Removal method for protection layer on surface of device

A device surface and protective layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as incomplete removal of protective layer, damage to the metal layer of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

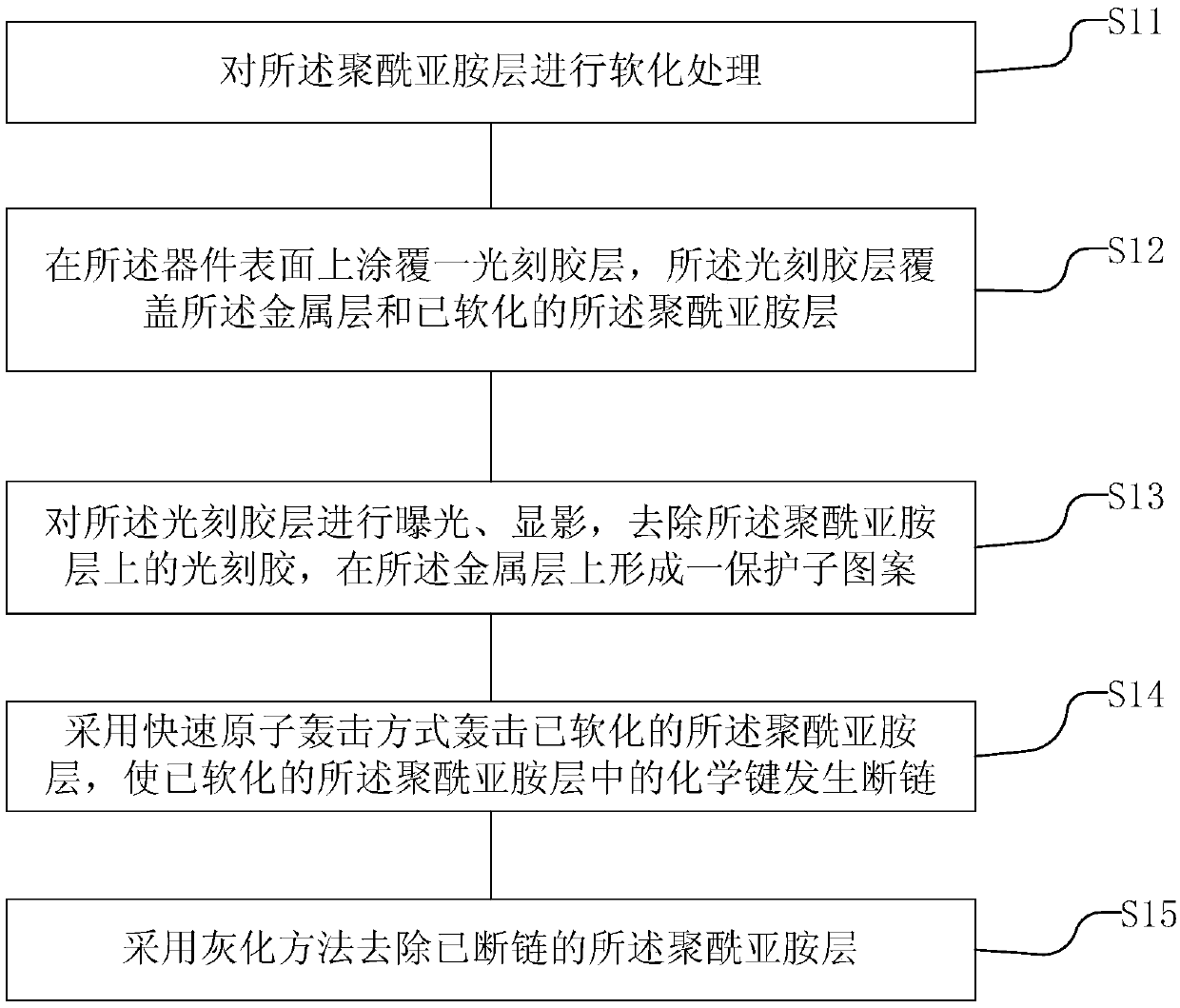

[0044] see figure 2 , which shows a specific flow chart of the removal method of the polyimide layer described in Embodiment 1 of the present invention, the removal method includes:

[0045] Step S11, softening the polyimide layer;

[0046] Step S12, coating a photoresist layer on the surface of the device, the photoresist layer covering the metal layer and the softened polyimide layer;

[0047] Step S13, exposing and developing the photoresist layer, removing the photoresist on the polyimide layer, and forming a protective sub-pattern on the metal layer;

[0048]Step S14, using fast atom bombardment to bombard the softened polyimide layer, so that the chemical bonds in the softened polyimide layer are broken;

[0049] Step S15 , removing the broken polyimide layer by ashing method.

