Roughing furnace dust removal telescopic closed fume hood

A rough refining and fume hood technology, which is applied in furnaces, furnace components, waste heat treatment, etc., can solve the problems that are not suitable for factory use, input and output are not proportional, and cannot completely solve the problem of flue gas, so as to improve the effect of dust removal , The effect of convenient driving hanging bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

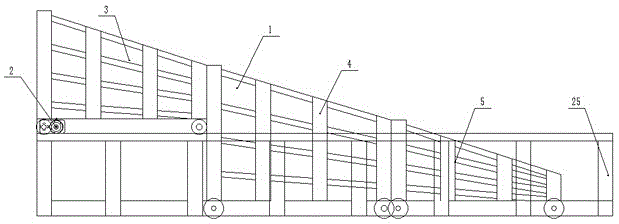

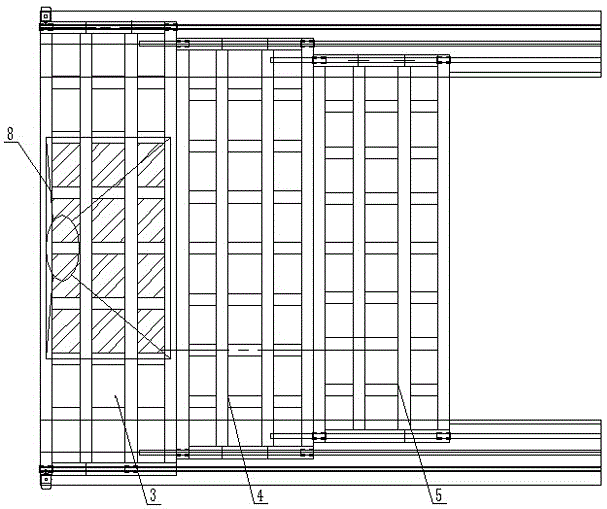

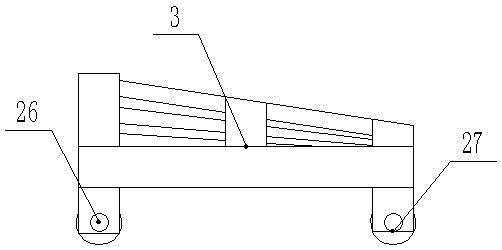

[0030] Such as Figure 1-Figure 3 As shown, this embodiment provides a dust-removing telescopic airtight fume hood for the refining furnace, including: a fume-collecting hood 1 that is movably arranged above the pit for covering the iron ladle in the pit and whose coverage area can be changed. The fume-collecting hood 1 is unfolded Afterwards, it can cover the entire pit, and after shrinking, it is located on the side of the pit away from the taphole; it is fixedly installed on the fume collecting hood 1, and can drive the driving device 2 that the fume collecting hood 1 expands and contracts.

[0031] When the telescopic airtight fume hood of the present invention is used, when the taphole begins to pour, the fume collecting hood 1 is unfolded to cover the whole pit, so that the whole pit is in a state of negative pressure, which can effectively improve the gas flow rate connected with the fume collecting hood 1. The dust collection effect of the dust collector and the dust r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com