Vacuum glass and preparation method thereof

A technology of vacuum glass and glass, which is applied in the field of vacuum glass and its preparation, and can solve the problems of high pollution of fiber solder, low yield rate, small contact surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

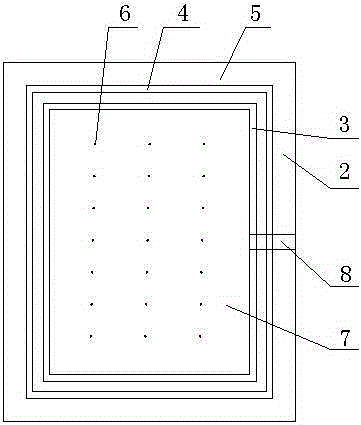

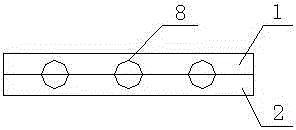

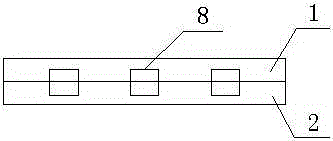

[0036] like Figure 1-5 As shown, a vacuum glass includes an upper glass 1 and a lower glass 2 bonded to each other by an organic binder 5 and an inorganic metal material 4; the relative bonding surfaces of the upper glass 1 and the lower glass 2 have at least An annular groove 3 for placing the getter 11 is opened on one side; the outer edge of the annular groove 3 of the upper glass 1 and / or the lower glass 2 is provided with an inorganic metal material 4 arranged along the annular groove 3; the inorganic metal The outer edge of the material 4 is provided with an organic binder 5; the upper glass 1 and the lower glass 2 are arranged with the inner area of the inorganic metal material 4 to form a vacuum layer 7, and the support 6 arranged in a lattice is arranged inside the vacuum layer 7 .

[0037] The organic binder 5 of the present invention adopts one or more of light-shadow glue, 502 glue, double-pipe glue, and resin glue. The inorganic metal material 4 is metal indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com