Medium density fiberboard employing high-permeability nano water-based resin edge banding

A water-based resin and high-permeability technology, applied in epoxy resin coatings, coatings, powder coatings, etc., can solve the problems of limited mechanical properties of the coating surface, complicated edge banding process, and weak adhesion of the fiberboard body. Achieve the effects of excellent electrical insulation and chemical resistance, simple and convenient edge banding process, and good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The high-permeability nanometer water-based resin edge-sealed medium-fiber board includes a medium-fiber board body, wherein the side of the board body has an edge-sealing coating, and the edge-sealing coating and the surface of the board body have a thermosetting coating. The solid coating is obtained after electrostatic spraying and curing of low-temperature curing powder coatings on the edge-sealing coating and the surface of the board body. get;

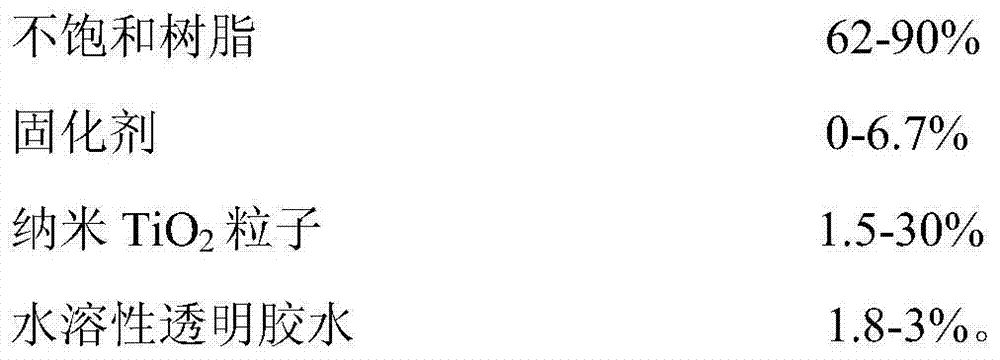

[0041] Described high-permeability nano water-based resin is made of the raw materials of following mass percentage:

[0042]

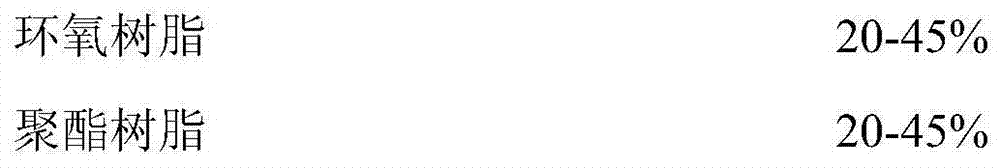

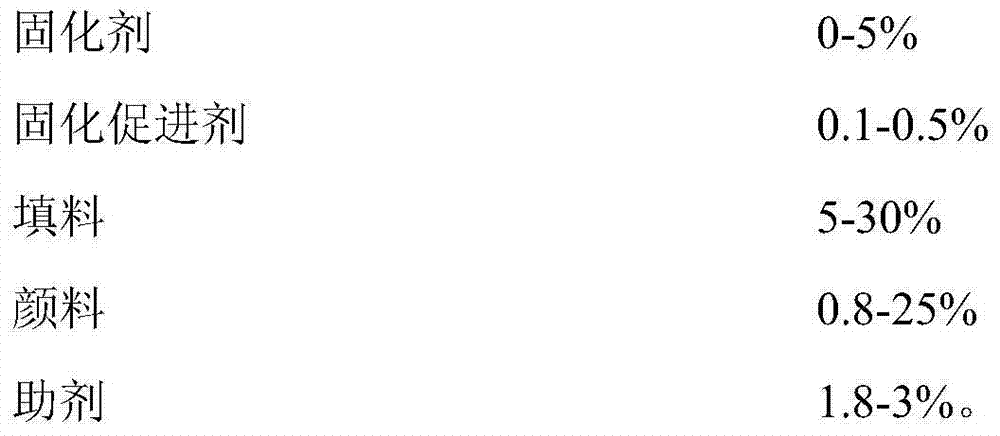

[0043] Described low-temperature curing powder coating is made of the raw materials of following mass percentage:

[0044]

[0045] The curing accelerator is a combination of TE-230 and JT-6015A, and the mass ratio of the two is 1:1.5.

[0046] The mass ratio of leveling agent, defoamer and degasser in the additive is 1:1:1.

[0047] The whole process steps are:

[0048] (1) Cut the MDF ...

Embodiment 2

[0053] Described high-permeability nano water-based resin is made of the raw materials of following mass percentage:

[0054]

[0055] Described low-temperature curing powder coating is made of the raw materials of following mass percentage:

[0056]

[0057] The curing accelerator is a combination of TE-230 and JT-6015A, and the mass ratio of the two is 1.5:1.

[0058] The mass ratio of leveling agent, defoamer and degasser in the additive is 1:1:1.

[0059] The curing method adopts mid-wave infrared pulse irradiation heating, curing at 150° C. for 5 minutes, and the rest is as in Example 1. Example 3

Embodiment 3

[0060] Described high-permeability nano water-based resin is made of the raw materials of following mass percentage:

[0061]

[0062] Described low-temperature curing powder coating is made of the raw materials of following mass percentage:

[0063]

[0064] The curing accelerator is a combination of TE-230 and JT-6015A, and the mass ratio of the two is 1:1.

[0065] The mass ratio of leveling agent, defoamer and degasser in the additive is 1:1:1.

[0066] The curing method adopts mid-wave infrared pulse irradiation heating, curing at 140° C. for 7 minutes, and the rest is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com