High-performance reaction kettle special for conductive slurry production

A technology of conductive paste and reactor, which is applied in chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, chemical instruments and methods, etc., to improve the stirring effect, increase the contact area, and improve the stirring efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

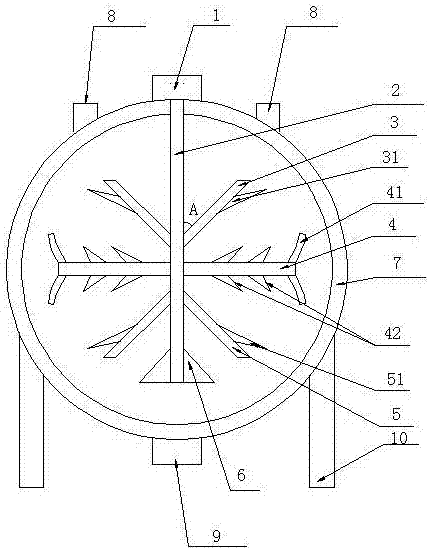

[0024] A special high-performance reactor for the production of conductive paste, comprising a reactor shell, characterized in that, the reactor shell is provided with a motor, a stirring shaft, a feed port, a discharge port and a supporting foot; the reaction The kettle shell has a hollow spherical structure, the motor is fixed on the highest point of the top center of the reactor shell by bolts, the bottom of the motor is connected to the stirring shaft, the top of the stirring shaft is connected to the motor, the bottom of the stirring shaft runs through the reactor shell and Extending into the inside of the reactor shell; the number of the feed inlets is two, respectively at the two ends of the top of the reactor shell; the number of the outlet is one set at the lowest point in the center of the bottom of the reactor ; The supporting feet are square metal brackets, two in number, fixed at both ends of the bottom of the reactor by welding;

[0025] The stirring shaft is a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com