Patents

Literature

36results about How to "With shading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

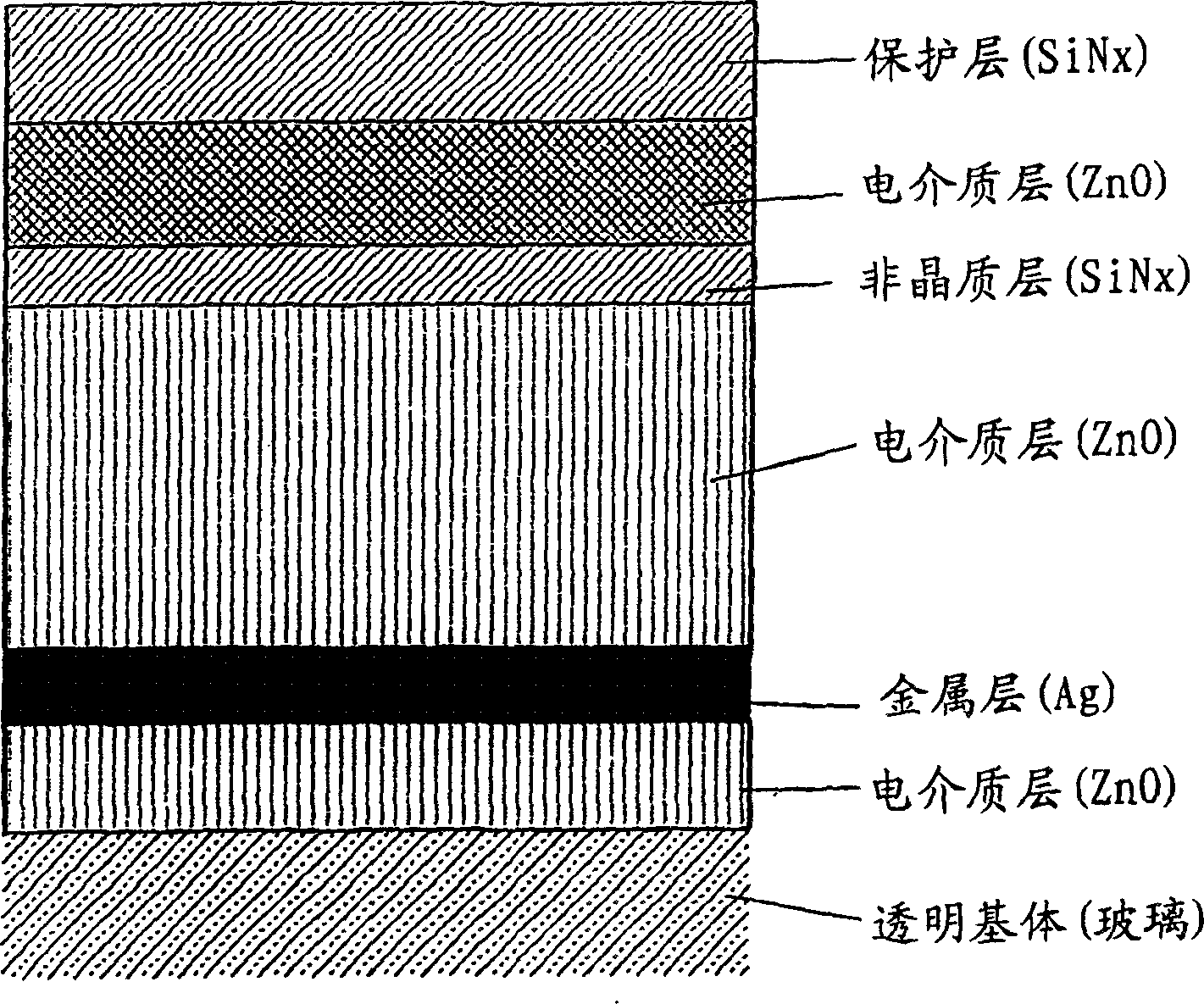

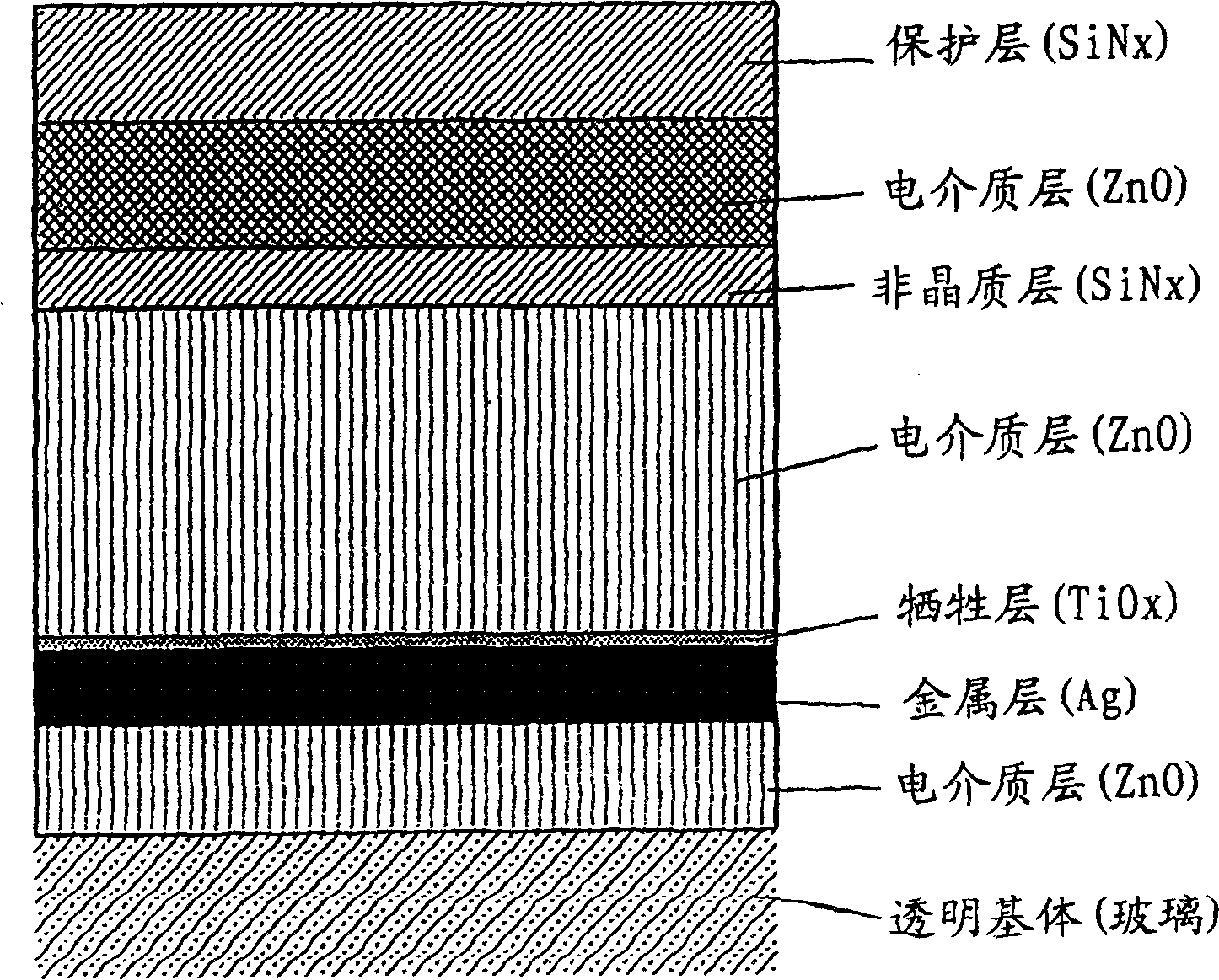

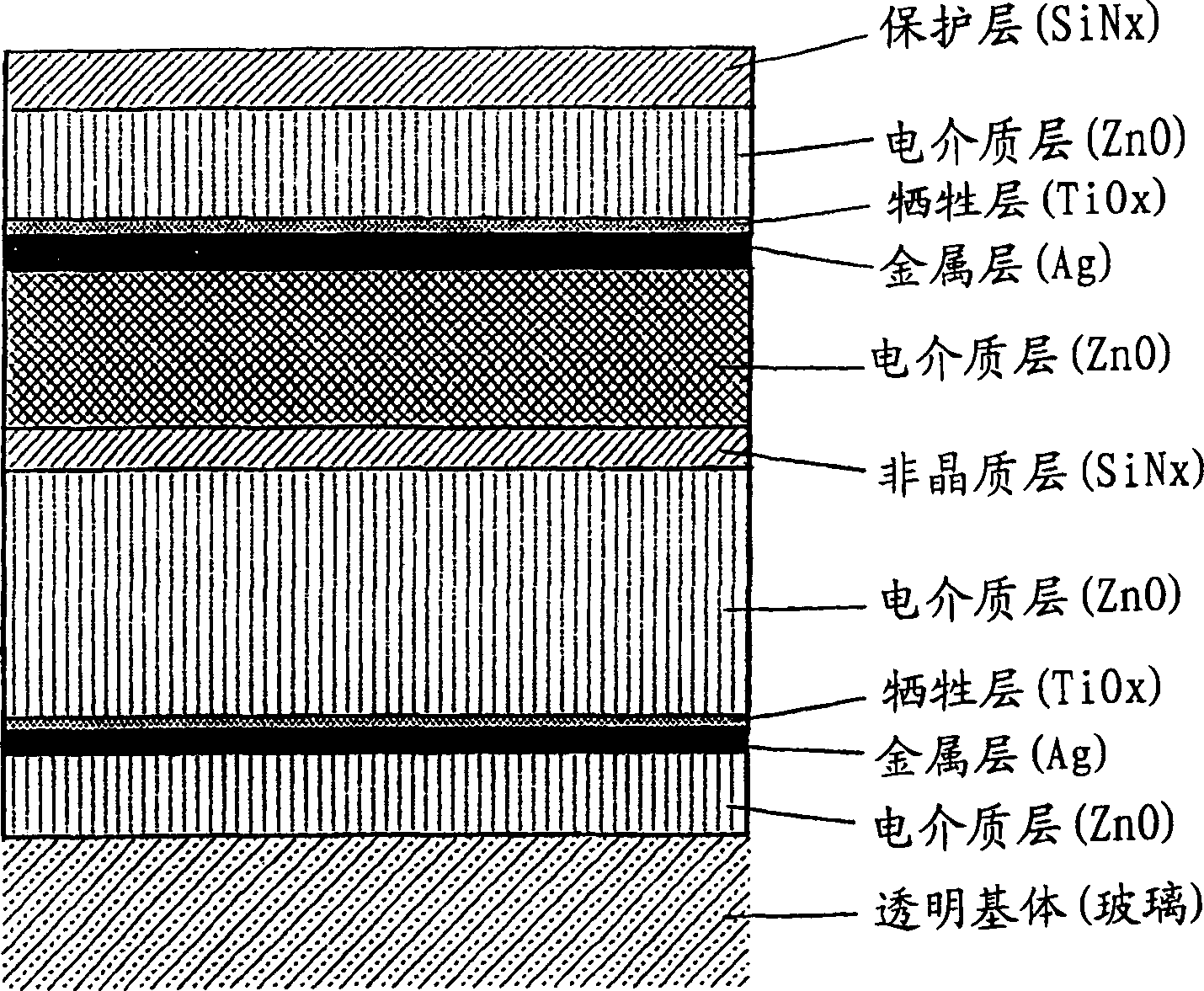

Transparent laminate having low emissivity

InactiveCN1476379AInhibit crystallizationImprove wear resistance and durabilityVacuum evaporation coatingSputtering coatingLow emissivityZinc

A transparent laminate having low emissivity which has one or more dielectric layers such as a zinc oxide (ZnO) film and one or more metal layers such as a silver (Ag) film being laminated on one another, characterized in that at least one dielectric layer is divided in the direction of film thickness by at least one amorphous layer. The transparent laminate having low emissivity exhibits improved durability of the metal layer, since the formation of a zinc oxide film as a dielectric layer on an amorphous layer causes the collapse of the columnar crystal structure of zinc oxide and, as a result, not only the amorphous layer but also the dielectric layer act also as a barrier preventing the entry of moisture or a gas.

