Plastic masterbatch for starch-based degradable packaging film and preparation method of plastic masterbatch

A technology of plastic masterbatch and packaging film, applied in the field of plastic packaging film, can solve the problems of poor water resistance, affecting the development and application of starch-based degradable plastics, etc., to improve heat resistance, improve subsequent water resistance, and broaden the processing temperature range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

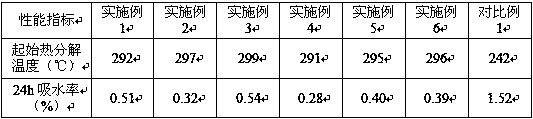

Examples

Embodiment 1

[0032](1) First dry the starch thoroughly and grind it to particles with a particle size of 30 μm, then add titanate coupling agent and alcohol solution to disperse evenly, then add inorganic porous microspheres, and perform ultrasonic dispersion treatment to make the starch particles loaded on the inorganic porous In the pores of the microspheres, the temperature is finally raised to 60°C and dried to obtain inorganic porous microspheres loaded with starch particles;

[0033] The starch is corn starch; the titanate coupling agent is isopropyl triisostearyl titanate; the inorganic porous microspheres are porous glass microspheres; It is methanol; the ultrasonic frequency of ultrasonic dispersion treatment is 28kHz, and the power density is 0.32W / cm 2 , the time is 75min; each raw material component is, according to mass fraction, starch 12%, titanate coupling agent 1%, alcohol solution 64%, inorganic porous microsphere 23%;

[0034] (2) Add the inorganic porous microspheres l...

Embodiment 2

[0040] (1) First dry the starch fully and grind it to particles with a particle size of 70 μm, then add titanate coupling agent and alcohol solution to disperse evenly, then add inorganic porous microspheres, and perform ultrasonic dispersion treatment to make the starch particles loaded on the inorganic porous In the pores of the microspheres, the temperature is finally raised to 60°C and dried to obtain inorganic porous microspheres loaded with starch particles;

[0041] The starch is tapioca starch; the titanate coupling agent is isopropyl tri(dioctyl phosphate acyloxy) titanate; the inorganic porous microspheres are spherical diatoms; in the alcohol solution, the quality of the alcohol is 80% of the water quality. %, wherein the alcohol is ethanol; the ultrasonic frequency of ultrasonic dispersion treatment is 35kHz, and the power density is 0.38W / cm 2 , the time is 65min; each raw material component is, according to mass fraction, starch 17%, titanate coupling agent 3%, a...

Embodiment 3

[0048] (1) First dry the starch thoroughly and grind it to particles with a particle size of 80 μm, then add titanate coupling agent and alcohol solution to disperse evenly, then add inorganic porous microspheres, and perform ultrasonic dispersion treatment to make the starch particles loaded on the inorganic porous In the pores of the microspheres, the temperature is finally raised to 60°C and dried to obtain inorganic porous microspheres loaded with starch particles;

[0049] The starch is rice starch; the titanate coupling agent is bis(dioctyloxypyrophosphate) ethylene titanate ; the inorganic porous microspheres are porous ceramic microspheres; 90%, of which, the alcohol is ethylene glycol; the ultrasonic frequency of ultrasonic dispersion treatment is 35kHz, and the power density is 0.4W / cm 2 , the time is 60min; the raw material components are, according to the mass fraction, 20% starch, 3% titanate coupling agent, 47% alcohol solution, and 30% inorganic porous microsphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com