

The invention relates to an integrated full-automatic boxing system. The integrated full-automatic boxing system comprises box feeding units, a roller conveying line, a finished box pushing-in unit, a box expanding unit, a box wing folding unit and a box bundling unit. The two box feeding units are symmetrically arranged. Finished boxes are conveyed to an inlet of the box expanding unit through the roller conveying line, and a box plate unit is arranged at the other inlet of the box expanding unit. After the box plate unit conveys box plates into the box expanding unit, box bodies are expanded and pushed into the stacked finished boxes. After cover plates of the box bodies are folded in half through the box wing folding unit, the cover plates are fed in the box bundling unit to be packaged. The system is stable in performance, reliable in quality, high in applicability and packaging efficiency and long in service life. Machine parts are precise and durable in performance, the structural design is strict, vibration is avoided in the running process, and running is stable and reliable. The automation degree is high, automatic box opening, automatic cover plate folding and automatic packaging are achieved, operation is greatly facilitated, and the integrated full-automatic boxing system is an unnecessary device for automatic large-scale production.

Owner:天津惠坤诺信包装设备有限公司

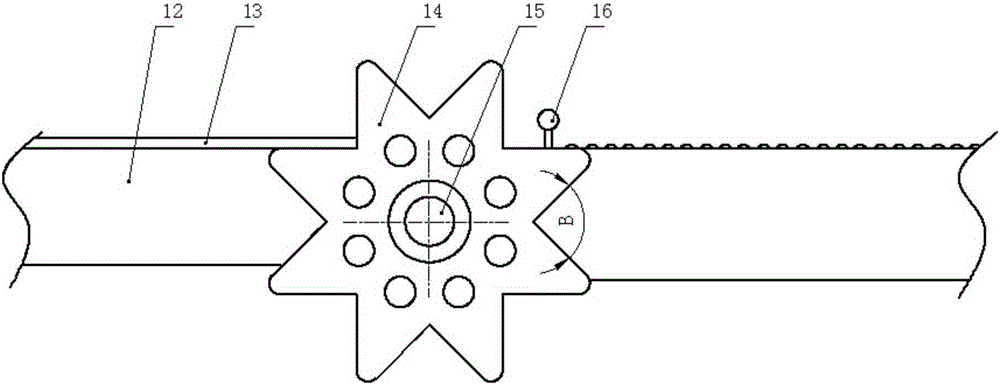

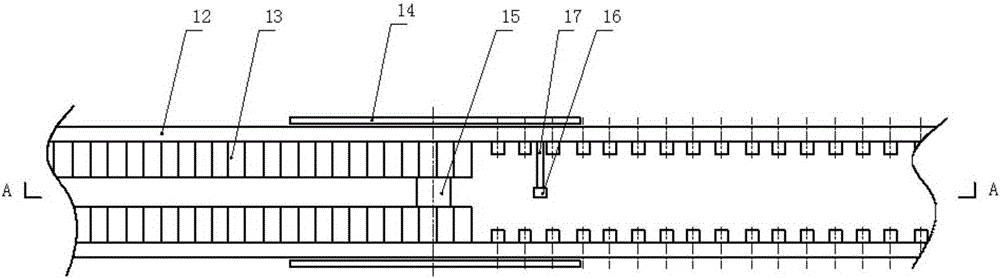

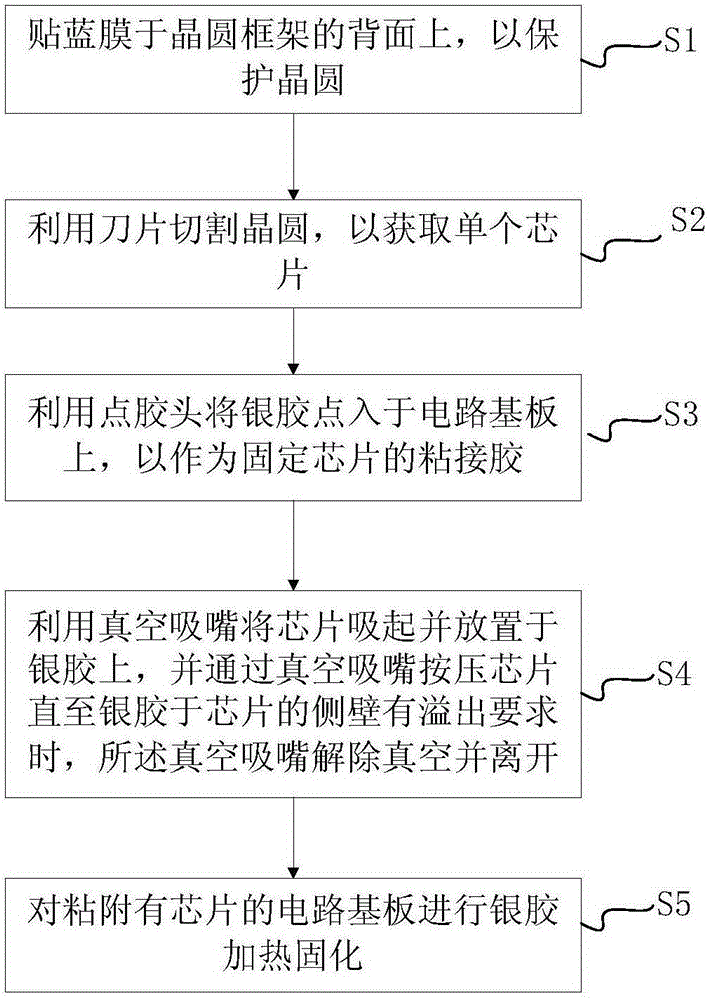

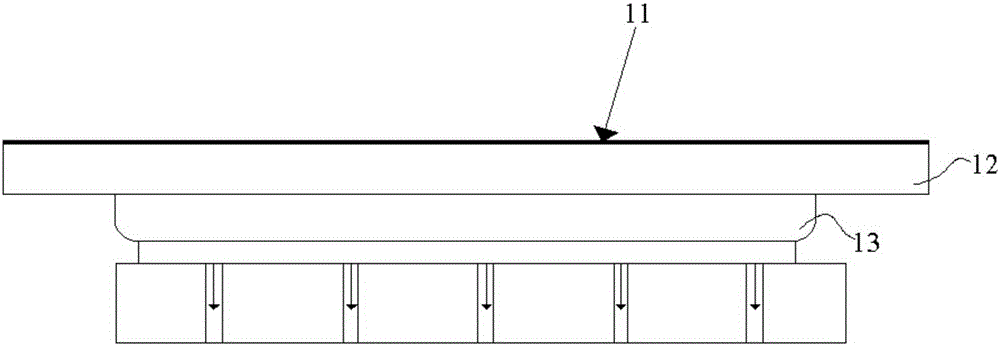

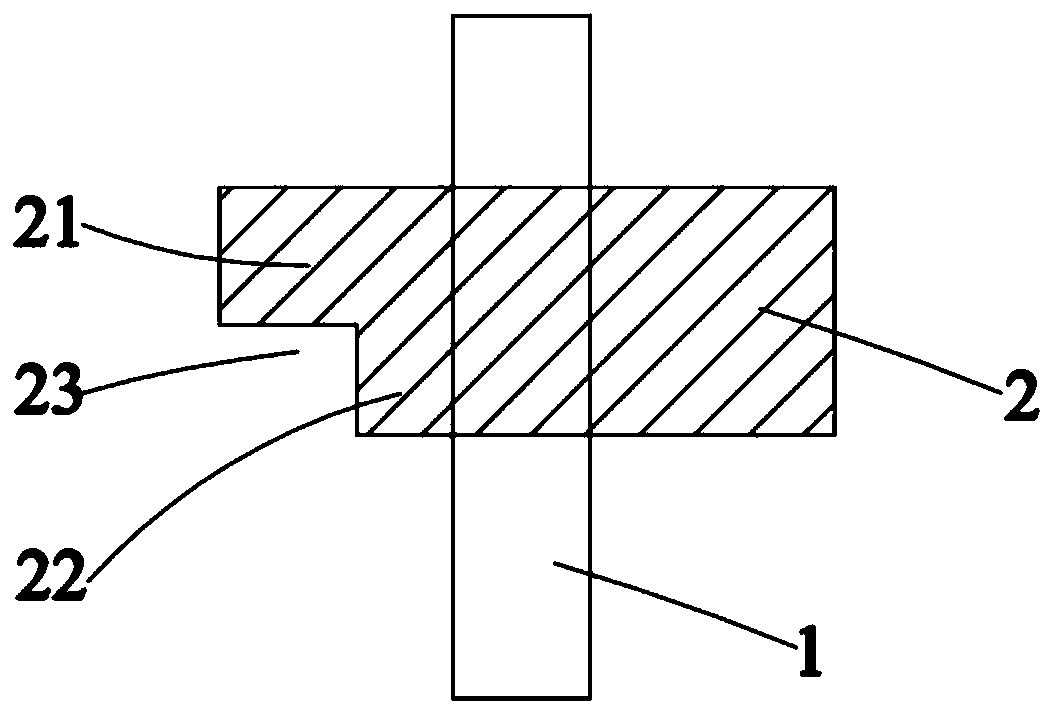

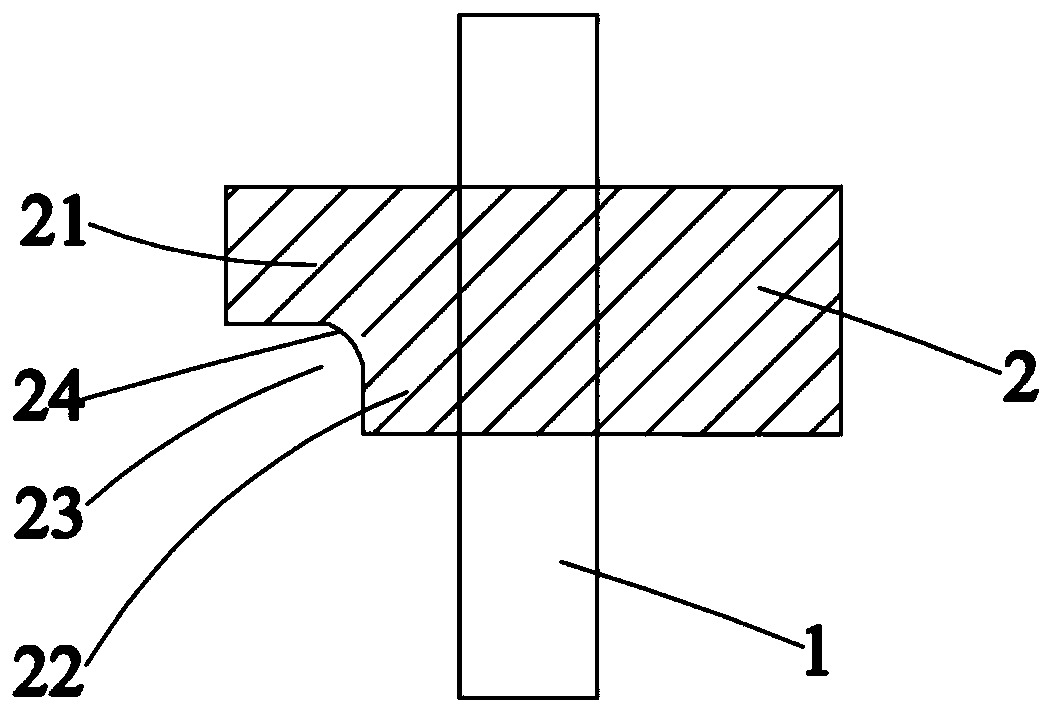

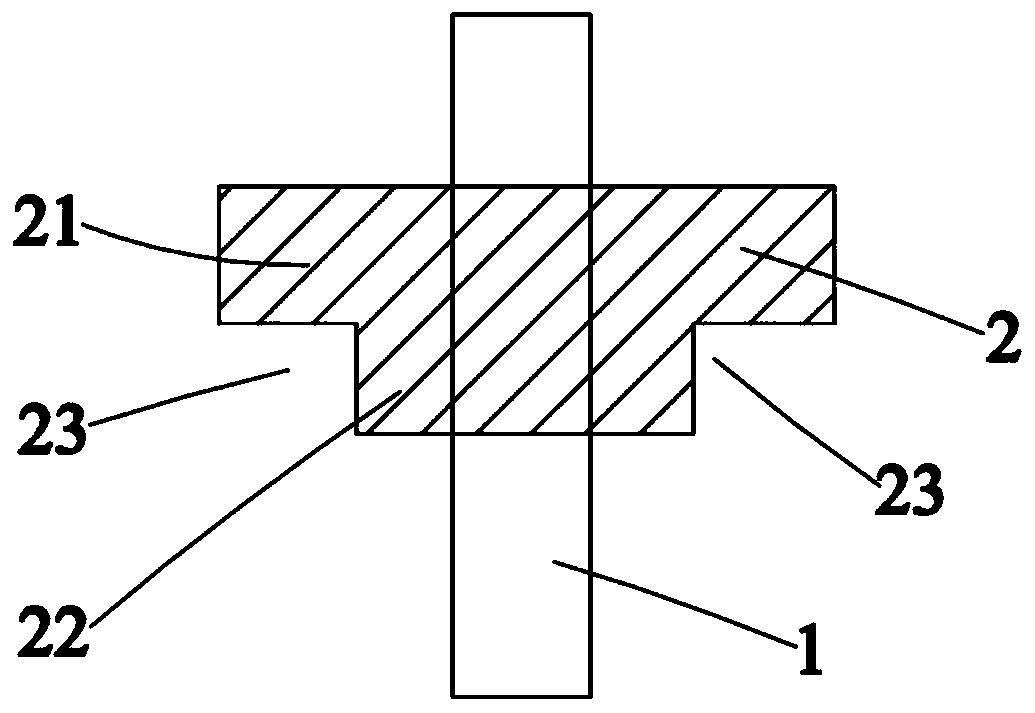

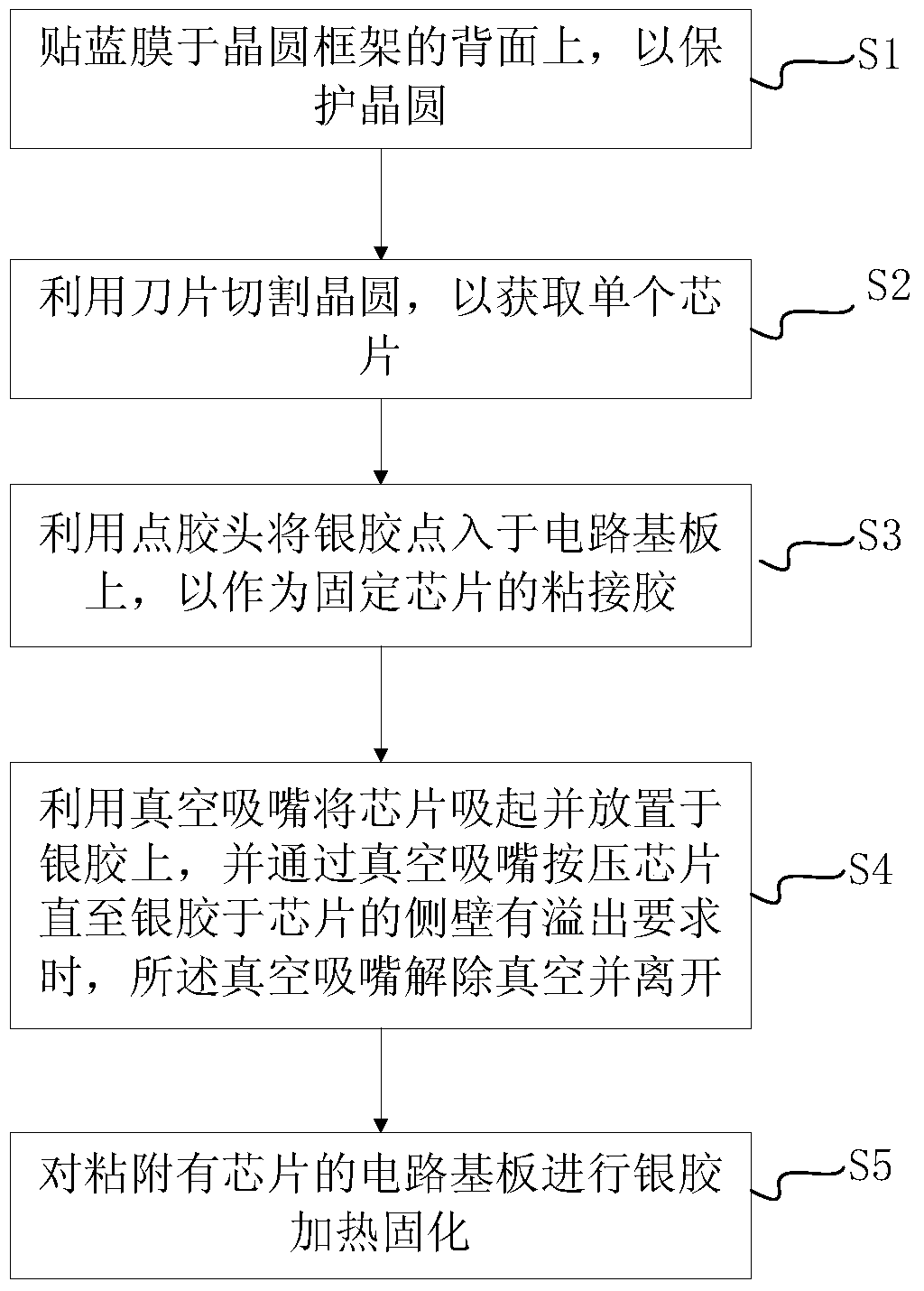

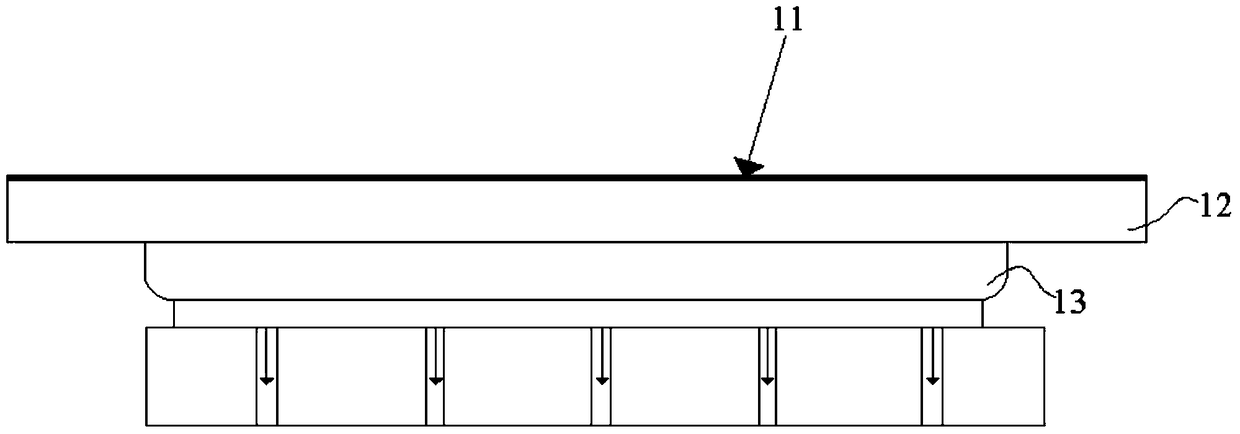

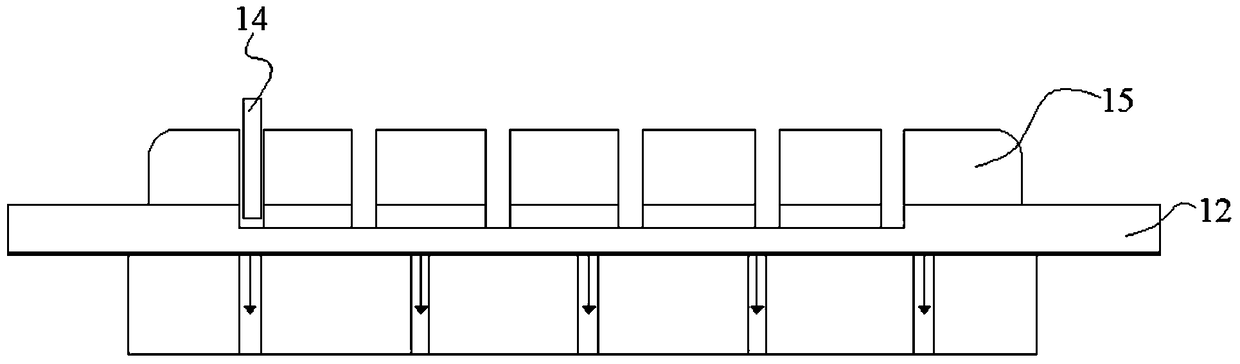

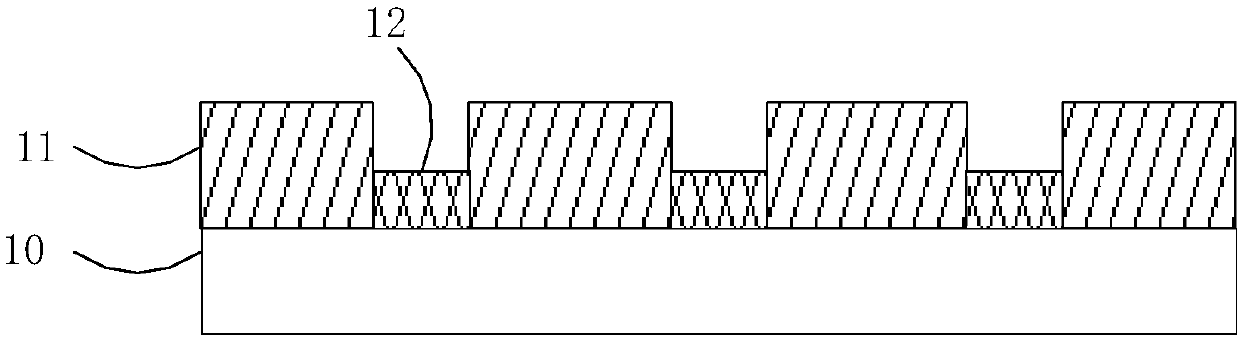

Chip encapsulation structure, manufacture method thereof and electrostatic powder spraying device

ActiveCN106505047AAvoid functional failureGuaranteed reliabilitySemiconductor/solid-state device detailsSolid-state devicesPowder SprayElectrical and Electronics engineering

The present invention provides a chip encapsulation structure, a manufacture method thereof and an electrostatic powder spraying device. The chip encapsulation structure includes a circuit substrate, an adhesive layer arranged on the circuit substrate, and a chip arranged on the adhesive layer; and the side wall of the chip is provided with a non-stick material layer. The manufacture method of the chip encapsulation structure includes the following steps that: a chip for encapsulation is provided; a non-stick material layer is arranged on the side wall of the chip; a circuit substrate for carrying the chip is provided; an adhesive layer is arranged on the circuit substrate; the chip is arranged on the adhesive layer, and the bottom of the chip is completely covered with the adhesive layer; and the adhesive layer is heated, so that the adhesive layer can be cured. According to the chip encapsulation structure, the manufacture method thereof and the electrostatic powder spraying device of the invention, the non-stick material layer is arranged on the side wall of the chip, so that the overflowed adhesive layer will not adhere to the upper surface of the chip, and therefore, the malfunctioning of the chip can be avoided, the reliability of the chip can be ensured, and the quality of the chip encapsulation structure can be improved.