Owner:CARDINAL CG +1

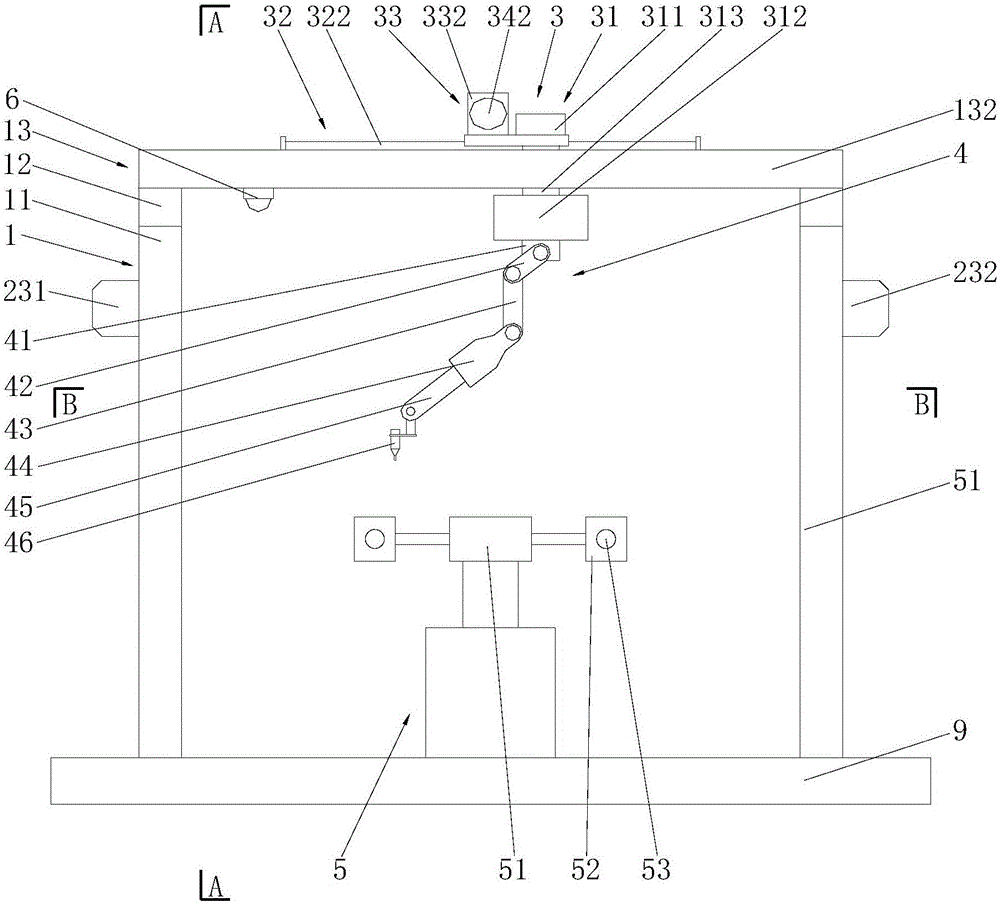

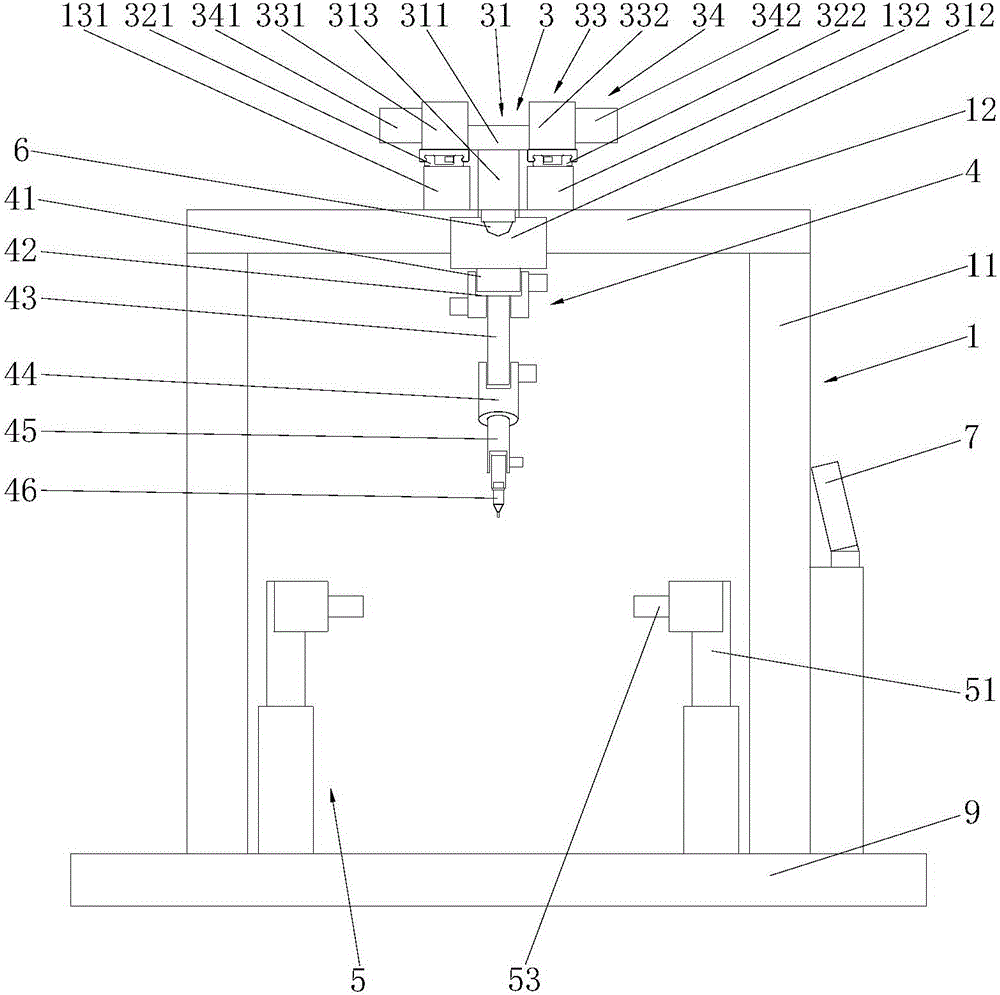

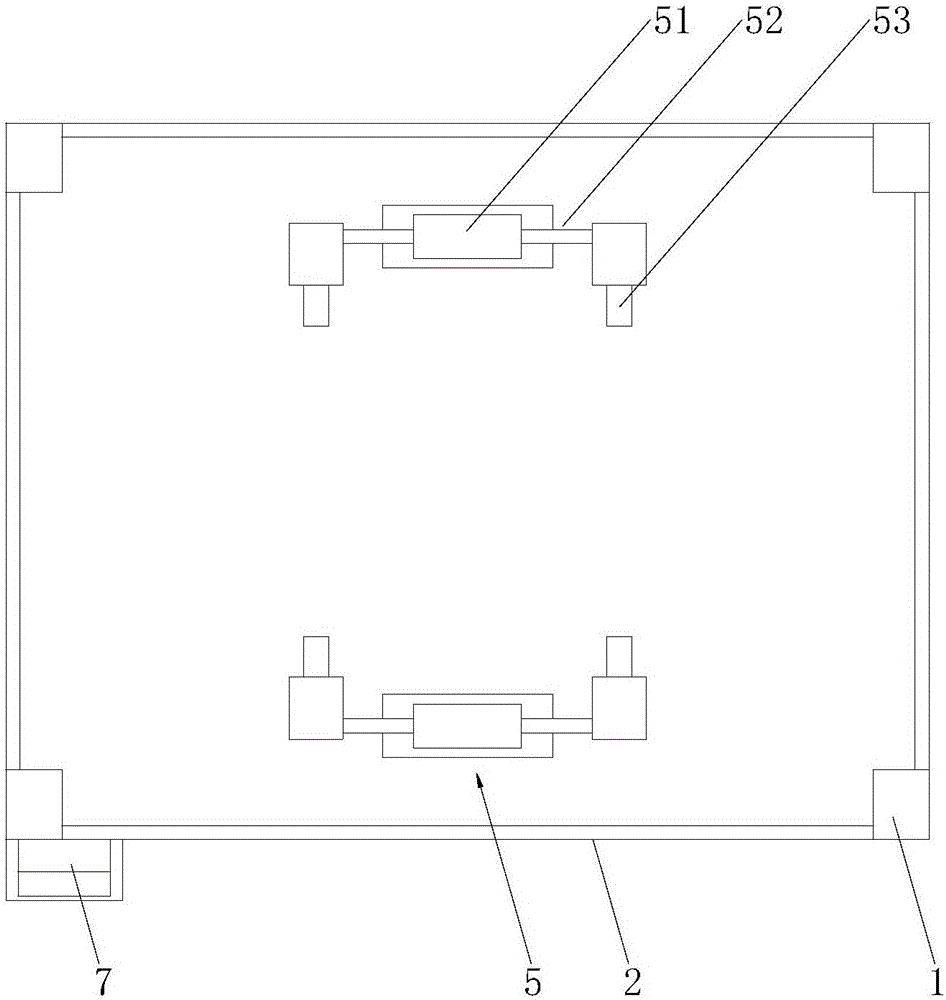

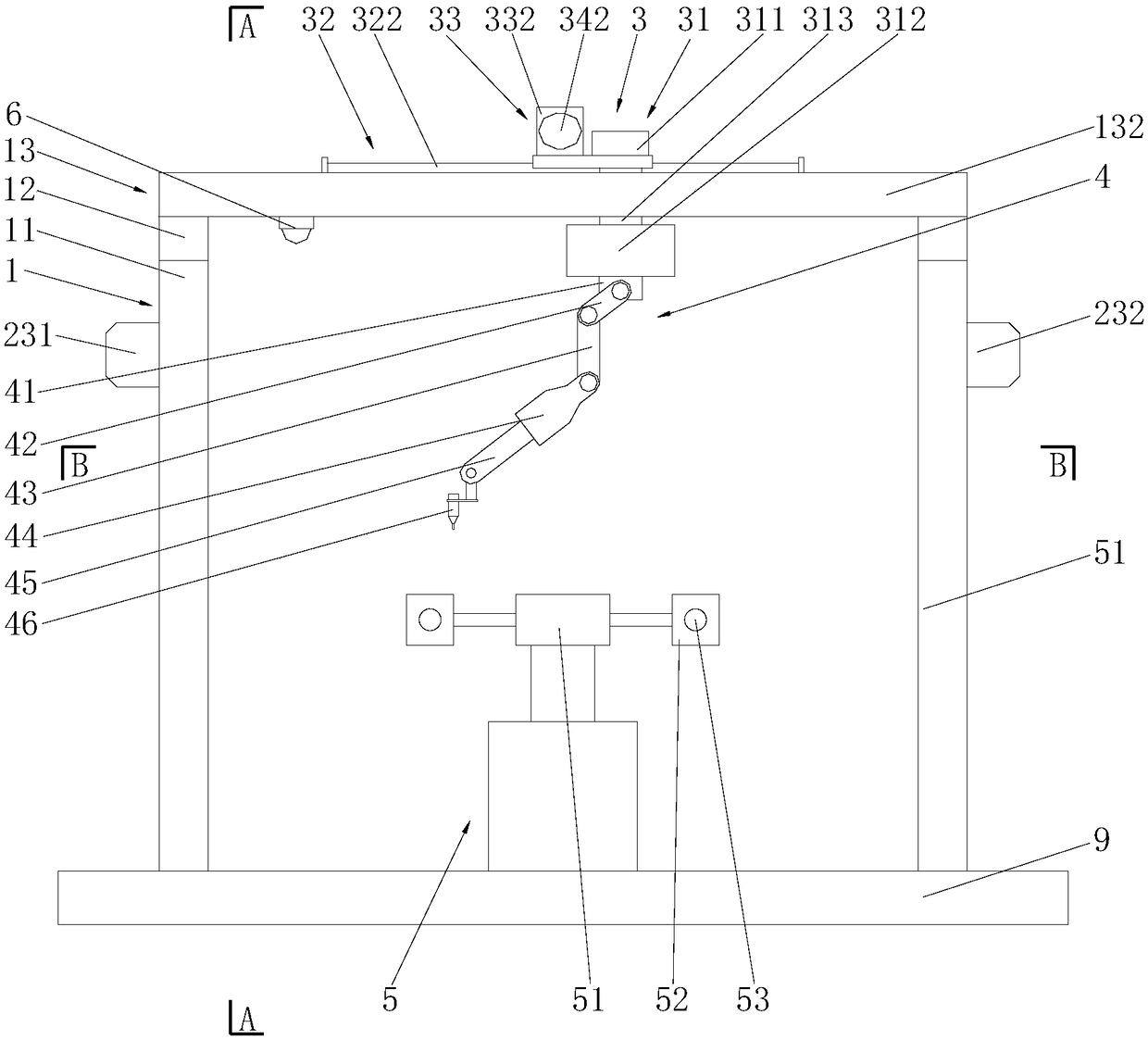

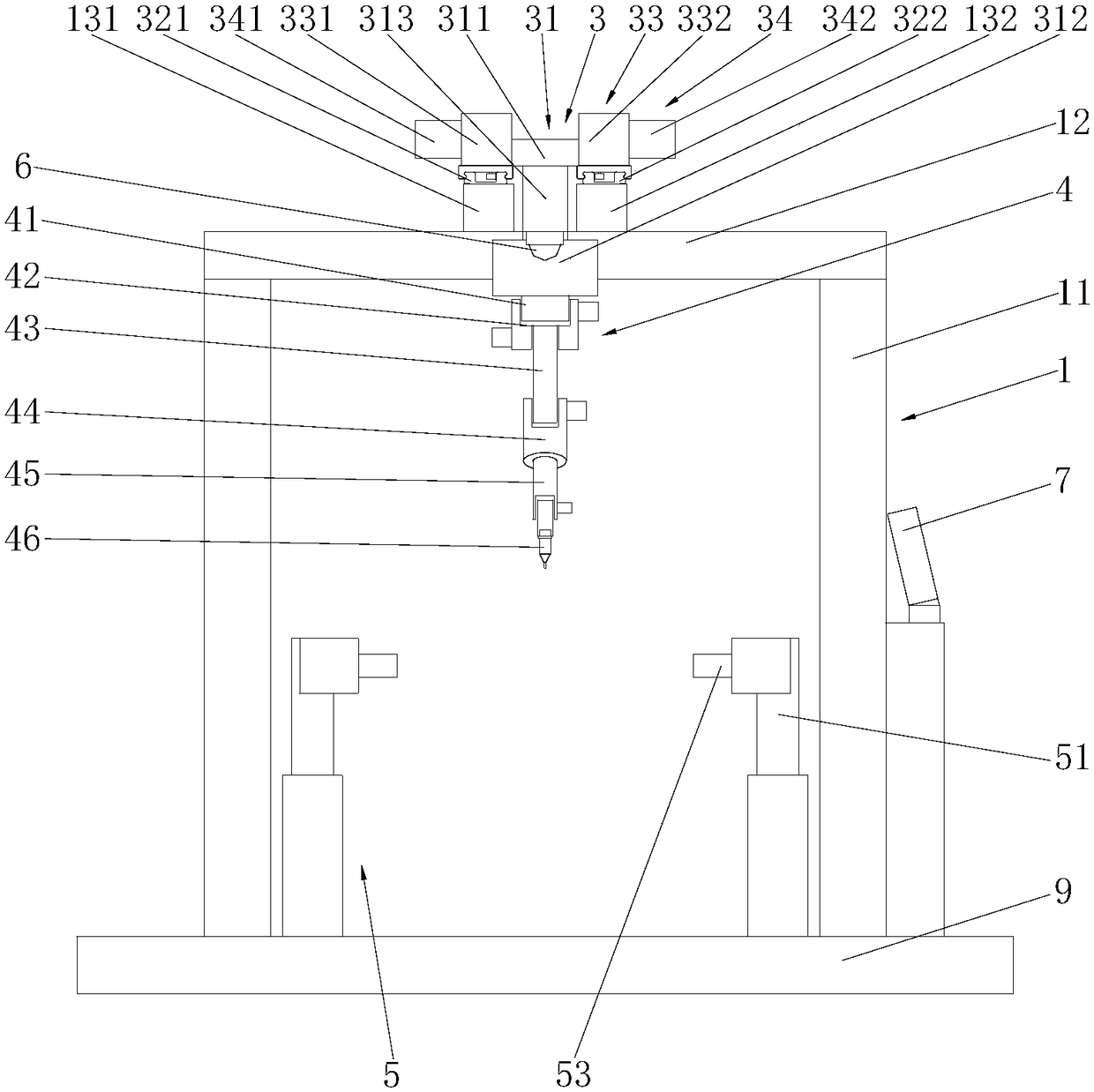

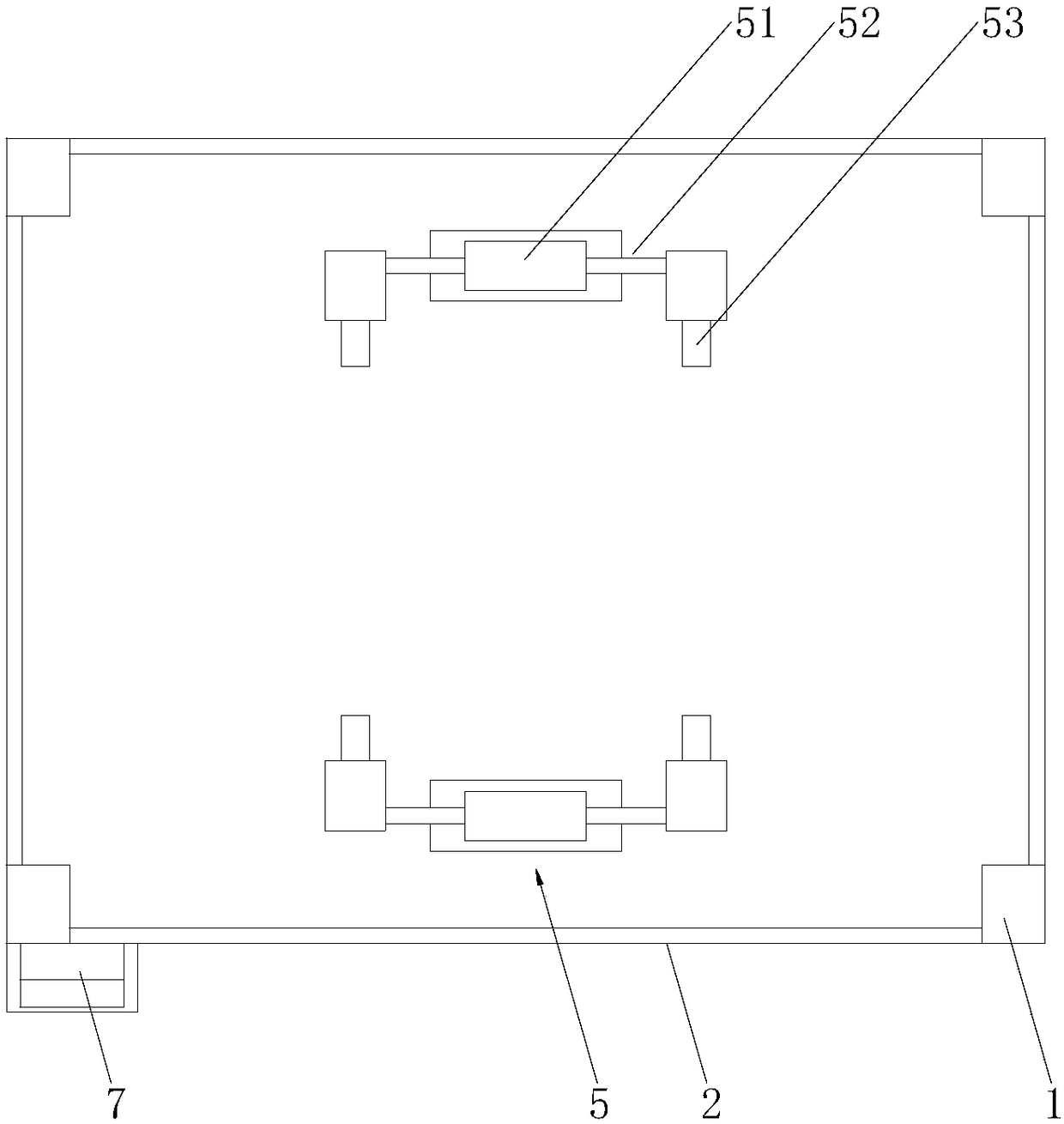

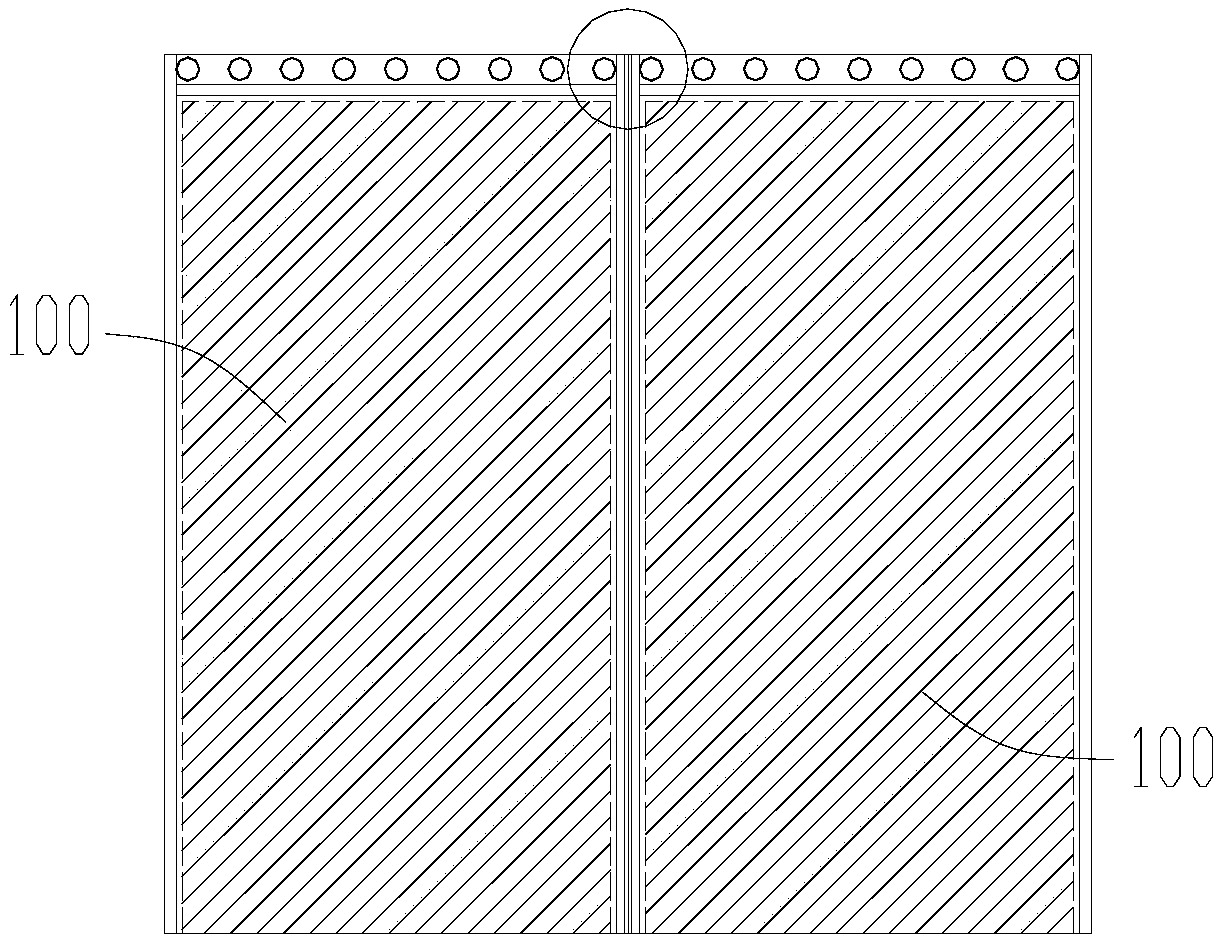

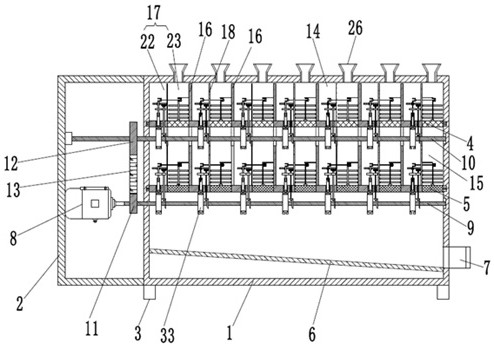

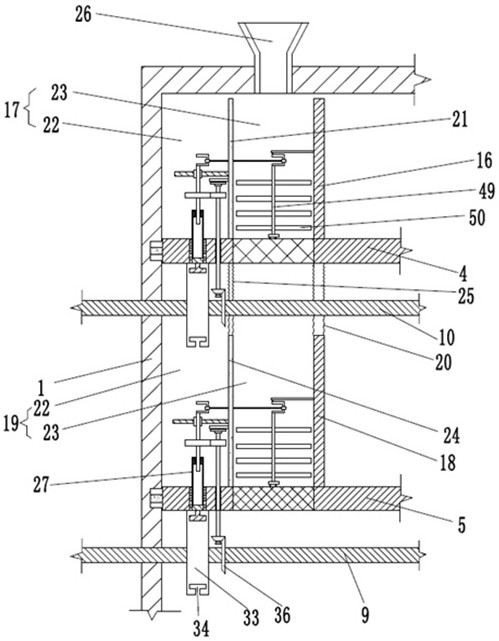

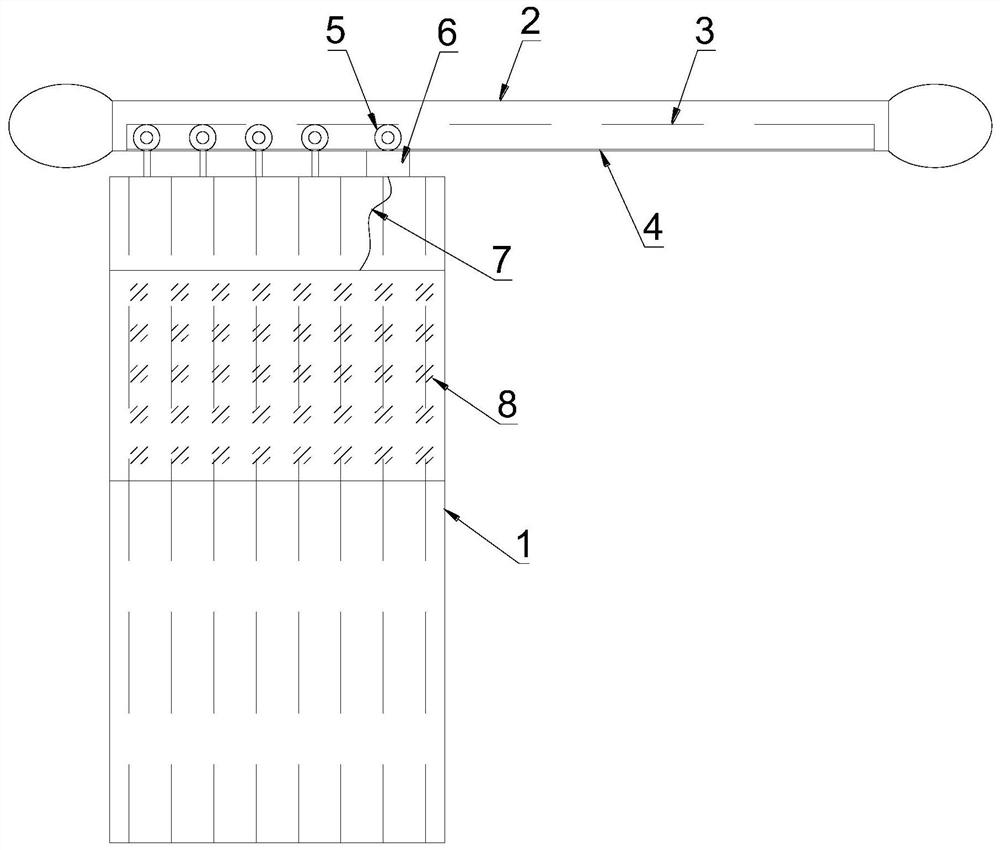

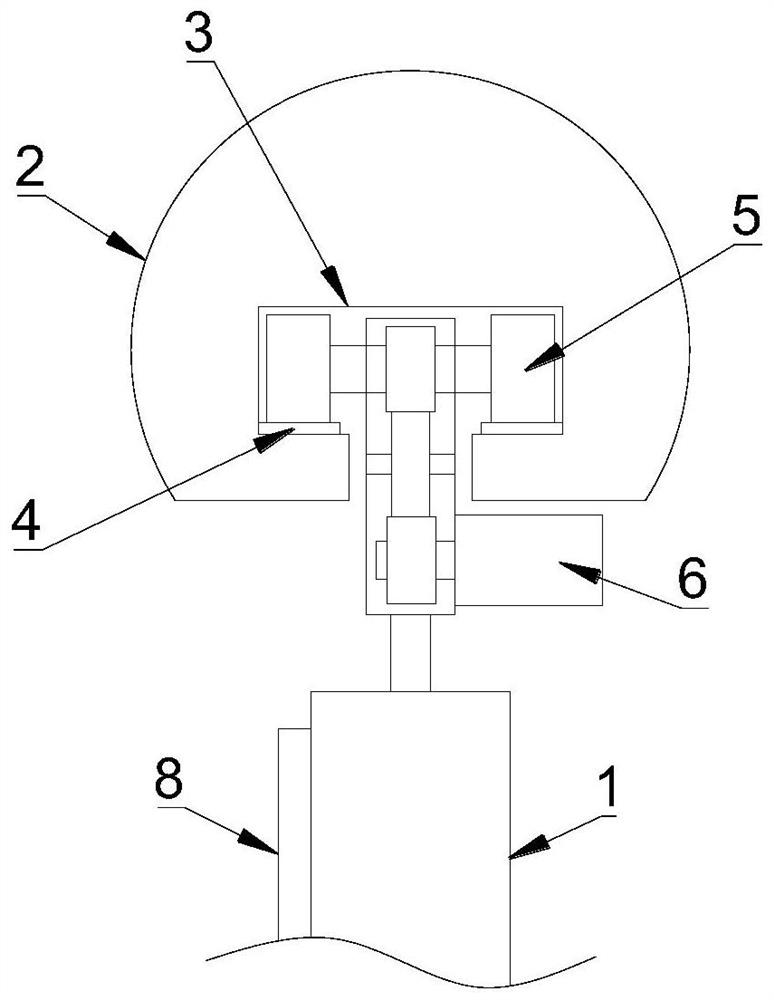

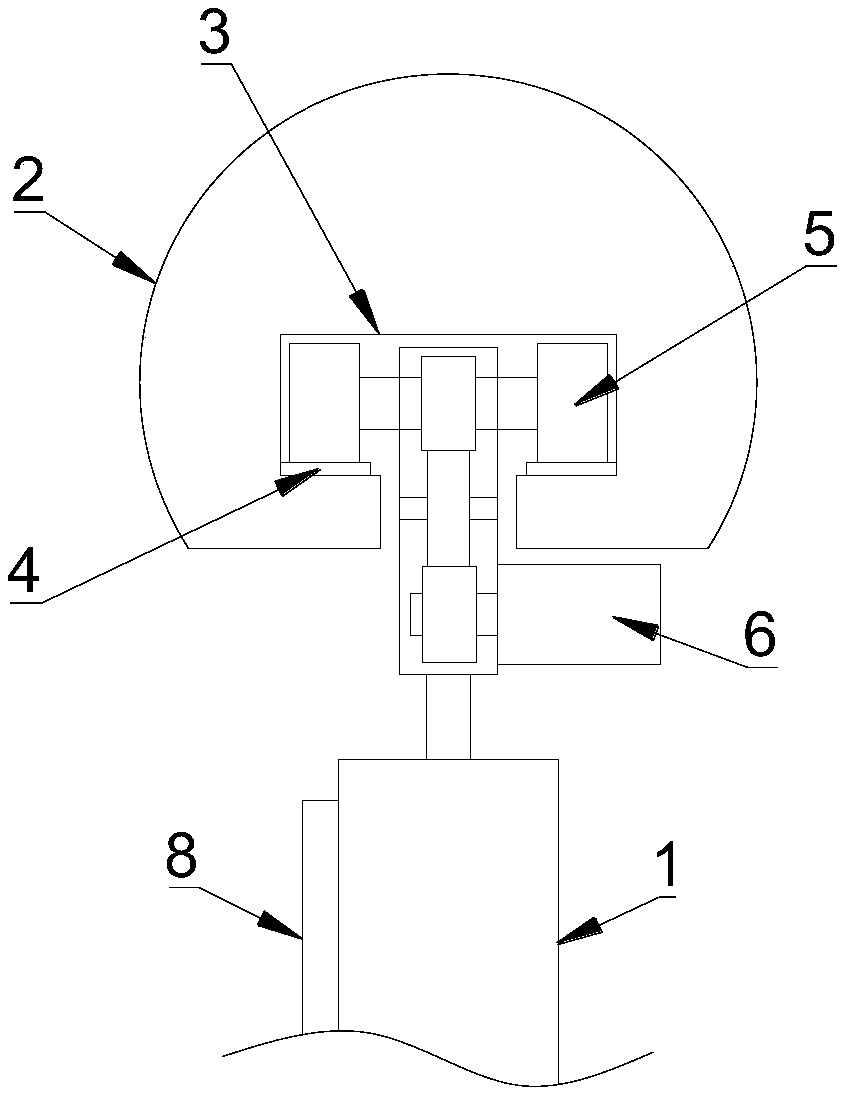

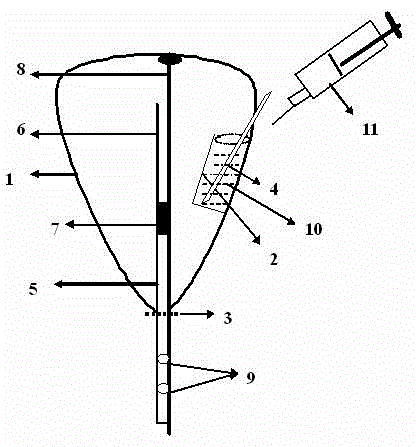

Laser cutting machine used for machining automobile interior trim part and machining method

ActiveCN106378537AImprove the state of stressImprove stability and machining accuracyVehicle componentsMetal working apparatusTransmission systemLaser cutting

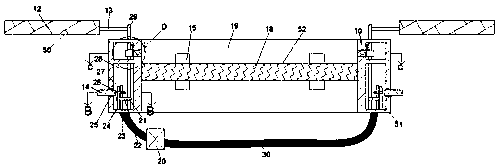

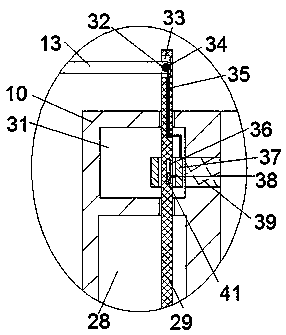

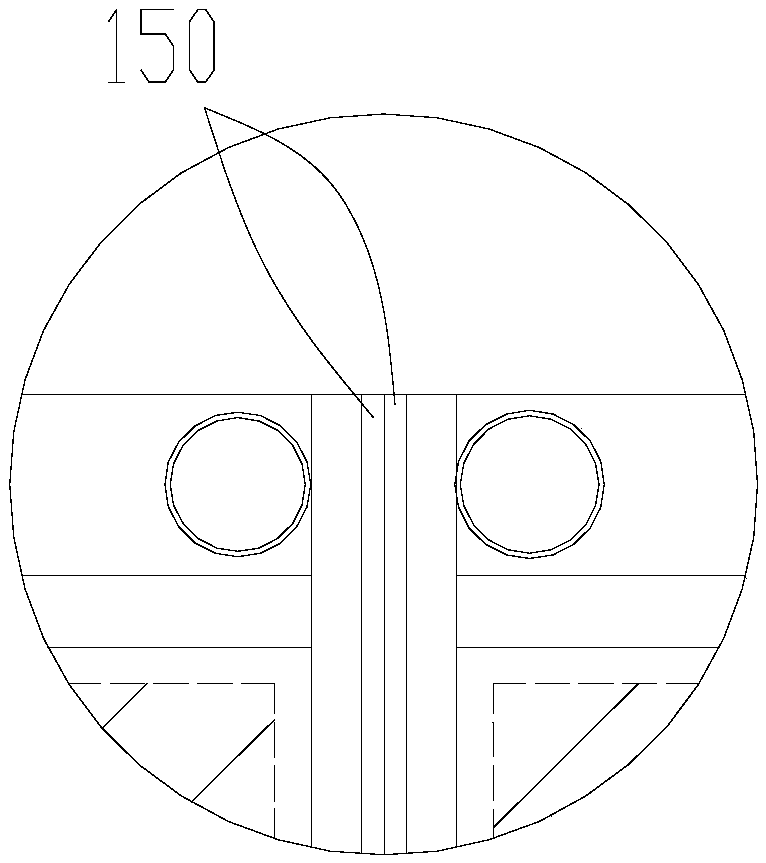

The invention discloses a laser cutting machine used for machining an automobile interior trim part. The cutting machine comprises a machine base, a supporting frame, an upper moving device, a cutting robot, a laser cutting enclosure device, a fixing device, a camera device and an electric control device; the supporting frame is mounted on the machine base, the upper moving device is supported above the machine base through the supporting frame, the upper moving device comprises a gear and rack transmission system driven by a stepping motor, the upper end of the cutting robot is connected with the lower end of the upper moving device, the fixing device is arranged on the machine base and close to the laser cutting enclosure device, the camera device is arranged on a cutting machine inlet and located on the upper portion of the supporting frame, and the electric control device is arranged outside the supporting frame; the laser cutting machine used for machining the automobile interior trim part can increase the cutting range, the laser cutting enclosure device and the cutting clamp fixing device are arranged, the influence on the surroundings is reduced, the fixing time of a cutting clamp is shortened, and the production efficiency is improved.

