Edge sealing material as well as preparation method and application thereof

An edge-sealing material, water-based polyurethane technology, applied in coatings, photovoltaic power generation, etc., can solve the problems of poor solvent resistance of edge-sealing agents, and achieve the effect of increasing concentration, increasing cross-linking degree, and improving solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

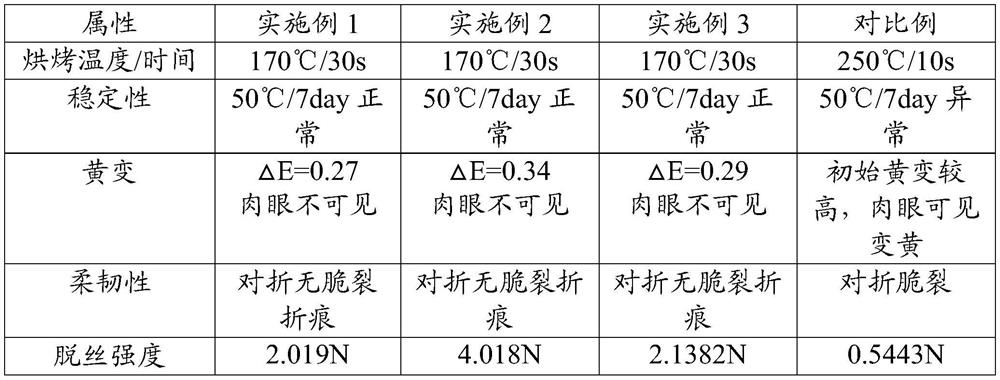

Examples

preparation example Construction

[0088] On the other hand, an embodiment of the present invention provides a method for preparing an edge-sealing material, the method is used to prepare the above-mentioned edge-sealing material, and the method includes:

[0089] According to the parts by weight of each component, water-based polyurethane resin, wetting agent, defoamer, thickener and film-forming auxiliary agent are added in sequence, and the edge sealing material is obtained after stirring and reacting.

Embodiment 1

[0093] Mix 95 parts of water-based polyurethane resin, 0.3 parts of wetting agent (product code: BYK-345), 0.5 parts of defoamer (product code: BYK-094), 0.6 parts of associative polyurethane thickener (product code: PUR- 85), and 3 parts of film-forming aid ethylene glycol butyl ether were mixed evenly to obtain the edge-sealing material prepared in this embodiment.

[0094] Wherein, waterborne polyurethane resin is prepared by the following method:

[0095] Add 25 parts of hexamethylene diisocyanate (HDI) and 700 parts of polycarbonate diol T5651 into a stirring device with a stirrer, keep warm at 90°C for 3 hours, after the reaction is completed, cool down to 50°C, and add 725 parts Acetone and 36 parts of 2,2-dimethylolpropionic acid continued to keep warm for 3 hours, then added 27 parts of acrylate isocyanate (2-IsocyanatoethylAcrylate, product code AOI-VM) for 1 hour, then added 10 parts of methanol and kept stirring for 10 hours ;

[0096] Add triethylamine, adjust t...

Embodiment 2

[0100] Mix 80 parts of water-based polyurethane resin, 0.3 parts of wetting agent (product code: BYK-345), 0.5 parts of defoamer (product code: BYK-094), 0.6 parts of associative polyurethane thickener (product code: PUR- 85), and 3 parts of film-forming aid ethylene glycol butyl ether were mixed evenly to obtain the edge-sealing material prepared in this embodiment.

[0101] Wherein, waterborne polyurethane resin is prepared by the following method:

[0102] Add 25 parts of hexamethylene diisocyanate (HDI) and 700 parts of polycarbonate diol T5651 into a stirring device with a stirrer, keep warm at 90°C for 3 hours, after the reaction is completed, cool down to 50°C, and add 725 parts Acetone and 36 parts of 2,2-dimethylolpropionic acid continued to keep warm for 3 hours, then added 27 parts of acrylate isocyanate (AOI-VM) to react for 1 hour, then added 10 parts of methanol and kept stirring for 10 hours;

[0103] Add triethylamine, adjust the pH value of the system to 7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com