Pre-milling device and edge banding machine

A pre-milling and milling cutter technology, which is applied in the field of wood machinery, can solve the problems of poor integrity and aesthetics, and the edge banding strip is not tightly attached to the workpiece, so as to achieve good edge banding effect, better integrity and aesthetics , close fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

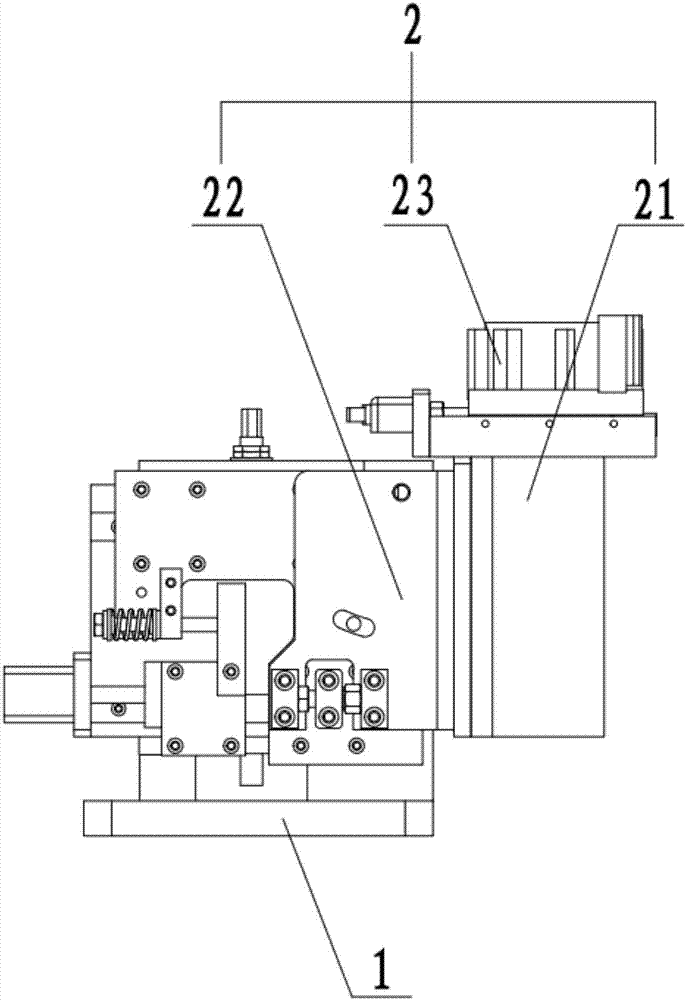

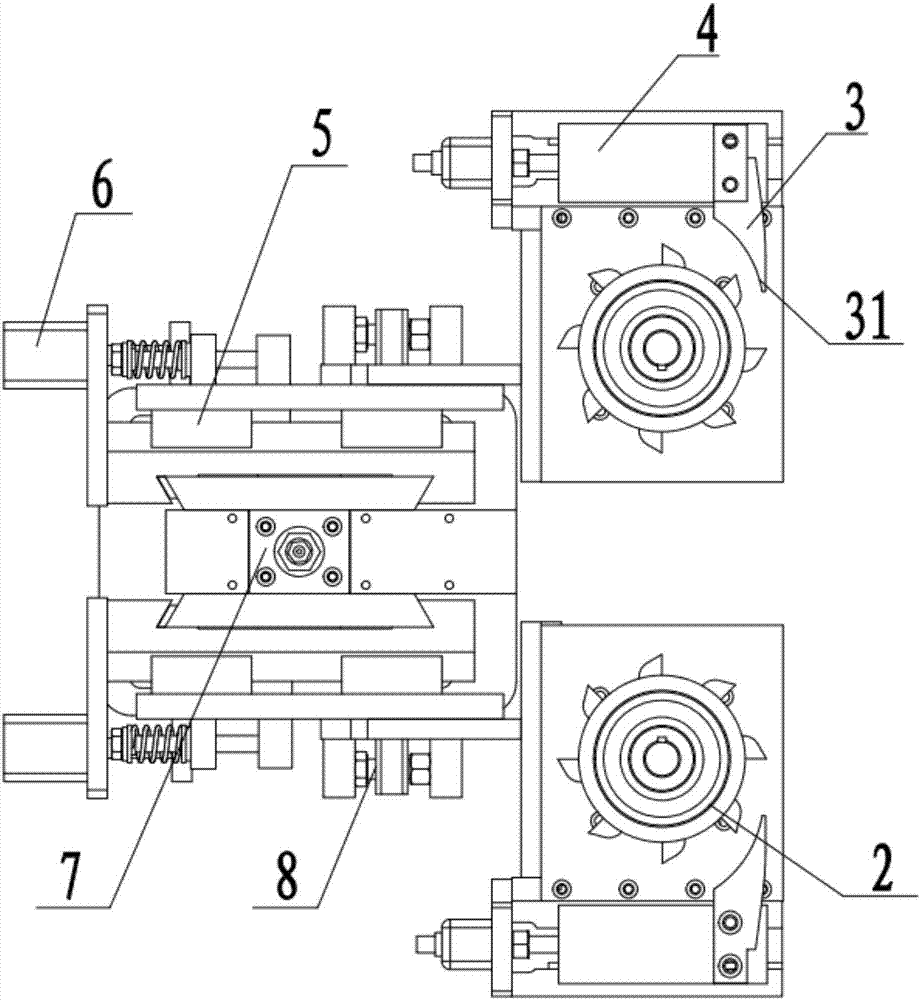

[0027] Such as figure 1 As shown, the present invention provides a pre-milling device, including a base 1 and a milling cutter assembly 2, and the milling cutter assembly 2 includes a drive mechanism 21, a fixing seat 22 for fixing the drive mechanism 21 and a milling cutter 23 connected to the drive mechanism 21 The milling cutter assembly 2 is slidably disposed on the base 1, and the moving direction of the milling cutter assembly 2 is the longitudinal direction perpendicular to the axis of the milling cutter 23.

[0028] Pre-milling is a process before edge banding, which can modify the corrugated marks, burrs or non-vertical phenomena on the workpiece (plate) caused by the panel saw or cutting saw after processing, so as to achieve better edge banding effect .

[0029] Wherein, the driving mechanism 21 can be configured as a motor, an air cylinder or a hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com