Owner:JIAXING JINXILAI TECH CO LTD

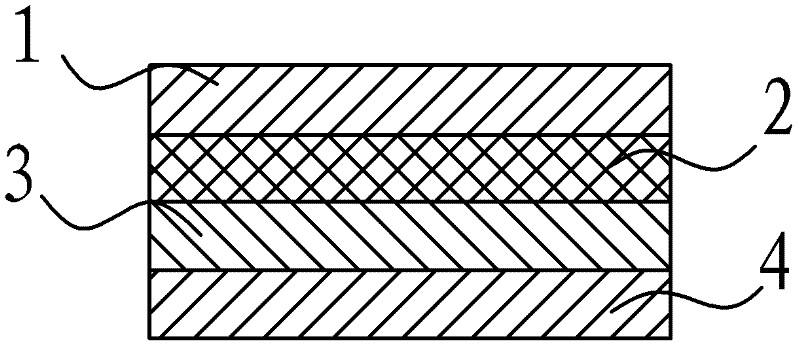

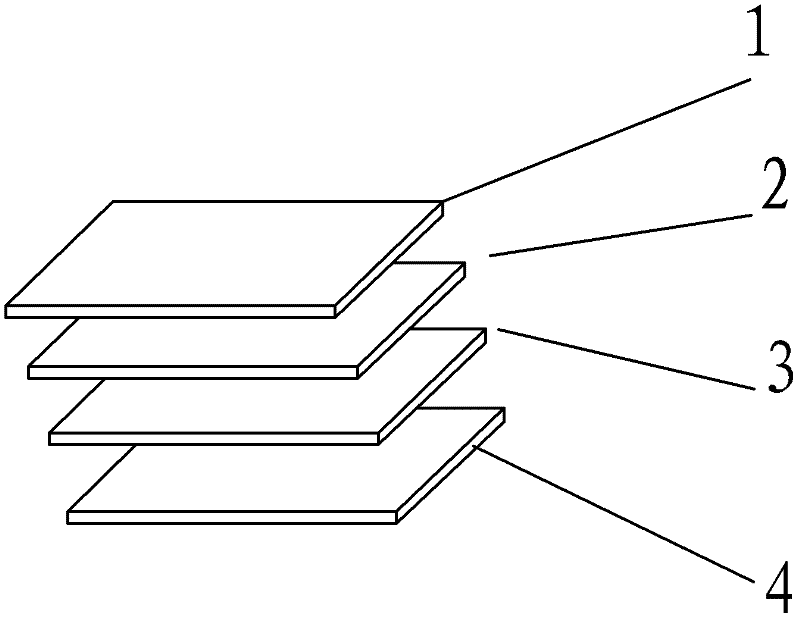

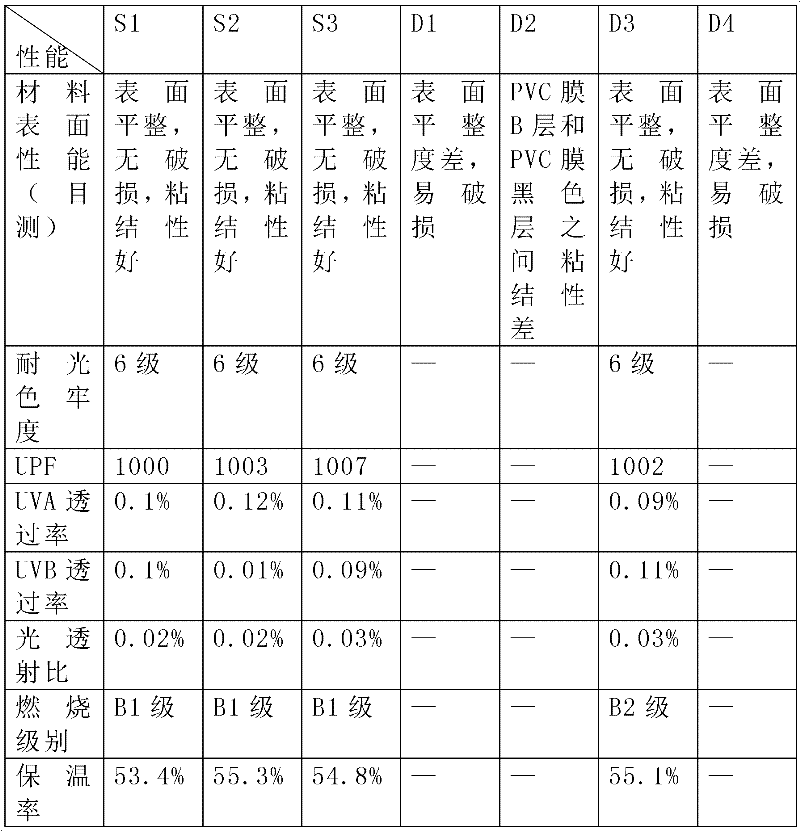

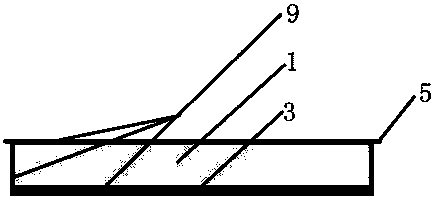

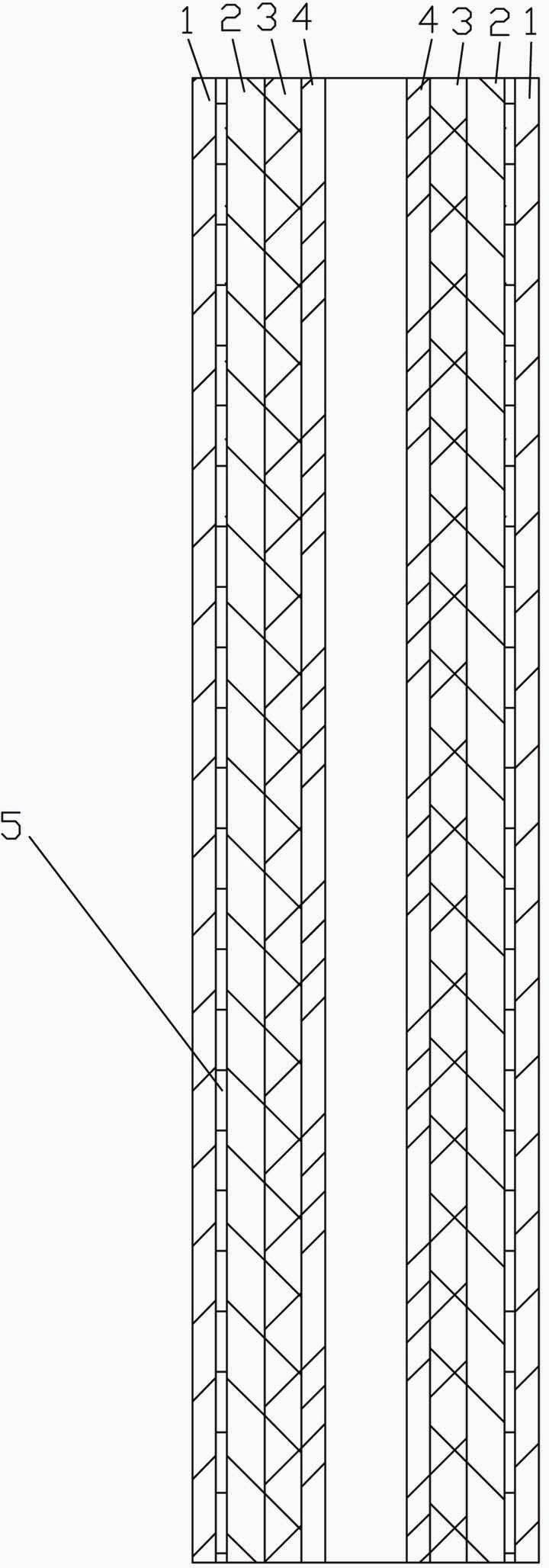

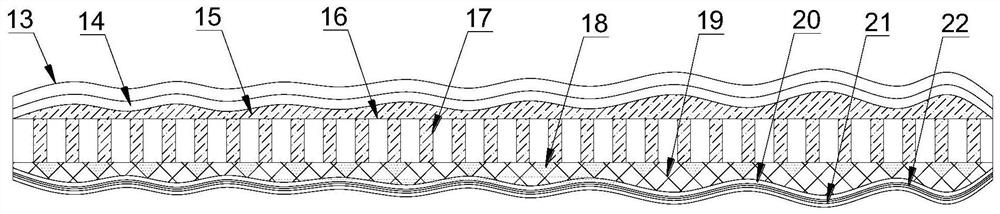

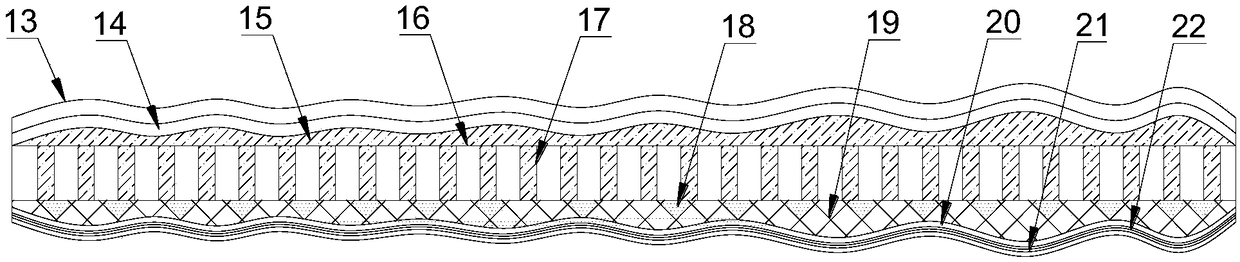

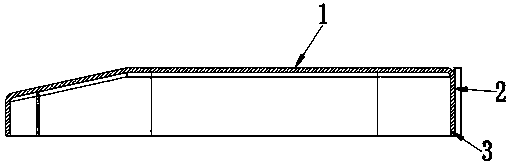

Glass fiber/PVC (polyvinyl chloride) composite membrane material and preparation method thereof

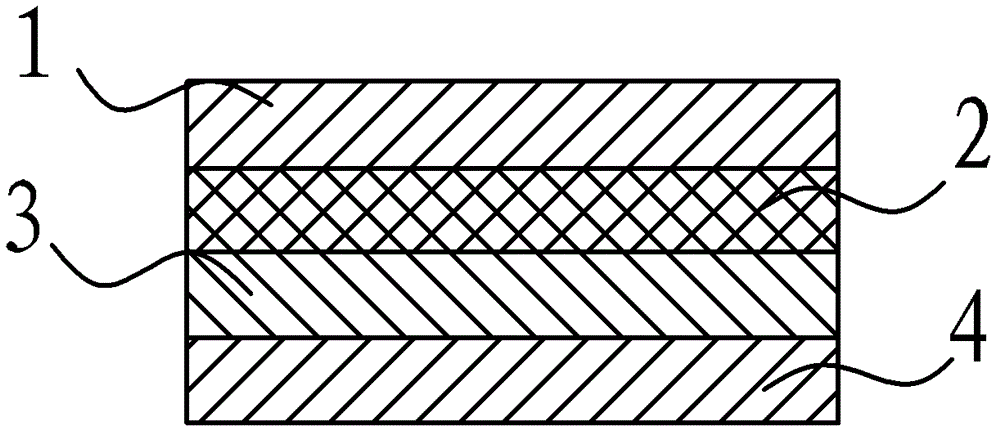

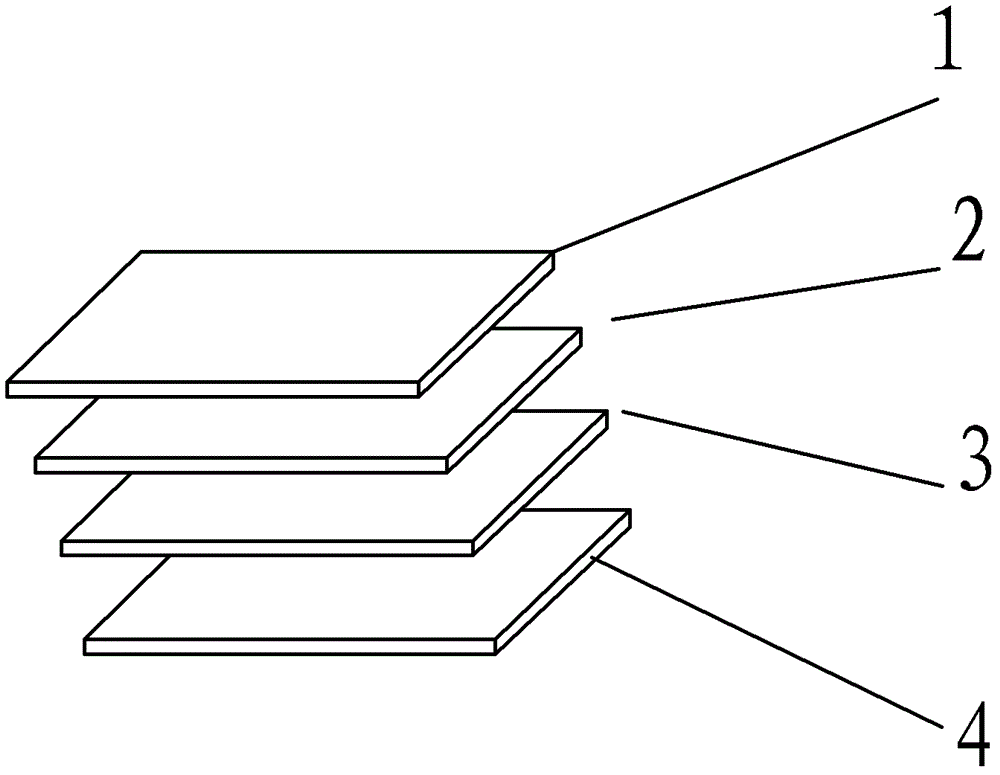

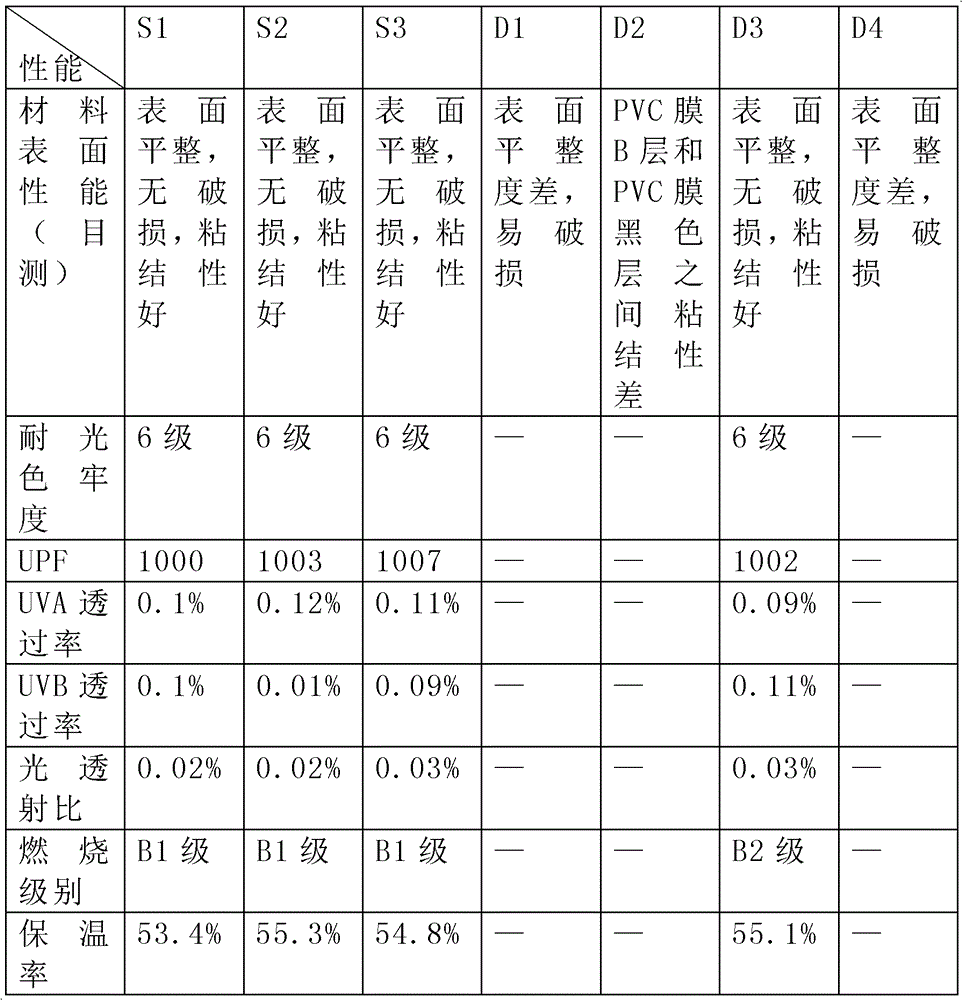

ActiveCN102555352AWith shadingWith heat insulation effectSynthetic resin layered productsLaminationFiberGlass fiber

The invention provides a glass fiber / PVC (polyvinyl chloride) composite membrane material. The glass fiber / PVC composite membrane material comprises a first PVC membrane layer, a second PVC membrane layer, a glass fiber base fabric layer and a third PVC membrane layer from bottom to top in sequence, wherein the second PVC membrane layer is a black PVC membrane layer. The invention also provides a preparation method for the glass fiber / PVC composite membrane material. The glass fiber / PVC composite membrane material provided by the invention has good shading and thermal insulation performances on the premise of ensuring good comprehensive color fastness and combustion performances. The preparation method for the glass fiber / PVC composite membrane material, provided by the invention, is simplified in the process and easy to perform.

Owner:NINGBO XIANFENG NEW MATERIAL

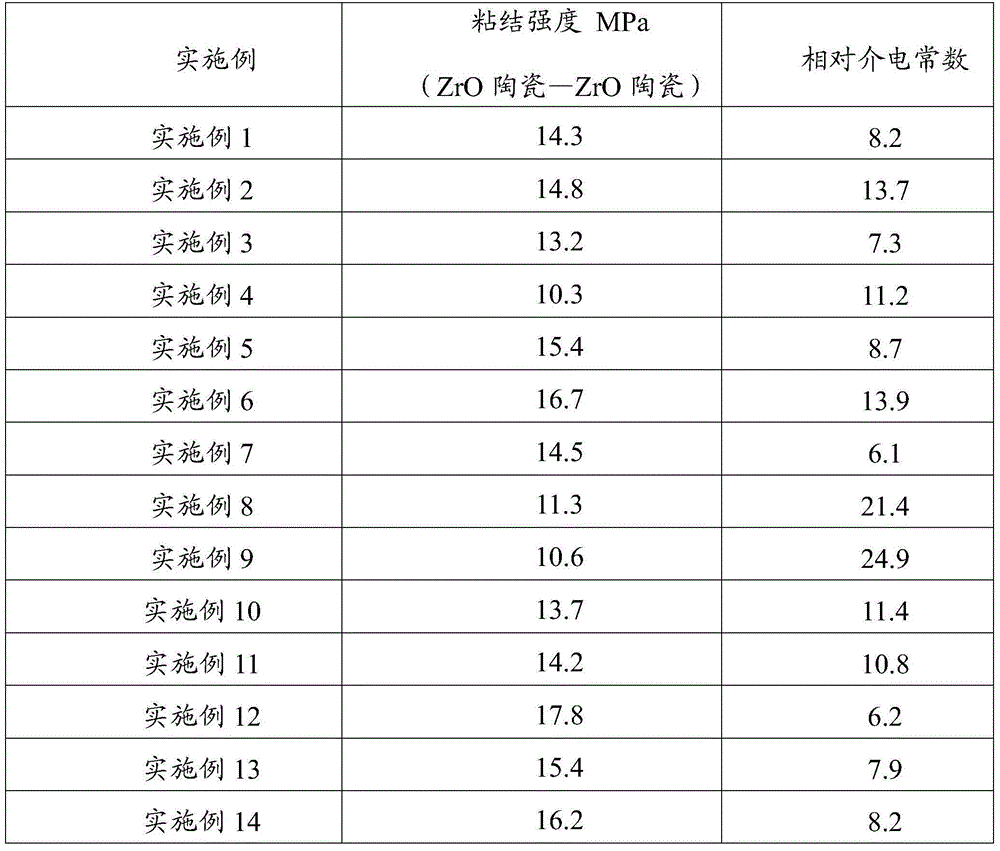

Adhesive composition, adhesive film, adhesive film roll and preparation methods thereof

InactiveCN104592924AGood compatibilityUniform thicknessNon-macromolecular adhesive additivesFilm/foil adhesivesDielectricRoom temperature

The invention provides an adhesive film. The adhesive film has the characteristic of simple assembling, the adhesive film also has the characteristics of high relative dielectric constant, good light proofness, adjustable color, strong adhesive strength, and the like, and the relative dielectric constant in over 6, therefore, the adhesive film is especially applicable to the adhering of capacitive fingerprint recognition chip module encapsulation. The adhesive film is a semi-cured adhesive film which has low viscosity at room temperature, but has high viscosity in the process of thermal curing; compared with a common dispensed adhering mode, the adhesive film provided by the invention has the advantages of uniform film-forming thickness, controllable adhering shape, no bubble produced, simple assembling process, and the like, therefore, the adhesive film is especially suitable for plane adhesive assembly. The invention provides an adhesive composition for forming the adhesive film. The adhesive composition has the characteristics of high relative dielectric constant, and the like. The invention also provides an adhesive film roll. The adhesive film is protected by covering PET release liner or release paper on both sides of the adhesive film in the adhesive film roll, thereby preventing the environment from polluting the adhesive film.

