Smoke exhaust backflash energy-saving device and method

An energy-saving device and tail gas technology, which is applied in the direction of combustion method, combustion type, and energy efficiency improvement, can solve the problems of difficulty in cleaning electric traps, reduced collection efficiency, and emission pollution, and achieves convenient construction, considerable energy saving, and toxic Effect of Reduction of Toxic Substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

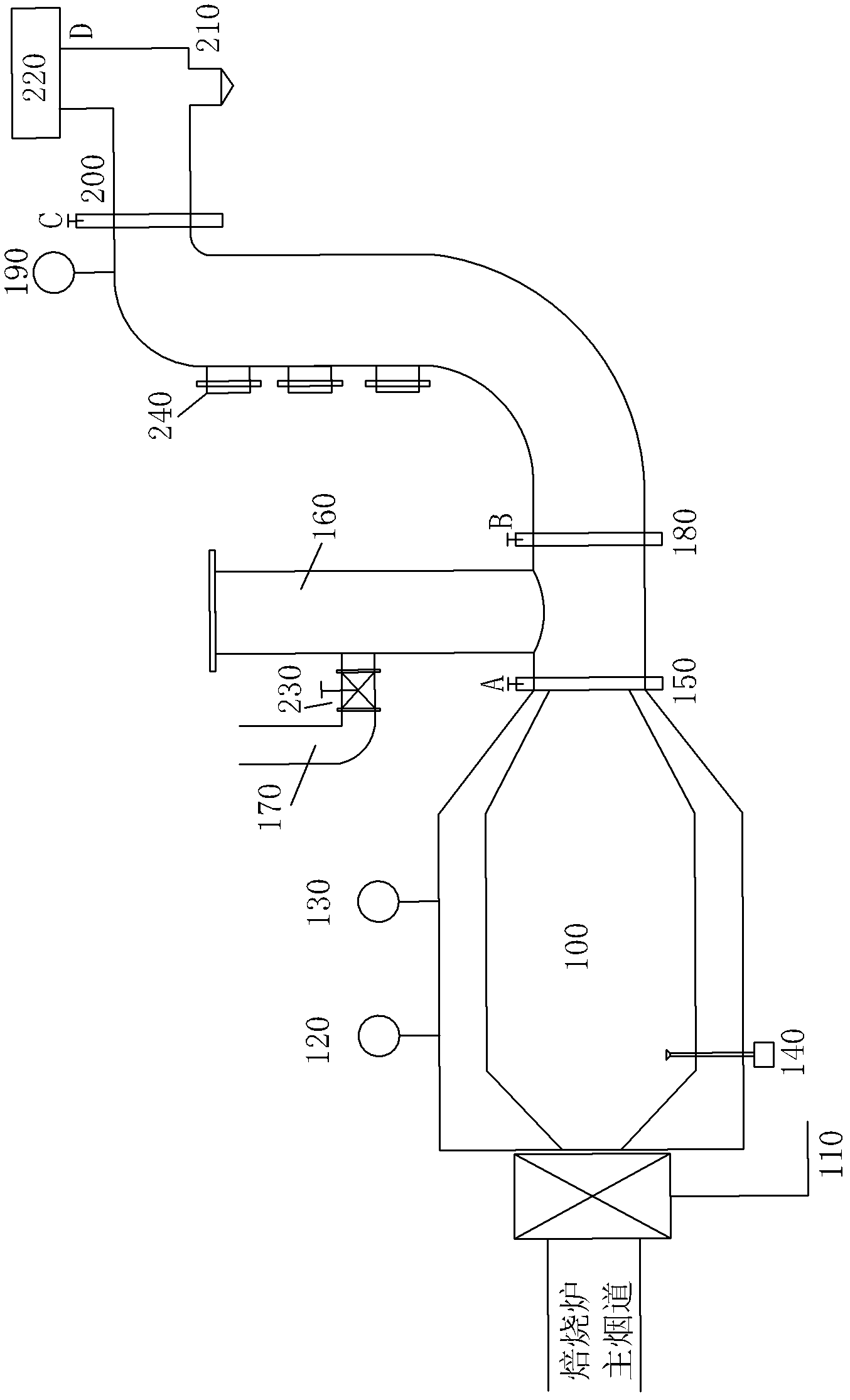

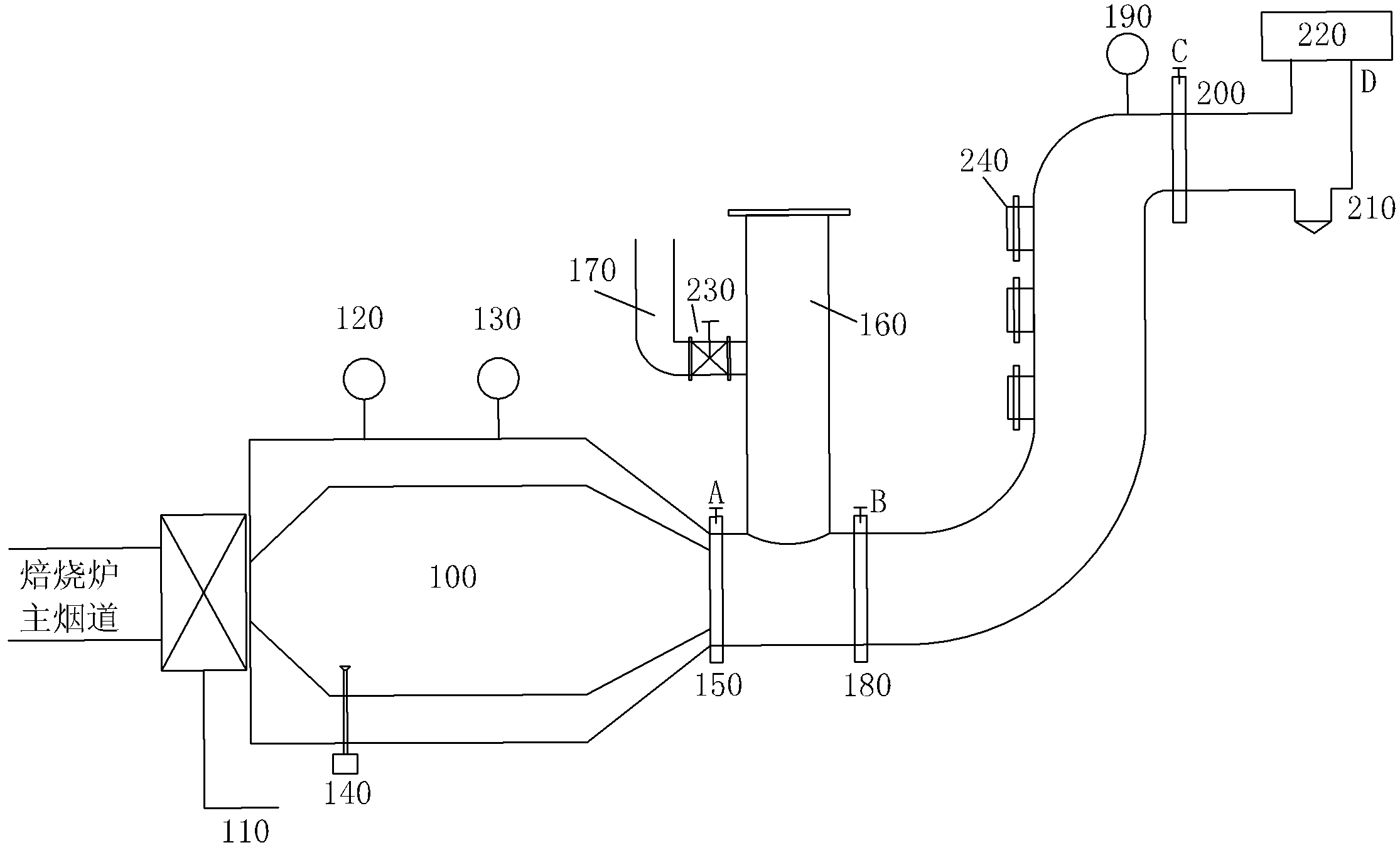

[0024] The structure of the exhaust gas back-burning energy-saving device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, a smoke tail gas back-burning energy-saving device, specifically as follows:

[0026] A fan 110 is arranged at the outlet of the main flue of the roasting furnace. The outlet of the fan 110 is placed at the entrance of the positive pressure furnace body 100. The outlet of the positive pressure furnace body 100 is connected to the first pipeline, that is, the entrance of the AB section, and the outlet of the first pipeline is connected to The heat energy recovery main line is the entrance of the BC section, and the heat energy recovery main line outlet is connected to the smoke exhaust pipe, that is, the CD section entrance. The side wall of the heat energy recovery main line is provided with multiple interfaces, as shown in the interface 240; wherein, in the An ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com