Packaging case and pouch battery

A technology for soft-pack batteries and packaging shells, which is applied to secondary batteries, battery boxes/coats, and battery pack components. It can solve the problems of adding tape, tape warping or turning corners, and cumbersome procedures to improve edge sealing. The effect of improving energy density and simplifying the edge banding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

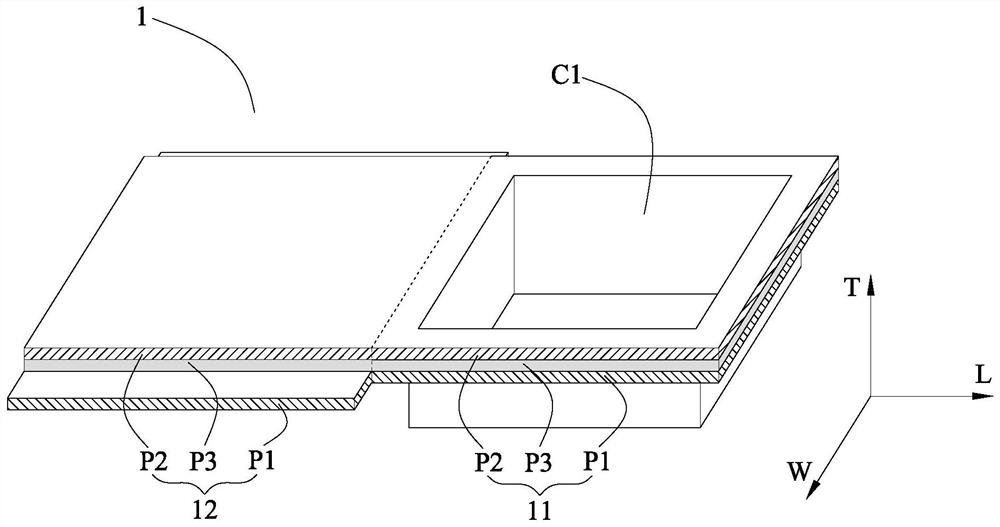

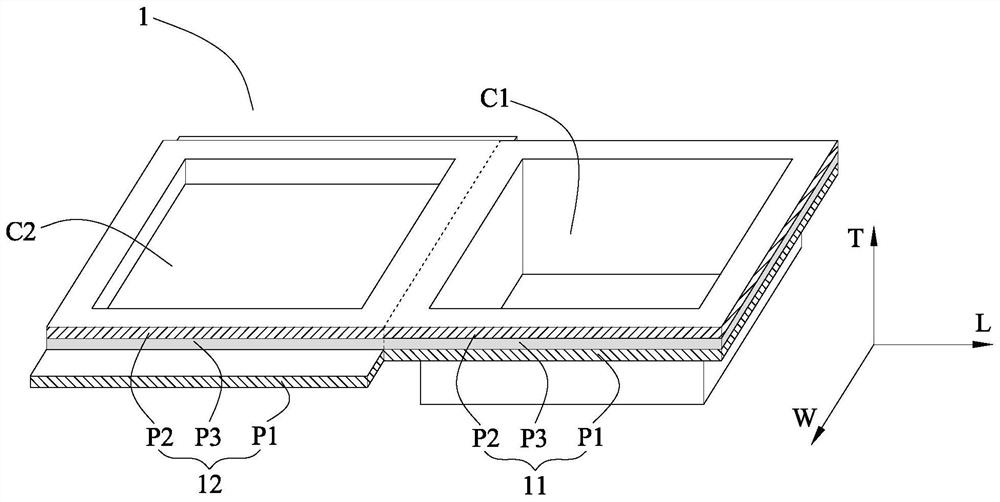

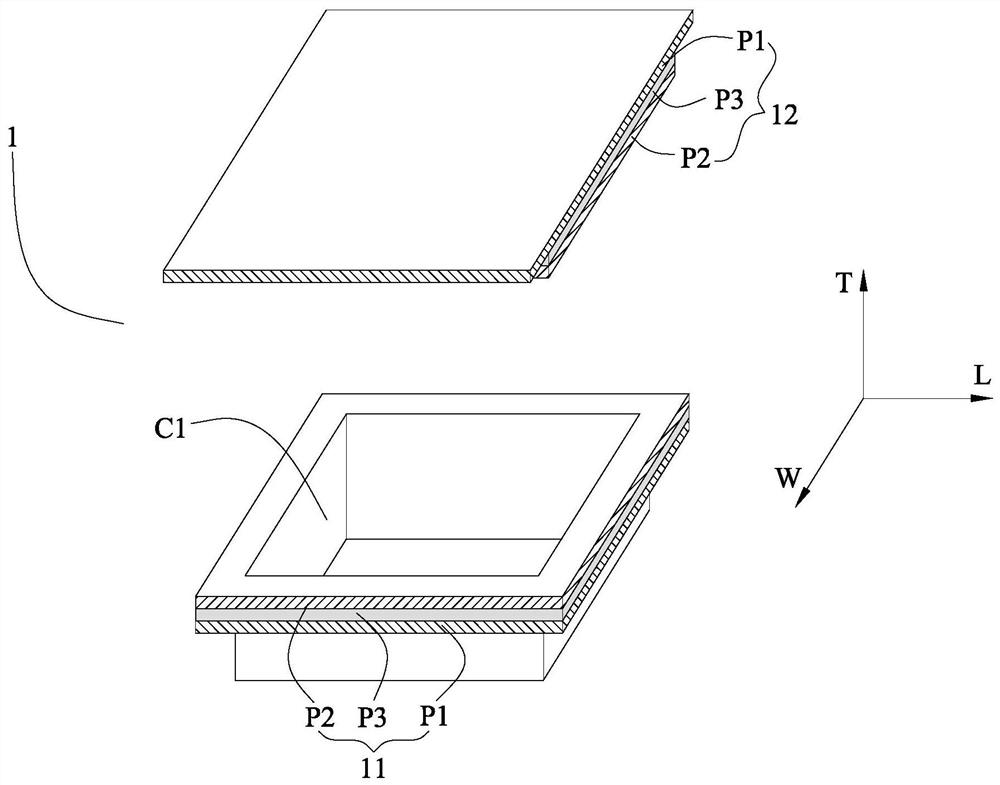

[0035] The packaging case and pouch battery of the present invention will be described in detail below with reference to the accompanying drawings.

[0036] First, the packaging case according to the first aspect of the present invention will be described.

[0037] refer to Figure 1 to Figure 13 , the packaging case 1 according to the present invention includes a first packaging film 11 and a second packaging film 12, and both the first packaging film 11 and the second packaging film 12 include an outer protective layer P1, an inner fusion layer P2, and a layer located on the outer protective layer P1. The metal layer P3 between the inner fusion layer P2. The first packaging film 11 is formed with a cavity C1; the inner fusion layer P2 of the second packaging film 12 is used to connect with the inner fusion layer P2 of the first packaging film 11 around the cavity C1 and seal the cavity C1.

[0038] When the inner fusion layer P2 of the second packaging film 12 and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com