Owner:CHAOZHOU THREE CIRCLE GRP

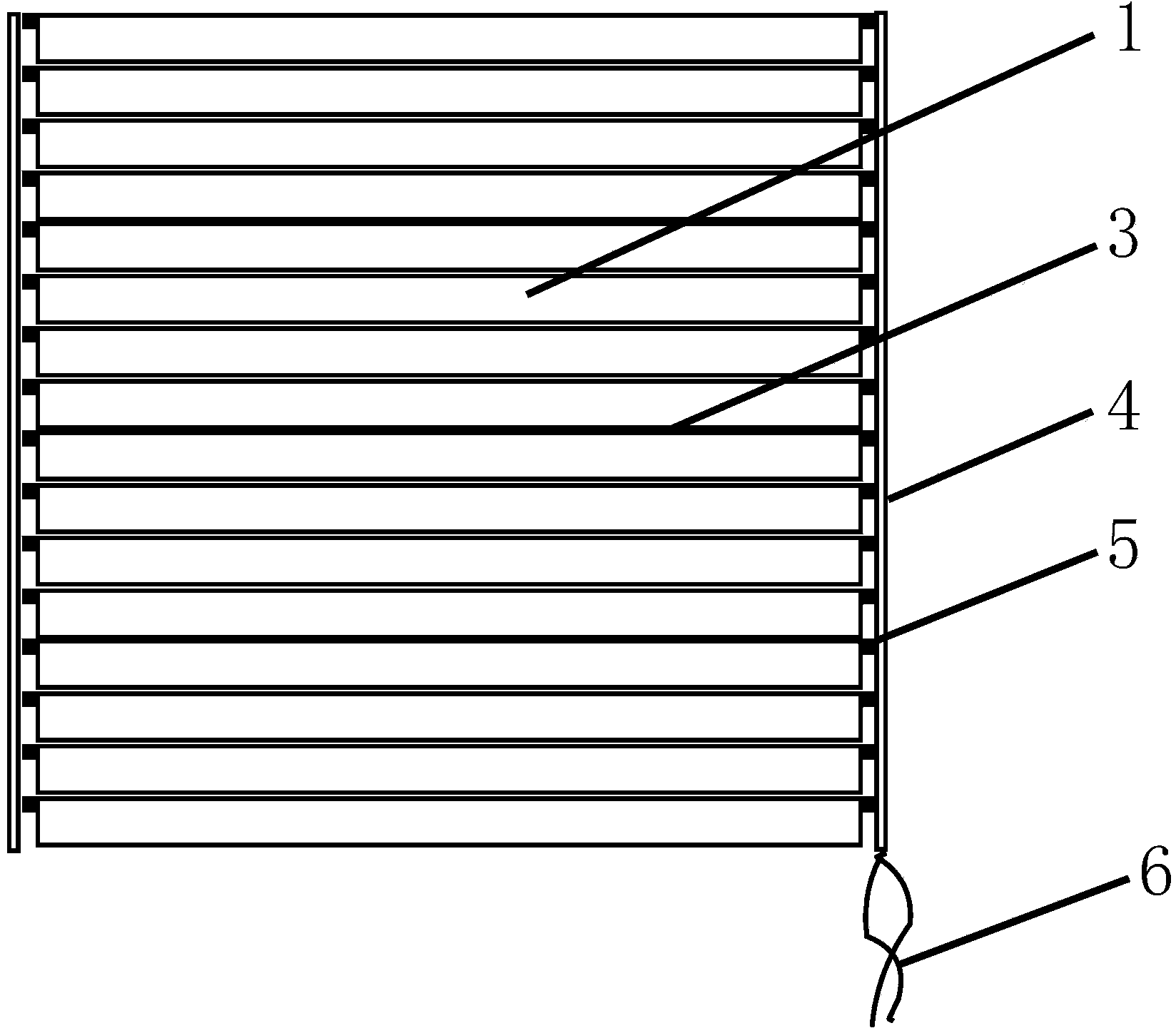

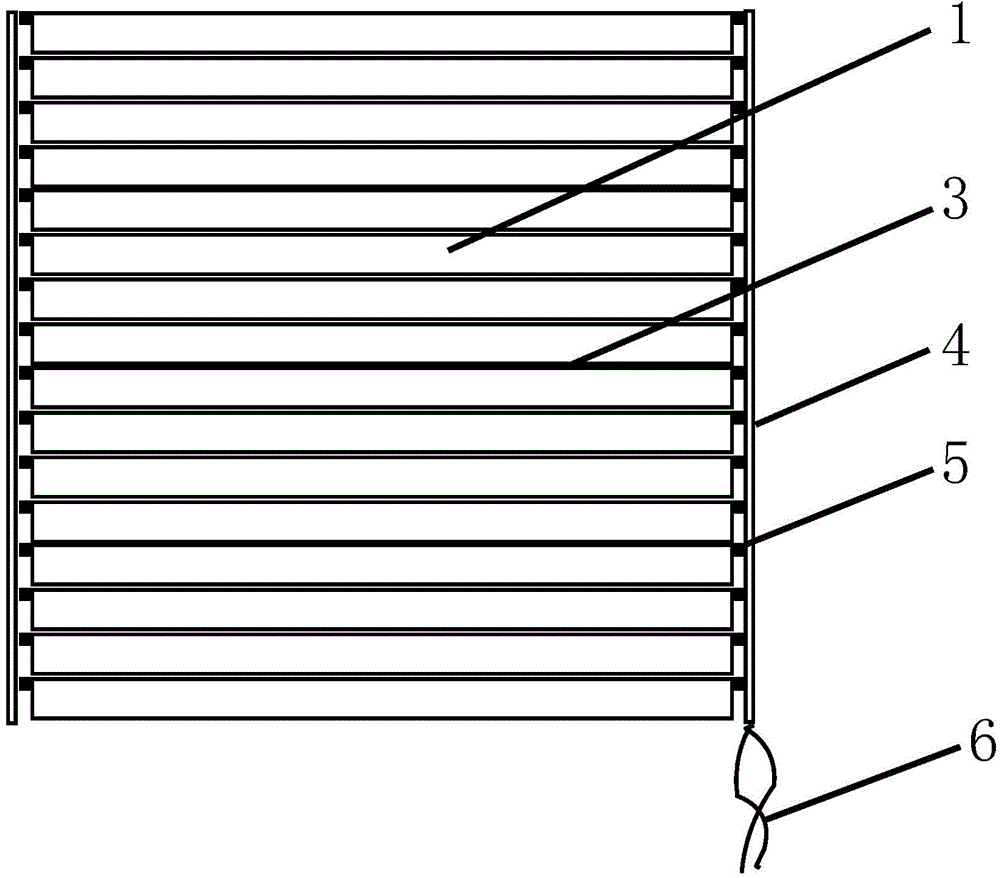

Replaceable dual-layer shutter with anti-haze and denoising functions

InactiveCN103850634AWith shadingWith noise reductionDoor/window protective devicesActivated carbonEngineering

The invention relates to a replaceable dual-layer shutter with anti-haze and denoising functions. The replaceable dual-layer shutter with the anti-haze and denoising functions comprises a soundproof felt curtain piece, anion curtain pieces, sealing rubber, an aluminum alloy curtain fixing frame, curtain piece rotary shafts, pull ropes, replaceable activated carbon cloth, rotary gears and a soundproof curtain piece alloy outer frame. The replaceable dual-layer shutter with the anti-haze and denoising functions adopts the dual-layer structural mode with the two layers using different materials, such as the soundproof felt curtain piece and the anion curtain pieces and realizes the functions of anti-haze, denoising and the like by the fact that people select and use different curtains, so the life of people is more comfortable.