Owner:SEMICON MFG INT TIANJIN +1

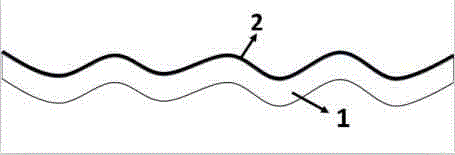

Novel PVC tile and preparing method thereof

InactiveCN106188940AGuaranteed aestheticsWill not affect the processSynthetic resin layered productsFoaming agentSurface layer

The invention discloses a novel PVC tile and a preparing method thereof. The middle of the PVC tile is a downward concave arc, in other words, the PVC tile is wavy so as to facilitate drainage of a roof. The preparing method comprises the steps of preparing a PVC composite plate firstly, and then forming anti-UV resin surface layer on the upper surface of the plate through co-extrusion. The formula of the novel PVC tile comprises PVC, a foaming agent, a biobased material or inorganic filler, an MBS resin, an inorganic flame retardant and anti-UV resin. According to the PVC tile, on the premise that sun shading and rain sheltering are guaranteed, flame retardant property, light weight, sound insulation, attractiveness, aging resistance and heat insulation are all improved, cost can be reduced, and the environment-friendly requirement for sustainable development is met; the preparing method is simple, and industrialization can be achieved easily. Furthermore, installation is convenient, construction period is short, and the novel PVC tile can be widely applied to top surface installation of various buildings.

Owner:无锡市天聚科技有限公司

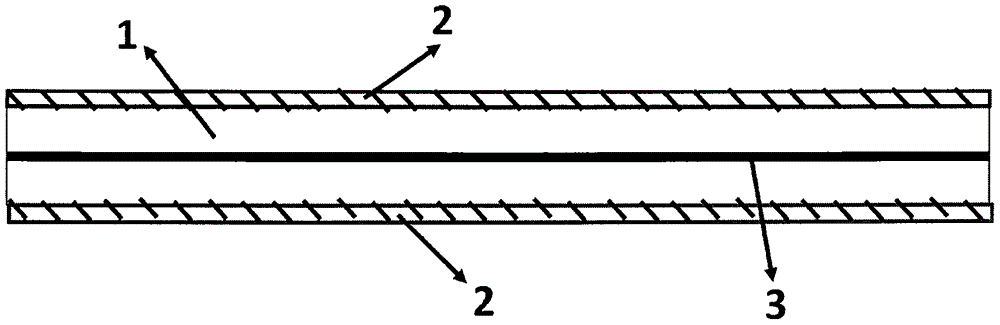

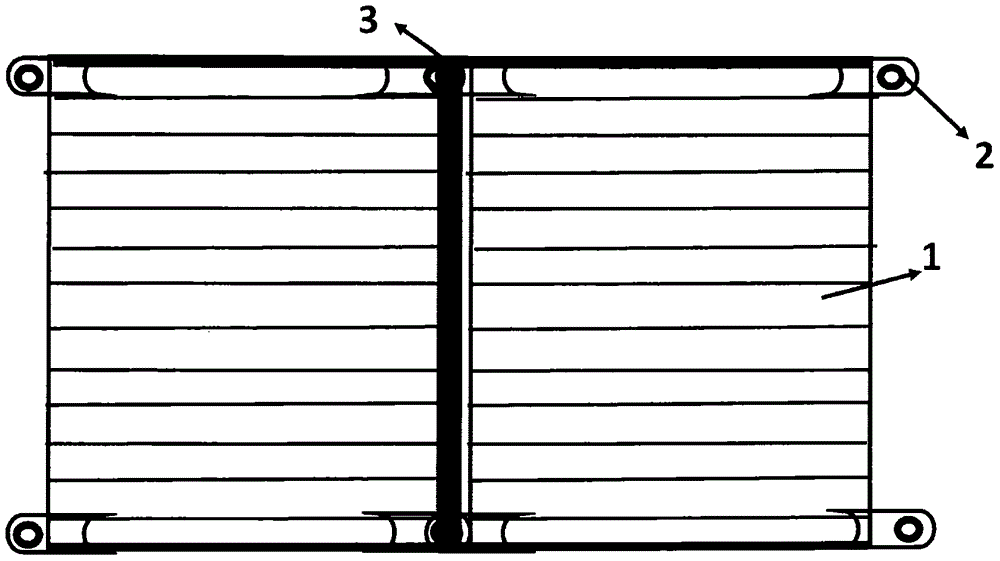

Tab having special-shaped tab film, preparation method thereof and lithium ion battery

PendingCN110265617ASolve the hardnessSolve the problem of corner extrusion battery coreSecondary cellsCell component detailsEngineeringLithium-ion battery

The invention belongs to the technical field of a battery and especially relates to a tab having a special-shaped tab film. The tab having the special-shaped tab film comprises a metal tape and the special-shaped tab film arranged on the two surfaces of the metal tape. The special-shaped tab film comprises a first film portion and a second film portion, which are integrated. The length of the first film portion is larger than the length of the second film portion; and at least one gap is formed between the first film portion and the second film portion. Compared with the prior art, under the condition where the tab meets a limit design, the inner exposed portion of the special-shaped tab film of the tab does not participate in side sealing process of a battery, thereby helping to improve package reliability and safety of an electrical core. Besides, the invention also relates to a preparation method of the tab having the special-shaped tab film and the lithium ion battery comprising the tab.

Owner:东莞市恒源新材料有限公司

Seal coating process and manufacturing method of wood furniture

The invention relates to a seal coating process and a manufacturing method of wood furniture. The seal coating process includes the steps of 1), using, by weight, 10-35% of air-drying resin, 60-85% o plastics and 5-30% of a thinner to blend brushing plastics; 2), coating the brushing plastics on a work piece with the coating weight controlled within 80-120g / m<2>; 3), starting a movable-type UV (ultraviolet) drier, and drying the plastics through motion of the movable-type UV drier; 4), diluting the sealing plastics to coat the same on the work piece; 5), starting the movable-type UV drier, and drying the plastics through motion of the movable-type UV drier. The coating process has the advantages of operation easiness; environment pollution, production space, polishing manpower, paint consumption, damages to human health, time on the coating process can all be reduced and the like.

Owner:JIANGMEN GUOMEI CHEM

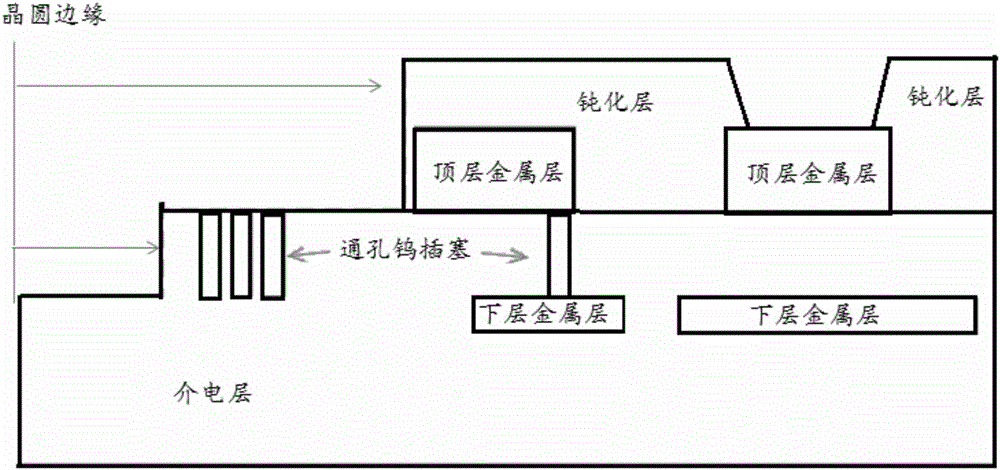

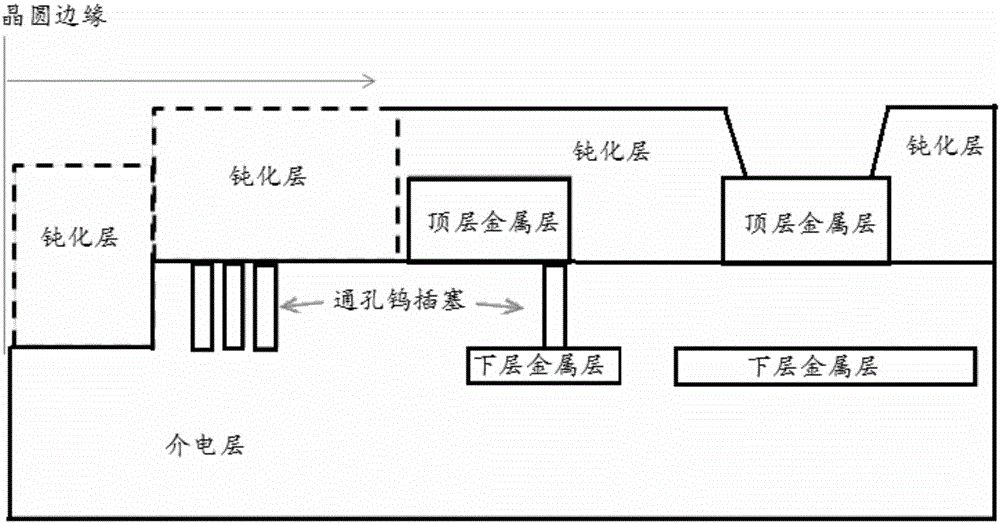

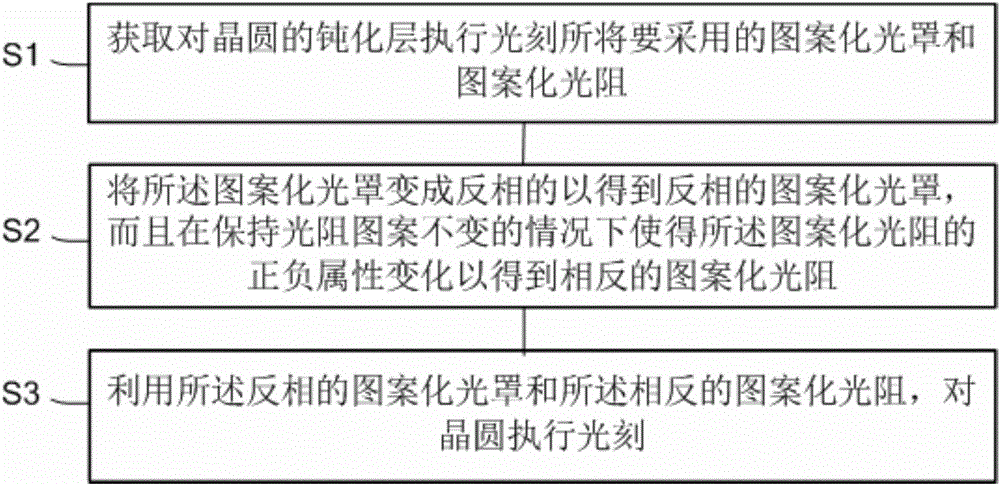

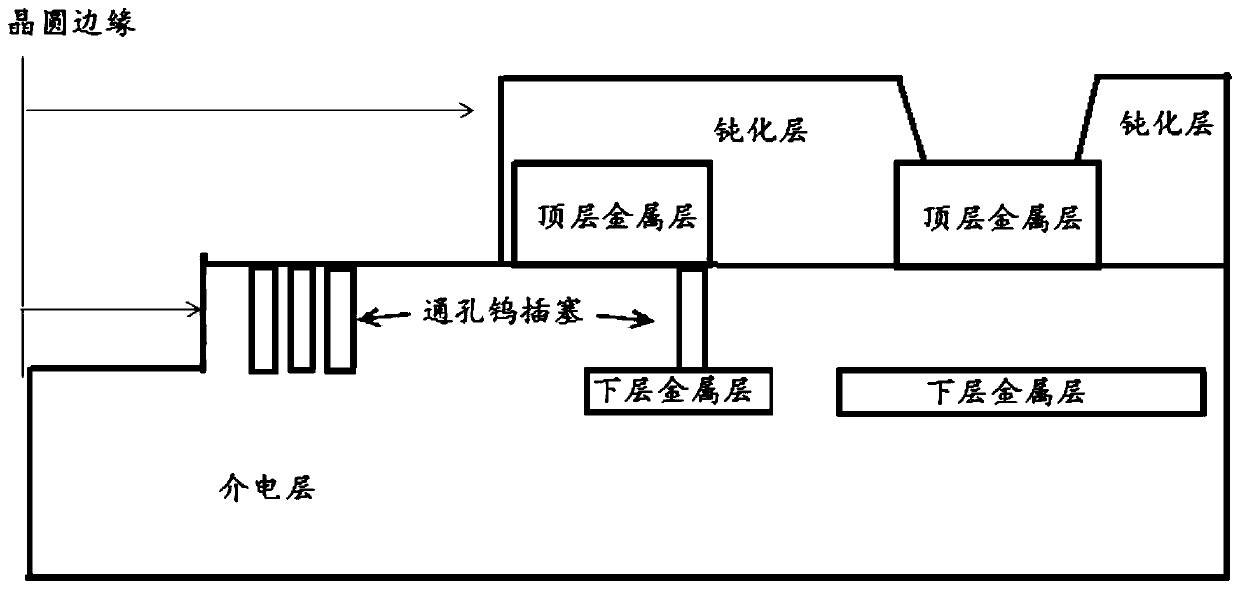

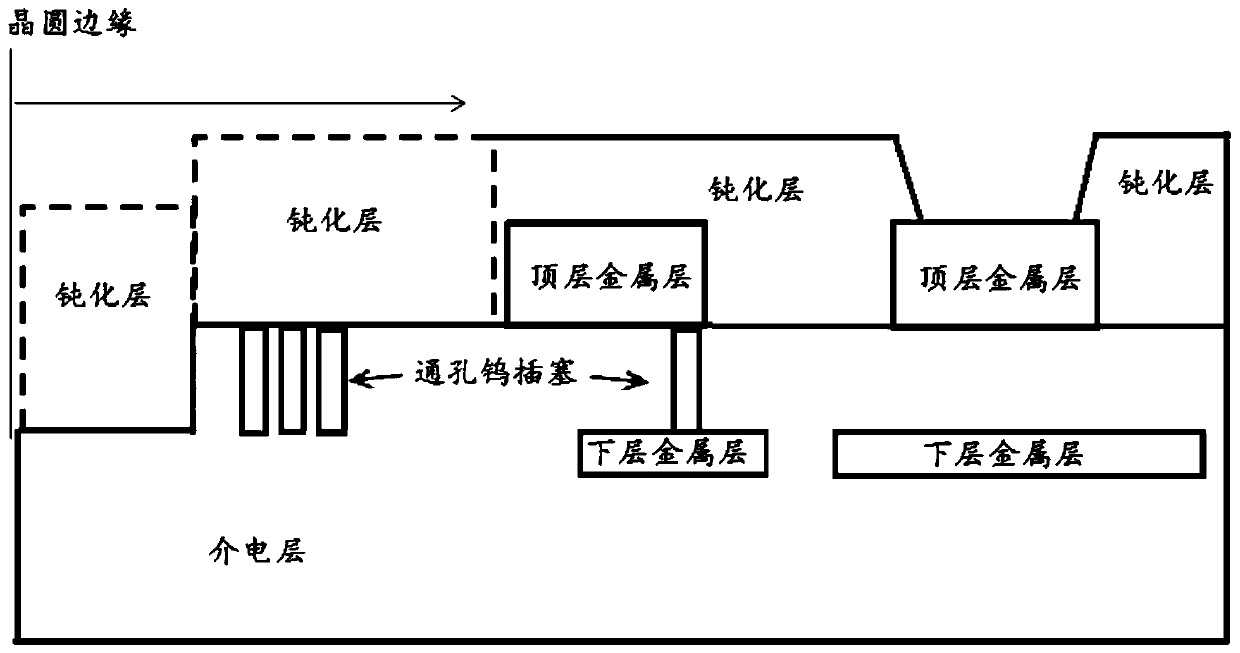

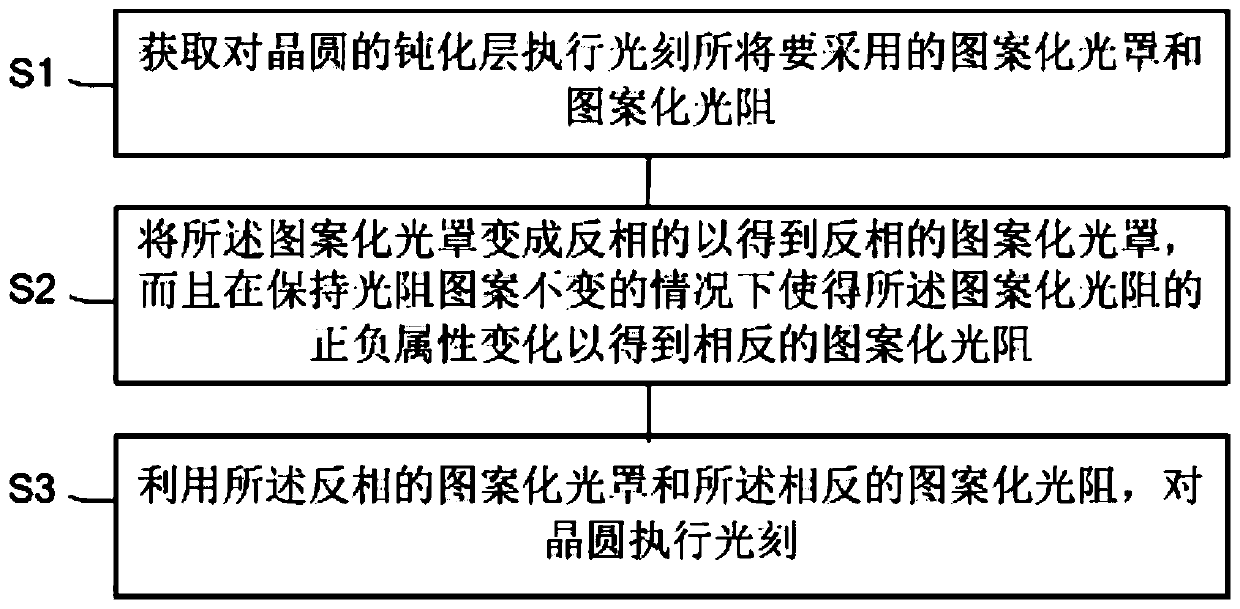

Method used for reducing wafer edge yield test problems

ActiveCN106803482AWill not affect the processNo false test failuresSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringPhotoresist

The present invention provides a method used for reducing wafer edge yield test problem. The method comprises a first step of obtaining a patterned photomask and the patterned photoresist adopted to execute the photoetching on a passivation layer of a wafer; a second step of inverting the patterned photomask to obtain an inverted patterned photomask, and changing the positive and negative attributes of the patterned photoresist on the condition of keeping a constant photoresist pattern to obtain the reverse patterned photoresist; a third step of utilizing the inverted patterned photomask and the reverse patterned photoresist to execute the photoetching on the wafer. According to the method used for reducing the wafer edge yield test problems of the present invention, the photomask and the photoresist of the passivation layer both become inverted, so that the figures of other parts, except a predetermined part starting at an edge position, in the wafer, do not change, and the passivation layer is retained from the edge to the predetermined part, and accordingly, a test false failure problem is not generated.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

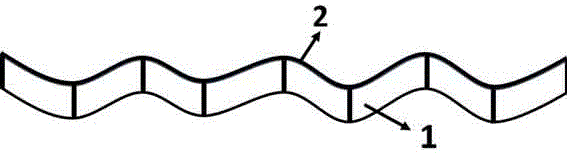

Novel flame-retardant hollow wallboard and preparation method thereof

InactiveCN106121127AWill not affect the processDoes not affect performanceConstruction materialFiberglass meshGlass fiber

The invention discloses a novel flame-retardant hollow wallboard and a preparation method thereof. The preparation method comprises the steps that extrusion is conducted through a hollow board extruder, concave portions and convex portions are arranged alternately on the upper surface and the lower surface of a hollow board, the concave portions of the upper surface and the lower surface are filled with magnesium powder paste and sealed, two layers of glass fiber gridding cloth are laid on the upper surface and the lower surface correspondingly, and screeding is conducted on the magnesium powder paste; and in addition, supporting racks are additionally arranged in the interior hollow space. According to the flame-retardant hollow wallboard, on the premise that the partition function of the wallboard is guaranteed, the light weight property, the sound insulation property, the anti-aging property, the thermal insulation property, the flame-retardant property and the like are improved, the cost can be reduced, and the environment protection requirements of sustainable development are met. The preparation method of the flame-retardant hollow wallboard is simple and can be widely used for building wall construction under various conditions, and industrialization can be achieved easily.

