Smart film edge sealing technology for laminated PVB (polyvinyl butyral) smart glass

A technology of dimming glass and dimming film, which is applied in optics, nonlinear optics, instruments, etc., can solve the problem of high cost of dimming film and achieve the effect of eliminating shrinkage of dimming film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0022] A dimming film edge sealing process for PVB laminated dimming glass, comprising the following steps:

[0023] G. Cleaning: place the dimming film 1 on the platform, and clean the 0.5-10mm area of the edge of the dimming film with a cleaning agent to remove oil and other impurities. Cleaning agents are generally organic solvents such as alcohol.

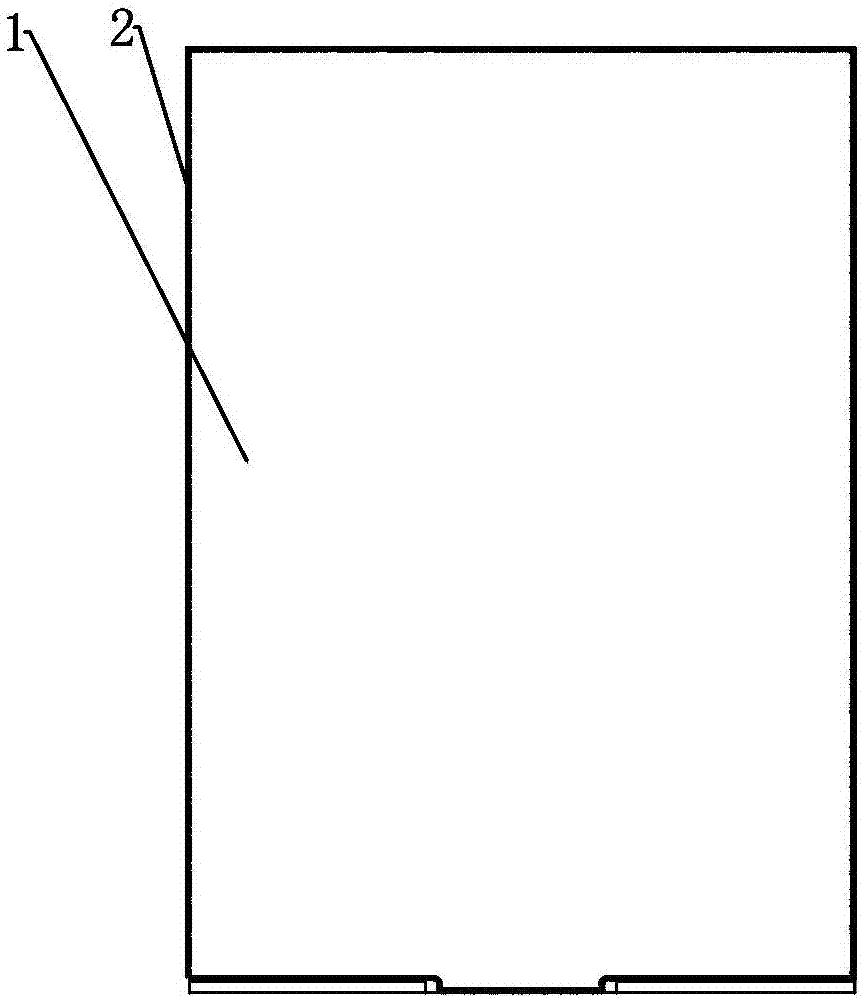

[0024] H. Cutting: Use a cutting tool to half-cut a step 2 of 0.5-3mm on each side of the dimming film (except for the electrodes of the dimming film, because the electrodes of the dimming film have already formed a step); the cutting tool used in this case is Electrode machete or laser cutter. That is to say, the electrode machete for cutting electrodes can be used for cutting, and there is no need t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com