Soft package battery

A soft-pack battery and cell technology, applied in battery pack components, battery boxes/jackets, circuits, etc., can solve the problems of cumbersome processes, increase tapes, and increase glue sticking processes, so as to simplify the edge sealing process and improve the sealing performance. The effect of the edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The pouch battery of the present invention will be described in detail below with reference to the accompanying drawings.

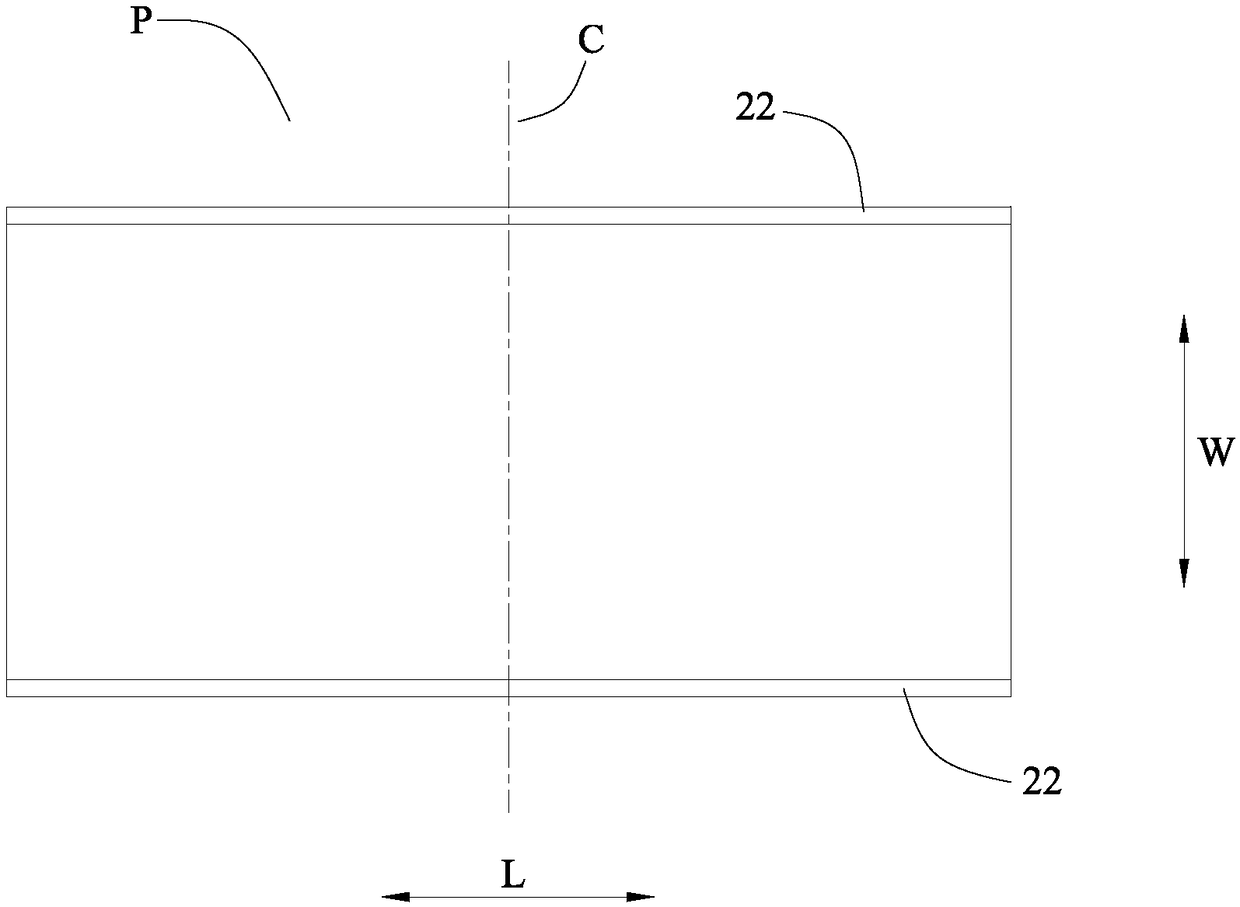

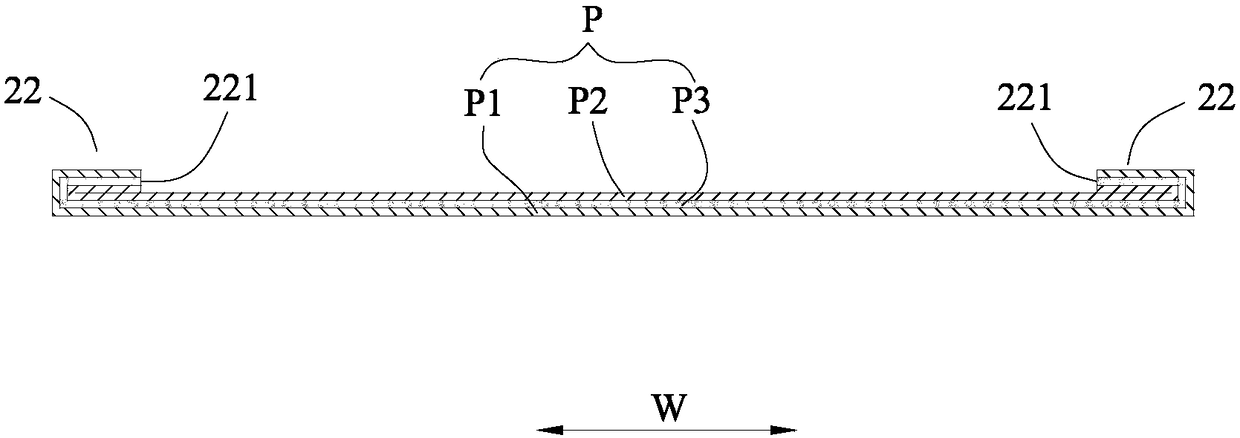

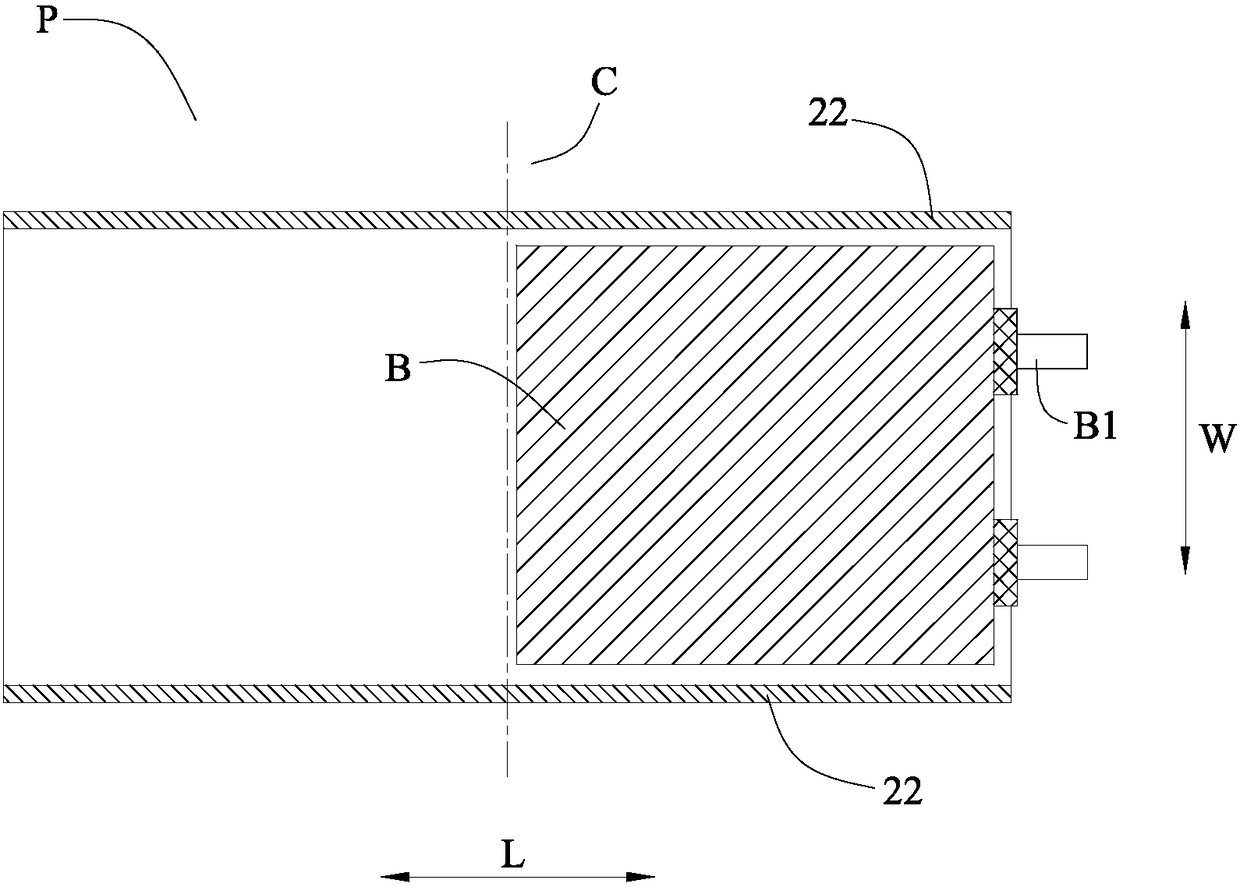

[0028] refer to Figure 1 to Figure 7 , according to the present invention, the pouch battery includes two layers of packaging film P and a cell B packaged between the two layers of packaging film P. Each layer of packaging film P includes an outer protective layer P1, an inner fusion layer P2, and a metal layer P3 located between the outer protection layer P1 and the inner fusion layer P2. The two-layer packaging film P forms the main body part 3 in the middle to accommodate the battery B, and is sealed and connected around the main body part 3 to form a top seal part 1 and a side seal part 2, wherein the side seal part 2 is bent and bonded to the main body On the side 31 of the part 3. Each layer of packaging film P is divided into a body 21 and a free end 22 on the side sealing part 2, and the free end 22 is folded back to the corresponding bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com