Owner:无锡市天聚科技有限公司

Square plate process flow for manufacturing reflective mould

InactiveCN109423668ASimple structureReasonable designElectroforming processesEngineeringElectroforming

The invention discloses a square plate process flow for manufacturing a reflective mold. The square plate process flow is characterized in that the process flow is used for manufacturing the reflective mold and comprises the following steps of (1) original plate processing; (2) cleaning and passivation; and (3) electroforming. According to the square plate process flow, a square metal original plate is adopted, so that the structure is simple, the design is reasonable, and fixing, cleaning and use are more convenient; moreover, the shielding and sealing treatment in the original plate treatment can reduce the loss of electroforming bath liquid and nickel rods on the premise of meeting the required size, waste is reduced, the cost is saved, and stripping of the reflective mold is facilitated; and the metal original plate is fixed by an insulating plate, so that the role of fixing the metal original plate can be played, cleaning and electroforming of the metal original plate are convenient, and the electroforming process are not affected; and carbonate is added into the electroforming bath liquid, the number of ions in the bath can be increased, and the electroforming rate is increased.

Owner:泉州市同兴反光材料有限公司

Calibration method and system for operating tools

ActiveCN112190332BReduce the risk of infectionWill not affect the processSurgical navigation systemsComputer-aided planning/modellingSurgical operationSurgical Manipulation

The invention provides a calibration method and a calibration system for a surgical operation tool, which uses a non-contact device to obtain the virtual features of the characteristic parts of a surgical operation tool; obtains the coordinates of the tool target in the base coordinate system, and obtains the tool by fitting Target coordinate system; obtain the pose parameters of the virtual feature in the tool target coordinate system to obtain the pose parameters of the feature part in the tool target coordinate system; compare the feature part in the tool target coordinate system An error value between a pose parameter in the target coordinate system and a standard parameter; if the error value is greater than an expected value, it is determined that the surgical operation tool is deformed. Such a configuration eliminates the steps of disinfection, reduces the risk of infection during the operation, and will not affect the operation process. It will not cause additional wear and tear on surgical operation tools, and has good universality, and can adapt to various surgical operation tools of different shapes, while the non-contact equipment itself does not need to be adjusted.

Owner:SUZHOU MICROPORT ORTHOBOT CO LTD

Technological process of circular plate for manufacturing reflective mould

InactiveCN109423669AEasy to cleanConvenient electroformingElectroforming processesLand resourcesMetal

The invention discloses a technological process of a circular plate for manufacturing a reflective mould. The technological process is characterized by being used for manufacturing a reflective mouldand comprising the following steps of (1) raw plate processing; (2) wash passivation; and (3) electroforming. According to the technological process, a tetragonal metal raw plate is rolled into a cylindrical metal raw plate for electroforming, and therefore the occupied space can be reduced. When the reflective moulds with the same size are electroformed, the occupied space of the cylindrical metal raw plate is obviously smaller, the land resources are saved, and the production cost is reduced. Moreover, in the raw plate processing, shielding and sealing treatment can reduce the loss of an electroforming bath solution and a nickel rod on the premise of meeting the required size, waste is reduced, cost is saved, and the stripping of the reflective mould is also convenient. The metal raw plate is fixed by an insulating plate, so that the insulating plate can play a role in fixing the metal raw plate, the washing and electroforming of the metal raw plate are convenient, and the process ofelectroforming cannot be affected.

Owner:泉州市同兴反光材料有限公司

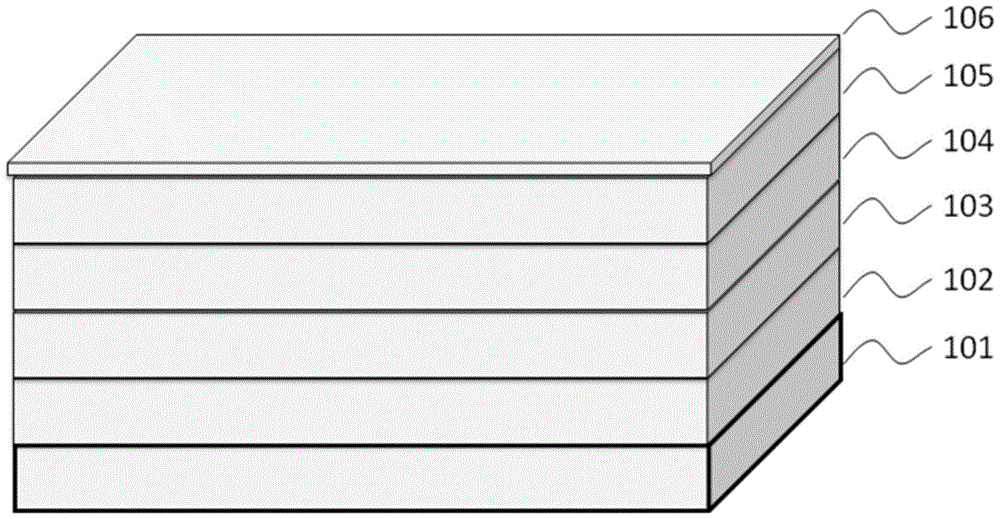

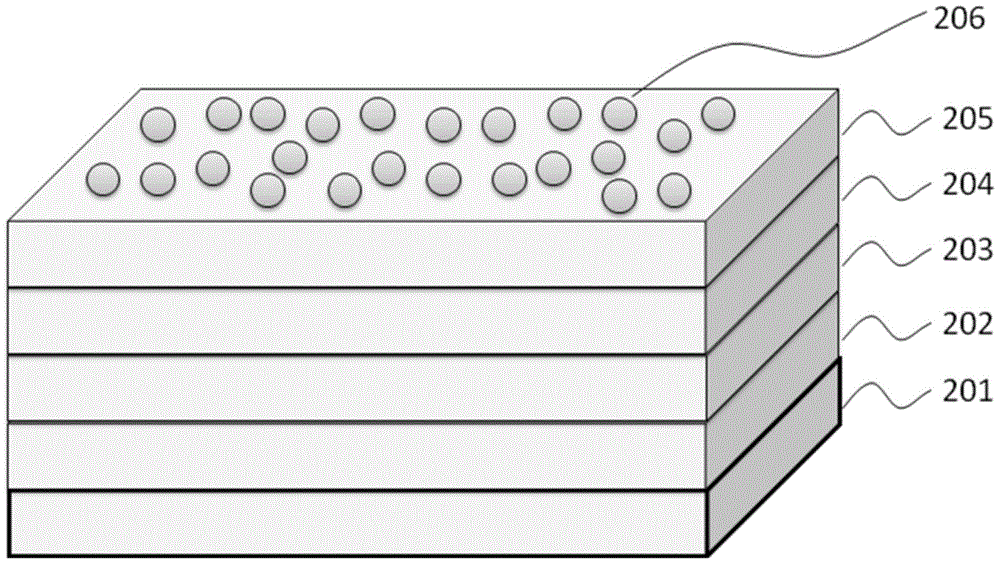

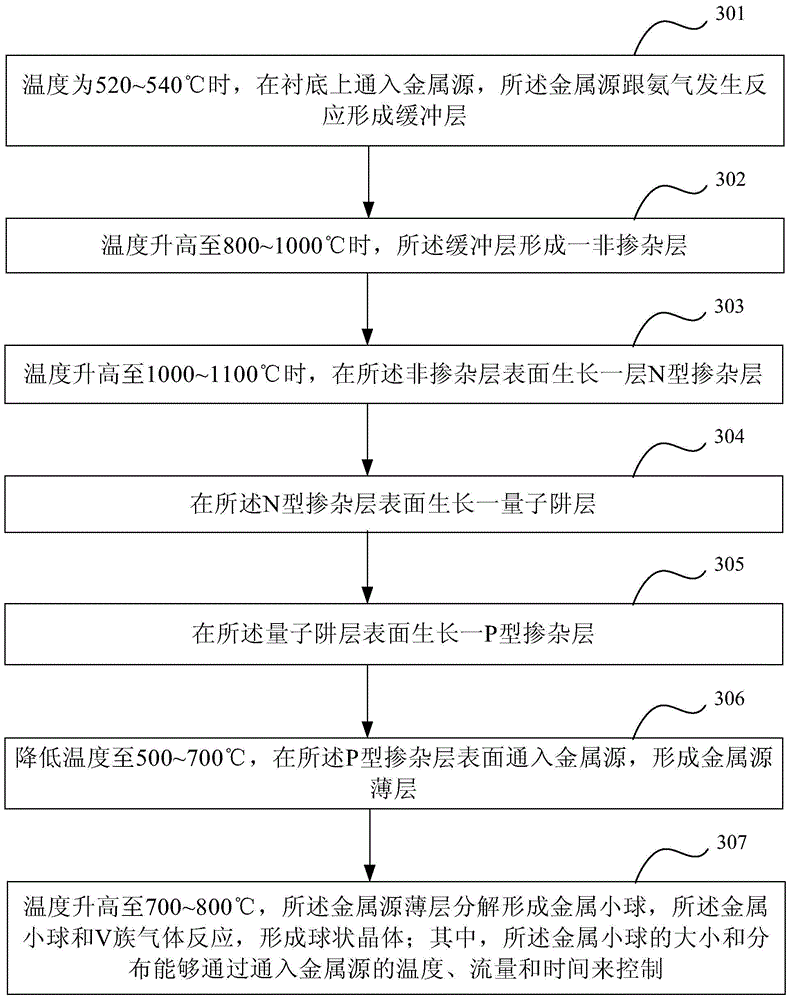

Light-emitting diode led growth method with p-type layer roughening

ActiveCN104157751BImprove electrical performanceWill not affect the chip processSemiconductor devicesThin metalQuantum well

Owner:EPITOP PHOTOELECTRIC TECH

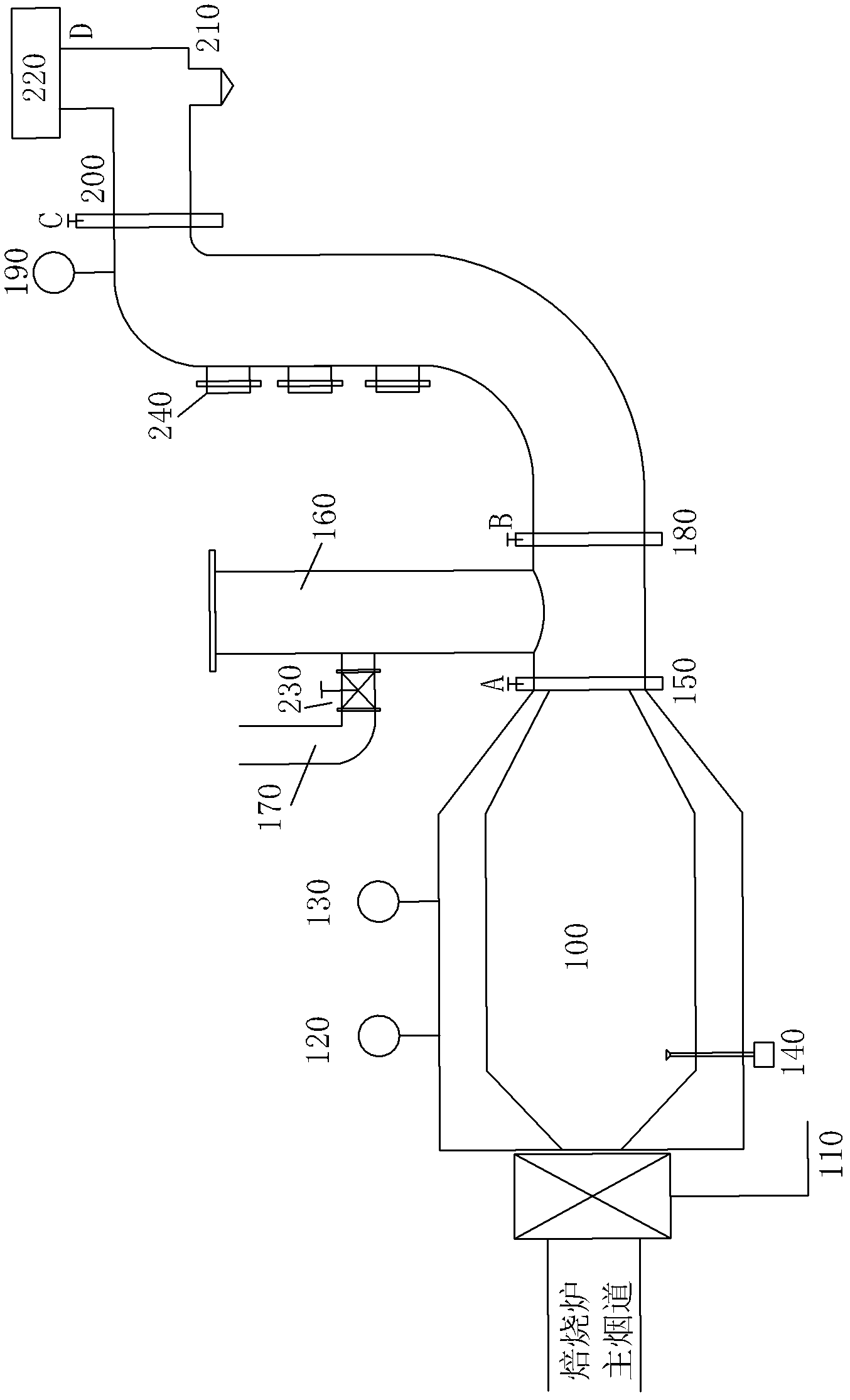

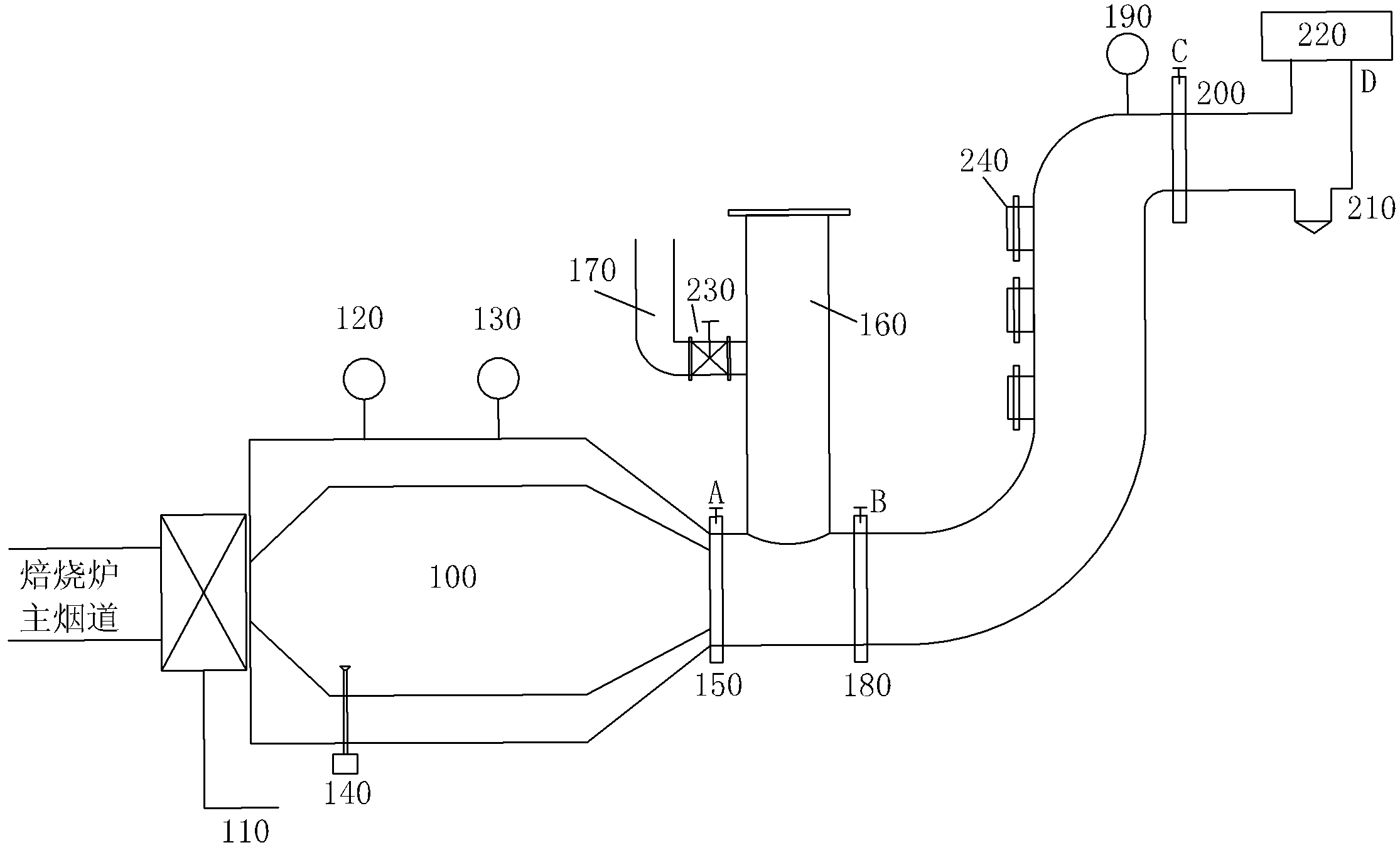

Smoke exhaust backflash energy-saving device and method

InactiveCN102538490AReduce dosageConsiderable energy savingIncreasing energy efficiencyIncinerator apparatusCooking & bakingAtmospheric air

The invention discloses a smoke tail gas backflash energy-saving device and a method, which belong to the filed of energy-saving devices, wherein a fan is arranged on a main flue outlet of a baking furnace, smoke tail gas in a main flue is lead into a burner by the fan, an outlet of the burner is connected with a first pipeline inlet, a first pipeline outlet is connected with a heat energy recover main pipeline inlet, a heat energy recover main pipeline outlet is connected with a smoke exhaust pipeline inlet, the side wall of the heat energy recover main pipeline is provided with a plurality of interfaces, and the interfaces are connected with a flue high temperature section of the baking furnace. The smoke tail gas backflash energy-saving device can reduce above 30 percent of gas dosage in the baking furnace, and smoke tail gas which is discharged into the atmosphere is superior to the national standard.

Owner:邹洪军

Novel composite sandwich wallboard and preparation method thereof

InactiveCN105971187AWill not affect the processDoes not affect performanceBuilding componentsFire retardantCement mortar

The invention discloses a novel composite sandwich wallboard and a preparation method thereof. The preparation method of the novel composite sandwich wallboard comprises the three-layer sandwich process, specifically, cement mortar, inorganic flame retardants and foaming macromolecule plastic are together mixed and pressed to be a plate at first; after the plate is solidified, the two surfaces of the plate are coated with glue to serve as sandwich layers; and then two magnesium plates with the same size are taken and are pasted on the upper surfaces and the lower surfaces of the sandwich layers. According to the novel composite sandwich wallboard, the heat preservation performance, the sound insulation performance, the waterproof performance and the flame retardant performance are improved on the premise of ensuring the mechanical strength, the cost can be reduced, and the environmental protection requirement of sustainable development is met. The preparation method of the novel composite sandwich wallboard is easy and capable of achieving industrialization easily and can be widely used in indoor wallboards under various circumstances.

Owner:无锡市天聚科技有限公司

Chip package structure and manufacturing method thereof, electrostatic powder coating device

ActiveCN106505047BAvoid functional failureGuaranteed reliabilitySemiconductor/solid-state device detailsSolid-state devicesPowder SprayStatic electricity

The present invention provides a chip encapsulation structure, a manufacture method thereof and an electrostatic powder spraying device. The chip encapsulation structure includes a circuit substrate, an adhesive layer arranged on the circuit substrate, and a chip arranged on the adhesive layer; and the side wall of the chip is provided with a non-stick material layer. The manufacture method of the chip encapsulation structure includes the following steps that: a chip for encapsulation is provided; a non-stick material layer is arranged on the side wall of the chip; a circuit substrate for carrying the chip is provided; an adhesive layer is arranged on the circuit substrate; the chip is arranged on the adhesive layer, and the bottom of the chip is completely covered with the adhesive layer; and the adhesive layer is heated, so that the adhesive layer can be cured. According to the chip encapsulation structure, the manufacture method thereof and the electrostatic powder spraying device of the invention, the non-stick material layer is arranged on the side wall of the chip, so that the overflowed adhesive layer will not adhere to the upper surface of the chip, and therefore, the malfunctioning of the chip can be avoided, the reliability of the chip can be ensured, and the quality of the chip encapsulation structure can be improved.

