Chip package structure and manufacturing method thereof, electrostatic powder coating device

A technology of chip packaging structure and electrostatic powder, which is applied in the direction of electrostatic spraying device, spraying device, spray discharge device, etc., can solve the problem of chip function failure, achieve the effect of improving quality, good corrosion resistance, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] See Picture 10 with Picture 11 The chip packaging structure of this embodiment includes a circuit substrate 21, an adhesive layer 22 provided on the circuit substrate 21, and a chip 23 provided on the adhesive layer 22, wherein the sidewall of the chip 23 is provided with Non-stick material layer 24.

[0052] The adhesive layer 22 is a conductive adhesive layer, such as conductive silver adhesive. The conductive silver adhesive includes epoxy resin, acid anhydride curing agent and modified imidazole compound accelerator.

[0053] The non-stick material layer 24 is preferably a polytetrafluoroethylene (PTFE) material. Of course, the present invention includes but is not limited to polytetrafluoroethylene materials, as long as other non-stick materials with similar properties to polytetrafluoroethylene materials can also be used.

[0054] Using polytetrafluoroethylene material, on the one hand it has excellent heat resistance characteristics, can withstand high temperature t...

Embodiment 2

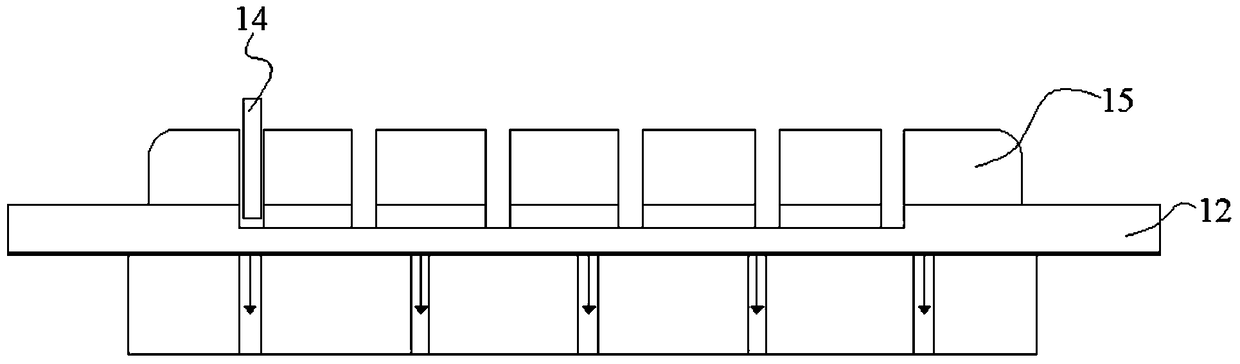

[0074] This embodiment provides an electrostatic powder spraying device for spraying electrostatic powder on the sidewall of the chip during the chip packaging process to form a non-stick material layer. Using electrostatic spraying can not only save paint, improve chip packaging efficiency, but also save labor costs.

[0075] Such as Figure 14 As shown, the electrostatic powder spraying device of this embodiment includes a powder supply unit 30 and a spray unit 40 connected to the powder supply unit 30, wherein the powder supply unit 30 is used to provide powder 31, and the spray unit 40 is used to spray The powder 31 is atomized or atomized more uniformly, and then electrostatically adsorbed on the side wall of the chip 51 to be sprayed. Here, the atomization means that the particles in the powder contain the same kind of electric charge, so that the powders repel each other on the transmission path, thereby forming a uniform cloud-like spray, and the spraying effect is good. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com