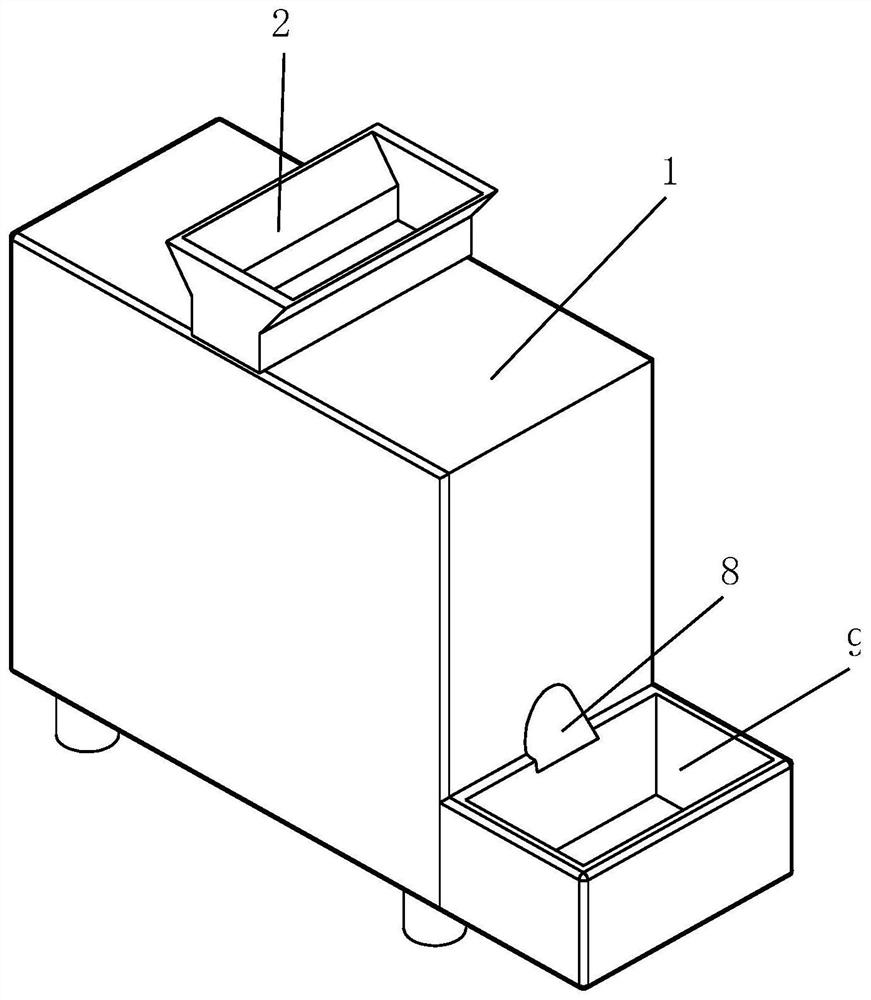

Industrial solid waste crushing and cleaning equipment and operation method thereof

A technology for cleaning equipment and industrial solid waste, applied in the direction of cleaning methods using tools, cleaning methods and utensils, cleaning methods using liquids, etc. Standards and other issues to achieve the effect of saving water sources and cleaning up simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

