Bean coarse cereal production method applying radio frequency sterilization

A production method and a technology of a radio frequency generator, applied in the field of sterilization, can solve the problems of rough taste of miscellaneous grains, difficult to arouse people's appetite, and difficult to digest.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] See Figure 1-3 , The present embodiment is a method of producing a legume grains radiofrequency sterilization, comprising the steps of:

[0031] Step a: Following weighed 100 parts by weight parts of beans, 10 parts of sugar, 20 parts of water, standby;

[0032] Step 2: Wash the dry beans, milling through a 50 mesh screen to obtain flour, the flour, sugar, water mixed form a dough, the dough is pressed into a 0.1cm sheet, after the sheet at a temperature of 120 under conditions ℃ drying to constant weight, then crushed into granules, grains obtained preform;

[0033] Step 3: cereals preform hopper 104 is connected to the RF poured sterilizing apparatus, to start the conveyor 107, the conveyor 107 driven by the operation of moving forward the preform cereals;

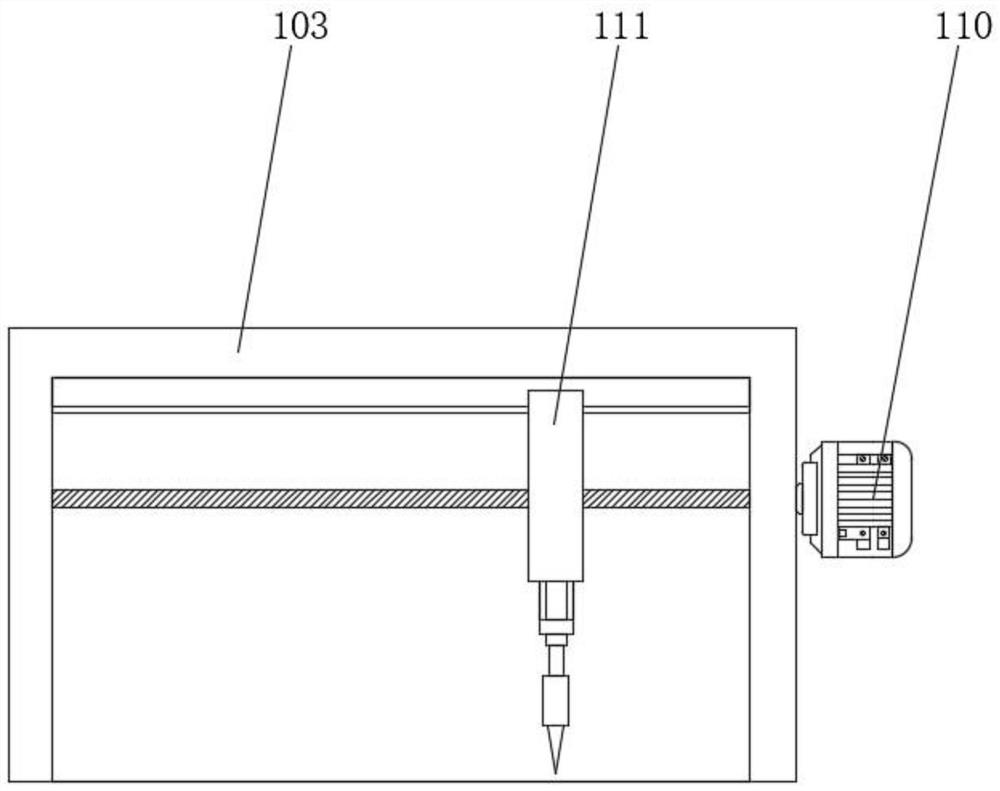

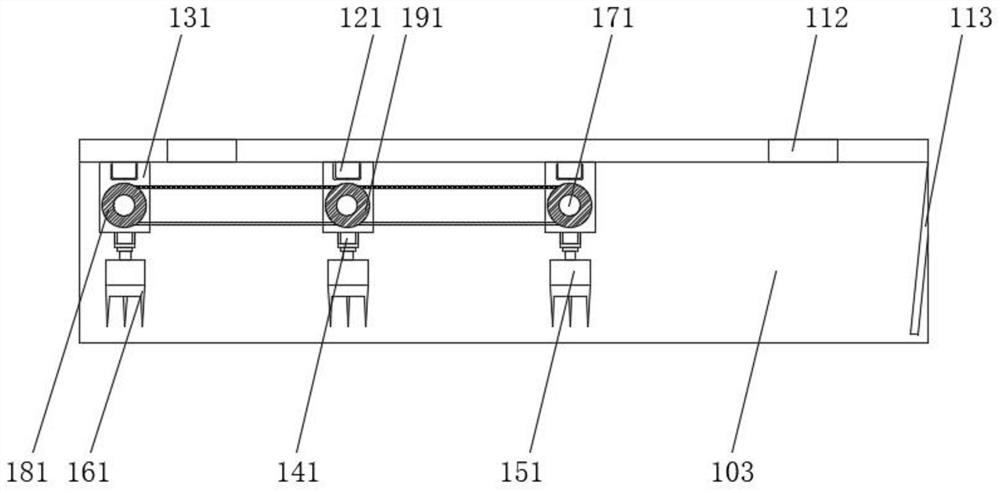

[0034] Step Four: starting the driving motor 110, the operation of the driving motor 110 drives a threaded shaft 171 which is rotated by a first pulley 181, second pulley 191 and the belt 171 are driven all the thread...