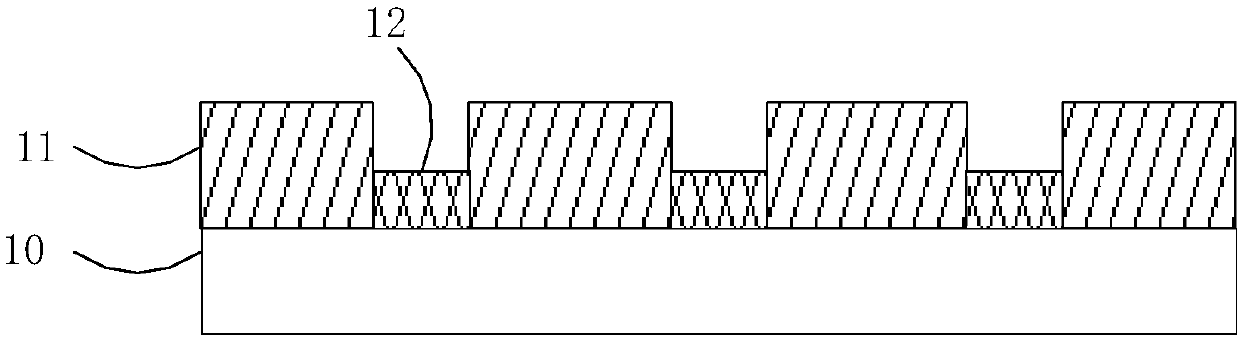

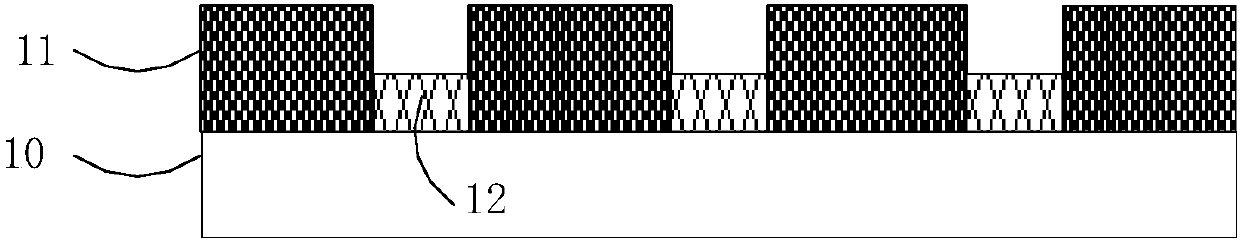

[0050] Next, in order to describe the removal method described in this embodiment more clearly, please refer to Figure 3-Figure 7 , which shows a schematic structural diagram corresponding ...

Embodiment 2

[0062] see Figure 8 , which shows a specific flow chart of the removal method of the polyimide layer described in Embodiment 2 of the present invention, the removal method comprising:

[0063] Step S21, coating a photoresist layer on the surface of the device, the photoresist layer covering the metal layer and the polyimide layer;

[0064] Step S22, exposing and developing the photoresist layer, removing the photoresist on the polyimide layer, and forming a protective sub-pattern on the metal layer;

[0065] Step S23, softening the polyimide layer;

[0066] Step S24, using fast atom bombardment to bombard the softened polyimide layer, so that the chemical bonds in the softened polyimide layer are broken;

[0067] Step S25 , using an ashing method to remove the broken polyimide layer.

[0068] see Figure 9 to Figure 11 , the reference numerals denote the same Figure 3-Figure 7 The same expression and the same structure in the removal method of the first embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com