Owner:BEIJING UNIV OF TECH

Preparation method of black extinction polyimide film

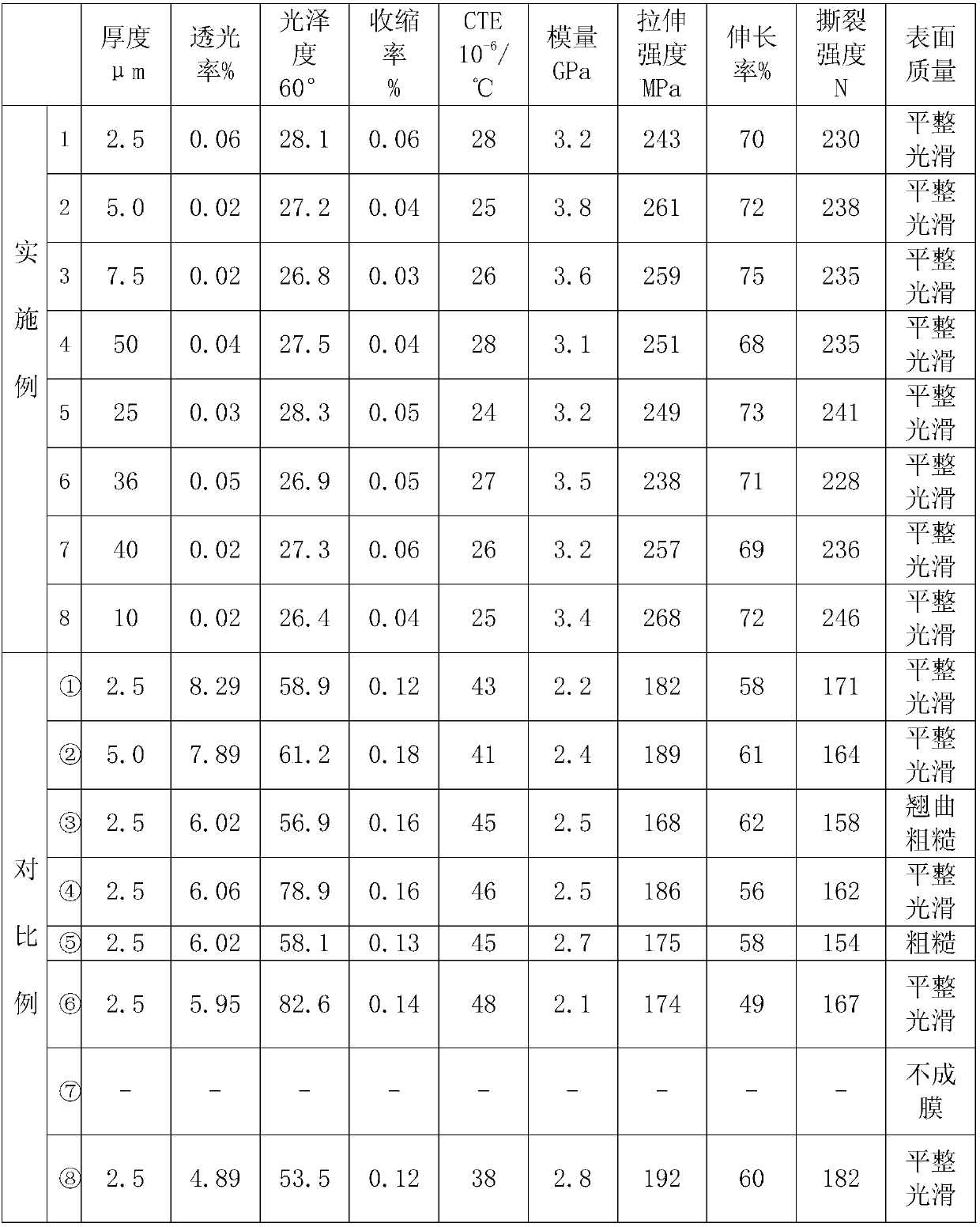

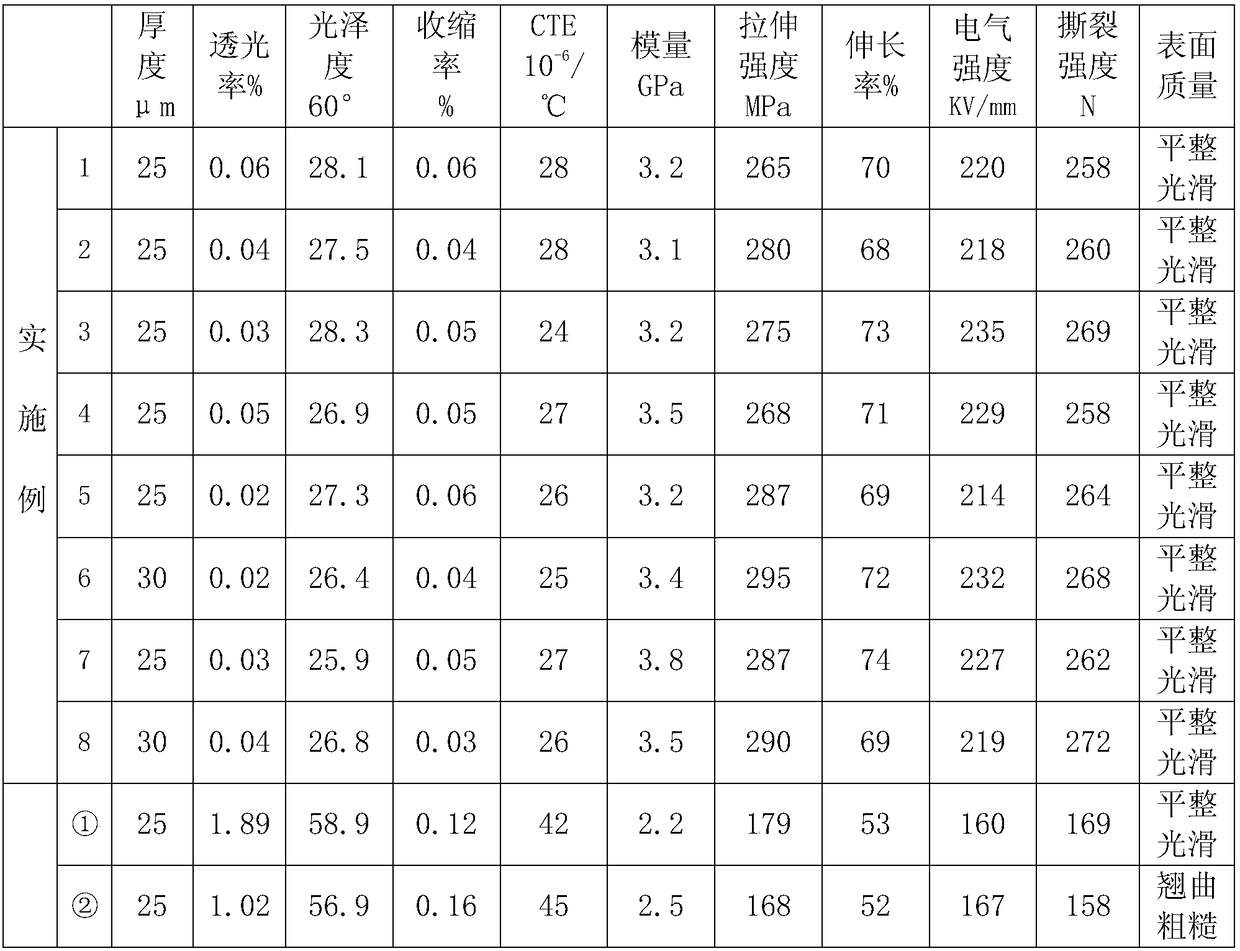

The invention relates to a preparation method of a black extinction polyimide film. The preparation method mainly comprises the following steps: (I) conventionally preparing a polyamide acid resin solution; (II) preparing black slurry, wherein the amount of a black pigment is 2wt%-20wt% of a solid content M of the polyamide acid resin solution; (III) preparing a black polyamide acid resin solution, blending and stirring the polyamide acid resin solution with the black pigment, and carrying out defoaming for later use; and (IV) salivating the black polyamide acid resin solution to a steel belt,carrying out high-temperature surface treatment at 300-400 DEG C for 5-90 seconds during drying, and carrying out stretching, imidization and formation, so as to obtain the black extinction polyimidefilm. An extinction agent dispersing solution containing 2wt%-20wt% of the weight M of an extinction agent can be added in the step (III). The black pigment and the extinction agent are moderate in average grain diameters, and high-temperature surface treatment is additionally carried out during the salivation formation of a resin solution, so that the light transmittance, glossiness and physicaland mechanical properties of the obtained film are obviously improved.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