Owner:SEMICON MFG INT TIANJIN +1

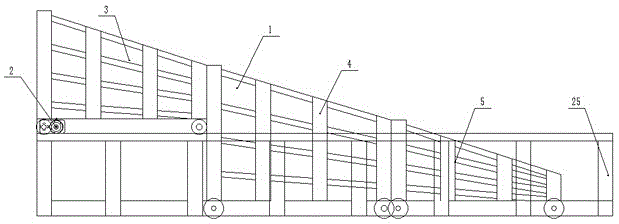

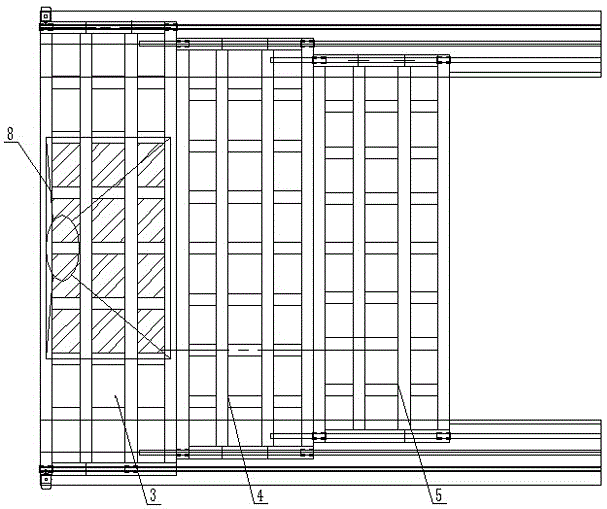

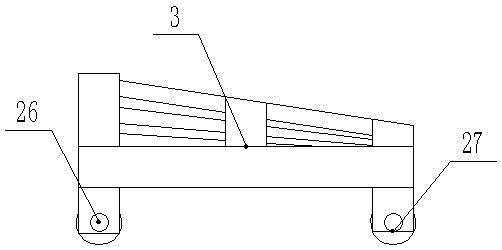

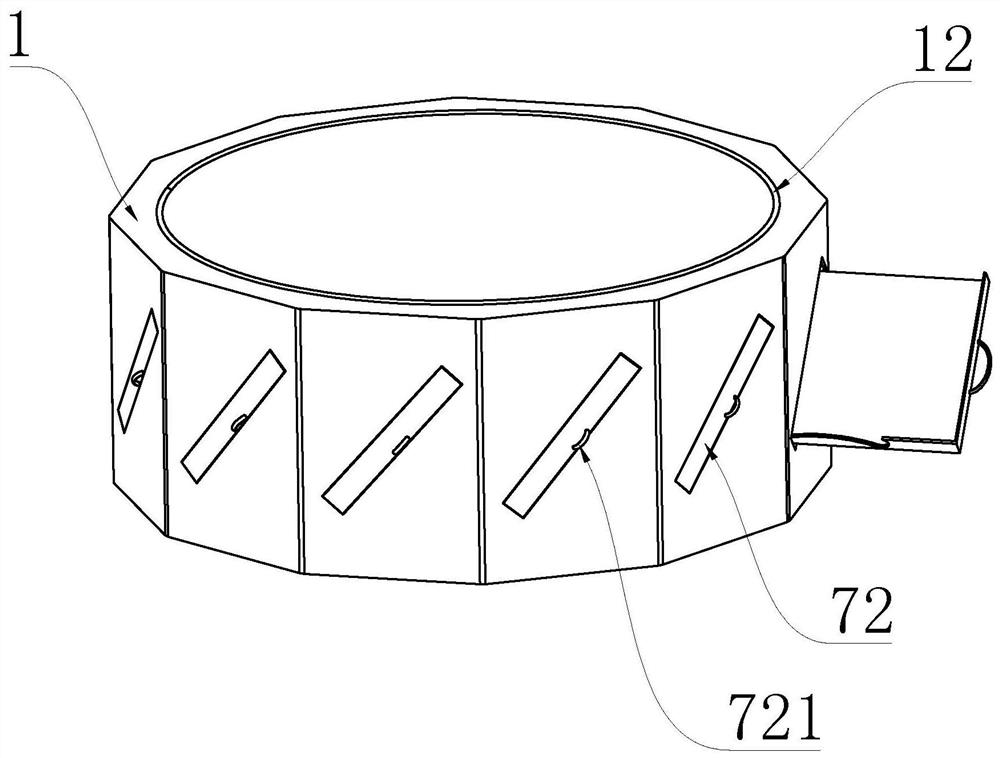

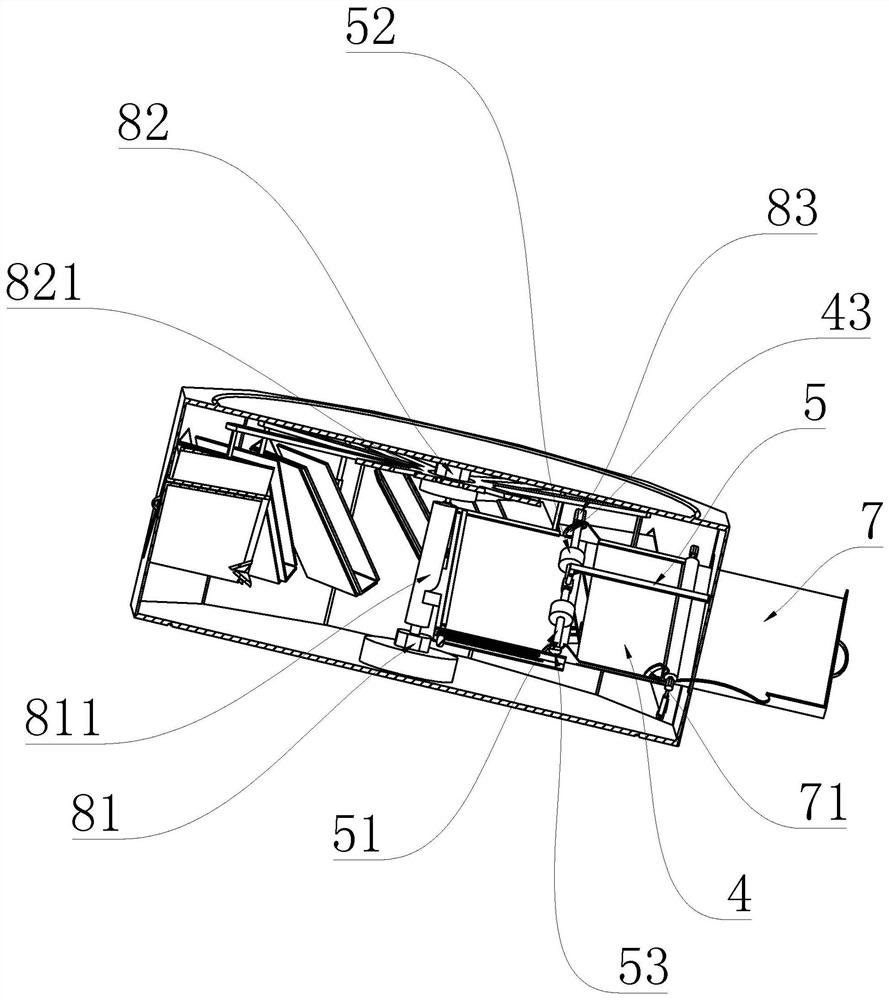

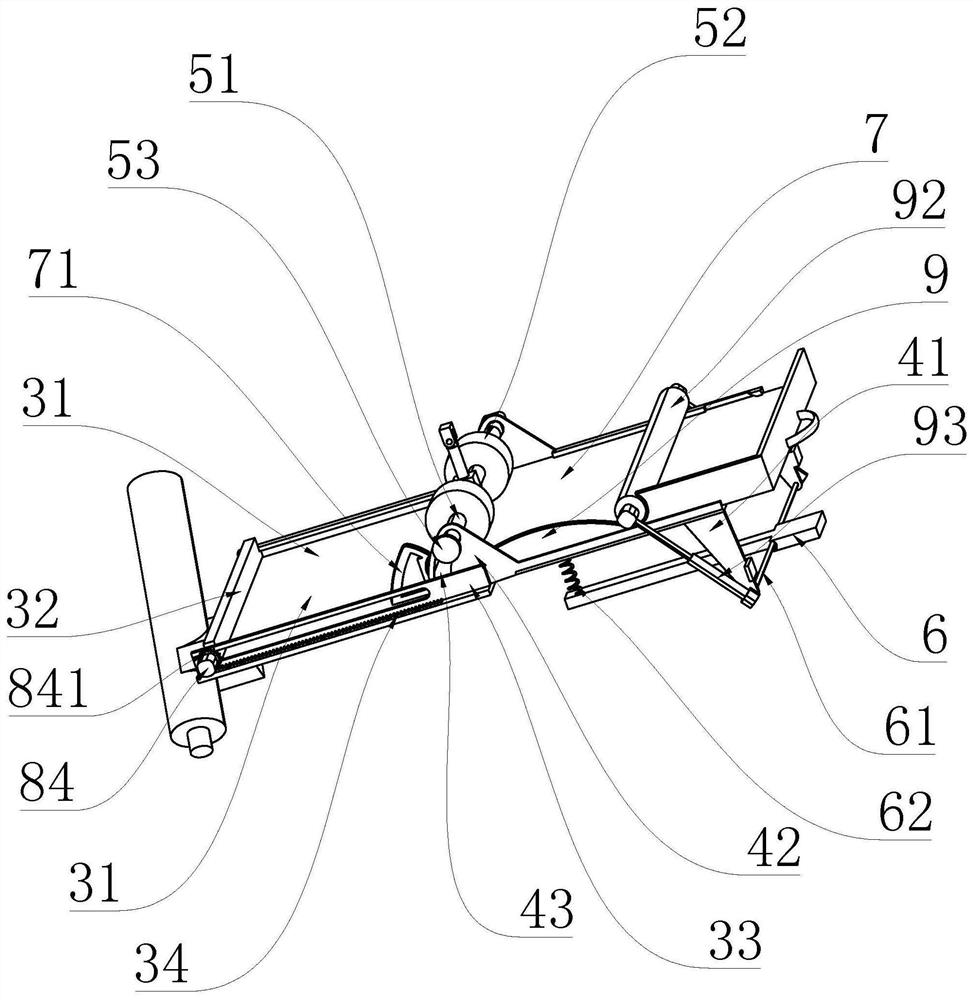

Roughing furnace dust removal telescopic closed fume hood

ActiveCN104215082BImprove dust removal effectWill not affect the processWaste heat treatmentSmoke hoodAutomation

The invention belongs to the field of dust removal smoke hoods, particularly discloses a stretchable / retractable closed dust removal smoke hood for a rough smelting furnace, solves the problems in the prior art, and aims at providing the stretchable / retractable closed dust removal smoke hood for the rough smelting furnace, which is low in design cost and manufacturing cost, convenient to use, high in automation degree, large in dust collection coverage area, good in dust removal effect and quite applicable to pit-type pouring. The stretchable / retractable closed dust removal smoke hood for the rough smelting furnace comprises a smoke collection hood and a driving device, wherein the smoke collection hood is movably arranged above a pit and is used for covering ladles in the pit, and the coverage area is changeable; after being stretched, the smoke collection hood can cover the whole pit; after being retracted, the smoke collection hood is positioned on one side, far away from an iron outlet, of the pit; the driving device is fixedly arranged on the smoke collection hood and can be used for driving the smoke collection hood to be stretched and retracted.

Owner:JIAOCHENG YIWANG FERROALLOY

An intelligent ironing and compacting filing cabinet

ActiveCN111685500BPrevent the phenomenon of flying outImprove ironing effectBook cabinetsBook-troughsEngineeringPaper sheet

Owner:深圳市厚朴空间智能家具有限公司

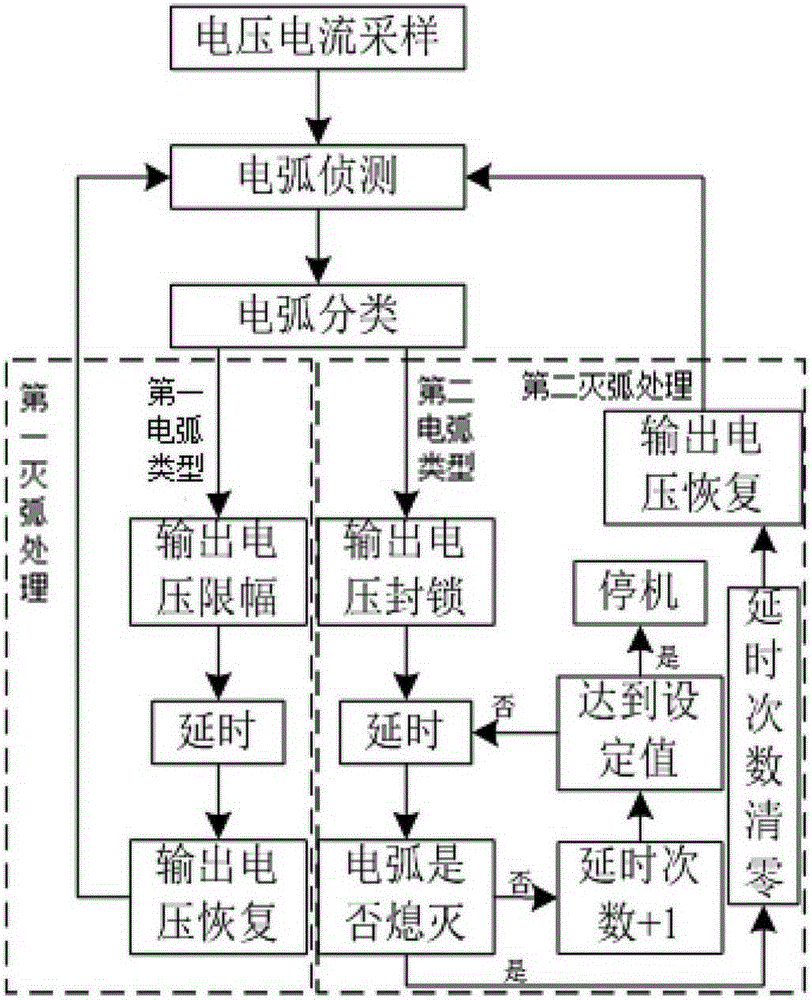

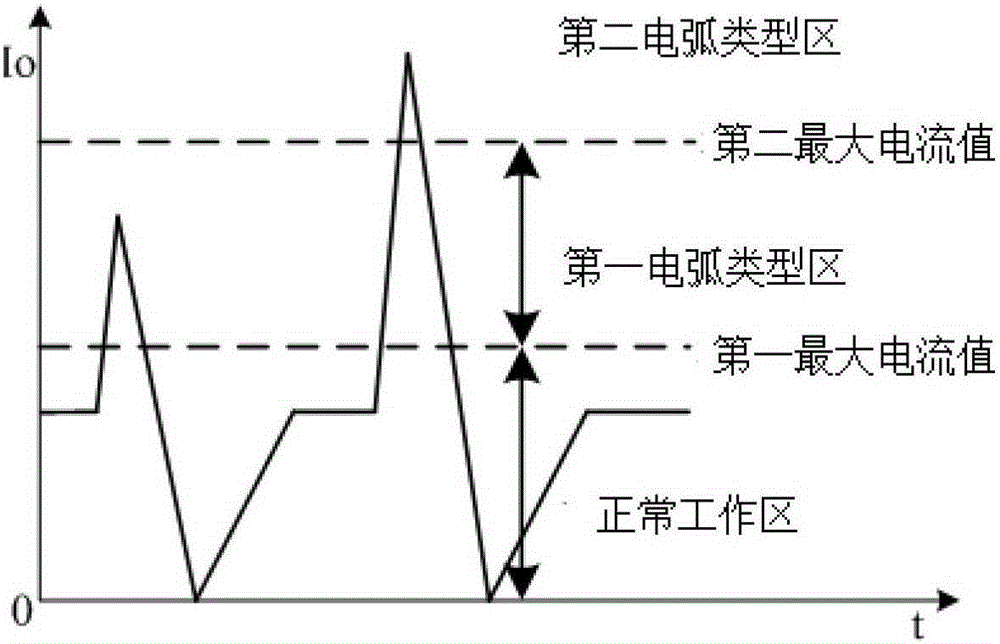

An arc extinguishing method for magnetron sputtering process

InactiveCN103436851BImprove detection rateWill not affect the processVacuum evaporation coatingSputtering coatingSputteringPower flow

The invention discloses an arc extinguishing method for a magnetron sputtering process. First, the output voltage and current of a magnetron sputtering power supply are sampled, and arc detection is performed according to the voltage slope and current amplitude to determine whether an arc is generated; secondly, according to Arc classification is performed on the magnitude of the current generated by the arc, and the arc is divided into a first arc type and a second arc type; finally, arc extinguishing treatment is performed on the first arc type and the second arc type respectively. The invention can quickly detect and extinguish the arc generated in the magnetron sputtering process, the method is simple, feasible and easy to realize, and makes up for the problems of false detection and missing detection and loss of process intervals in the previous arc detection and extinguishing methods, and can effectively Protect sputtering targets, process bays and power supplies.

