Pull cloth strip

A technology for pulling cloth strips and cloth bags, which is applied in the field of furniture decoration, can solve problems such as puncturing the seat, losing the tension of the sofa or seat, loss, etc., and achieves the effect of prolonging the service life, preventing functional failure and reducing losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

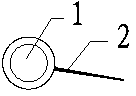

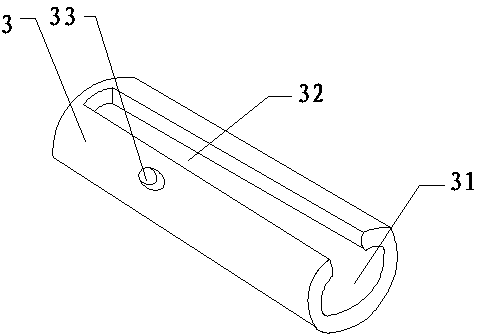

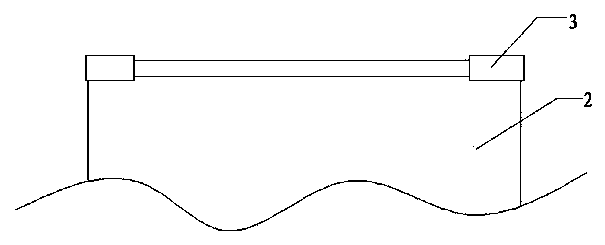

[0020] Fig. 1 is a schematic cross-sectional structure diagram of an embodiment of the present invention, image 3 It is a schematic diagram of the overall structure of an embodiment of the present invention.

[0021] Such as figure 1 and image 3 Shown: a cloth strip, including non-woven fabric 2 and fixing strip 1, in this embodiment, the fixing strip 1 is a steel strip, of course it can also be a plastic strip, when it is a plastic strip, its The material can be EVA foamed plastic, which is conducive to environmental protection. In this embodiment, the non-woven fabric 2 is wrapped on the outside of the fixing strip 1 and bonded and fixed up and down after covering the fixing strip 1 to form a storage cavity for the fixing strip, and the non-woven fabric 2 continues to Extending outward to form a cloth with a certain width, in add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com