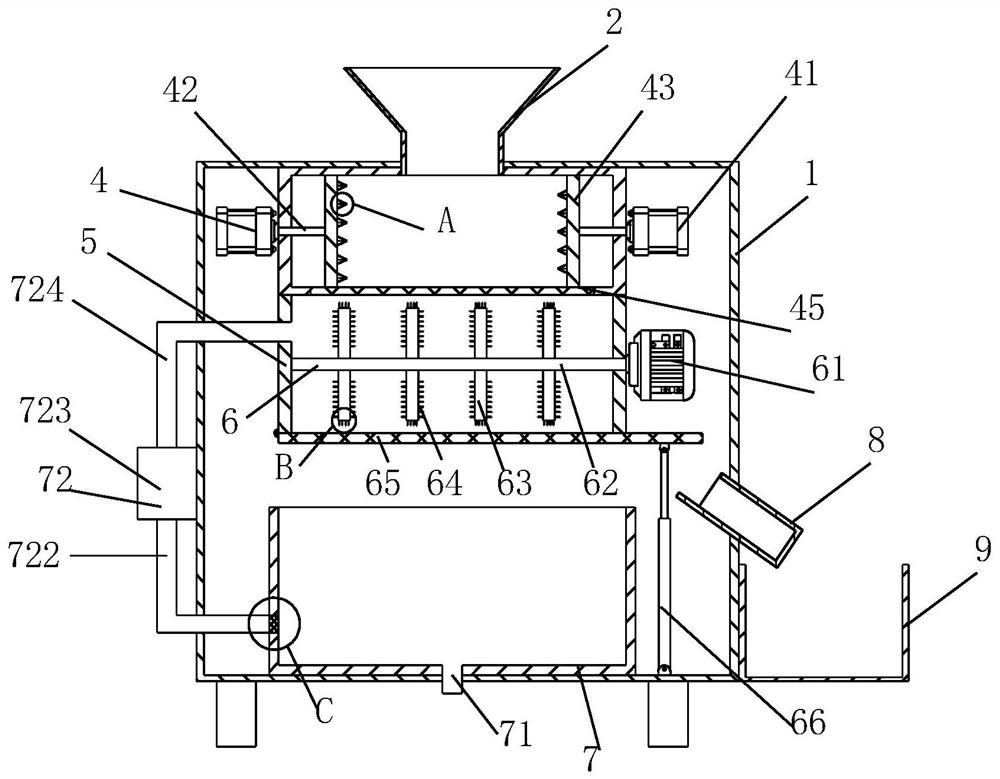

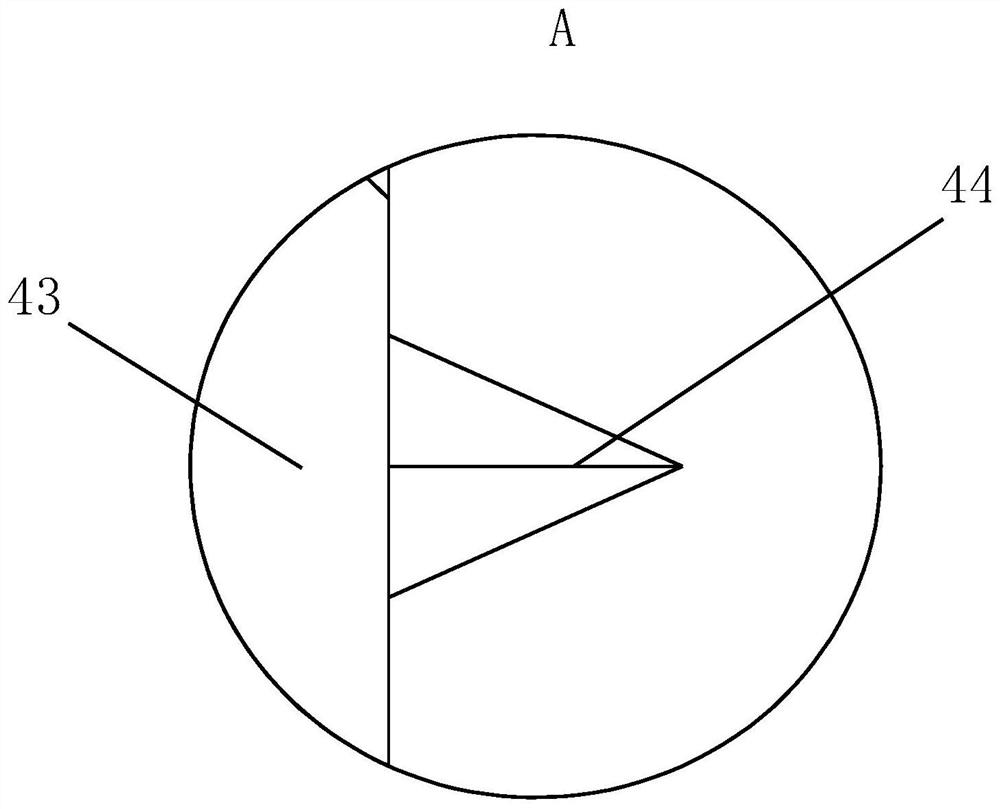

[0033] As an embodiment of the present invention, the crushing mechanism 4 includes a cylinder 41; a pair of the cylinders 41 are respectively fixed on both sides of the crushing box 3; the cylinder 41 is provided with a piston rod 42; the piston rod 42 The end away from the cylinder 41 extends into the crushing box 3, and is fixedly connected with a crushing plate 43; the crushing plate 43 is slidably connected in the crushing box 3, and the side wall away from the piston rod 42 is fixedly connected with crushing teeth 44; When working, start the cylinder 41, the cylinder 41 drives the crushing plate 43 to move through the piston rod 42, and the crushing plate 43 moves to drive the crushing teeth 44 to crush the material coming in from the feeding barrel 2, and the crushed material reaching the size standard passes through the first filter screen 45 Enter in the cleaning box 5.

[0034] As an embodiment of the present invention, the cleaning mechanism 6 includes a motor 61; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com