Blocking type electric engine iron core and manufacturing method thereof

A manufacturing method and block-based technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, salient poles, etc., can solve the problems of complicated processing, troublesome assembly, increased production costs, etc., and save silicon steel materials , high positioning accuracy and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

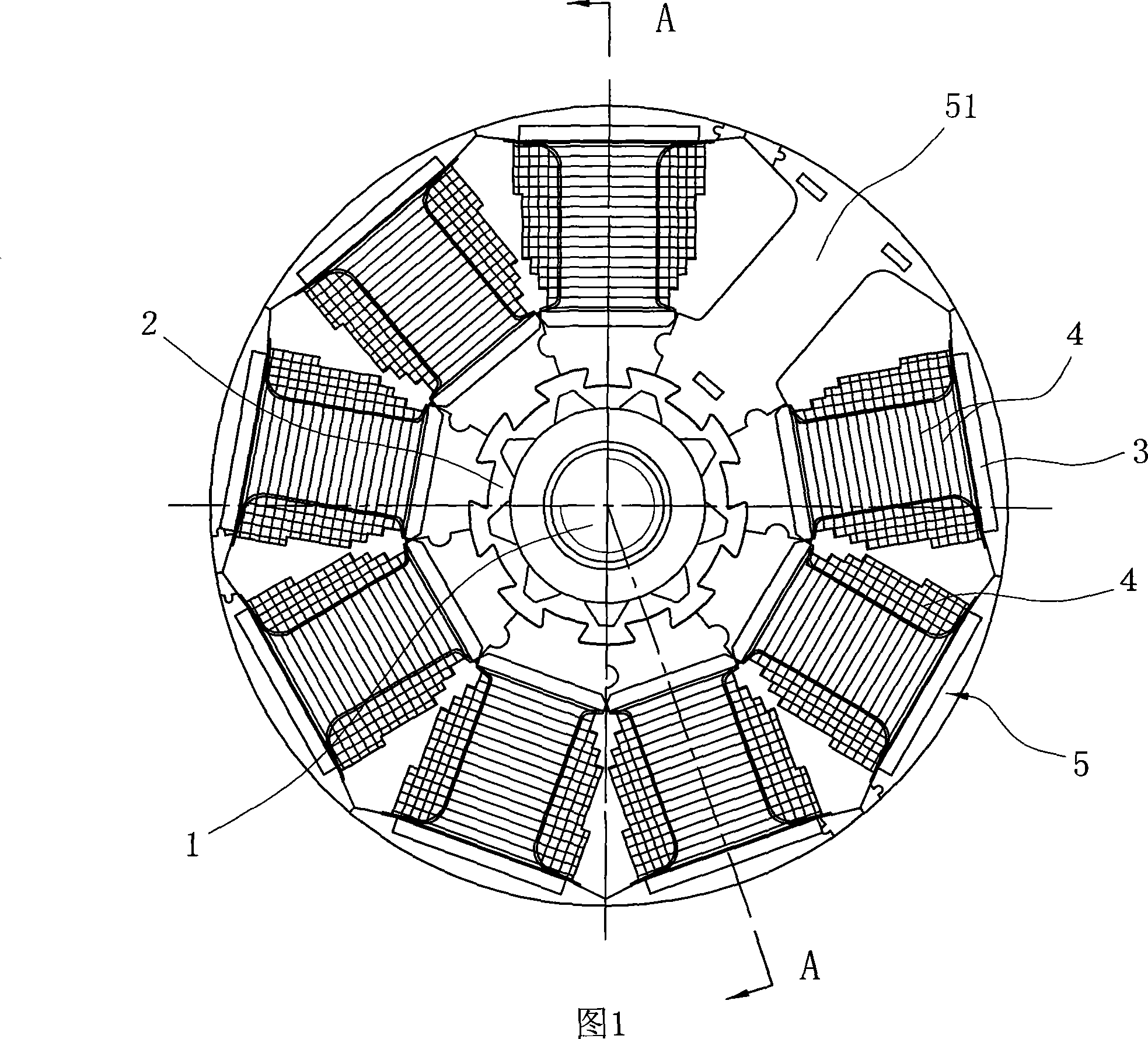

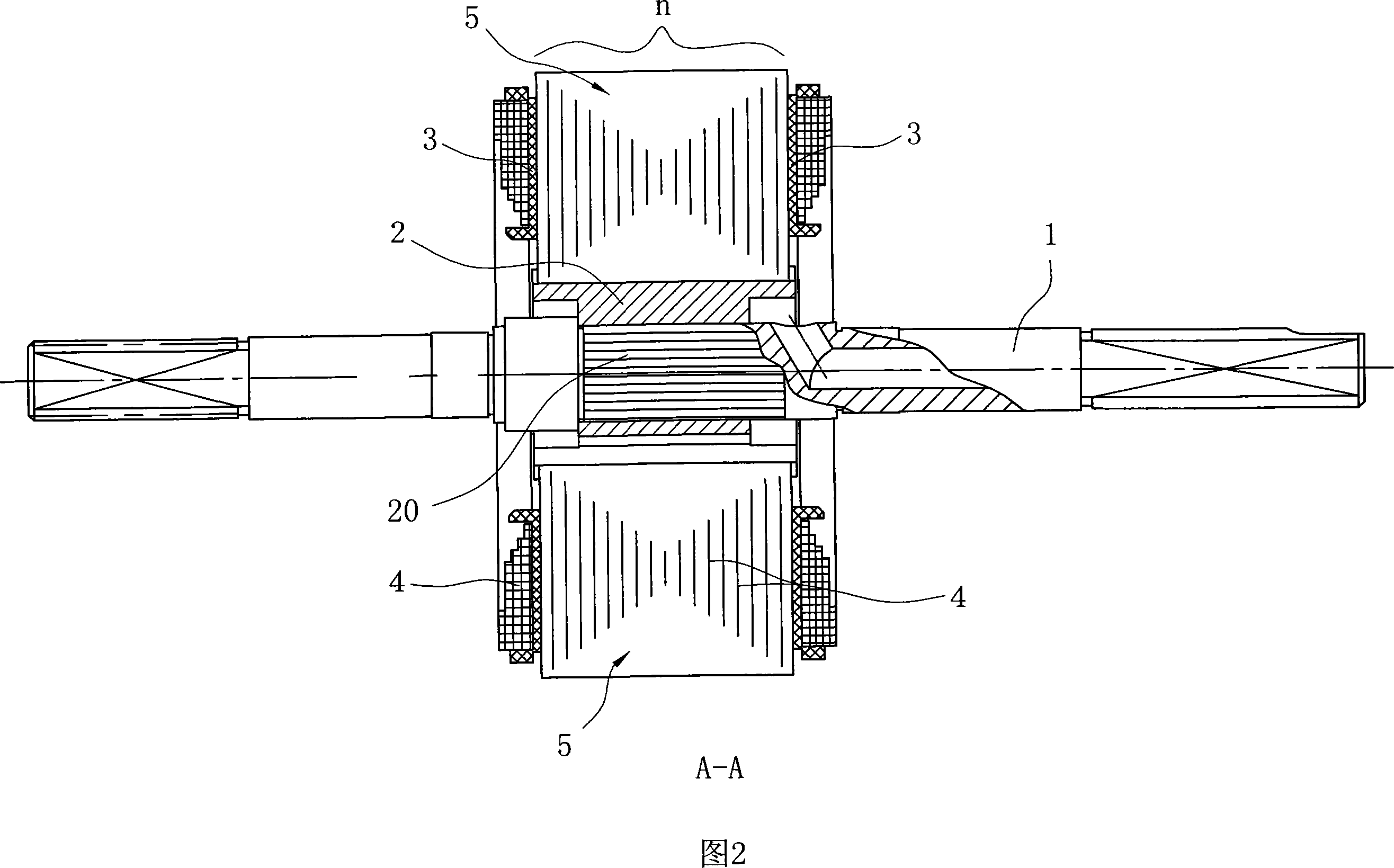

