Combination type excavator bucket tooth and die-forging method for tooth tip of combination type excavator bucket tooth

An excavator bucket tooth and combined technology, which is applied to the die forging field of combined excavator bucket teeth and their tooth tips, can solve the problems of unsustainable tooth tips, inconvenient disassembly and replacement of the combined bucket teeth, etc. Simple and practical structure, reasonable connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

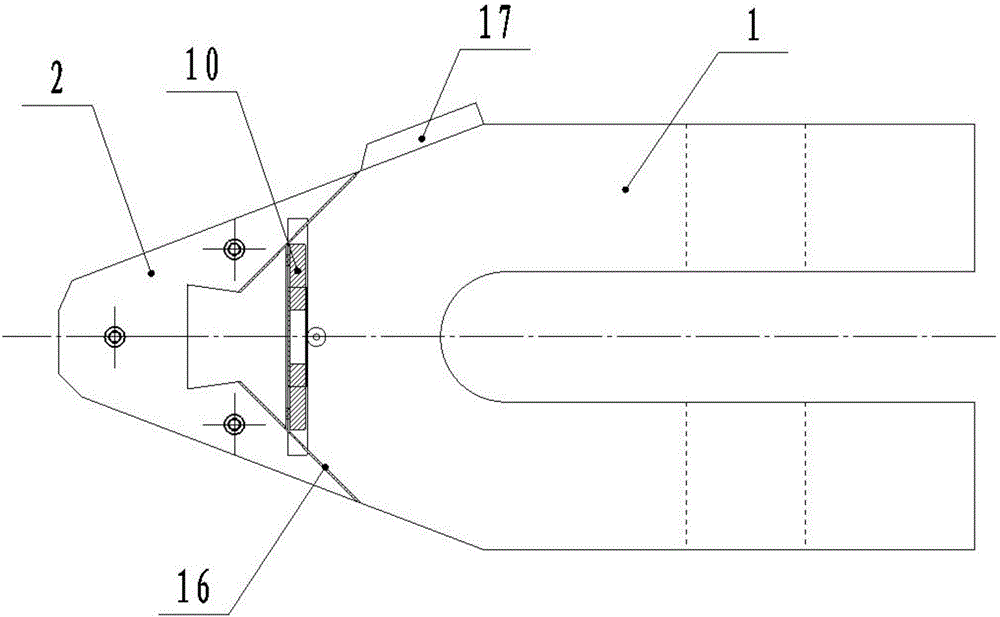

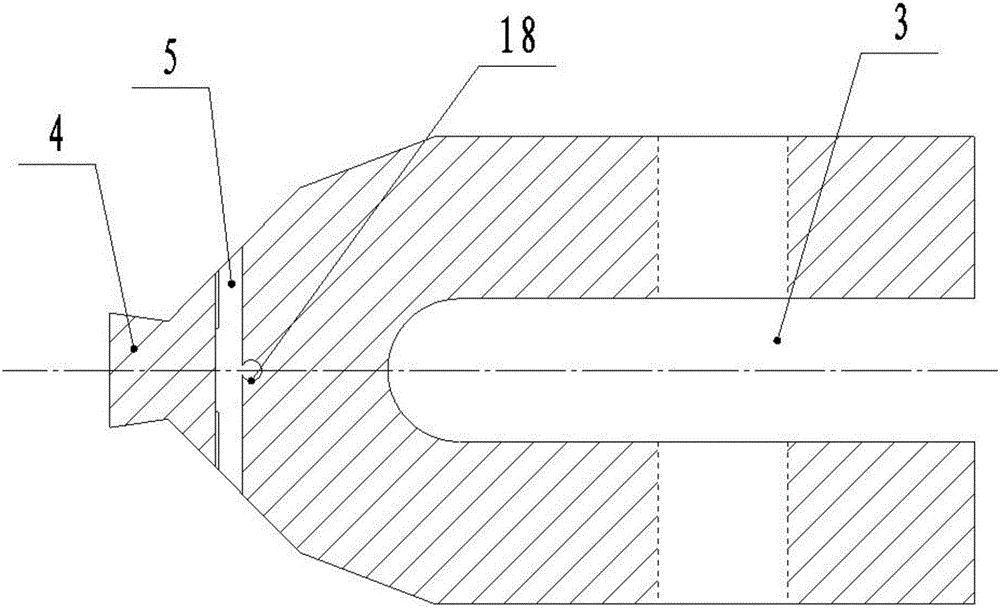

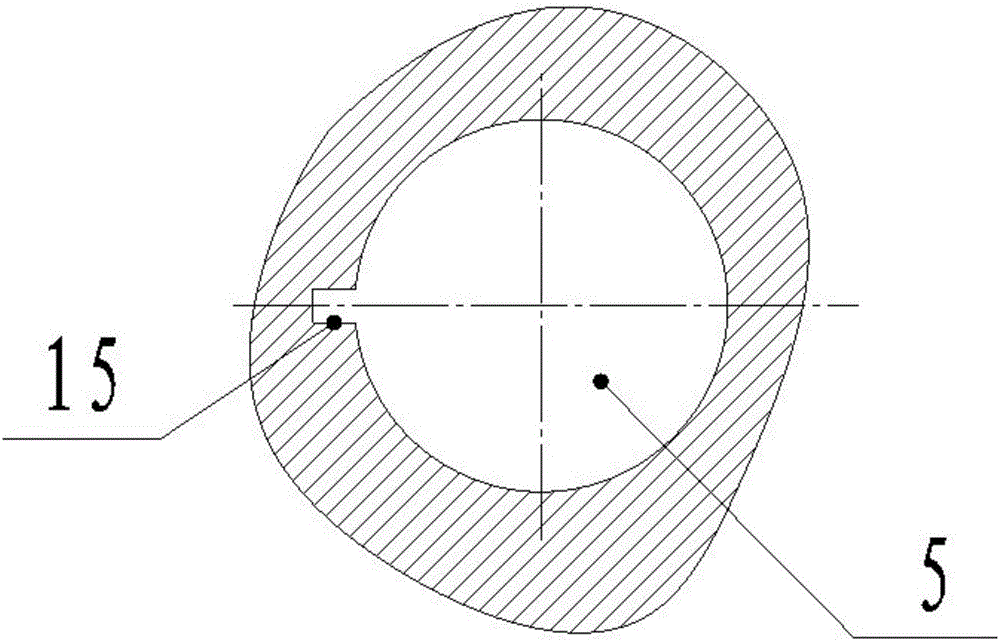

[0040] Such as Figure 1-6 As shown, a combined excavator bucket tooth of the present invention includes a tooth seat 1 and a tooth tip 2. The rear end of the tooth seat 1 is provided with a bucket lip installation opening 3, and the front end of the tooth seat 1 is provided with a tooth tip 2. A dovetail block 4, a pin hole 5 is provided at the joint between the front part of the tooth seat 1 and the tooth tip 2; the tooth tip 2 includes a middle tooth 6 and a guard side plate 7, and the two sides of the middle tooth 6 are respectively provided with guard sides Plate 7, the rear end of the middle tooth 6 is provided with a tooth seat installation port 8, the front end of the tooth seat installation port 8 is provided with a dovetail groove 19 cooperating with the dovetail block 4, and the upper lip and the lower lip of the tooth seat installation port 8 are respectively provided with There is a blind pin hole 9 corresponding to the pin hole 5 , and the middle tooth 6 is locke...

Embodiment 2

[0046] Such as Figure 4-5 As shown, a tooth tip die forging method of the present invention, the tooth tip 2 adopts A-100 alloy steel die forging forming, and the die forging process of the tooth tip 2 includes the following steps:

[0047] Step 1: cutting;

[0048] Step 2: The billet is machined; the heating process of the billet in step 2 is as follows: firstly, the temperature in the electric furnace is raised to 850°C, and then kept for 60 minutes, and then the temperature in the electric furnace is raised to 1050°C, and kept for 30 minutes; preheating of the mold in step 2 The temperature is 250°C-350°C, and the preheating time is 2 hours.

[0049] Step 3: Put the machined billet into the electric furnace for heating;

[0050]Step 4: Use a free forging hammer to forge, and air cool after completing the forging;

[0051] Step 5: Put the block into the electric furnace to heat, and preheat the mold at the same time; the heating process of the block in step 5 is to first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com