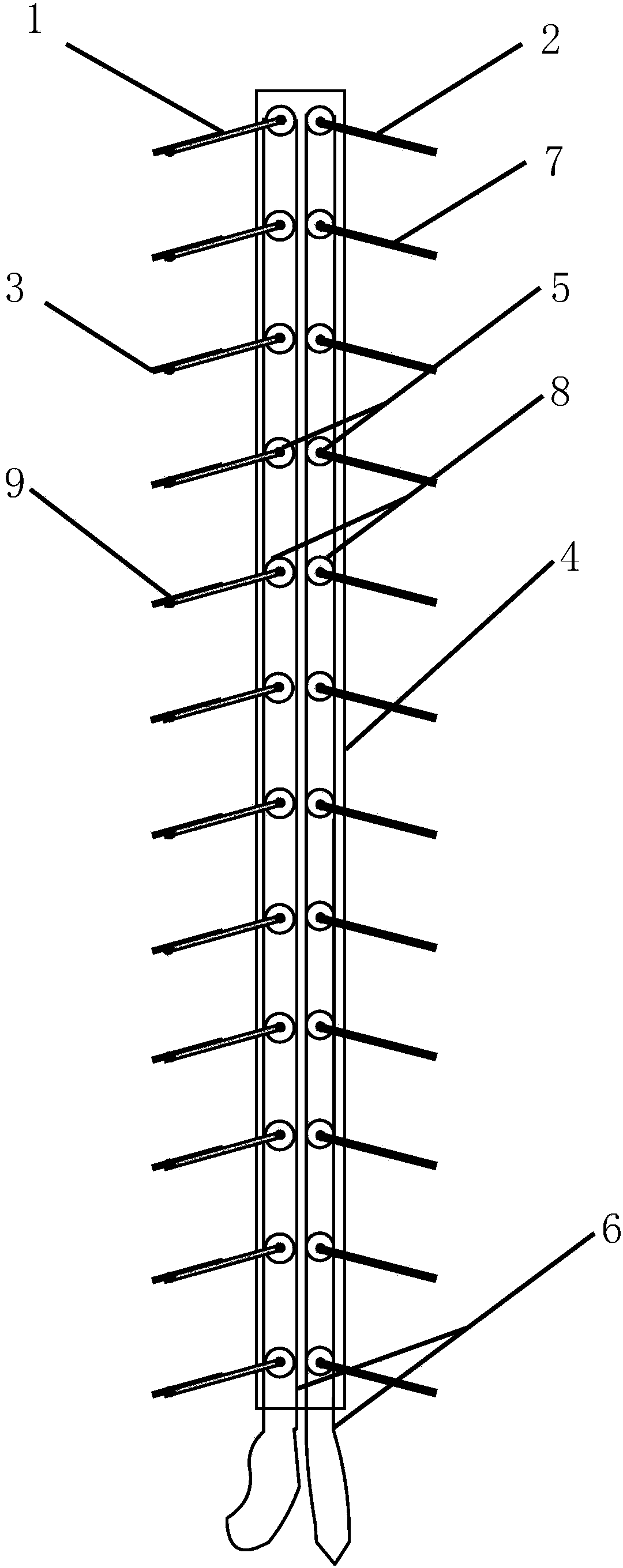

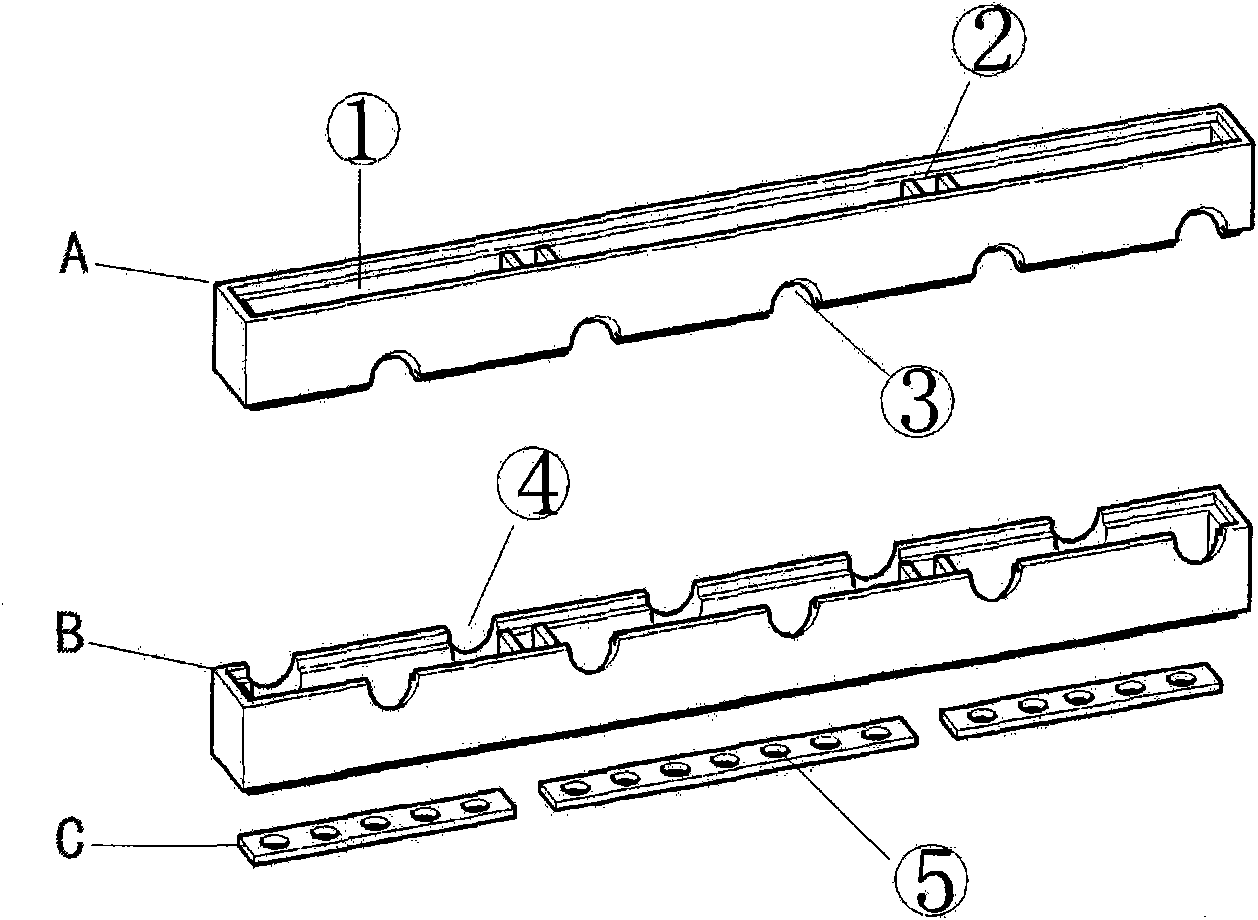

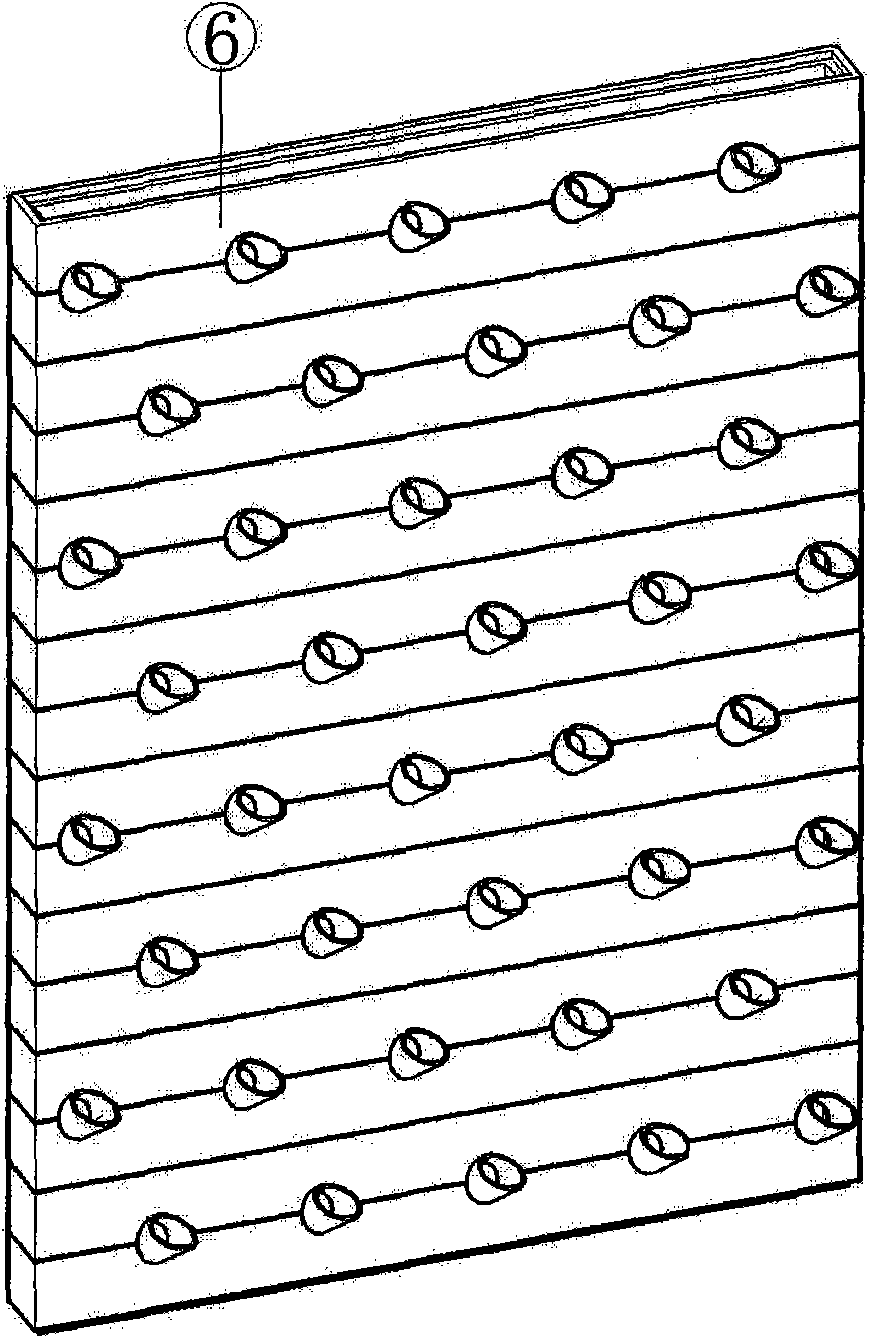

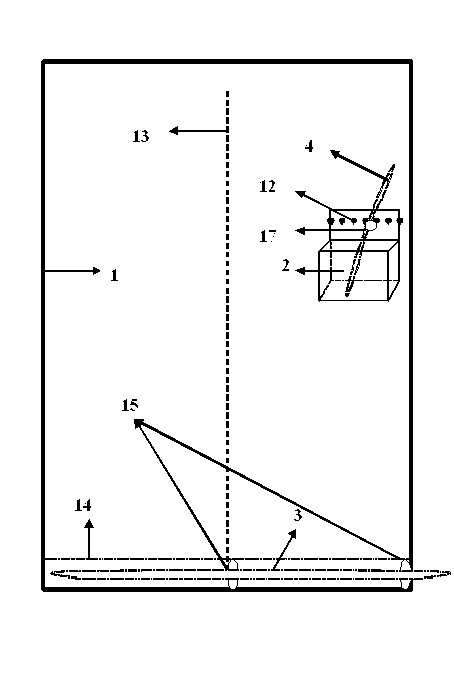

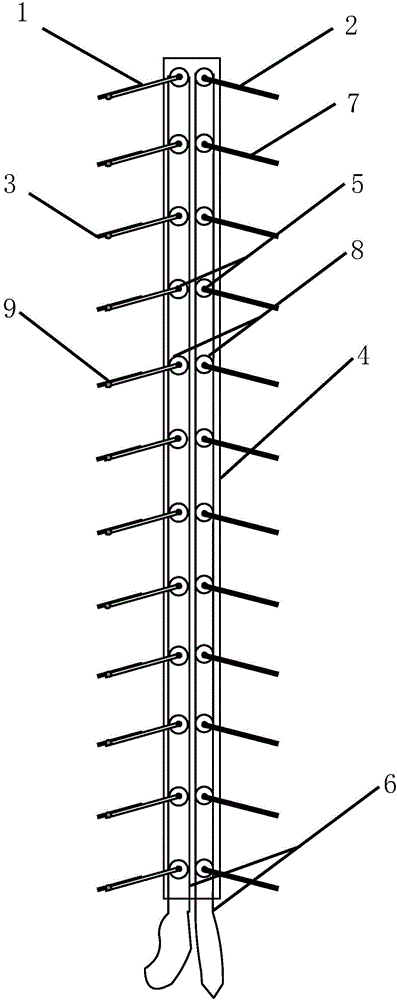

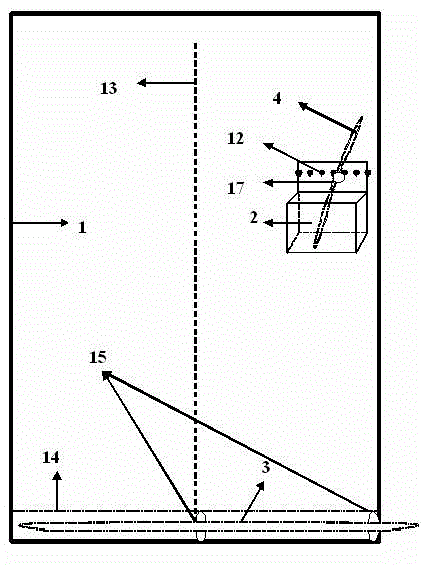

New-type wall cultivation device

InactiveCN101658125AStable structureFlexible structureAgriculture gas emission reductionCultivating equipmentsLiquid storage tankEngineering

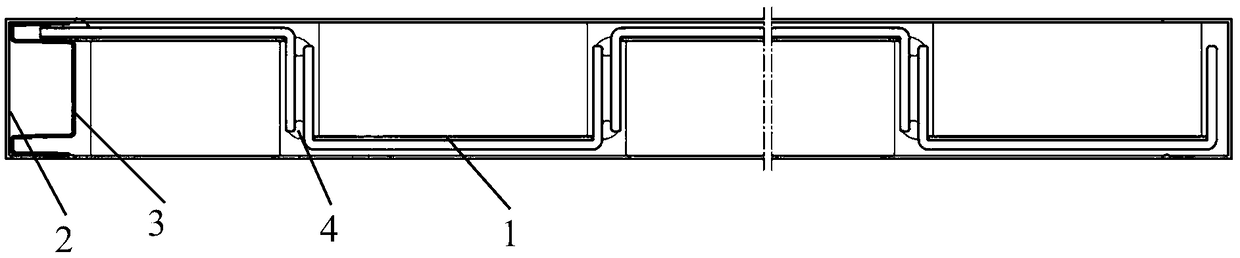

The invention relates to a new-type wall cultivation device which comprises wall cultivation tanks, a stainless steel square tube, transplanting cups, a liquid storage tank, a liquid feed pipe, a hairline pipe, liquid return pipes and a liquid return trough, wherein a plurality of wall cultivation tanks are penetrated and inserted on the stainless steel square tube through pipeline square holes onthe wall cultivation tanks, and are overlapped and jogged with each other to form a cultivation wall; each wall cultivation tank consists of an upper part and a lower part, and the upper part and thelower part of the cultivation wall are respectively provided with the upper half parts and the lower half parts of transplanting holes; the wall cultivation tanks are internally provided with diversion layer areas, and the bottom parts of the lower parts of the wall cultivation tanks are provided with liquid return holes; and the upper parts and the lower parts of the wall cultivation tanks are jogged and connected with each other, so that a whole wall cultivation tank can be formed. The new-type wall cultivation device is simple in assembly, convenient for operation, flexible in structure and easy in disassembly; the wall cultivation tanks have high tabling degree and uniform liquid supply, so as to avoid phenomena such as water plugging, liquid leakage, dry seedling and the like; simultaneously, the new-type wall cultivation device has wider application scope, and can be used for large area production and planting as well as appreciating in families, restaurants or office places.

Owner:BEIJING IEDA PROTECTED HORTICULTURE

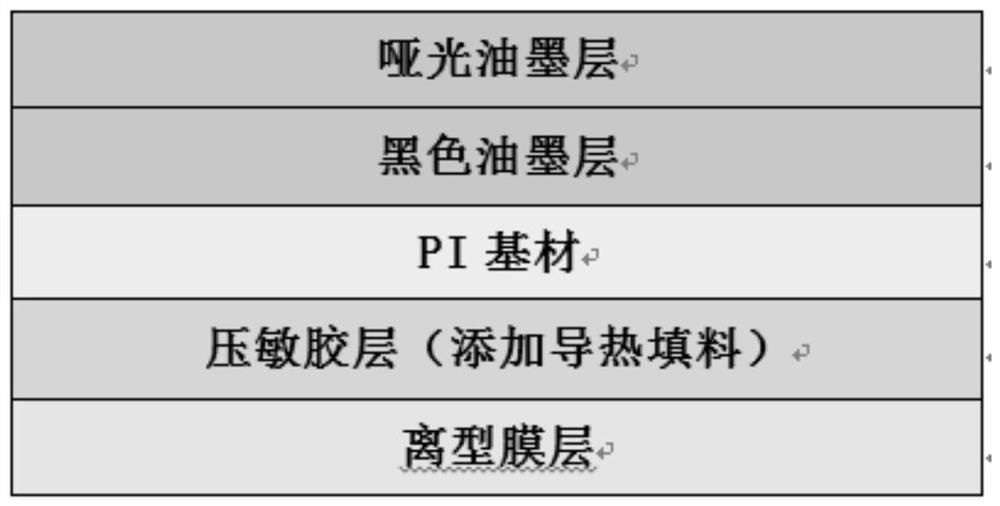

Heat-conducting matt black adhesive tape and preparation method thereof

PendingCN112898910AImprove thermal conductivityGood heat dissipationNon-macromolecular adhesive additivesInksSilicone tapePolymer chemistry