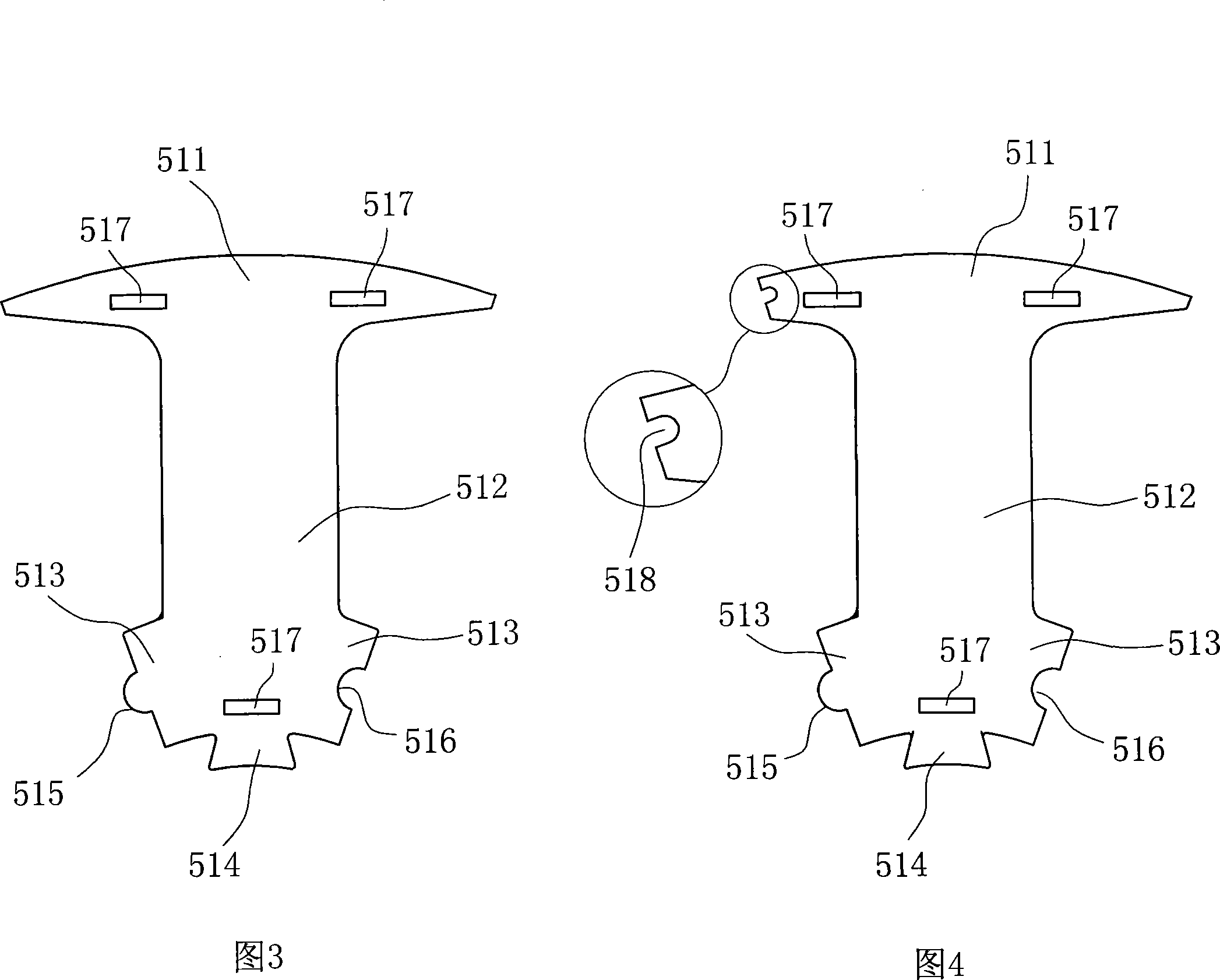

[0032] As shown in Figure 1 and Figure 2, it is a schematic structural diagram of the motor shaft assembly of the embodiment of the present invention, including a motor shaft 1, a positioning bracket 2 sleeved on the motor shaft, and a motor core fixed on the positioning bracket 2 , wherein, the motor iron core is positioned on the motor shaft 1 through the positioning bracket 2, the iron core is spliced by 9 groups of segmented gear blocks 5 wound with coils 4, and the stamping thickness of each group of segmented gear blocks 5 n are all the same, and are respectively composed of 88 fan-shaped punches 51 of each 0.5mm pressed against each other, see Fig. The coil 4 and the outer ring of the positioning bracket 2 are provided with a fastening structure that is compatible with each group of segmental tooth blocks 5, and the segmental tooth bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com