Method for simulation analysis on meshing stiffness of cylindrical spur gear undergoing damaged single-tooth failure

A technology of meshing stiffness and spur gears, which is applied in machine gear/transmission mechanism testing, special data processing applications, instruments, etc., can solve the problems of low efficiency, precision failure, unsatisfactory calculation of meshing stiffness of gears, and high calculation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

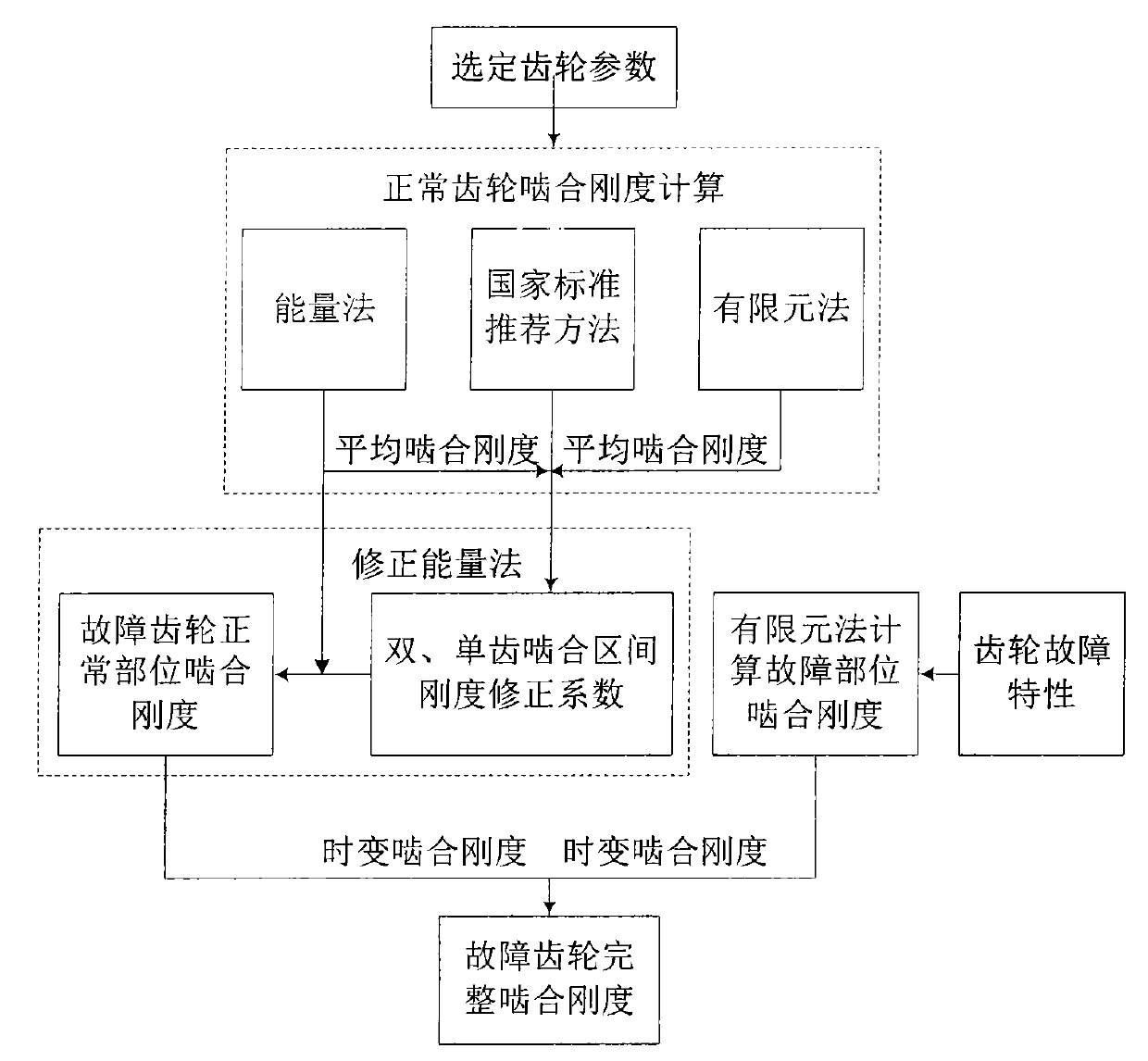

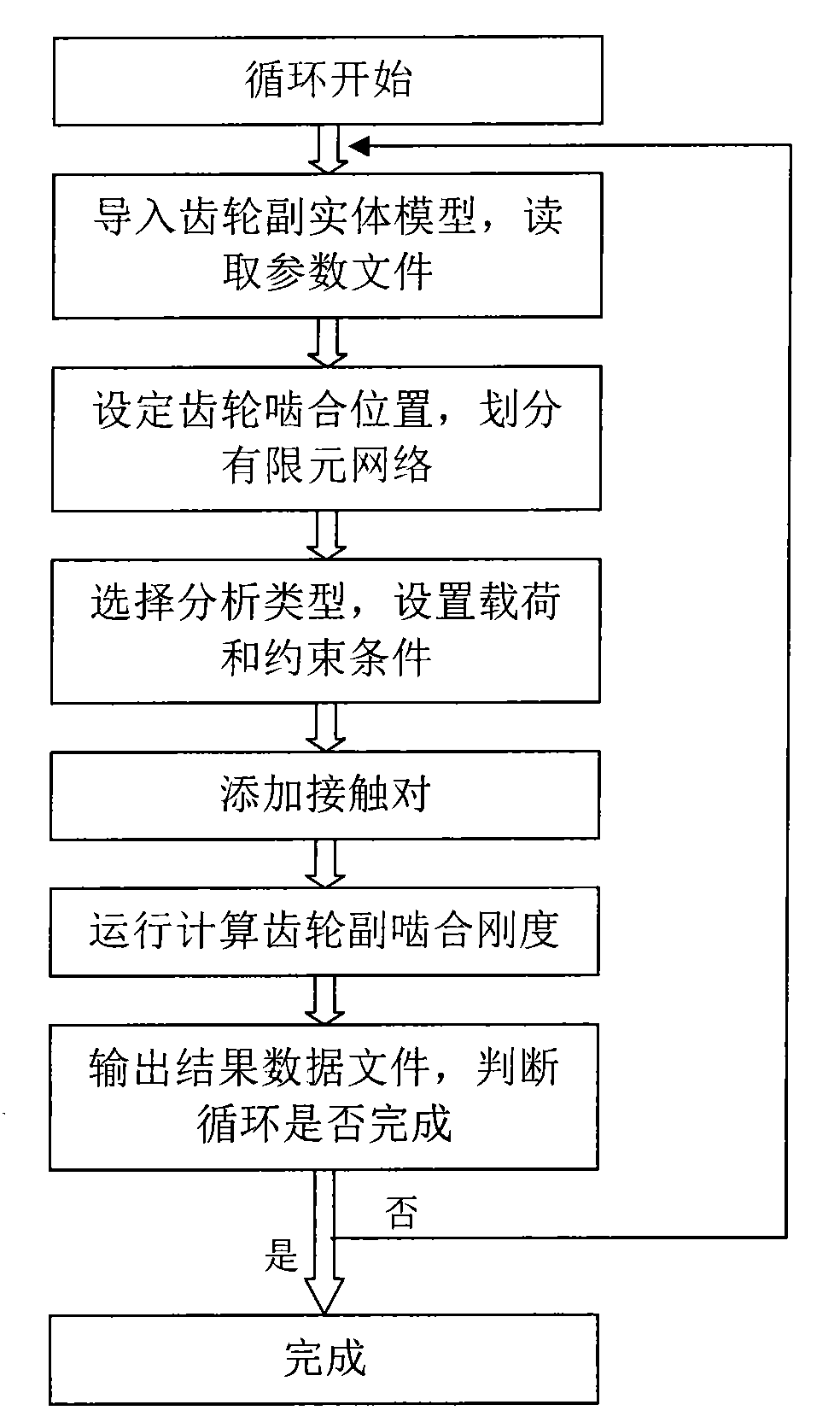

[0077] Such as figure 1 As shown, it is a working flow chart of the simulation analysis method for meshing stiffness of cylindrical spur gears with damaged single-tooth faults of the present invention. The specific implementation process is as follows:

[0078] Step 1 Simulation calculation of normal gear meshing stiffness

[0079] Step 1.1 Calculate the average meshing stiffness of the gear pair with the national standard method

[0080] Parameters and material properties of selected standard involute spur gears: modulus m=3.175, number of teeth z 1 / z 2 =19 / 48, gear thickness H=16mm, gear shaft hole radius r=20mm, elastic modulus E=6.028Gpa, Poisson’s ratio v=0.3, material density ρ=7800kg / m 3 . Using the calculation formula provided by GB-T 3480:

[0081] c'=c th C M C R C B cosβ

[0082] Calculate the stiffness of a single pair of teeth, where C M =0.8 is the theoretical correction coefficient, C R =1 is the coefficient of wheel tower structure, C B =1 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com