Owner:XIAN UNIV OF TECH

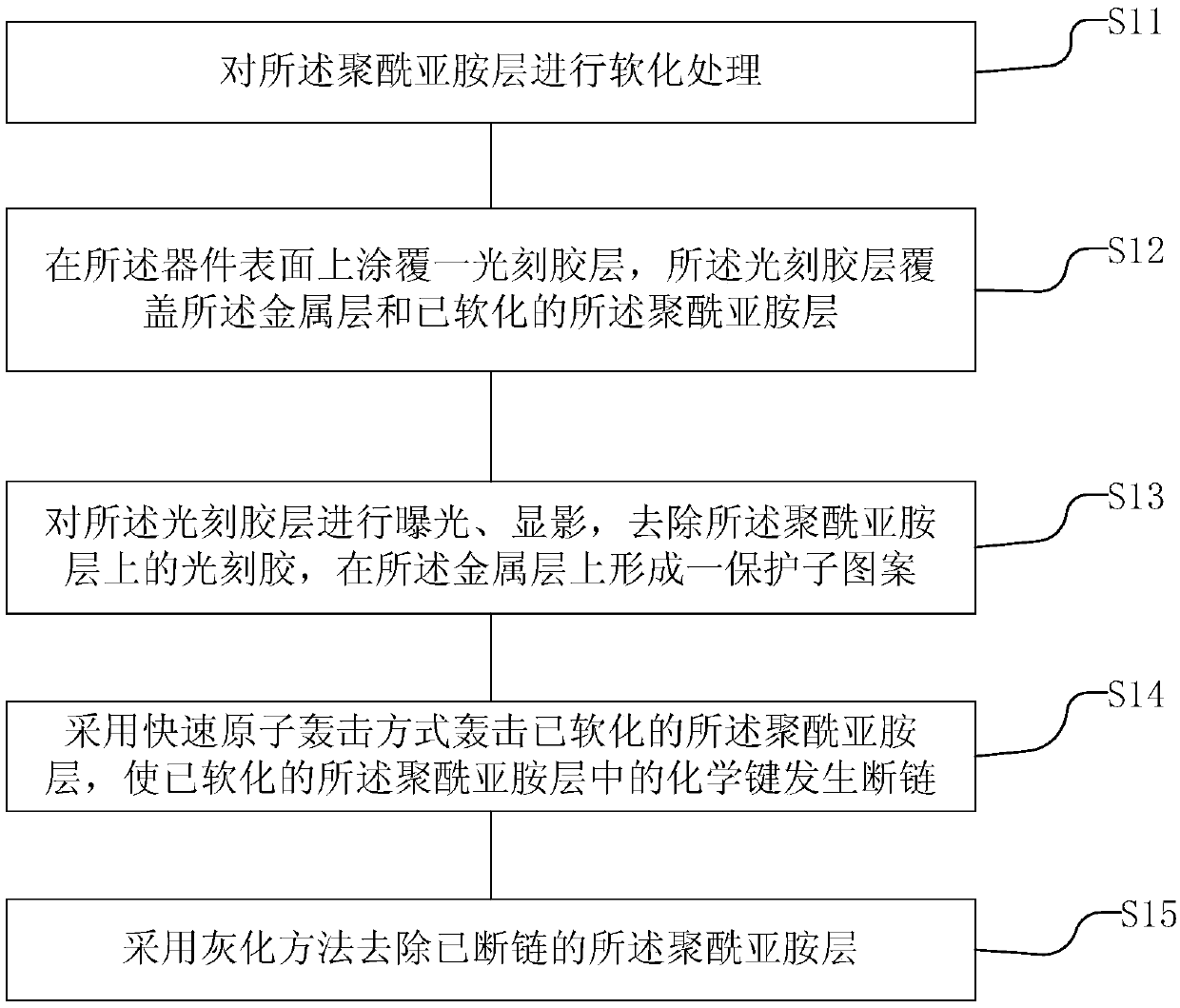

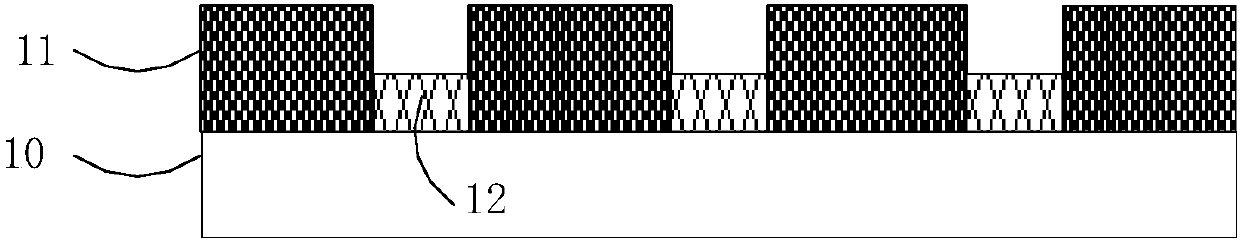

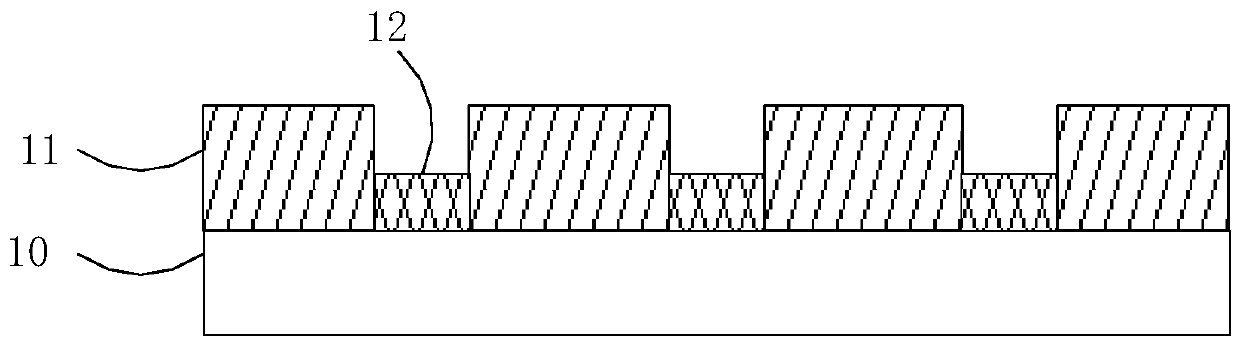

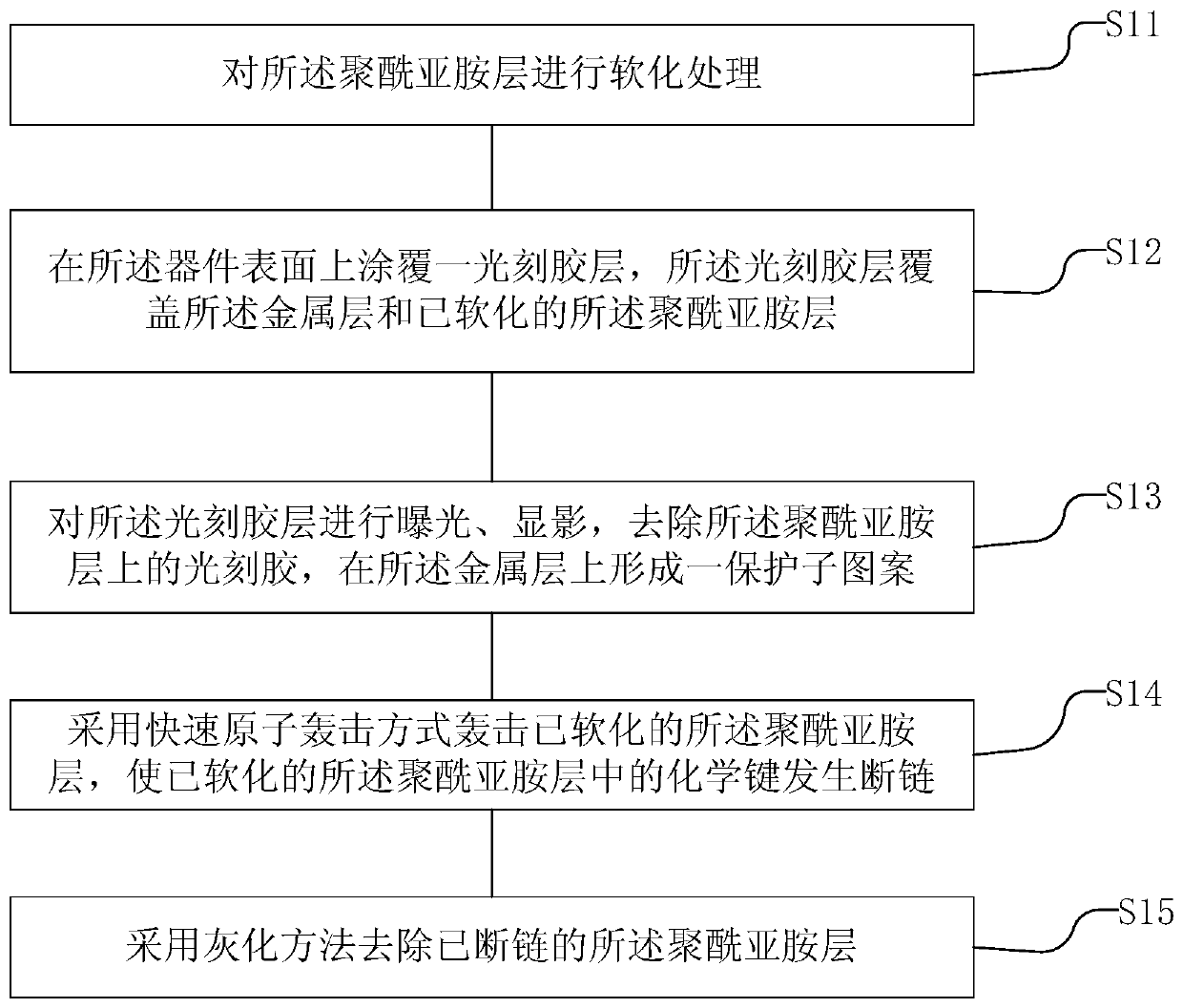

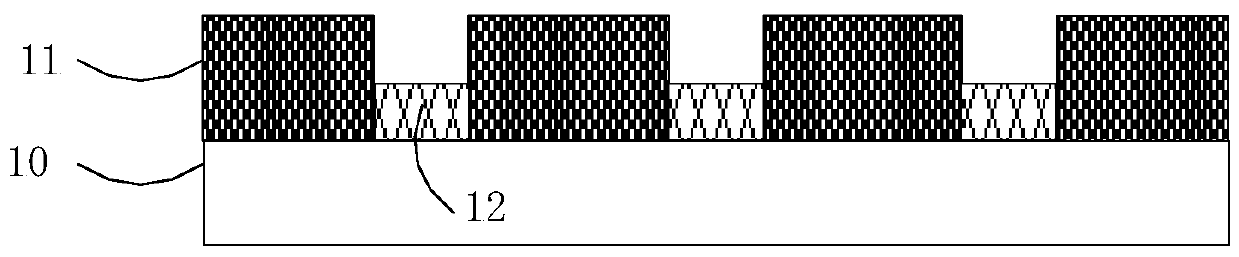

Removal method for protection layer on surface of device

ActiveCN107768232AReduce hardnessGood removal effectSemiconductor/solid-state device manufacturingHardnessProtection layer

The invention discloses a removal method for a protection layer on a surface of a device. The removal method comprises the steps of softening the protection layer; bombarding the softened protection layer by employing a rapid atomic bombardment mode so that a chemical bond in the softened protection layer is broken; and removing the broken protection layer by an ashing method. By softening the protection layer, the hardness of the cured protection layer is reduced; with the adoption of the rapid atomic bombardment mode, the chemical bond of a protection layer material is broken, more broken chemical bonds are formed, so that the property of the protection layer is changed, and the subsequent ashing process is facilitated; and finally, the broken protection layer material can be easily removed by an ashing mode. With the adoption of the removal method provided by the invention, the protection layer can be completely removed, and the subsequent rework process and the electric property ofan electrical appliance cannot be affected.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A Method for Reducing Wafer Edge Yield Test Issues

ActiveCN106803482BWill not affect the processNo false test failuresSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingWaferEngineering

The present invention provides a method used for reducing wafer edge yield test problem. The method comprises a first step of obtaining a patterned photomask and the patterned photoresist adopted to execute the photoetching on a passivation layer of a wafer; a second step of inverting the patterned photomask to obtain an inverted patterned photomask, and changing the positive and negative attributes of the patterned photoresist on the condition of keeping a constant photoresist pattern to obtain the reverse patterned photoresist; a third step of utilizing the inverted patterned photomask and the reverse patterned photoresist to execute the photoetching on the wafer. According to the method used for reducing the wafer edge yield test problems of the present invention, the photomask and the photoresist of the passivation layer both become inverted, so that the figures of other parts, except a predetermined part starting at an edge position, in the wafer, do not change, and the passivation layer is retained from the edge to the predetermined part, and accordingly, a test false failure problem is not generated.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

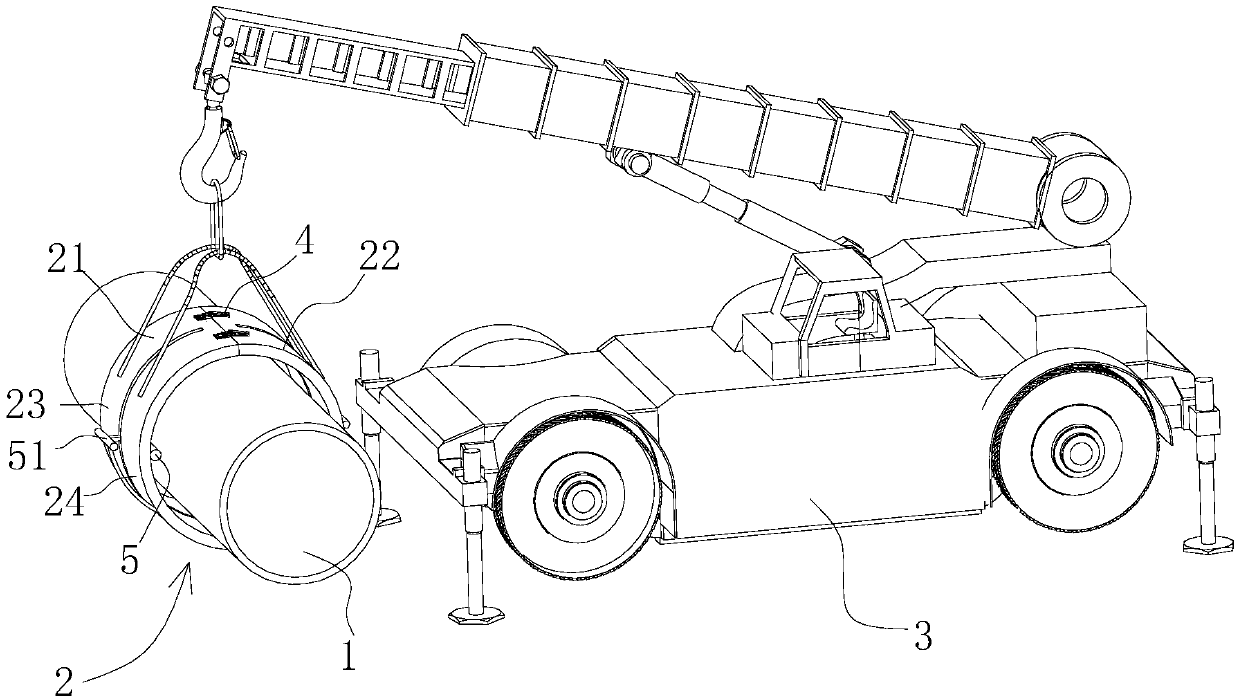

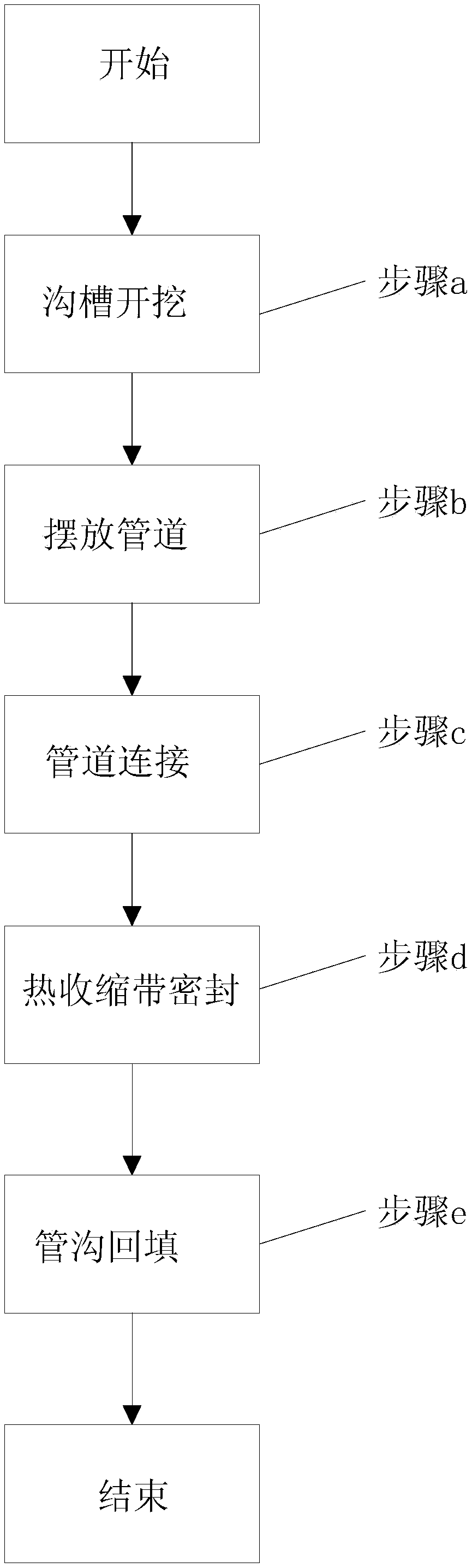

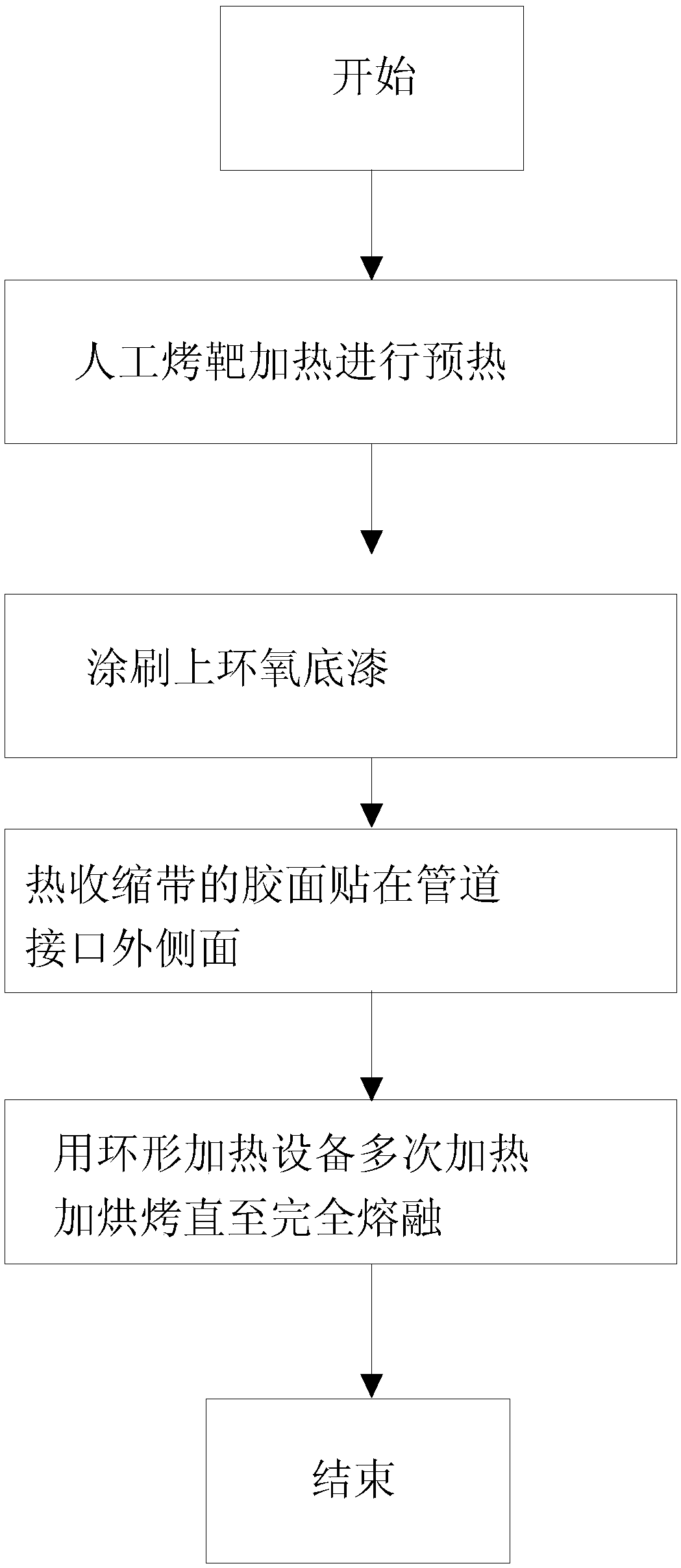

Installation and construction technology of large-diameter hdpe plastic-steel winding pipe

ActiveCN106969198BSolve uneven heatingExcellent adhesionPipe laying and repairPipe heating/coolingCooking & bakingMechanical engineering

The invention discloses a large-diameter HDPE plastic steel winding pipeline installation construction process. The problems that a heat shrinkable tape anticorrosion repaired mouth is baked mainly though artificial flame, and especially for a large-diameter pipeline, heating is nonuniform during construction are solved. According to the main points of the technical scheme, the inside and the outside of a connector between pipelines is welded and sealed through a heat shrinkable tape; heat shrinkable tape welding and sealing comprise the steps that preheating is conducted through manual target baking heating till the temperature of the pipeline connector is 50 DEG C-70 DEG C; epoxy primer with the thickness not smaller than 150 [mu]m is brushed on the pipeline connector evenly; the rubber face of the heat shrinkable tape is attached to the outer side face of the pipeline connector; and annular heating equipment is installed on the outer side of a pipeline repaired mouth, and the repaired mouth is heated and based till complete fusion is achieved; and a good adhesion effect is ensured, thus the service life of the heat shrinkable tape is longer, zero leakage of the pipelines is achieved, fluid in the pipelines does not flow out, and a better environmental protection effect is archived.

