Packaging film and pouch battery

A soft-pack battery and packaging film technology, applied in secondary batteries, battery pack components, battery boxes/jackets, etc., can solve problems such as cumbersome processes, increased tape, tape lift or corners, etc., to simplify edge sealing Process, improve the effect of edge sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The packaging film and soft pack battery of the present invention will be described in detail below with reference to the accompanying drawings.

[0028] First, the packaging film according to the first aspect of the present invention will be described.

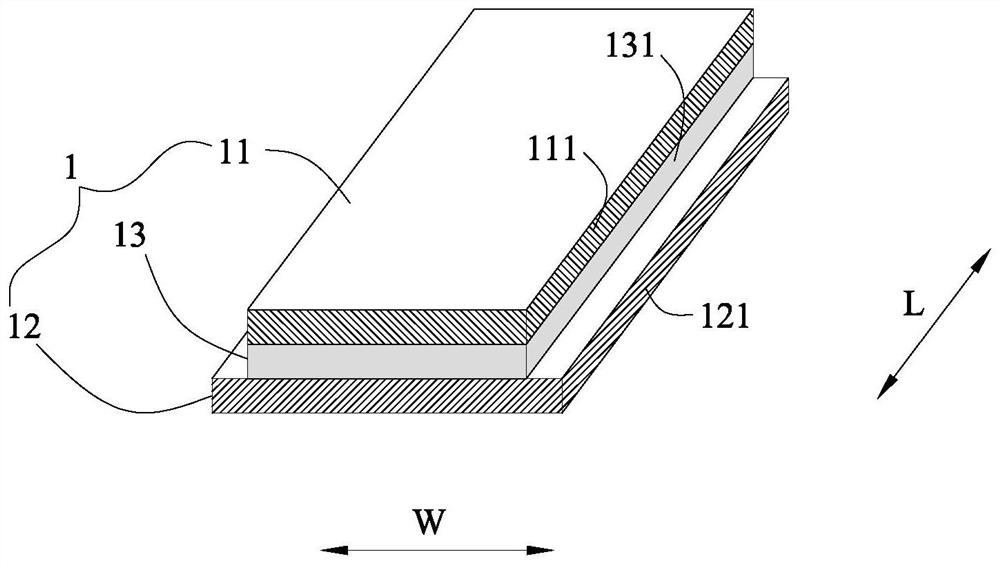

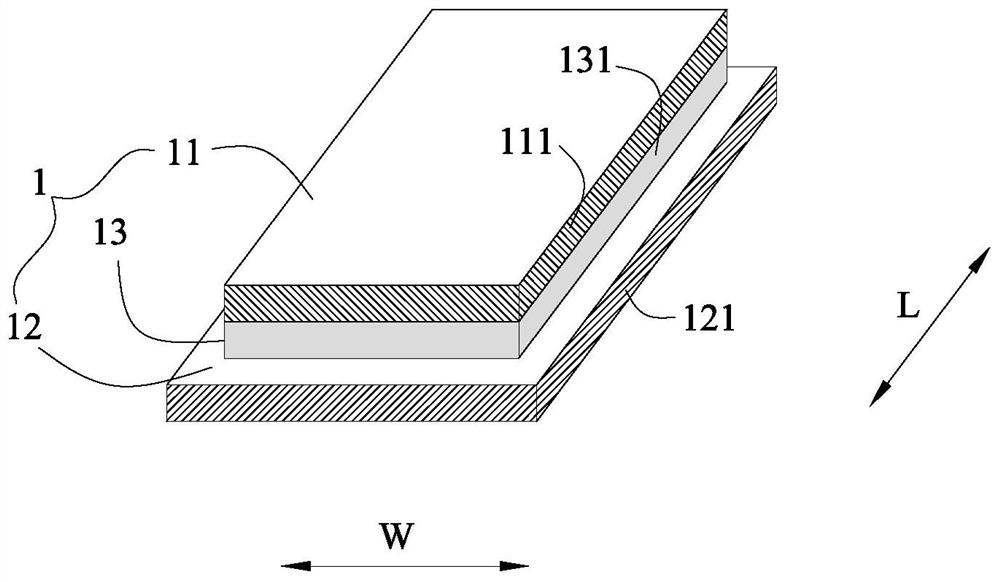

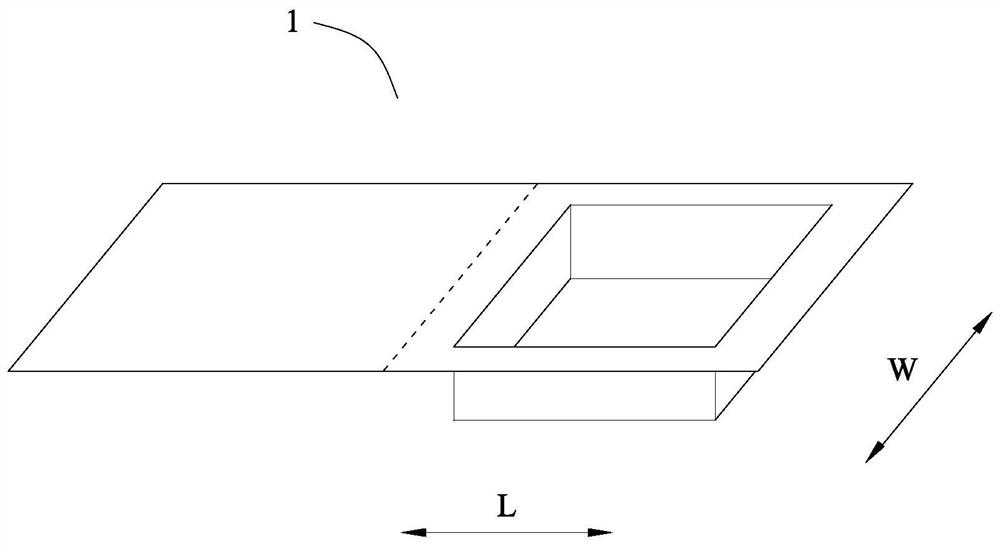

[0029] refer to Figure 1 to Figure 8 , the packaging film 1 according to the present invention includes an outer protective layer 11 , an inner fusion layer 12 and a metal layer 13 located between the outer protective layer 11 and the inner fusion layer 12 . Wherein, at least one outer end surface 121 of the inner fusion layer 12 at the edge exceeds the corresponding outer end surface 131 of the metal layer 13 .

[0030] In the packaging film 1 according to the invention, since at least one outer end face 121 of the inner fusion layer 12 at the edge protrudes beyond the corresponding outer end face 131 of the metal layer 13, then said inner fusion layer 12 protrudes beyond the corresponding outer end face 131 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com