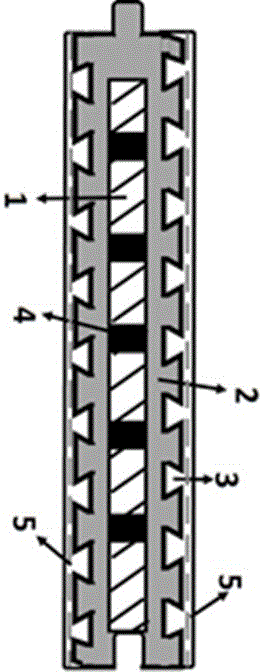

Novel flame-retardant hollow wallboard and preparation method thereof

A wallboard and hollow technology is applied in the field of flame-retardant hollow wallboard and its preparation, which can solve the problems of poor flexibility of indoor layout, and achieve the effects of increasing aesthetics, reducing cost and enhancing flame retardancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Weigh 10Kg of polyvinyl chloride and 3Kg of glycerol triacetate and blend them in a high-speed mixer for 20 minutes. The mixed sample is extruded through a hollow plate extruder, the hollow part is equipped with a support bracket, the surface is concave and convex, and the surface is filled with the prepared magnesium powder paste, and a layer of glass fiber mesh cloth is laid on the surface. The paste is smoothed out, set, sealed, and cut into squares.

Embodiment 2

[0015] Weigh 10Kg of polyvinyl chloride, 2Kg of wood powder, and 5Kg of glycerin and mix them in a high-speed mixer for 10 minutes. The mixed sample is extruded through a hollow plate extruder, the hollow part is equipped with a support bracket, the surface is concave and convex, and the surface is filled with the prepared magnesium powder paste, and a layer of glass fiber mesh cloth is laid on the surface. The paste is smoothed out, set, sealed, and cut into squares.

Embodiment 3

[0017] Weigh 20Kg of polyvinyl chloride, 3Kg of straw powder, and 4Kg of triethyl citrate and mix them in a high-speed mixer for 20 minutes. The mixed sample is extruded through a hollow plate extruder, the hollow part is equipped with a support bracket, the surface is concave and convex, and the surface is filled with the prepared magnesium powder paste, and a layer of glass fiber mesh cloth is laid on the surface. The paste is smoothed out, set, sealed, and cut into squares.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com