Owner:ZHEJIANG MINGTONG CONSTR ENG CO LTD

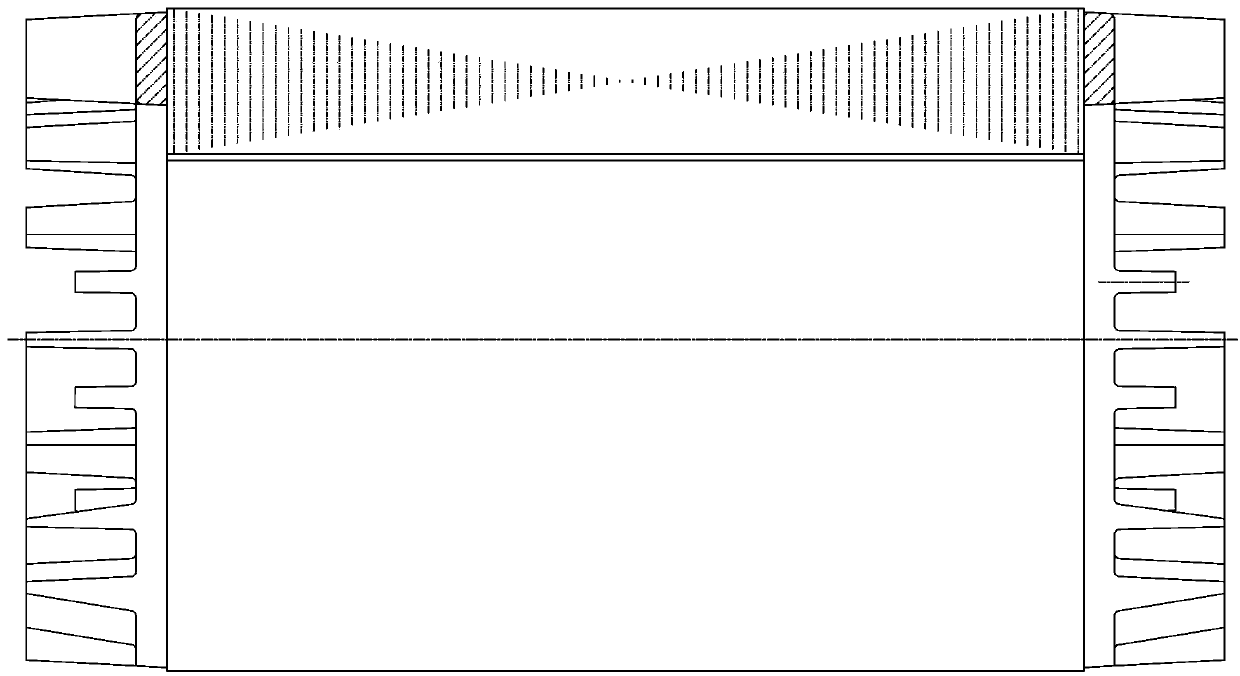

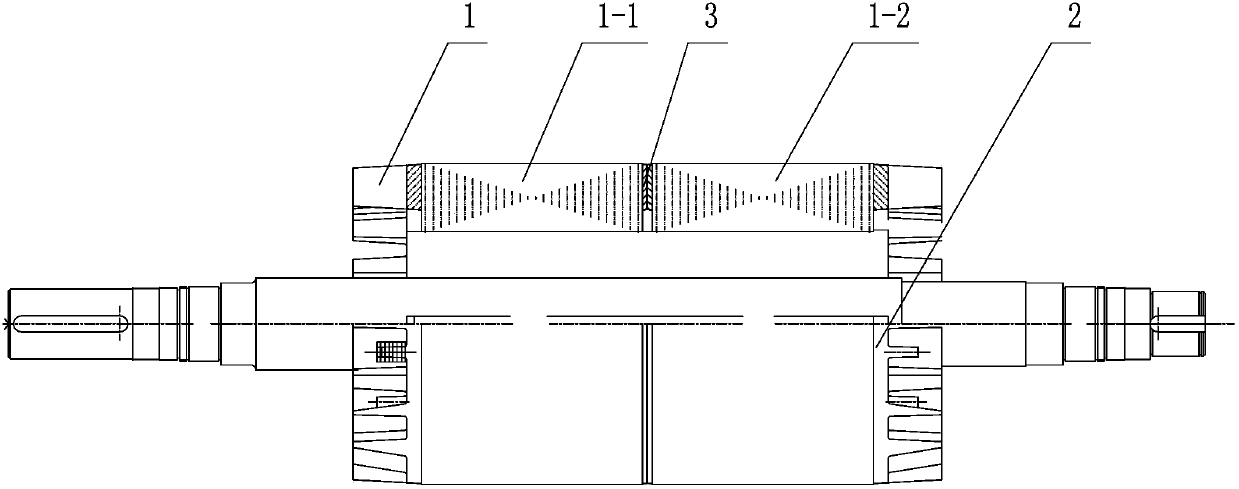

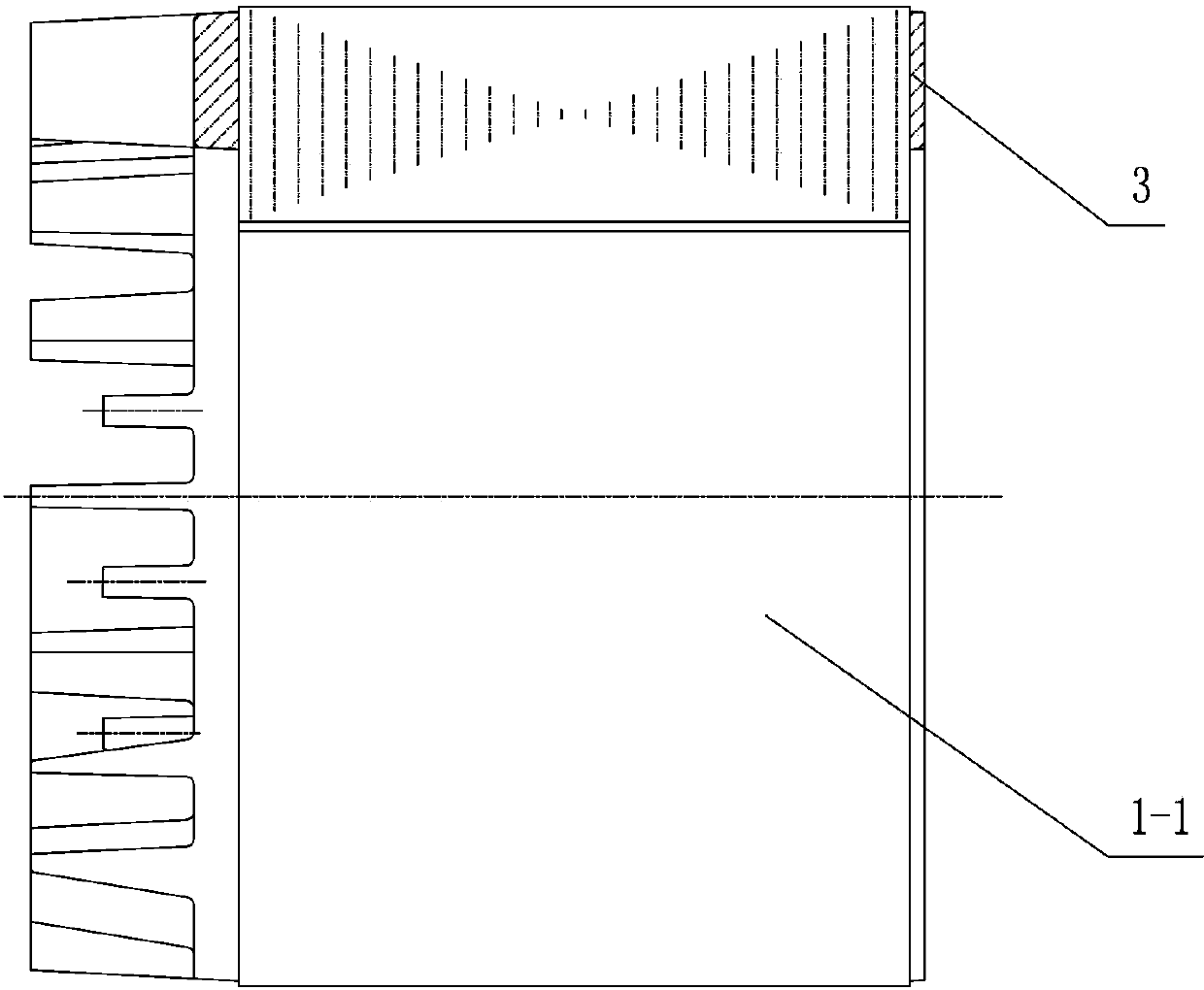

Rotor structure of three-phase asynchronous motor

InactiveCN103390944ASimple structureShorten the lengthMagnetic circuit rotating partsEngineeringThree phase asynchronous motor

The invention relates to a rotor structure of a three-phase asynchronous motor. The rotor structure comprises a cast-aluminum rotor main body, wherein an iron core is arranged in the middle of the cast-aluminum rotor main body, and overlapped rotor punching is arranged outside the iron core. The rotor structure is characterized in that the cast-aluminum rotor main body is symmetrically divided into a left rotor and a right rotor from the middle part; connecting parts are arranged on opposite sides of the left rotor and the right rotor respectively; and the left rotor and the right rotor are connected through the connecting parts. The rotor structure of the three-phase asynchronous motor is simple in structure, and the iron core is divided into two sections, so that the length is shortened; two sections of the cast-aluminum rotor are combined after processed, so that the cast-aluminum process cannot be influenced and can be controlled well; and further, the cost is low, and the qualified rate is high.

Owner:WUXI ZHONGDA MOTORS

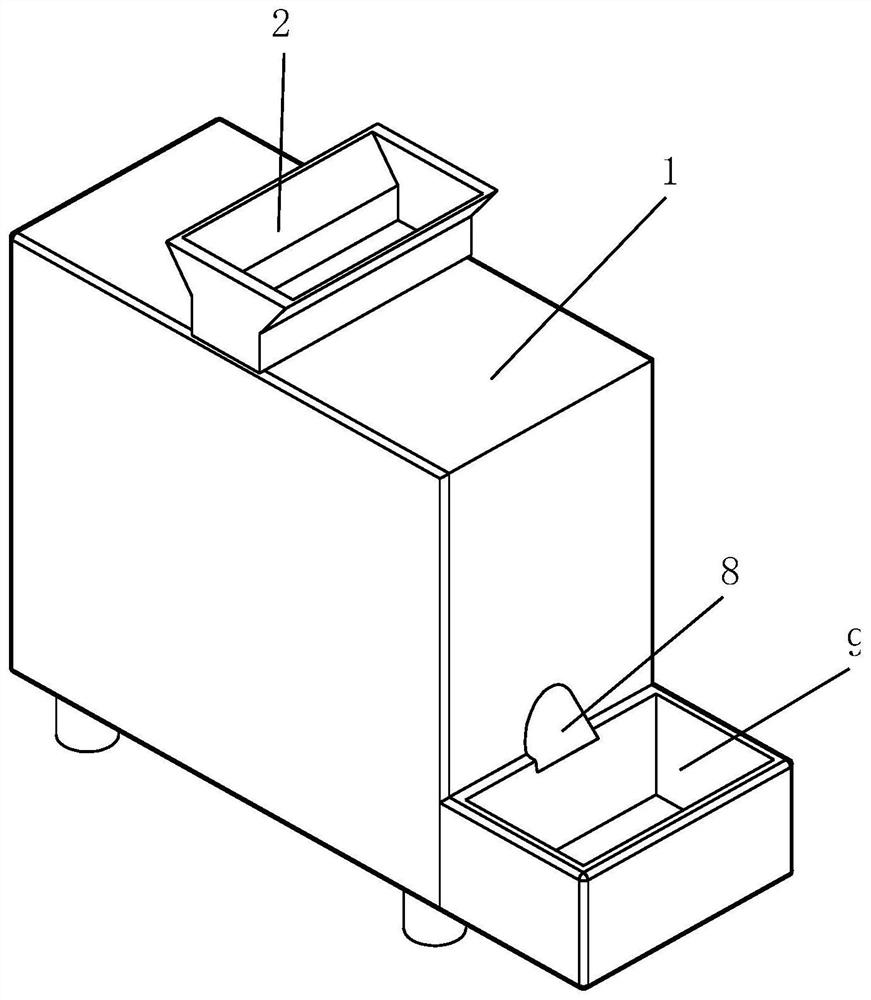

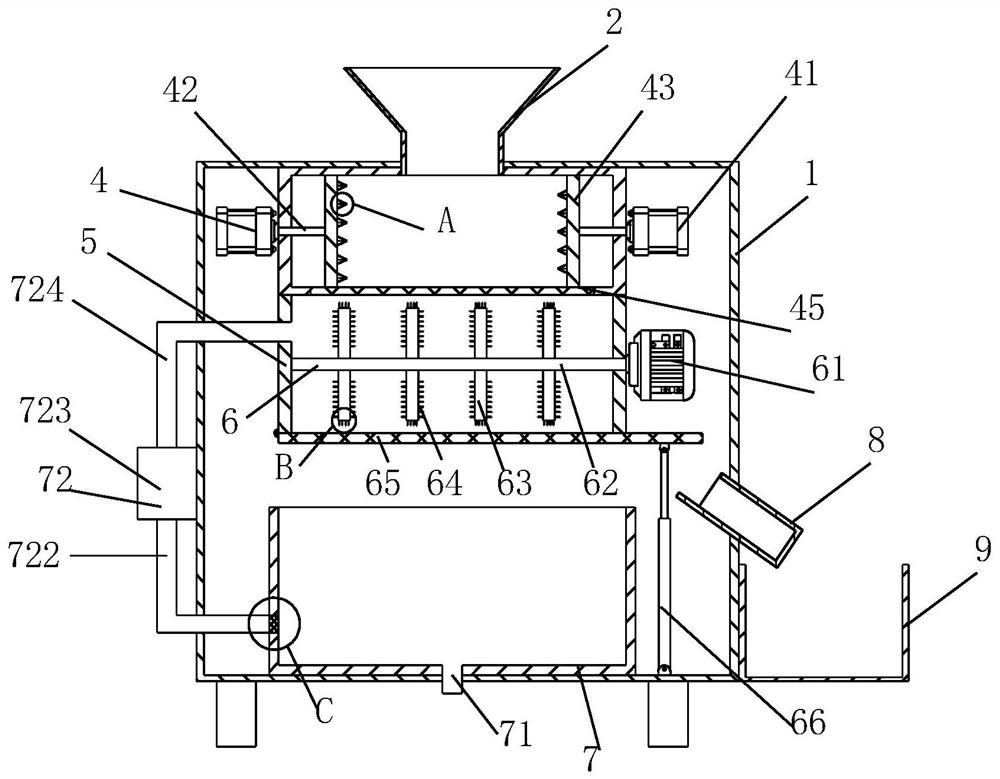

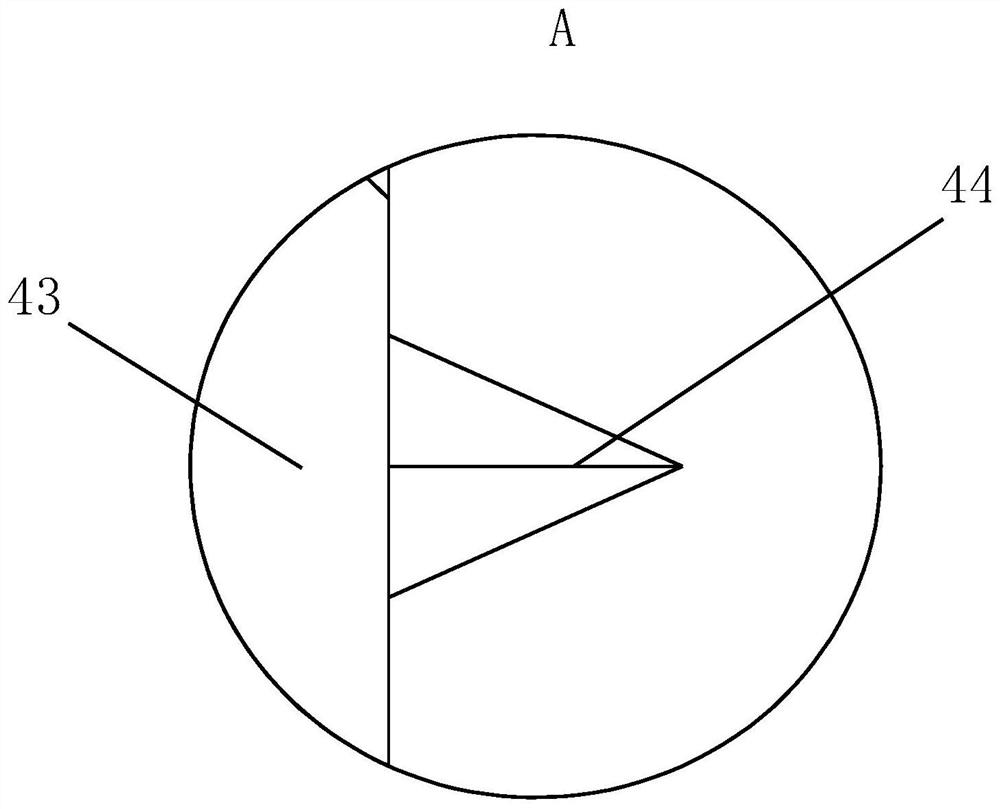

Industrial solid waste crushing and cleaning equipment and operation method thereof

PendingCN112275364ASave waterEasy to clean upCleaning using toolsCleaning using liquidsProcess engineeringWater storage tank

The invention belongs to the technical field of solid waste crushing and cleaning, and particularly relates to industrial solid waste crushing and cleaning equipment and an operation method thereof. The equipment comprises a shell and a water storage box; the bottom end of the shell is fixedly connected with a group of supporting columns; a feeding cylinder is arranged at the top end of the shell;a crushing box is fixedly connected to the inner side wall of the top end of the shell; the crushing box communicates with the feeding cylinder; a crushing mechanism is arranged in the crushing box;the bottom end of the crushing box is fixedly connected with a cleaning box; the cleaning box communicates with the crushing box through a first filter screen; a cleaning mechanism is arranged in thecleaning box; a second filter screen is hinged to the side wall of the bottom end of the cleaning box; and an electric telescopic rod is hinged to the bottom end, away from the hinged end, of the second filter screen. According to the industrial solid waste crushing and cleaning equipment and the operation method thereof, the problems that solid waste crushing cannot reach the crushing standard, the crushed material cleaning effect is low, cleaning is not thorough enough, consequently, subsequent procedure treatment of the solid waste is troublesome and the efficiency is not high are solved.

