PDLC dimming membrane and edge sealing process thereof

A light-adjustable film and process technology, applied in the field of light-adjustable film, can solve the problems of poor edge sealing, low bonding strength, and debonding of transparent dividing lines, so as to improve the problem of transparent dividing lines, improve edge sealing effect, increase The effect of a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The normal temperature mentioned in the present invention refers to the temperature range of 20-25°C. The present invention will be further described in detail below in conjunction with the accompanying drawings.

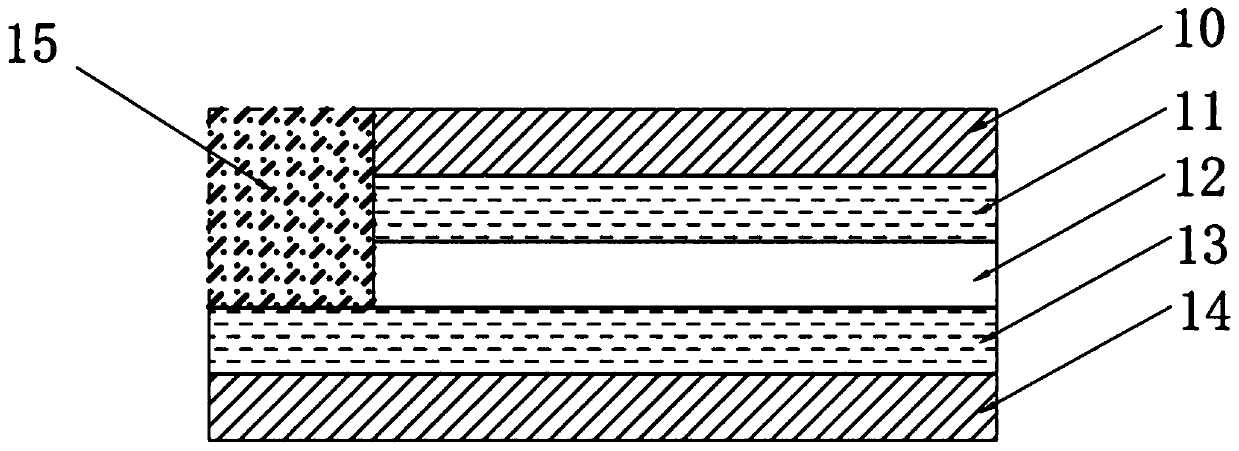

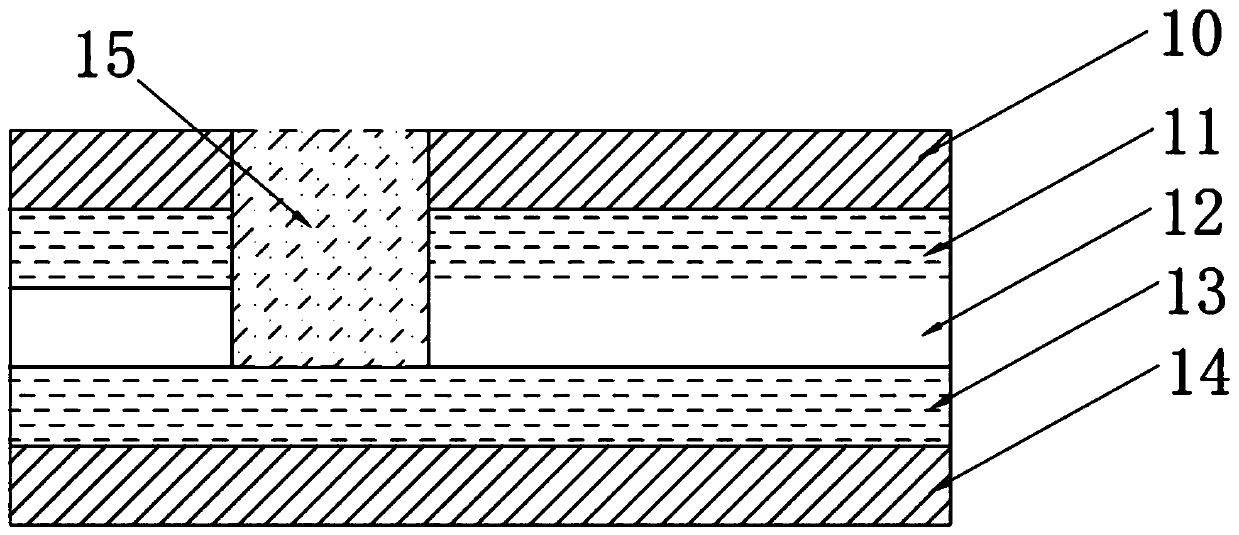

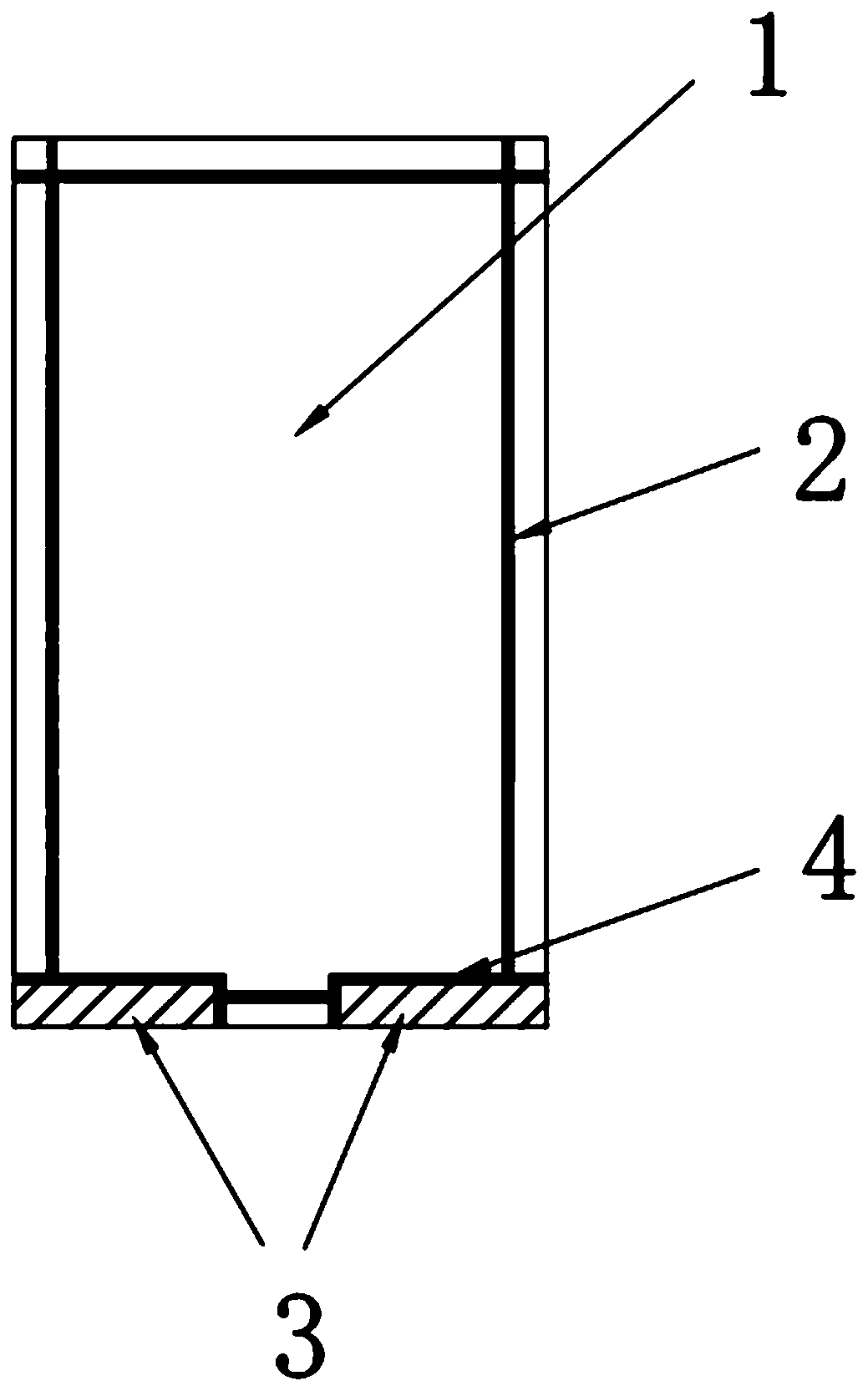

[0034] Such as figure 1 As shown, the edge banding groove in the prior art is located at the edge of the dimming film, and the embodiment of the present invention provides an edge banding process, which includes the following steps:

[0035] Step 1: making the electrode 3 of the PDLC dimming film 1, with a groove 4 between the electrode 3 and the PDLC dimming film 1;

[0036] Step 2: place the PDLC dimming film 1 with the electrodes 3 on the table, and clean the PDLC dimming film 1 with a cleaning agent;

[0037] Step 3: Cover and protect the electrode 3 area with adhesive tape;

[0038] Step 4: In the area where there is no electrode 3 on the PDLC dimming film 1, use a cutting device to cut out the edge sealing groove 2 at a position more than 5mm inward ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com