Water-based anti-skid coating and preparation method thereof

An anti-slip coating, water-based technology, applied in the direction of coating, etc., can solve the problems of complex spraying process, poor adhesion of anti-slip particles, unfavorable construction speed, etc., and achieve the effect of convenient spraying method, convenient film forming speed and improved mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

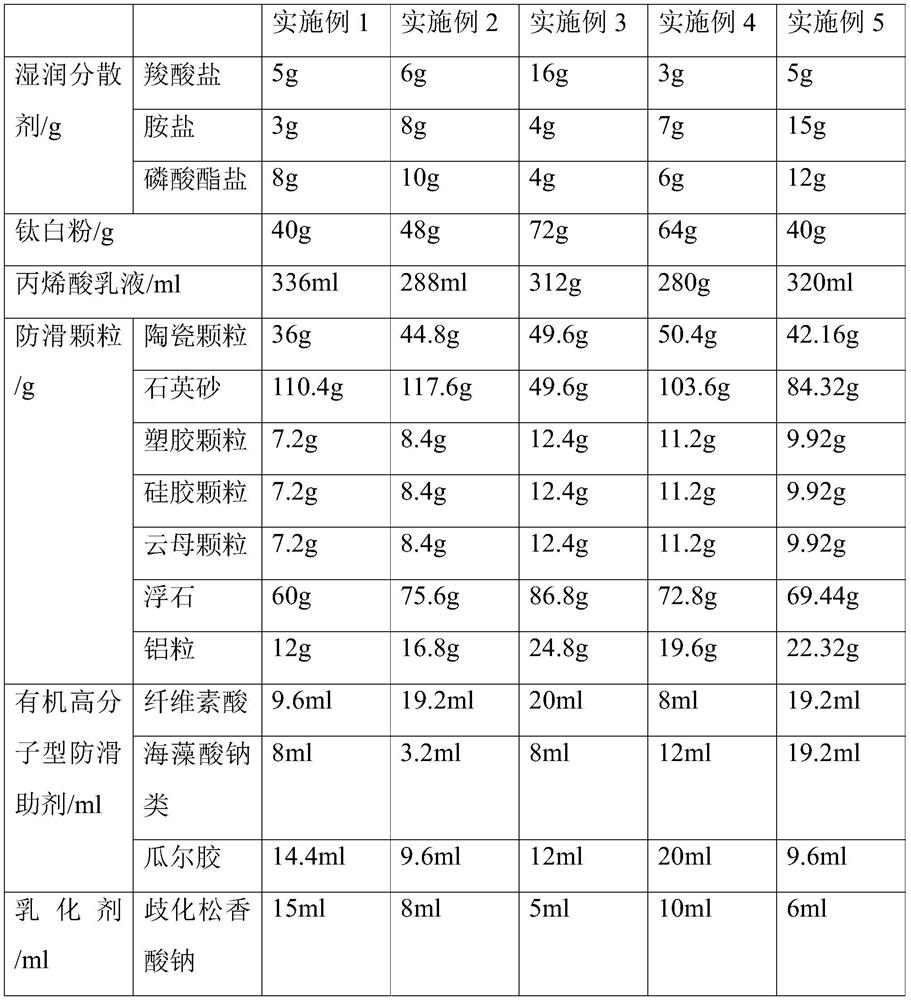

Embodiment 1

[0040] A water-based anti-skid coating, including A component and B component.

[0041] The main components of the A component are acrylic emulsion and anti-slip particles with a particle size range of 0.2-2mm: the acrylic emulsion is used as the basis of the water-based coating of the present invention; the anti-slip particles are uniformly mixed in the acrylic emulsion to make the water-based anti-slip coating have a good The anti-slip properties of common anti-slip particles that can be used in water-based anti-slip coatings include ceramic particles, quartz sand, plastic particles, silica gel particles, mica particles, pumice, aluminum particles, etc.; in addition, A component includes solvent water and a variety of functional Additive, used to improve the stability of A component.

[0042] The functional additives include wetting and dispersing agents, defoaming agents, titanium dioxide, leveling agents, bactericides, organic polymer anti-slip additives, suspending agents...

Embodiment 2

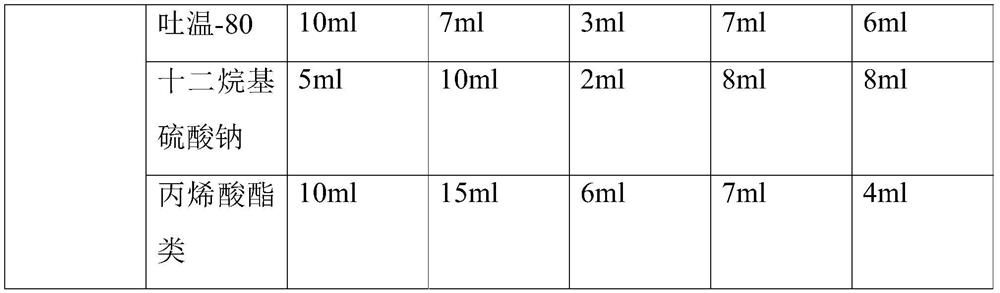

[0064] A kind of water-based antiskid coating, the preparation step of described A component comprises:

[0065] S1. Measure 40ml of water, weigh carboxylate, amine salt and phosphate salt powder according to the mass ratio in Table 1 to configure wetting dispersant, weigh 4g defoamer powder, weigh 48g titanium dioxide, mix the above materials, Stir at a speed of 500r / min for 10 minutes, add 8g of suspending agent, and stir at a speed of 700r / min for 20 minutes to obtain the first auxiliary agent. Grind the first auxiliary agent until the fineness reaches below 40 μm, and filter through a 120-mesh filter to obtain the first auxiliary agent. an additive slurry;

[0066] S2. Mix 24ml of water, 4g of leveling agent, and 4g of bactericide, and stir at 500r / min for 5 minutes to obtain the second auxiliary agent;

[0067] S3. Mix 288ml of acrylic emulsion with the second auxiliary agent obtained in step S2, stir at 500r / min for 10 minutes, and filter through a 120-mesh filter to ob...

Embodiment 3

[0075] A kind of water-based antiskid coating, the preparation step of described A component comprises:

[0076] S1. Measure 40ml of water, weigh carboxylate, amine salt and phosphate salt powder according to the mass ratio in Table 1 to configure wetting dispersant, weigh 4g of defoamer powder, weigh 72g of titanium dioxide, mix the above materials, Stir at a speed of 500r / min for 10 minutes, add 8g of suspending agent, and stir at a speed of 700r / min for 20 minutes to obtain the first auxiliary agent. Grind the first auxiliary agent until the fineness reaches below 40 μm, and filter through a 120-mesh filter to obtain the first auxiliary agent. an additive slurry;

[0077] S2. Mix 24ml of water, 4g of leveling agent, and 4g of bactericide, and stir at 500r / min for 5 minutes to obtain the second auxiliary agent;

[0078] S3. Mix 312ml of acrylic acid emulsion with the second auxiliary agent obtained in step S2, stir at 500r / min for 10 minutes, and filter through a 120-mesh f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com