Rotor structure of three-phase asynchronous motor

A rotor structure, three-phase asynchronous technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve problems such as temperature rise, current instability, rotor loss increase, etc., to achieve a simple structure , high pass rate, and the effect of shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings.

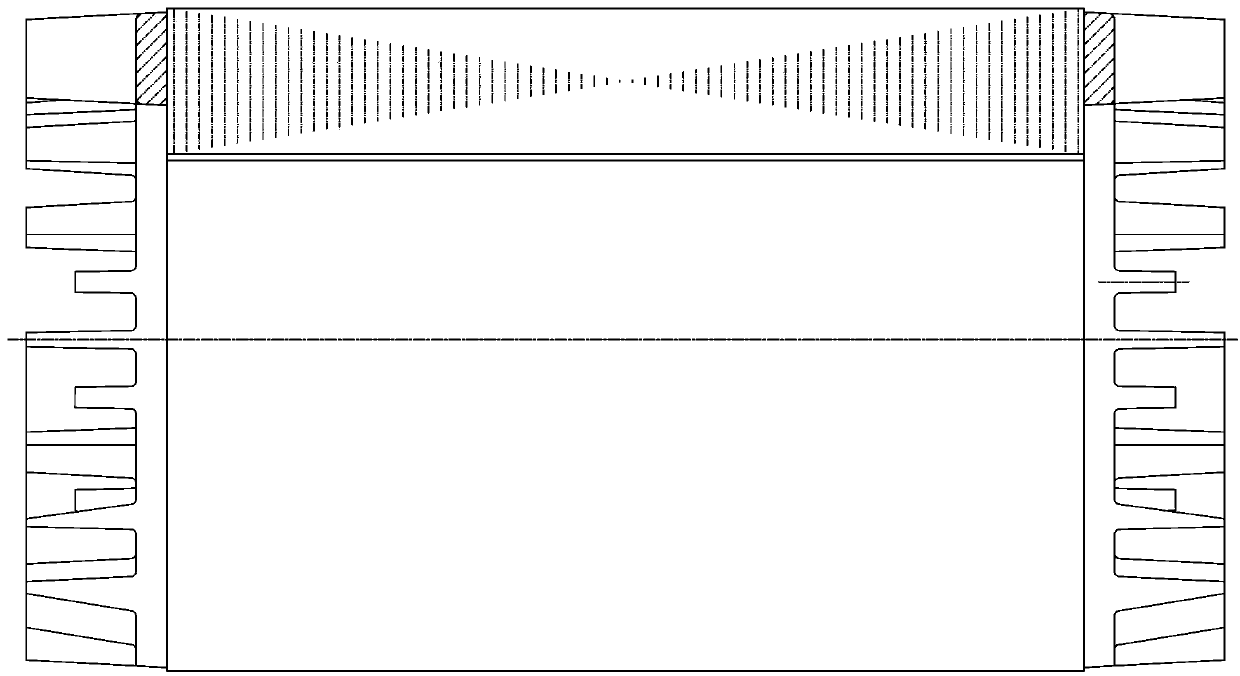

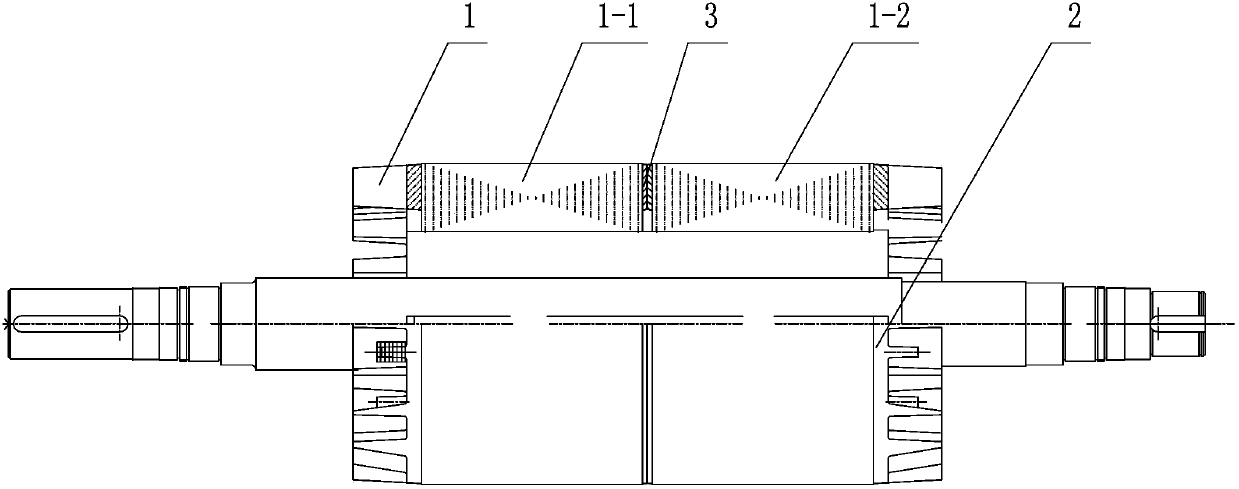

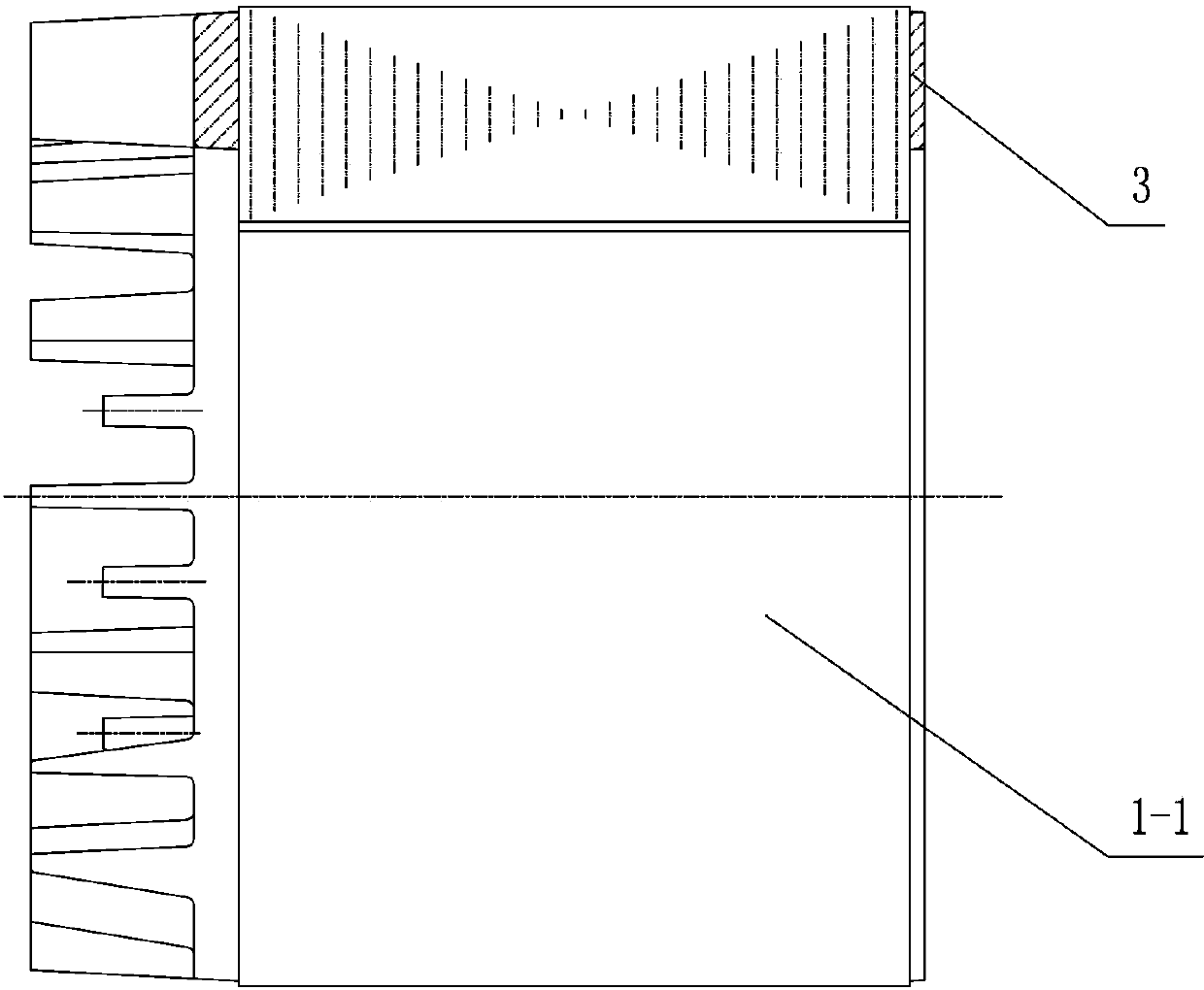

[0012] Such as Figure 2 ~ Figure 3 As shown: the rotor structure of the three-phase asynchronous motor includes a cast aluminum rotor main body 1, a left rotor 1-1, a right rotor 1-2, an iron core 2, a connecting part 3, and the like.

[0013] Such as figure 2 As shown, the present invention includes a cast aluminum rotor main body 1, the middle part of which is an iron core 2, and overlapping rotor punches are arranged outside the iron core 2; the cast aluminum rotor main body 1 is symmetrically divided into a left rotor 1 by the middle part -1 and right rotor 1-2;

[0014] Connecting parts 3 are provided on opposite sides of the left rotor 1-1 and the right rotor 1-2 respectively, and the left rotor 1-1 and the right rotor 1-2 are connected through the connecting parts 3;

[0015] The lengths of the left rotor 1-1 and the right rotor 1-2 are respectively 445 mm, the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com