Owner:沈会琼

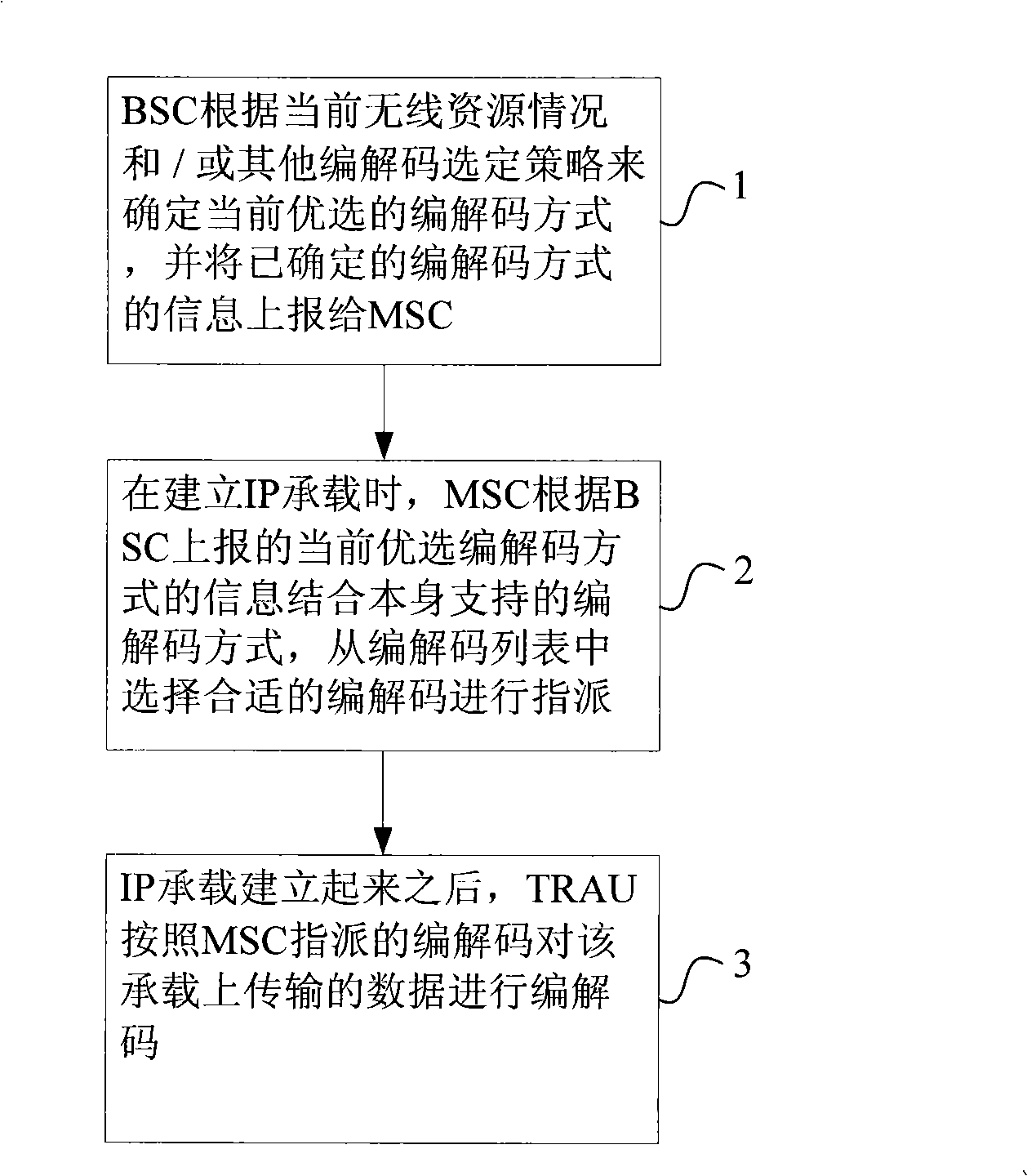

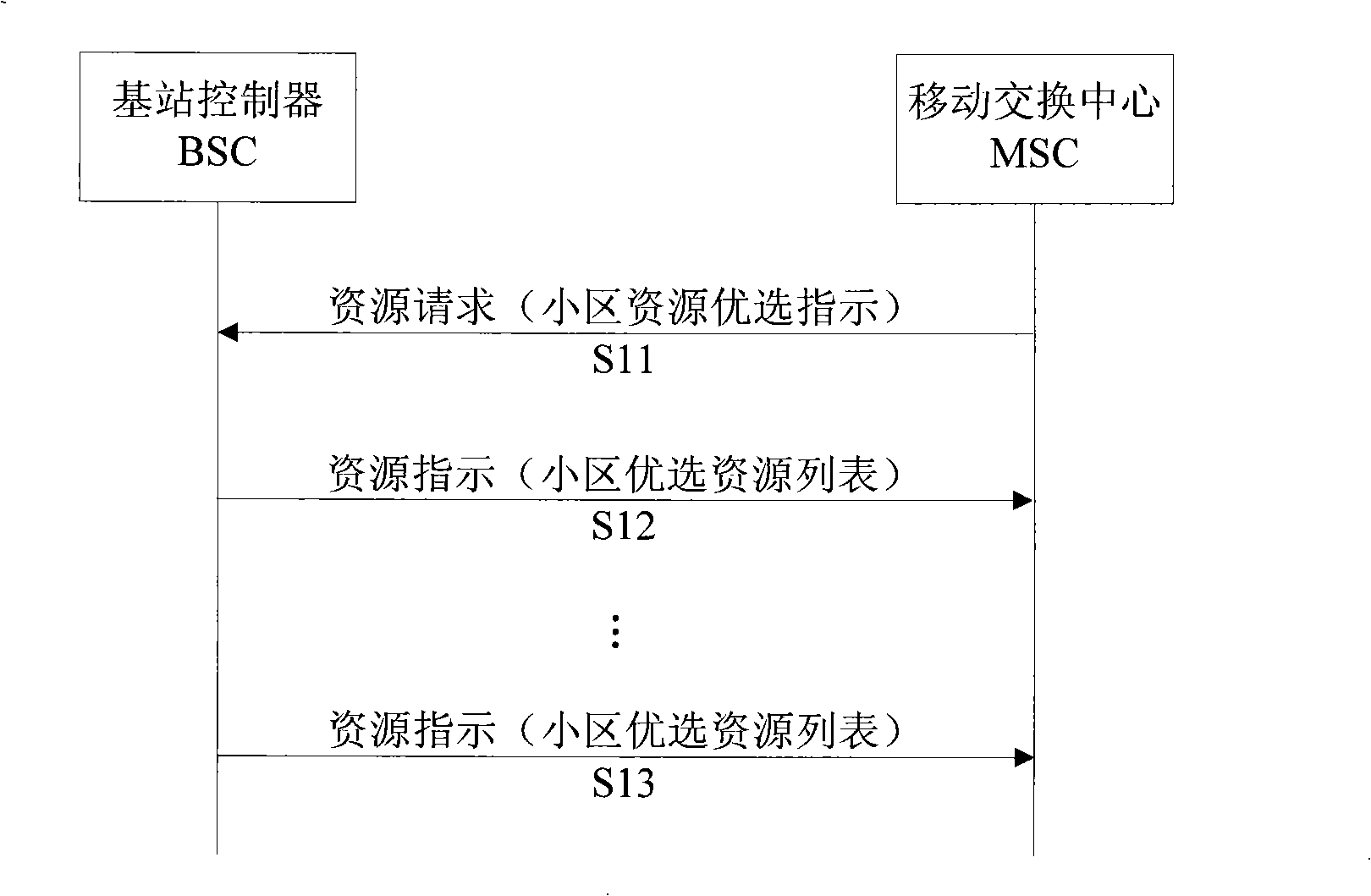

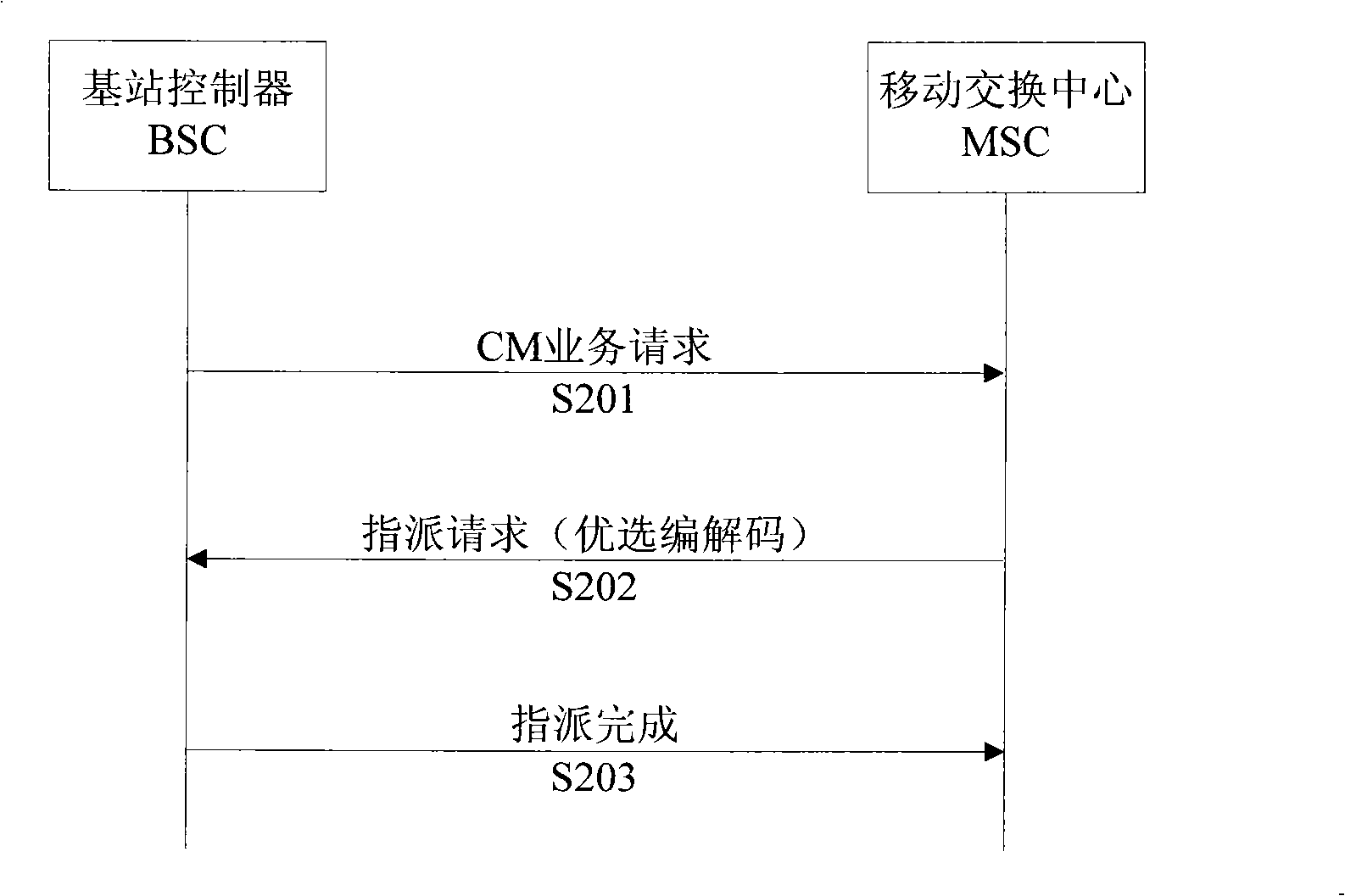

Method and system for acquiring current optimization code encoding/decoding mode information in mobile communication network

InactiveCN101330743AEasy to operateImprove business qualityRadio/inductive link selection arrangementsService qualityReal-time computing

The invention discloses an information acquisition method of current optimal codec manner in mobile communication network and a system. The mobile communication network comprises a mobile terminal MS, a mobile switching center MSC, a base station controller BSC and an interface A between the MSC and the BSC. An optimal codec manner request module on the MSC transmits a message to inform the BSC to report information of the current optimal codec manner; an optimal codec manner report module on the BSC reports the information of the determined current optimal codec manner to the MSC in response to the information message transmitted by the MSC; and an optimal codec manner storage module on the MSC receives the message from the BSC and stores the information of the current optimal codec manner contained in the received message. The method only expands the current message, and can achieve the information acquisition of the current optimal codec manner of the BSC without changing signaling flow of control surface of the interface A, thereby improving the service quality of the wireless communication.

Owner:ZTE CORP

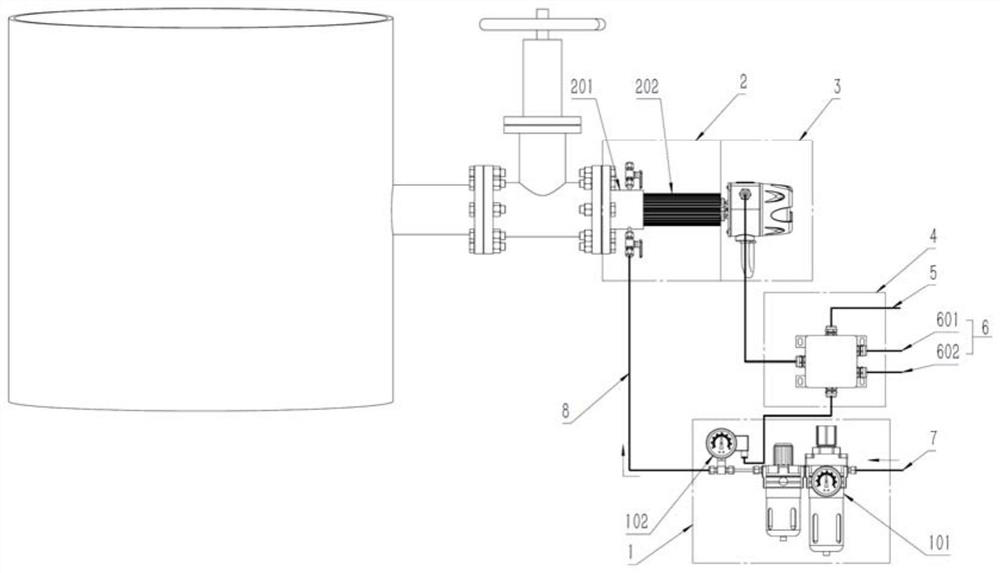

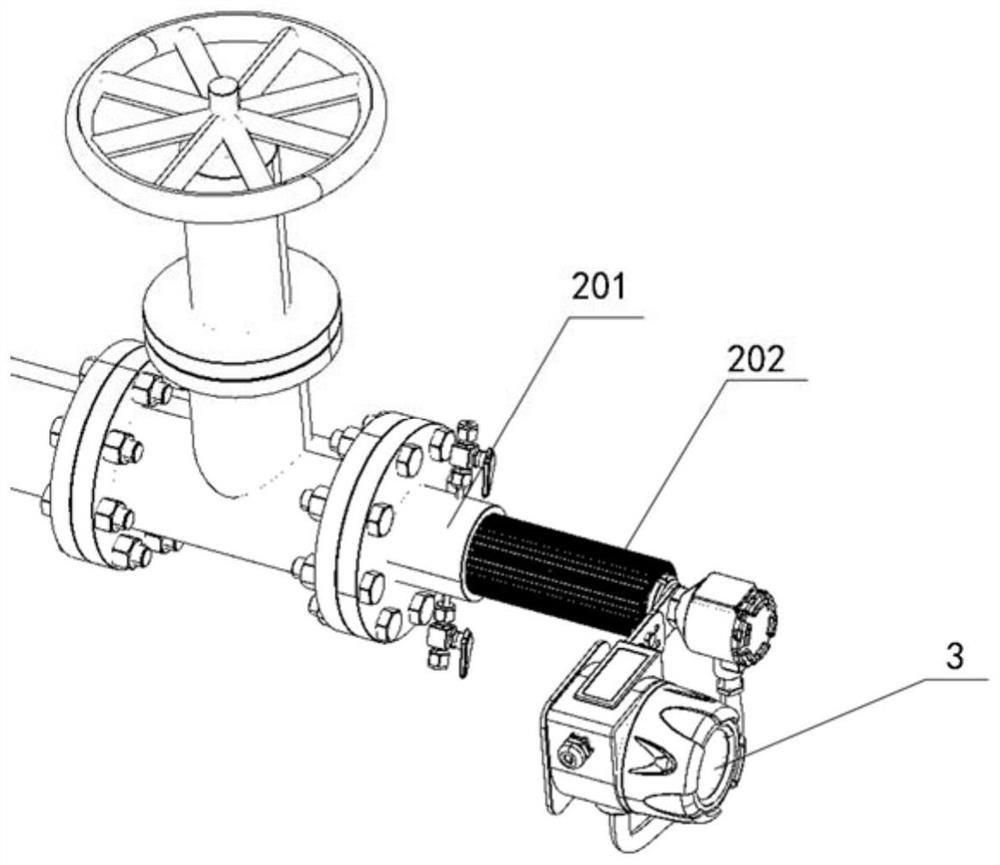

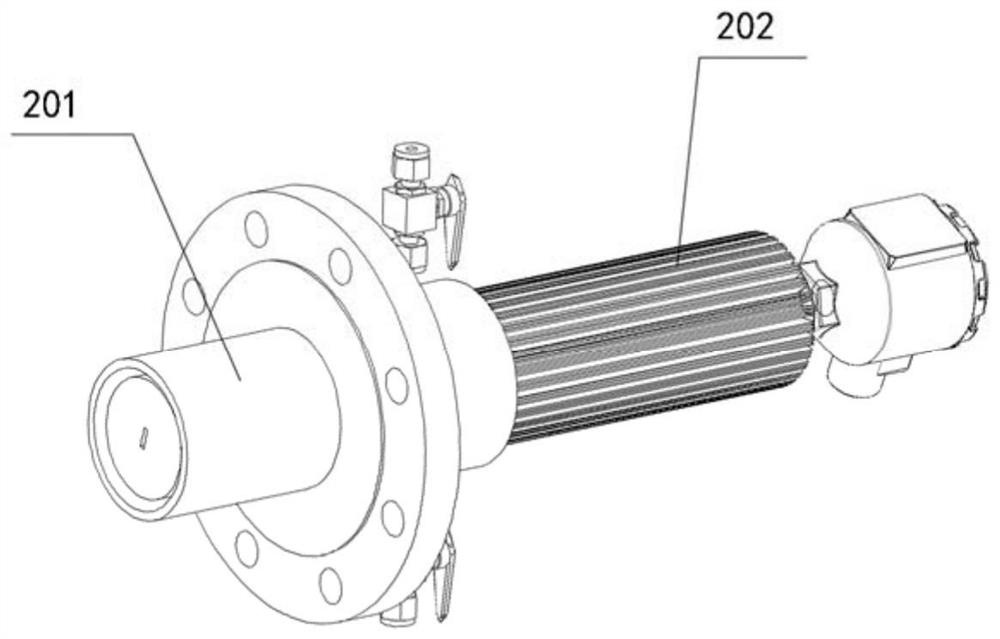

Non-contact particle size analyzer and application method thereof

PendingCN114324082AWide dynamic rangeImprove anti-interference abilityParticle size analysisParticle suspension analysisDigital signal processingParticulates

The invention discloses a non-contact particle size analyzer and an application method thereof, the non-contact particle size analyzer comprises a purging device, a signal acquisition device, a data analysis processing unit and an electrical connection unit, the signal acquisition device comprises a sensor and a radiator, the purging device is connected to the sensor, and the data analysis processing unit is connected to the radiator. The sensor is connected with the data analysis processing unit, the data analysis processing unit is connected with the electrical connection unit, and the electrical connection unit is connected with the power cable and the signal output cable. Based on a particulate matter electrostatic induction measurement core technology of a fluid / statistical model and digital signal processing, the system has an ultra-wide dynamic range and ultra-strong anti-interference capability; under the condition that the measurement requirement is met, any part of the sensor does not need to extend into the valve, and online installation and online maintenance can be realized; the non-contact measurement is realized, the sensitivity and the safety are ultrahigh, and the process is not influenced under the condition that the measurement accuracy is ensured; the adaptability is high.

