Solid carbide self-centering inner-cooling deep-hole twist drill for ABS valve body

A solid carbide, self-centering technology, applied in twist drills, drilling/drilling equipment, drill repairing, etc., can solve problems such as difficult chip removal, joint marks in holes, easy tool breakage, etc., and reduce costs , Guarantee rigidity and prevent the effect of breaking the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

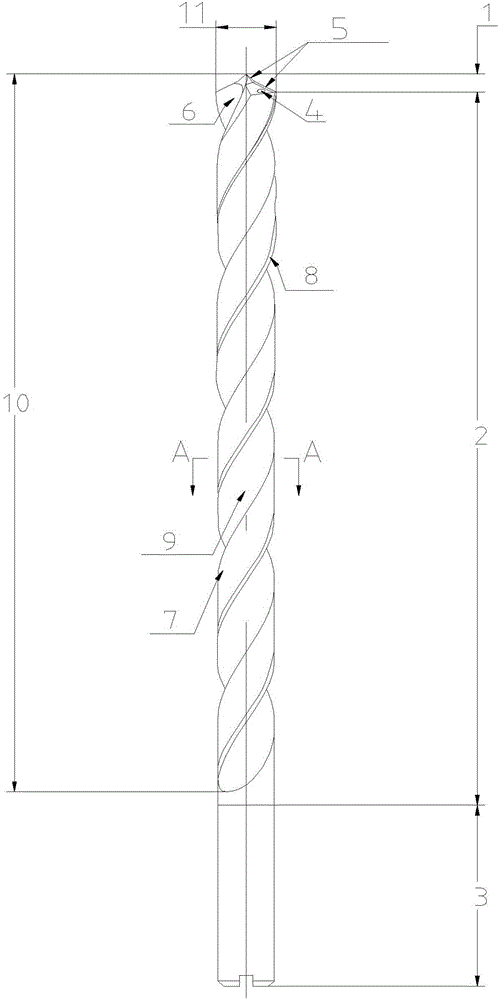

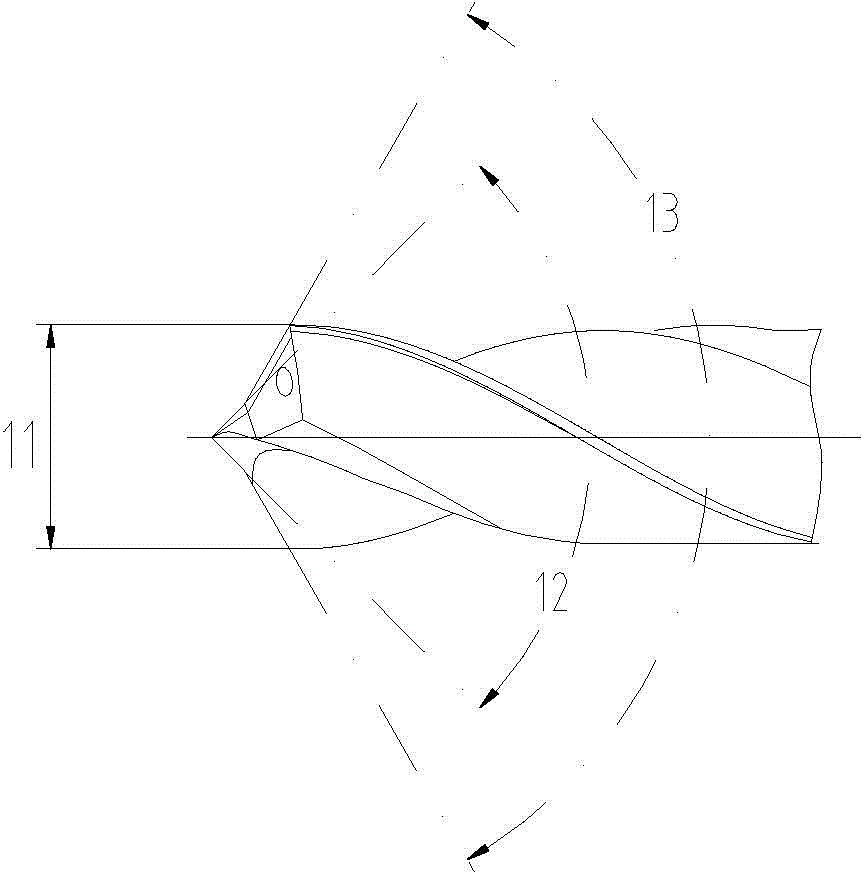

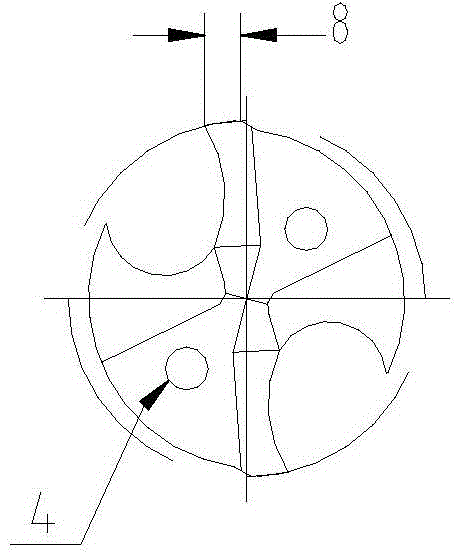

[0020] Such as figure 1 As shown, the integral hard alloy self-centering internal cooling deep hole twist drill for the ABS valve body includes a cutter body and a shank 3, the cutter body and the shank 3 are coaxial cylinders centered on the same central axis, and the cutter body Including the cutting part 1 and the working part 2, the cutting part 1 plays the role of centering and cutting, the working part 2 plays the role of guiding and chip removal, and the shank part 3 is a cylindrical straight shank structure for clamping. The cutter body is provided with a helical chip removal groove 9, two spiral grooves are used for chip removal, the solid part outside the chip removal groove 9 is the knife back 7, and two helical lands 8 are arranged on the outer cylinder of the knife back 7 for To ensure the size and orientation of the hole, the front end of the cutter body head is provided with an internal cooling hole 4 that runs through the cutter body in a spiral manner, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com