A kind of platinum asbestos catalyst ball for gas phase hydrogenation and preparation method thereof

A platinum asbestos and catalyst technology, applied in the field of platinum asbestos catalyst preparation, can solve the problems of inconvenient access, loss, and complicated steps, and achieve the effects of improving efficiency, improving efficiency, and improving specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

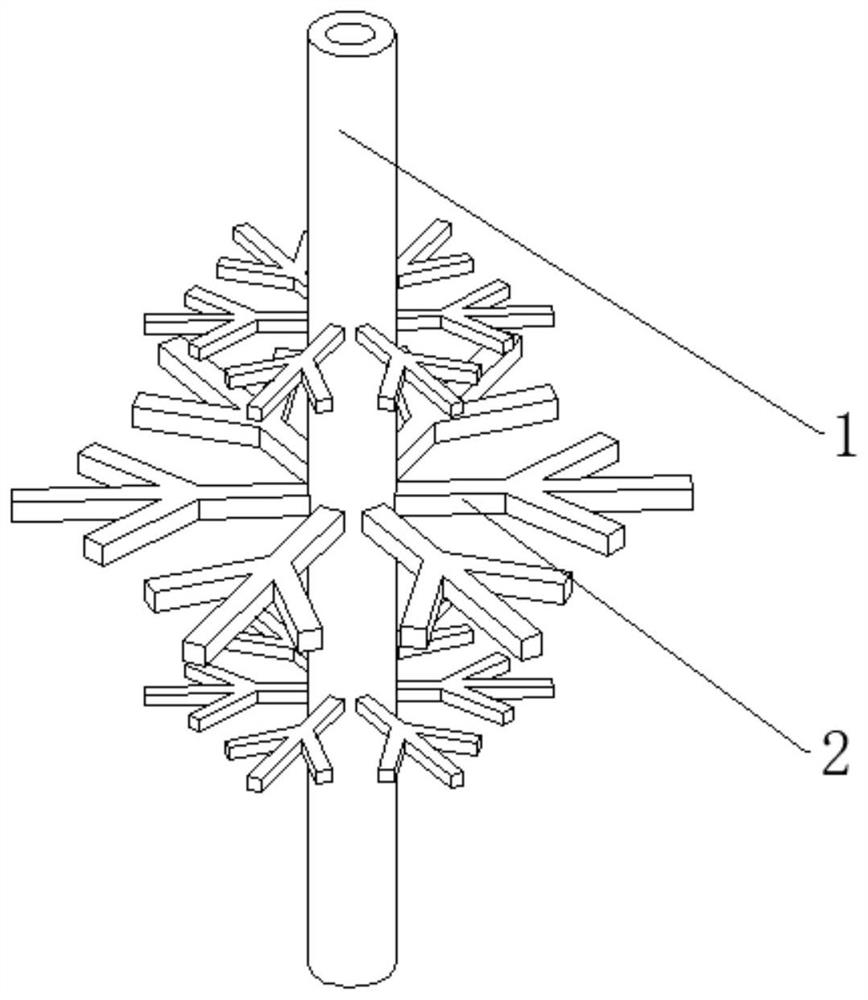

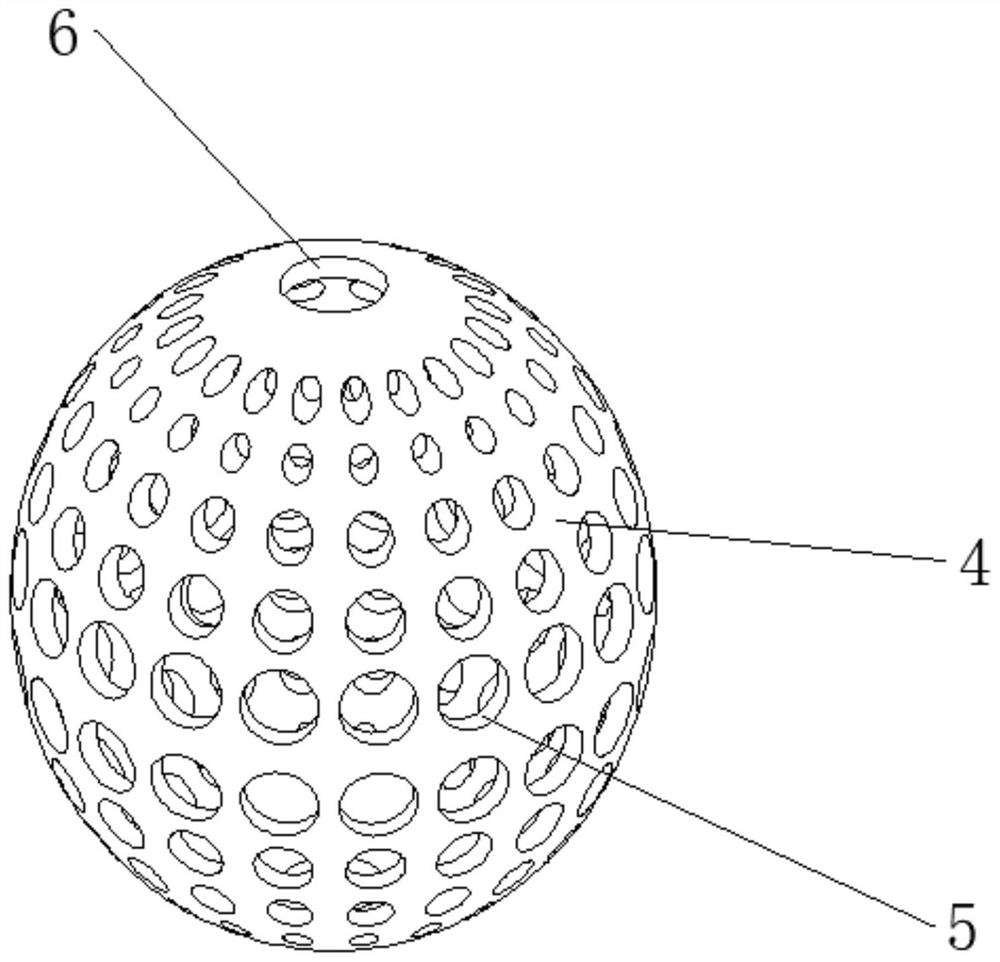

preparation example Construction

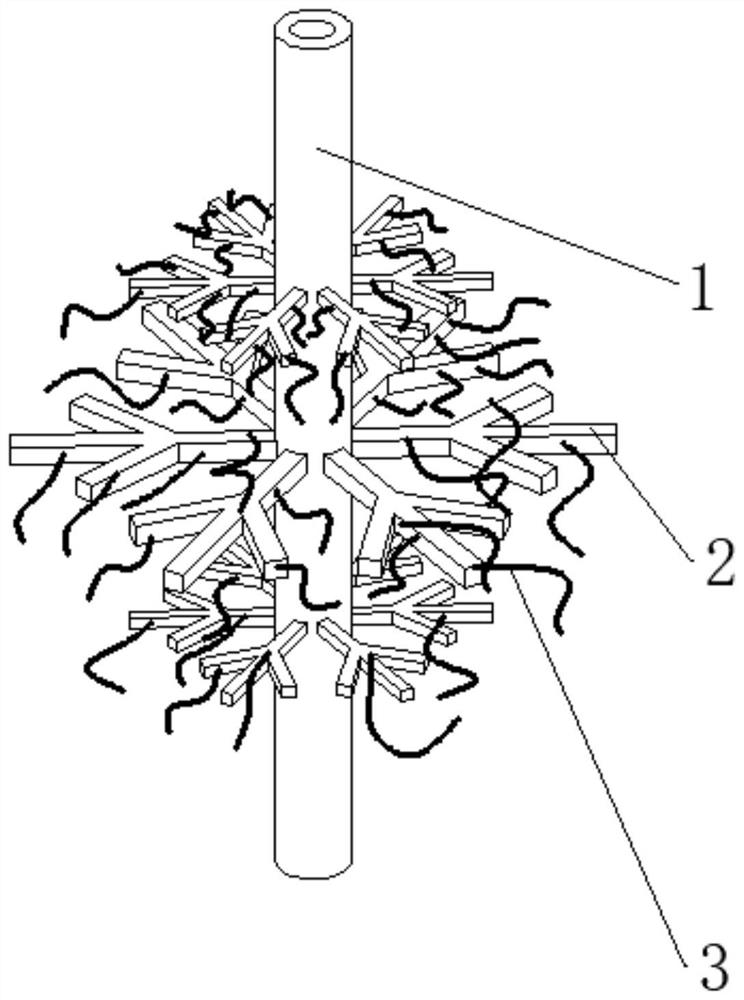

[0042] The present invention also provides a method for preparing platinum asbestos catalyst balls for gas-phase hydrogenation, the specific steps are as follows:

[0043]1. Combine the asbestos strip bracket with the asbestos strip 3 and the protective ball 4, first soak it in an alkaline solution for 10-20 minutes, the alkaline solution is a sodium hydroxide solution with a mass concentration of 5-20%, and then use a mass concentration Soak in 5-20% nitric acid solution for 10-20 minutes, wash with water until neutral, soften the asbestos strip 3 and make the inside of the asbestos strip 3 more fluffy, which can greatly increase the specific surface area of the asbestos strip 3, which is beneficial to the active components Adsorption, and then wash with warm water at 45°C to fully wash away the residual alkaline solution or nitric acid solution;

[0044] 2. Immerse the asbestos strip holder with the asbestos strip 3 and the protective ball 4 combination in the chloroplatin...

Embodiment 1

