Winding support of single tooth winding for insulation motor

A winding and winding wire technology, applied in the field of insulation, holding and wiring, can solve problems such as mutual contact and short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

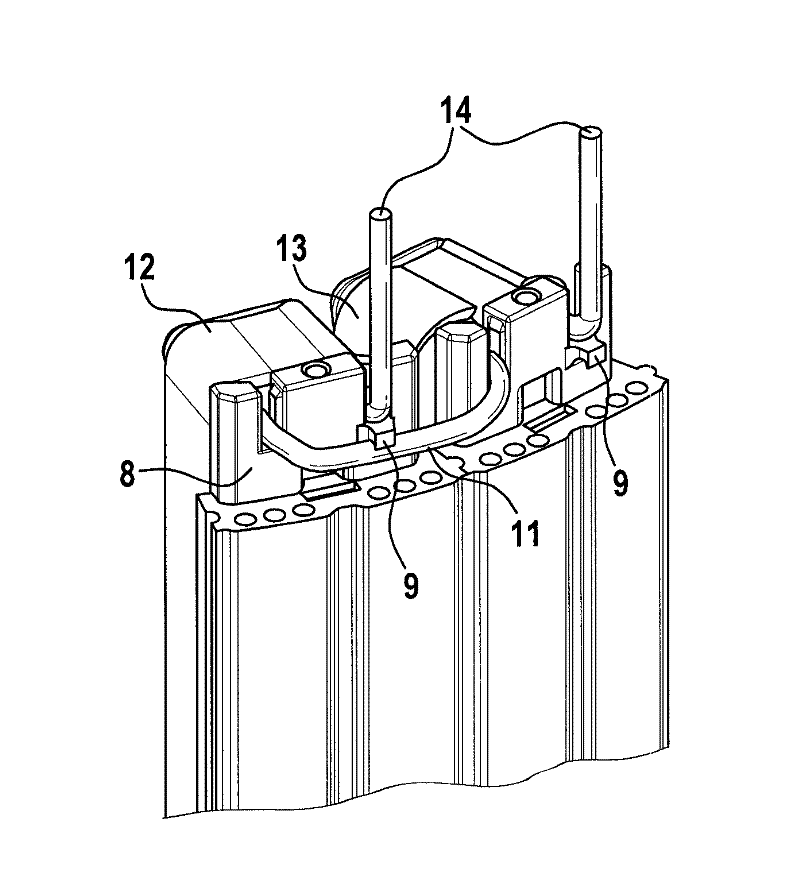

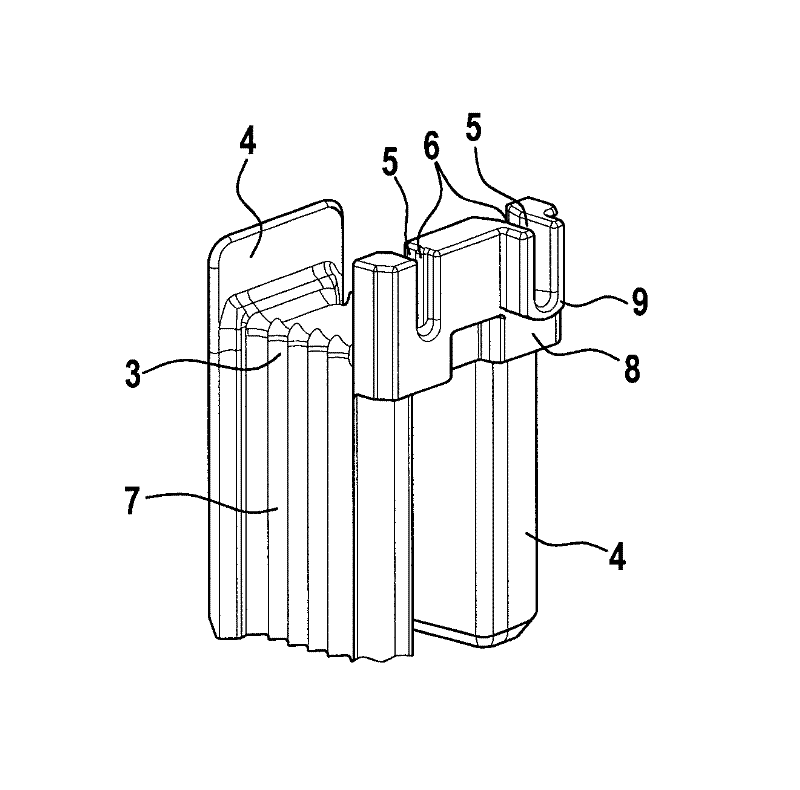

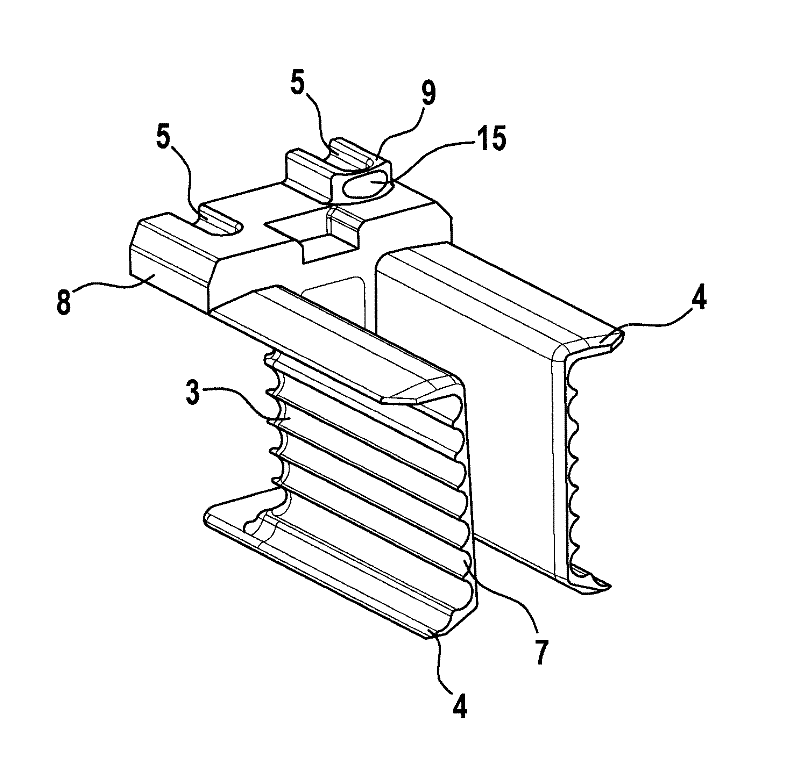

[0033] In order to insulate the winding wires of the stator tooth structure, a winding carrier is generally provided, which is often designed in two parts. The two winding carrier parts are attached from different sides to the stator tooth structure, which generally consists of metal laminations and is part of the stator.

[0034] exist Figures 1a to 1d Various views of an embodiment for one half of the winding support are shown in . Such a winding carrier part 1 is preferably placed axially on the stator tooth structure to be wound from both sides, so that the magnetic material of the stator tooth structure is completely surrounded by the winding carrier. The winding carrier part 1 is preferably formed from an electrically insulating material such as, for example, plastic, especially thermoplastic. Thermosetting plastics or other electrically insulating materials may also be used.

[0035] The winding carrier or the winding carrier part 1 can be produced as a separate stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com