Precise modeling method for biarc correction cycloidal gear

A technology of cycloid gear and modeling method, which is applied to elements with teeth, belts/chains/gears, hoisting devices, etc., can solve the problems of reduced production efficiency, insufficient bending strength of tooth roots, shortened service life, etc. Achieve the effect of improving work efficiency, eliminating programming calculations, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: A method for accurately modeling a cycloidal gear with double arc correction, comprising the following steps:

[0067] 1) Determine the basic parameters of the double-arc correction cycloidal gear, and its basic parameters include:

[0068] Number of teeth

[0069] modulus

[0070] tooth width

[0071] pressure angle

[0072] According to the basic formula of double circular arc correction cycloid gear, calculate the index circle , root circle , Addendum circle .

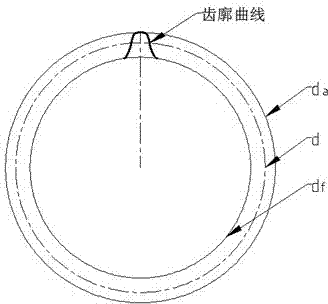

[0073] 2) Draw the pitch circle of the gear according to the calculation result , root circle , Addendum circle ,Such as figure 1 shown.

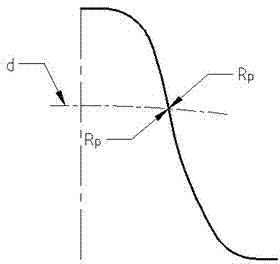

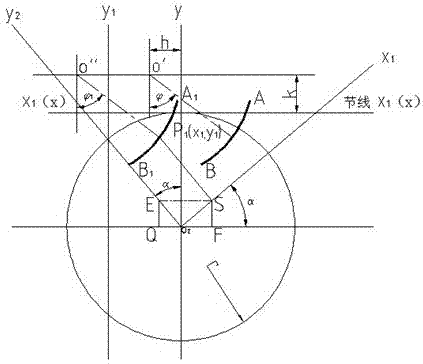

[0074] 3) According to the method described in the summary of the invention, calculate the tooth profile equation of the double-arc modified cycloid gear, and draw the double-arc modified cycloid according to the calculated tooth profile equation, and establish the basic tooth profile accordingly.

[0075] Wherein, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com