[0049] 1. Combine the asbestos strip bracket with the asbestos strip 3 and the protective ball 4, first soak it in alkaline solution for 10 minutes, the alkaline solution is a sodium hydroxide solution with a mass concentration of 5%, and then use a mass concentration of 5% Soak in nitric acid solution for 10 minutes, wash with water until neutral, the asbestos strip 3 can be softened, and the inside of the asbestos strip 3 can be relatively fluffy, which can greatly increase the specific surface area of the asbestos strip 3, which is beneficial to the adsorption of active components. After that, the use temperature is 45 Wash with warm water at ℃ to fully remove residual alkaline solution or nitric acid solution;

[0050] 2. Immerse the asbestos strip bracket with the asbestos strip 3 and the protective ball 4 in a chloroplatinic acid solution with a mass concentration of 3%, raise the temperature to 40°C, and keep stirring for 30 minutes at the same time, so that the chloro...

Embodiment 2

[0054] 1. Combine the asbestos strip support with the asbestos strip 3 and the protective ball 4, first soak it in alkaline solution for 20 minutes, the alkaline solution is a sodium hydroxide solution with a mass concentration of 20%, and then use a mass concentration of 20% Soak in nitric acid solution for 20 minutes, wash with water until neutral, the asbestos strip 3 can be softened, and the inside of the asbestos strip 3 is relatively fluffy, which can greatly increase the specific surface area of the asbestos strip 3, which is beneficial to the adsorption of active components. After that, the use temperature is 45 Wash with warm water at ℃ to fully remove residual alkaline solution or nitric acid solution;

[0055] 2. Immerse the asbestos strip bracket with the asbestos strip 3 and the protective ball 4 in the chloroplatinic acid solution with a mass concentration of 5%, raise the temperature to 40°C, and keep stirring for 50 minutes at the same time, so that the chloro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com