Owner:杭州科灵威识精密仪器有限公司

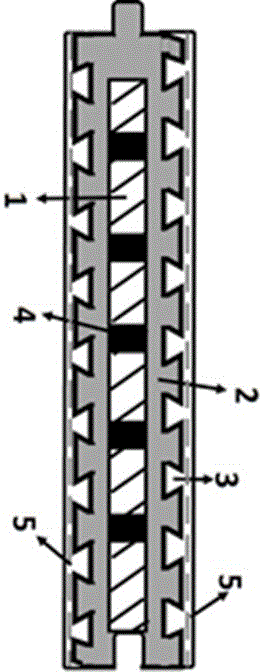

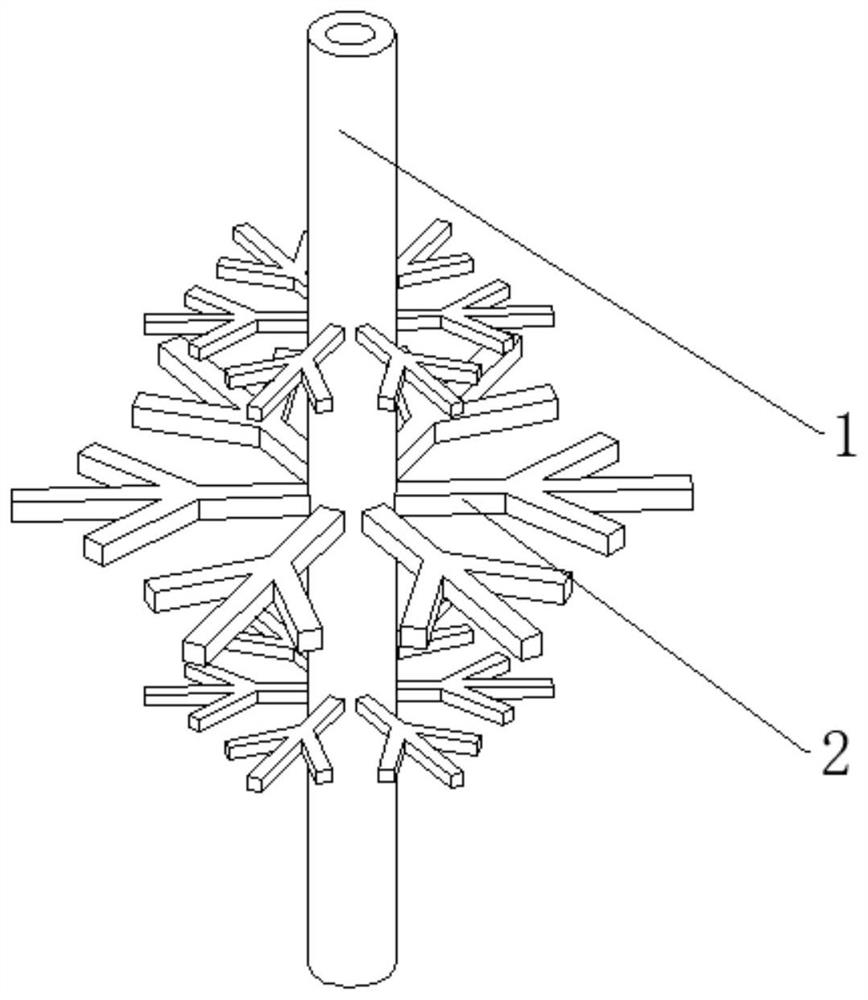

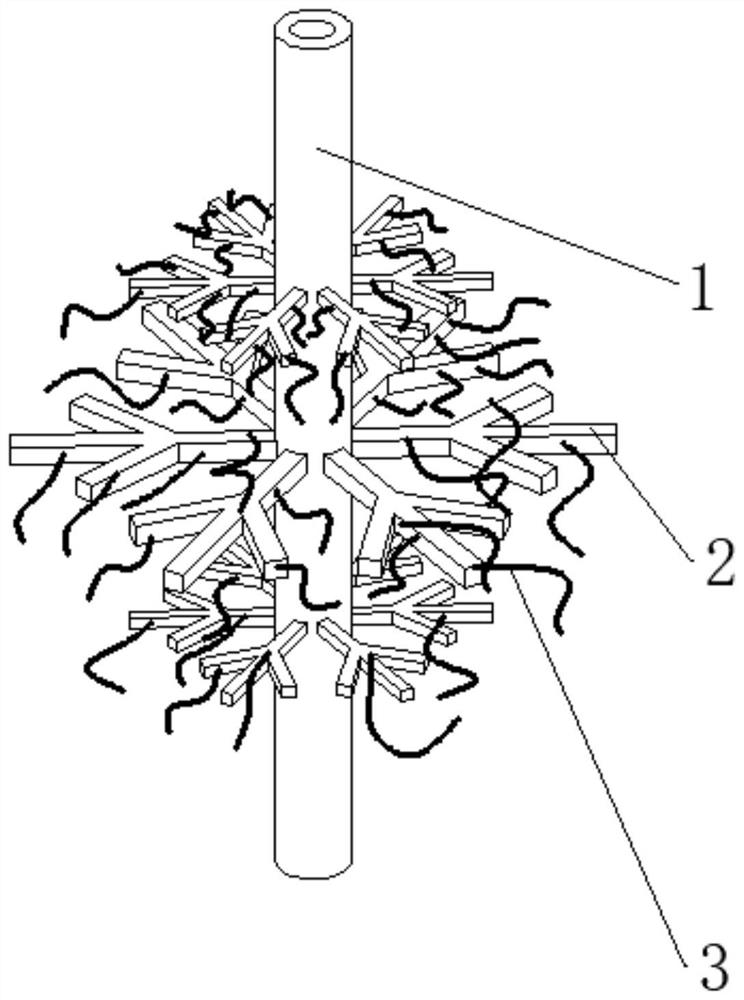

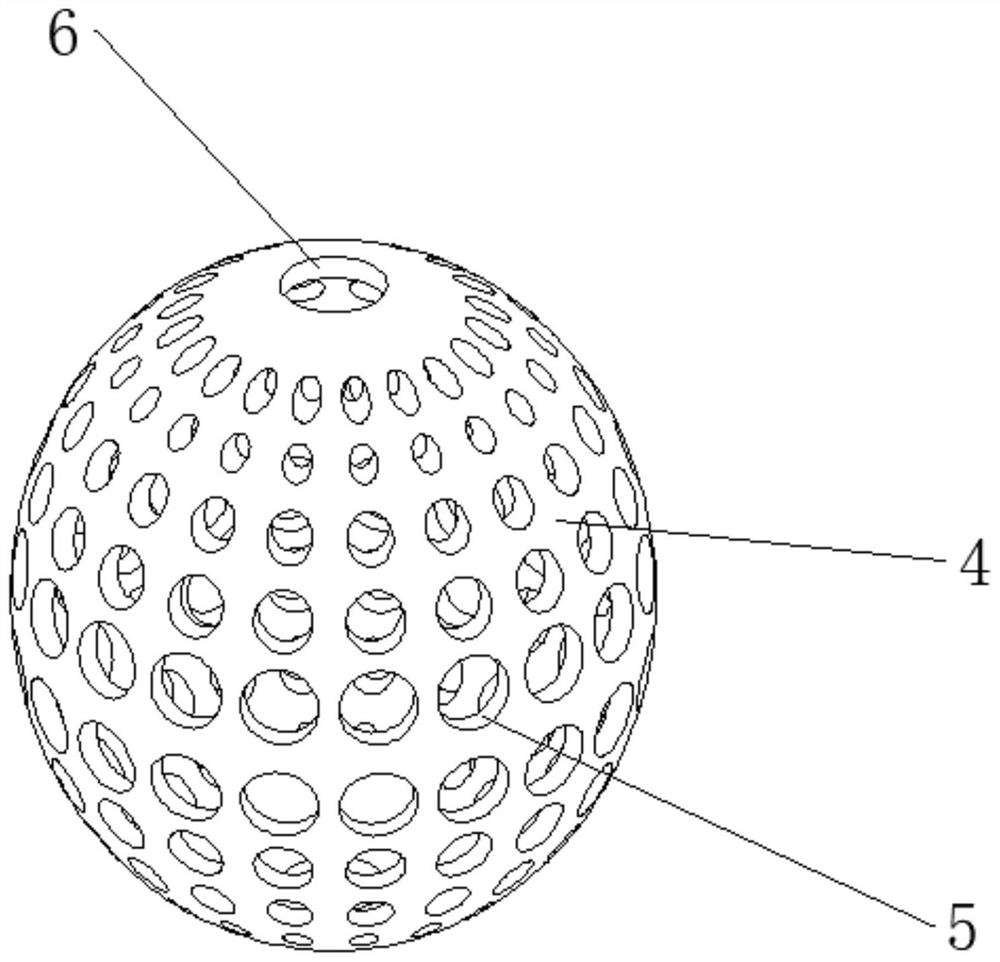

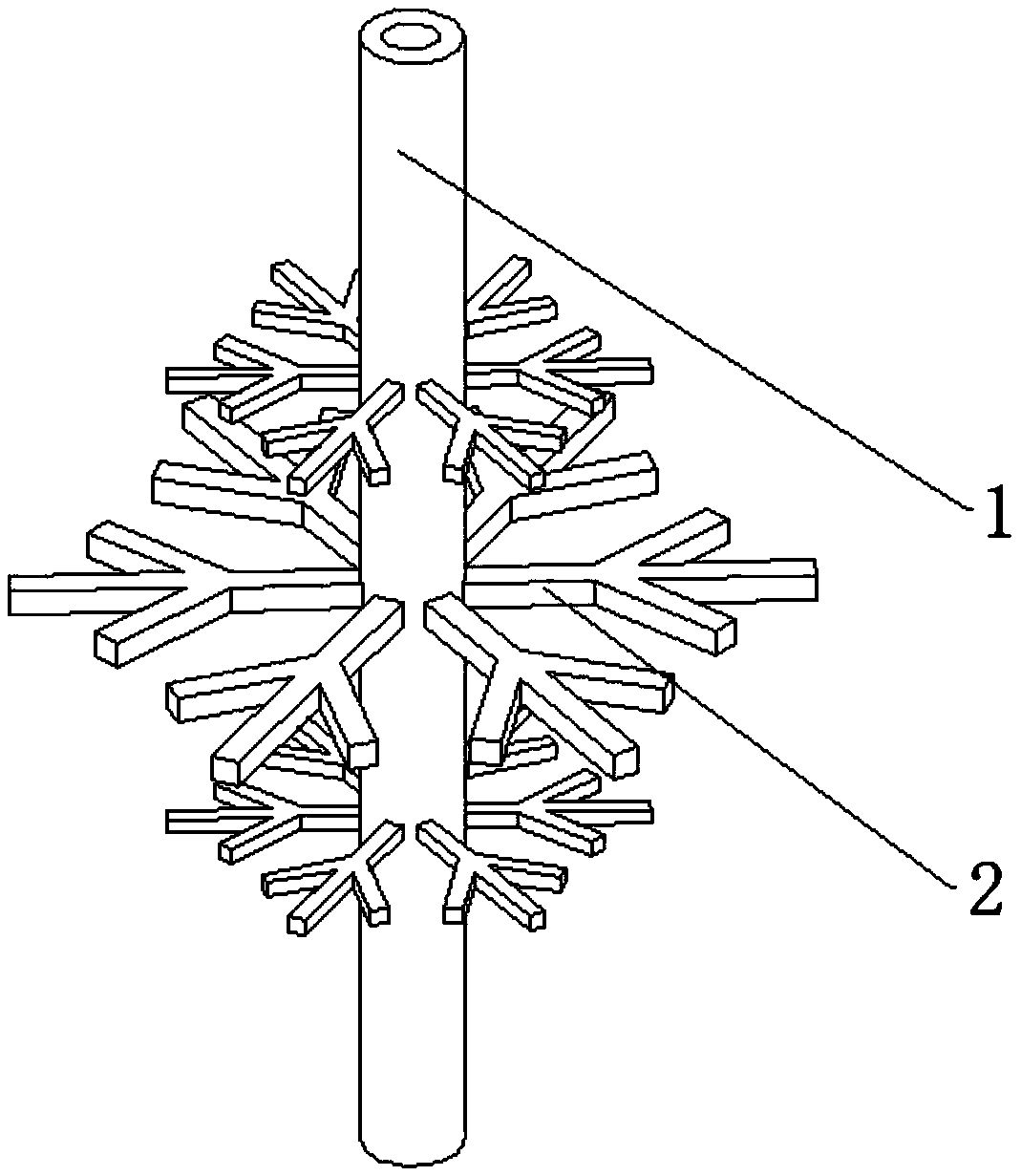

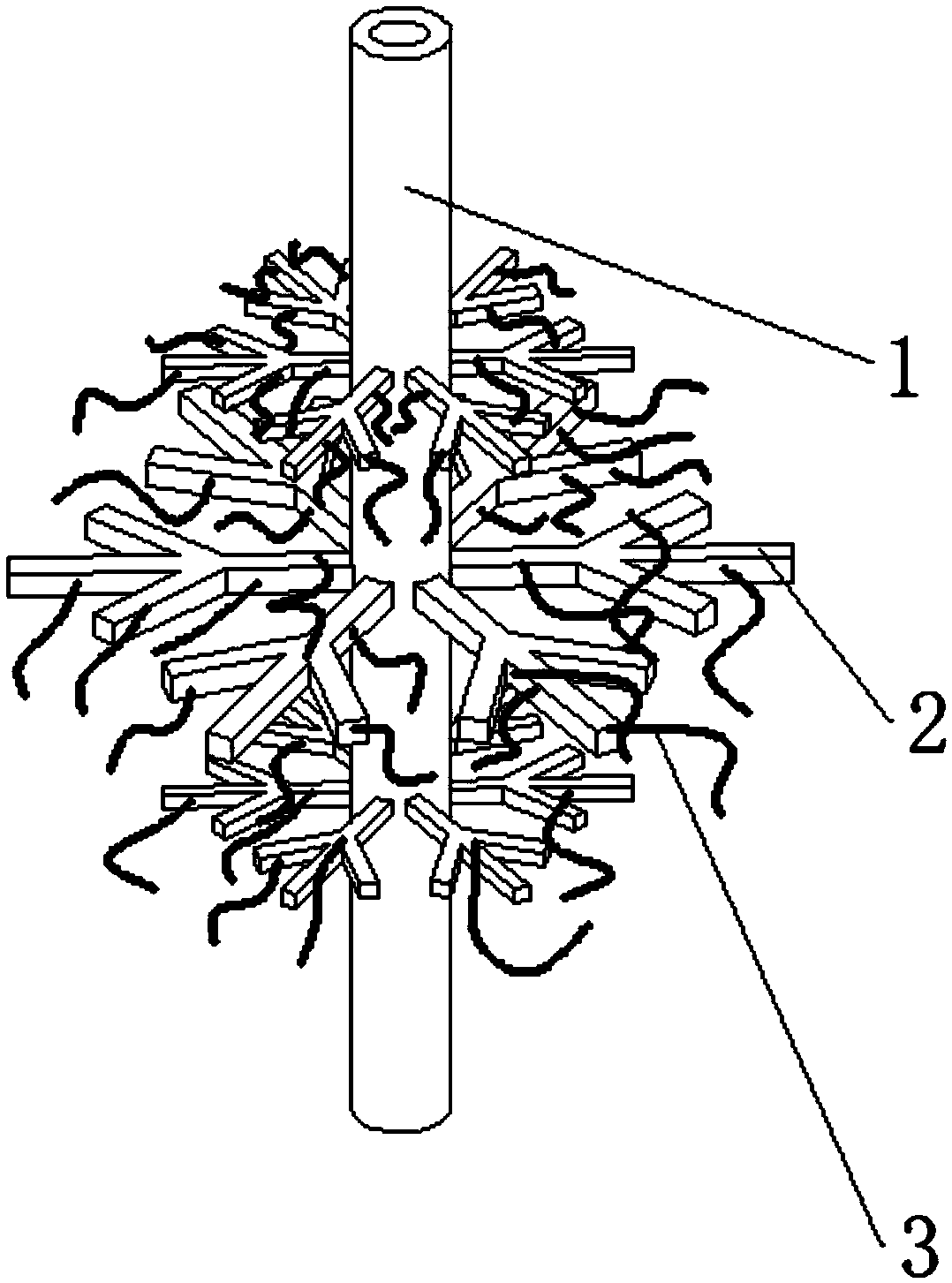

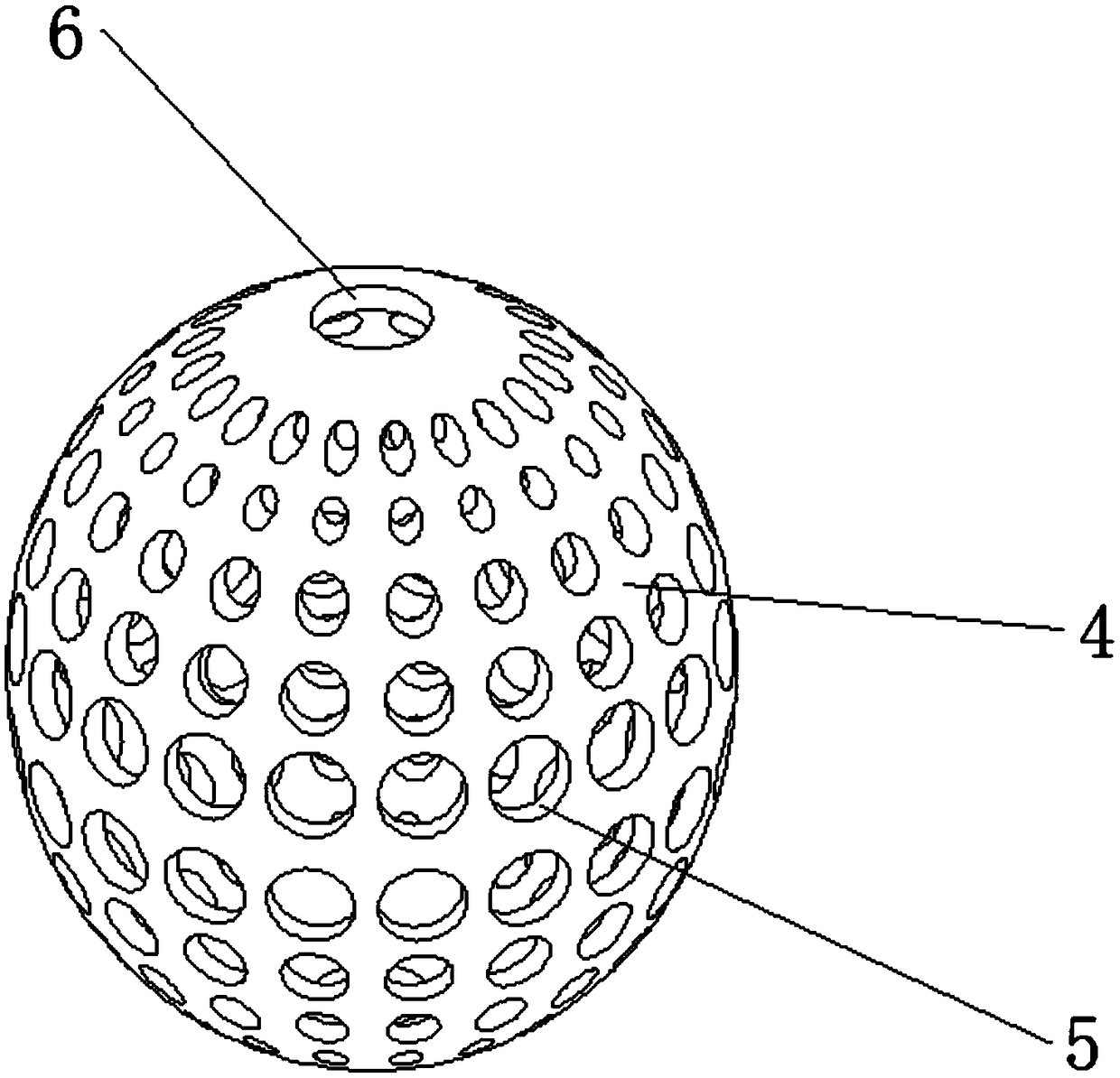

A kind of platinum asbestos catalyst ball for gas phase hydrogenation and preparation method thereof

ActiveCN109046343BNot easy to cause lossLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsPlatinumPtru catalyst

The invention discloses a platinum asbestos catalyst ball for gas-phase hydrogenation. The platinum asbestos catalyst ball includes a main support rod of an asbestos rod, a secondary support rod, an asbestos rod and a protective ball; one end of the secondary support rod is fixedly connected to the main support rod, The other end is fixedly connected with a plurality of evenly distributed asbestos strips; the protective ball is a hollow spherical shell, and the shell of the protective ball is dug with a plurality of evenly distributed ventilation holes; the upper and lower ends of the protective ball are dug with The fixing hole matched with the main support rod; the protection ball is sleeved on the main support rod of the asbestos strip through the fixing hole. The invention also discloses a preparation method of the platinum asbestos catalyst ball used for gas phase hydrogenation.

Owner:陕西瑞科新材料股份有限公司

Platinum asbestos catalyst ball for gas-phase hydrogenation and preparation method thereof

ActiveCN109046343ANot easy to cause lossHigh specific surface areaMetal/metal-oxides/metal-hydroxide catalystsPlatinumGas phase

The invention discloses a platinum asbestos catalyst ball for gas-phase hydrogenation. The platinum asbestos catalyst ball comprises an asbestos strip main strut, auxiliary struts, asbestos strips anda protection ball; one ends of the auxiliary struts are fixedly connected to the main strut, and the other ends of the auxiliary struts are fixedly connected with a plurality of asbestos strips uniformly distributed; the protection ball is an internally hollow spherical shell, and a plurality of vent holes uniformly distributed are formed on the shell of the protection ball; fixed holes matched with the main strut are formed at both upper and lower ends of the protection ball; the protection ball sleeves the asbestos strip main strut through the fixed holes. The invention further discloses apreparation method of the platinum asbestos catalyst ball for gas-phase hydrogenation.

Owner:陕西瑞科新材料股份有限公司

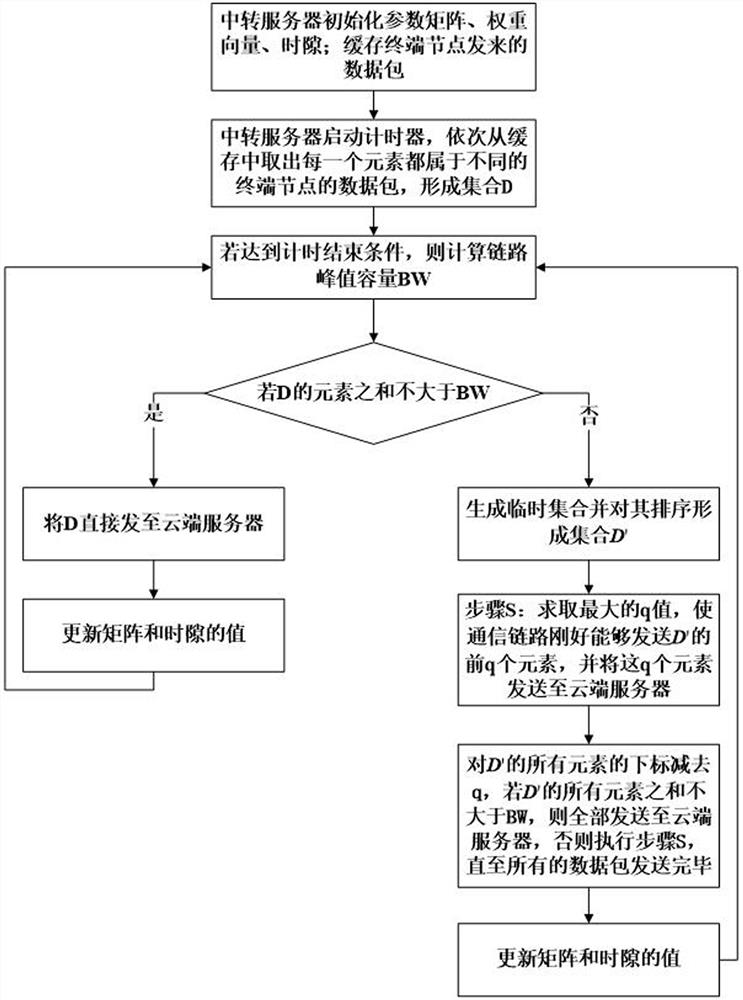

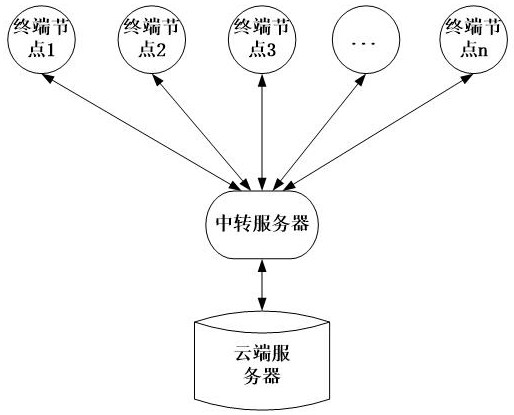

Internet of Things bandwidth resource dynamic adaptation method and system, and storage medium

The invention relates to a dynamic adaptation method for bandwidth resources of the Internet of Things. The method comprises the following steps: (1) initializing a transit server; caching a data packet sent by the terminal node; (2) starting a timer by the transit server, and sequentially taking out the data packets from the cache to form a set; (3) if a timing ending condition is reached, calculating a link peak capacity BW; (4) judging whether the sum of the elements in the set D is smaller than or equal to the link peak capacity BW; (4.1) if yes, directly sending the set D to a cloud server, and then executing the step (3); (4.2) if not, generating a temporary set and sorting the temporary set to form a set D '; (4.2. 1) subtracting q from subscripts of all the elements of D ', if the sum of all the elements of D' is not greater than BW, sending all the elements to the cloud server, otherwise, executing the step S until all the data packets are sent; and then executing the step (3).

Owner:广州优刻谷科技有限公司

Method for removing protective layer on device surface

ActiveCN107768232BReduce hardnessGood removal effectSemiconductor/solid-state device manufacturingStructural engineeringProtection layer

The invention discloses a removal method for a protection layer on a surface of a device. The removal method comprises the steps of softening the protection layer; bombarding the softened protection layer by employing a rapid atomic bombardment mode so that a chemical bond in the softened protection layer is broken; and removing the broken protection layer by an ashing method. By softening the protection layer, the hardness of the cured protection layer is reduced; with the adoption of the rapid atomic bombardment mode, the chemical bond of a protection layer material is broken, more broken chemical bonds are formed, so that the property of the protection layer is changed, and the subsequent ashing process is facilitated; and finally, the broken protection layer material can be easily removed by an ashing mode. With the adoption of the removal method provided by the invention, the protection layer can be completely removed, and the subsequent rework process and the electric property ofan electrical appliance cannot be affected.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

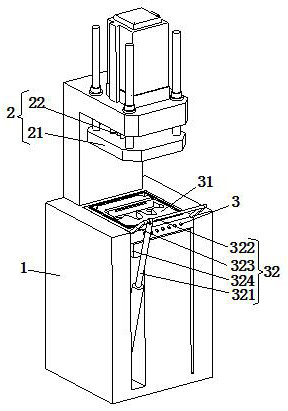

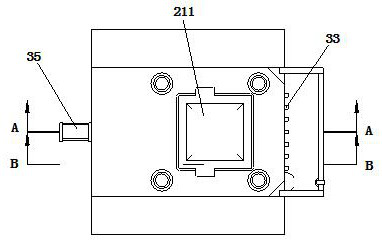

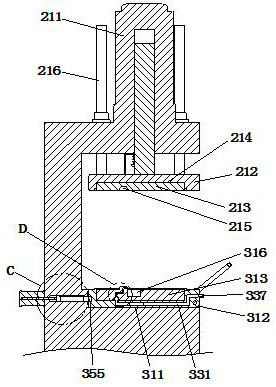

A kind of automatic cleaning insert hole die-casting mold

The present invention relates to the field of moulds, in particular to a die-casting mold for automatically cleaning insert holes, comprising a fixed seat, an upper mold mechanism and a lower mold mechanism matched with the upper mold mechanism, the lower mold mechanism and the upper mold mechanism are installed on The upper end of the fixed seat and the upper mold mechanism are located directly above the lower mold mechanism, and the upper mold mechanism includes an upper mold assembly and at least one limiting assembly, all of which are installed on the upper mold assembly, and the lower mold The mechanism includes a lower mold assembly, an overturning assembly, a blowing assembly, a mold ejection assembly and a limit assembly. The mold assemblies are all installed inside the lower mold assembly, the limiting assembly is arranged at the rear end of the fixing seat and the limiting assembly is matched with the lower mold assembly. The invention can effectively improve the automatic cleaning effect of the mould, and will not cause residues to splash during the cleaning process, thereby avoiding potential safety hazards.

Owner:佛山市顺德区柏久亿五金塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com