Process invention about CCGA welding column

A process and welding column technology, which is applied in the field of CCGA welding column welding materials, can solve the problems of oxidation and product voids, and achieve the effects of reducing incorporation, simple structure, and reducing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

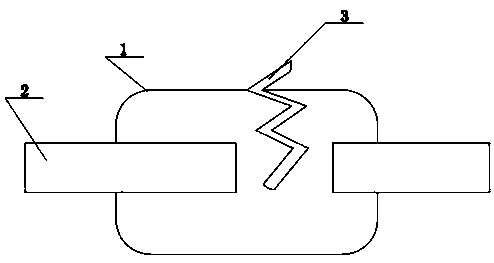

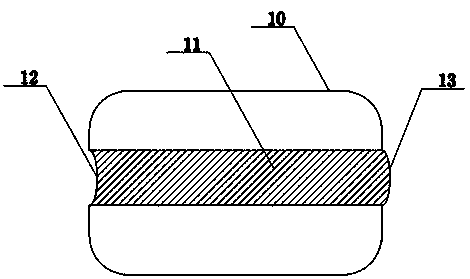

[0014] see Figure 1-2 As shown, the technical solution adopted in this specific embodiment is: it consists of a gas protection device 1, a material 2, and a laser generator 3. The gas protection device 1 includes a feed port 12, a discharge port 13, and a gas protection device shell 10. The material inlet 12 and the material outlet 13 are arranged on both sides of the gas protection device casing 10, the laser generator 3 is arranged above the inner edge of the gas protection device casing 10, and the material 2 enters the inside of the gas protection device 1 from the inlet 12 , sent out from the outlet 13.

[0015] Further, the gas protection device 1 is provided with a material tank 11 . Fit the material in the groove, so that the material is not easy to shift and offset, and it is convenient for the laser to perform precise positioning, cutting and shaping.

[0016] Further, the feed port 12 and the discharge port 13 are arranged in parallel on the same straight line. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com