Embodiment 2

[0039] See Figure 1-3 , The present embodiment is a method of producing a legume grains radiofrequency sterilization, comprising the steps of:

[0040] Step a: Following parts by weight of beans weighed 200 parts, 20 parts sugar, 50 parts of water, standby;

[0041] Step 2: Wash the dry beans, milling through a 100 mesh sieve, to obtain flour, the flour, sugar, water mixed form a dough, the dough is pressed into a 0.2cm sheet, after the sheet at a temperature of 160 under conditions ℃ drying to constant weight, then crushed into granules, grains obtained preform;

[0042] Step 3: cereals preform hopper 104 is connected to the RF poured sterilizing apparatus, to start the conveyor 107, the conveyor 107 driven by the operation of moving forward the preform cereals;

[0043] Step Four: starting the driving motor 110, the operation of the driving motor 110 drives a threaded shaft 171 which is rotated by a first pulley 181, second pulley 191 and the belt 171 are driven all the threaded...

Embodiment 3

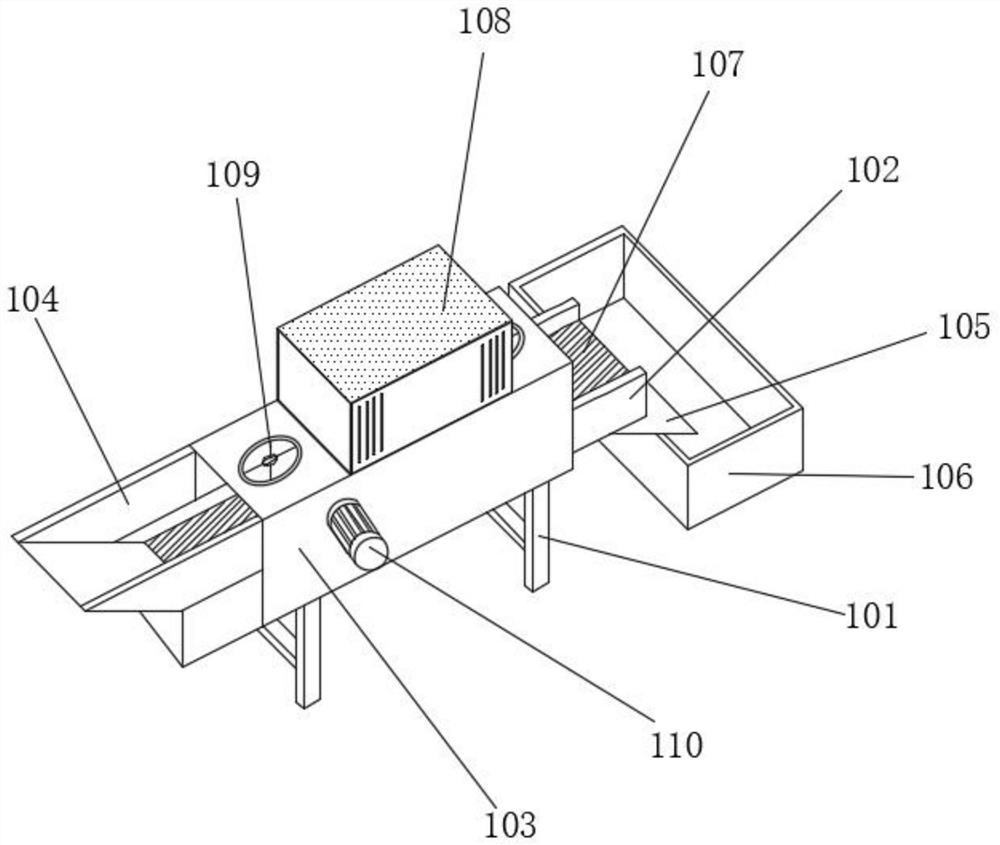

[0048] See Figure 1-3 , The present embodiment is a radio frequency sterilization apparatus, includes a support frame 101, mounting bracket 102, the mounting case 103, connecting arm 104, the lower hopper 105, the storage box 106, the conveyor 107, RF generator 108, the exhaust fan 109, the driving motor 110, stacker mechanism 111, the support frame 101 is mounted on top of mounting bracket 102, the mounting bracket 102 is attached to the outer mounting box 103, is mounted on both sides of the inner wall 103 of tank mount 102 connecting both sides of the outer wall, a top end of the mounting bracket 102 is attached to the connection arm 104, one end connected to one end of the arm 104 and the mounting box 103 is connected to the other bottom end of the mounting frame 102 is attached to the lower hopper 105, under the hopper 105 is provided immediately below the storage box 106, the mounting frame 102 is mounted inside conveyor 107, the mounting position of the top intermediate tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com