Foaming composite material and preparation method thereof

A technology of composite materials and foaming agents, applied in the field of 3D printing, can solve the problems of difficult to realize comprehensive control of material mechanical properties and light weight, large shrinkage rate of polymer products, and degradation of mechanical properties, and achieve the expansion of processing temperature range, Improve product appearance and reduce shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

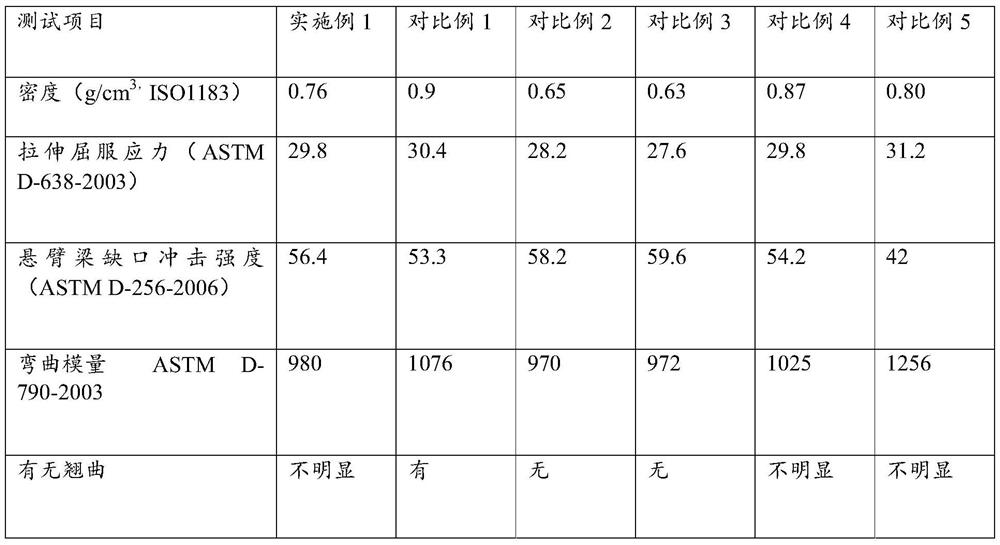

Examples

Embodiment 1

[0040] (1) 100 parts by weight of PP, 12 parts of foaming functional masterbatch EN412 parts, 0.3 parts of antioxidant 1076 and 0.3 parts of DLTP are mixed, and the foaming composite material is obtained by blending and extruding granulation through a twin-screw extruder;

[0041] (2) The mixture is directly added to the 3D printing polymer production device, and the final product is obtained through melt extrusion, product molding, and cooling. The melt extrusion temperature was 210°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com