Gear engagement fatigue testing device and method

A fatigue test and gear device technology, which is applied in the testing of machine gear/transmission mechanism, measuring device, and testing of mechanical components, etc., can solve the problems of difficult real-time monitoring, differences in actual stress changes, limited real-time and accuracy, etc. Good test quality, reduced motion range, and novel effects of test loading methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

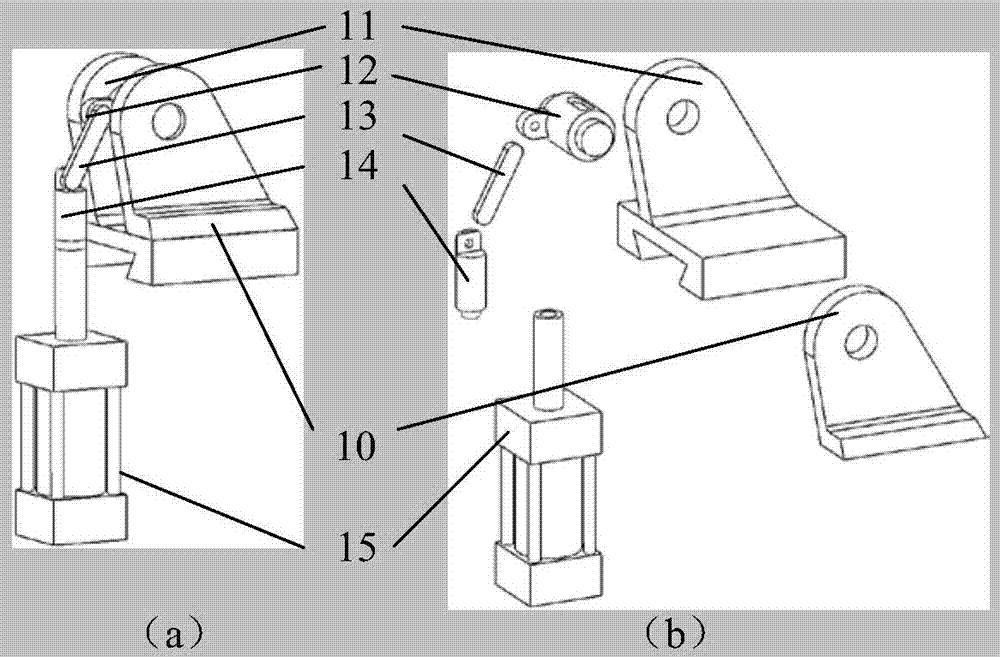

[0025] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

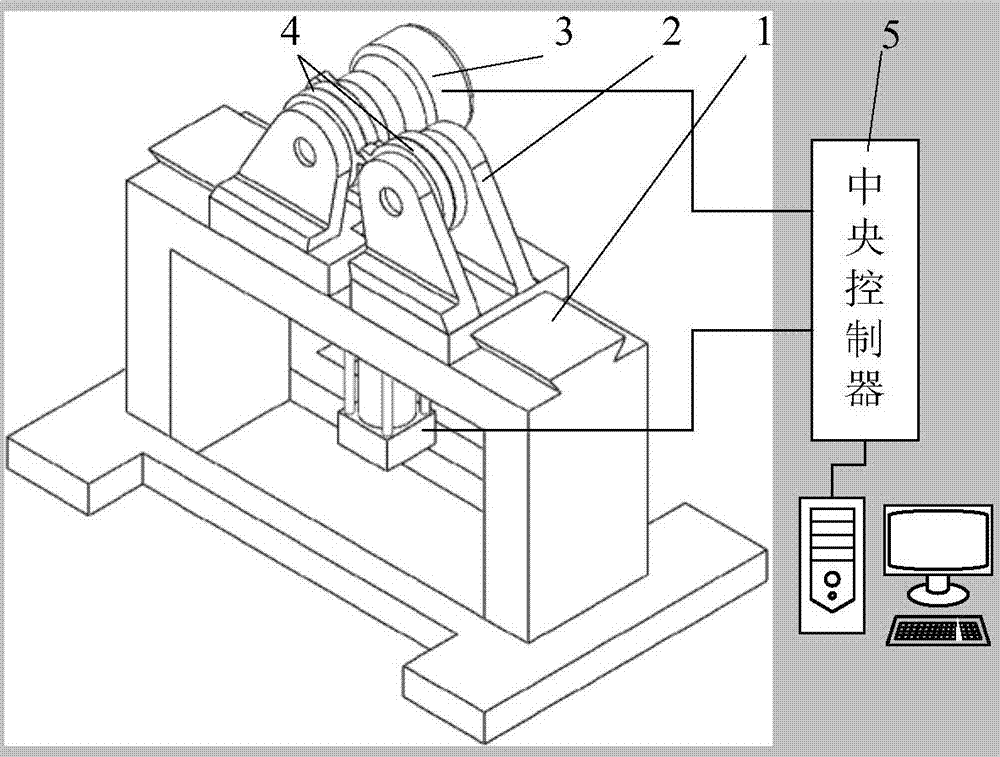

[0026] Such as figure 1 As shown, a fatigue test device for gear meshing includes a driving device 2 fixed on a base table 1, a simulated load device 3 and a test gear device 4, and the drive device 2 and the simulated load device 3 cooperate with the test gear device 4 respectively. The drive device 2 and the simulated load device 3 are respectively connected to the central controller 5, and the central controller 5 controls the drive device 2 by outputting a displacement-time curve signal, and controls the simulated load device 3 by outputting a load-time curve signal.

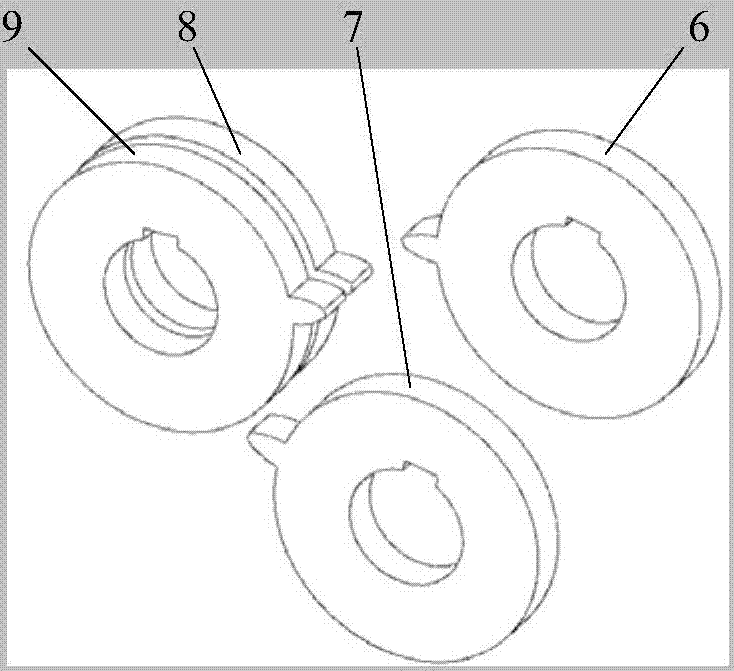

[0027] Such as figure 2 As shown, the test gear device 4 is composed of 4 single-tooth test gears, which are respectively the driving gear 7, the driven gear 9, the reset gear 6 and the reset gear 8, and the driving gear 7 is meshed with the 9 teeth of the driven gear. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com