The invention provides a heat-conducting matt black adhesive tape and a preparation method thereof. The heat-conducting matt black adhesive tape sequentially comprises a matt ink layer, a black ink layer, a PI base material layer, a pressure-sensitive adhesive layer added with heat-conducting filler and a release film layer from outside to inside, wherein the thicknesses of the matte ink layer, the black ink layer, the PI substrate layer, the pressure-sensitive adhesive layer added with the heat-conducting filler and the release film layer are 1-10 microns, 1-10 microns, 4.5-100 microns, 1-50 microns and 25-100 microns respectively. The heat-conducting matt black adhesive tape can be rapidly prepared, has the effects of shading, fingerprint prevention, scratch prevention and the like, can increase the heat-conducting property while having viscosity, improves the heat conduction effect of the adhesive tape, and effectively solves the problems that in the prior art, the adhesive tape does not have a heat dissipation effect, components are easy to damage, the service life is short and the like.

Owner:四川羽玺新材料股份有限公司

Preparation method of multi-layer low-gloss black polyimide thin film

The invention discloses a preparation method of a multi-layer low-gloss black polyimide thin film. The preparation method comprises the following main steps: I, preparing a polyamide acid film; II, preparing a black blending polyamide acid resin solution; III, evenly coating the upper and / or lower surface of the polyamide acid film with the black blending polyamide acid resin solution, heating andcuring to obtain a multi-layer black polyamide acid film; IV, and stretching in two ways, conducting imidization and sizing to obtain the multi-layer low-gloss black polyimide thin film. The preparation of the black blending polyamide acid resin solution in the step II comprises the following steps: preparing the polyamide acid resin solution, a black slurry and a delustrant dispersion solution,adding a flocculant into the three, blending, stirring at the low temperature, defoaming, preheating, and agglomerating. The average particle size of a black pigment and a delustrant is 0.01-0.8 [mu]m, the delustrant is added into the condensation polymerization synthesis process of a polyamide acid resin, and the light transmittance, the glossiness, the electrical property and the physical and mechanical property of the obtained multi-layer thin film are obviously improved.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

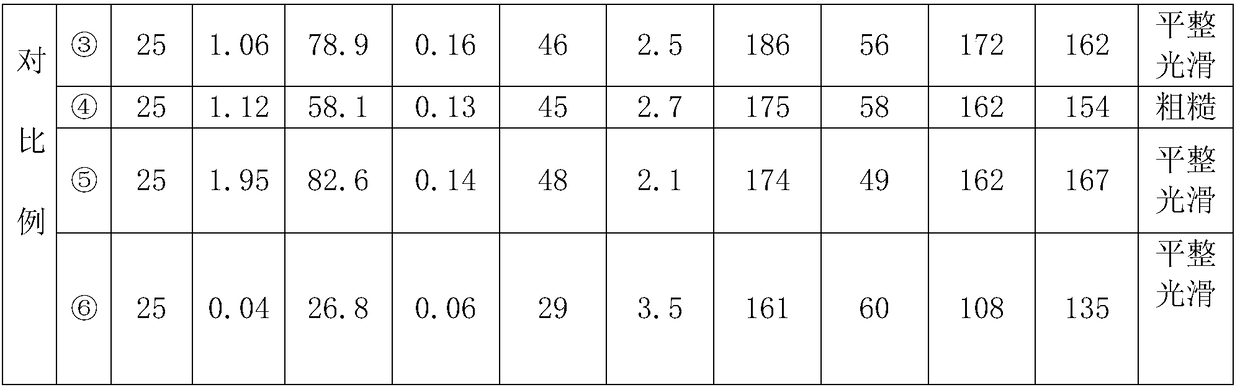

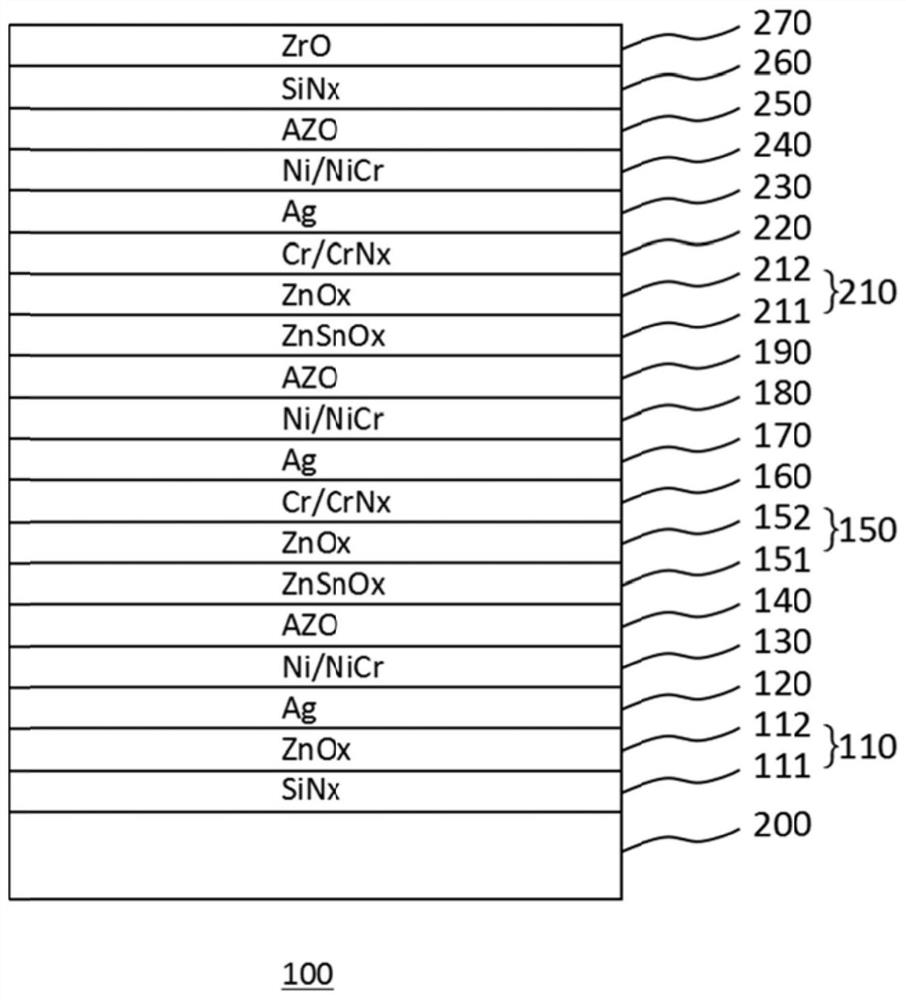

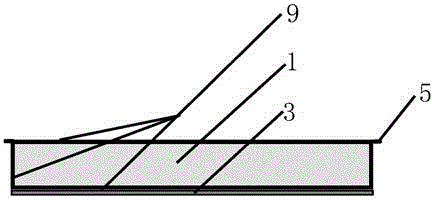

Low-radiation film, coated glass and preparation method of coated glass

PendingCN113683314ANeutral through colorHigh temperature resistantSynthetic resin layered productsGlass/slag layered productsMaterials scienceCoating

The invention discloses a low-radiation film, coated glass and a preparation method coated glass of coated glass. According to the low-radiation film, the coated glass and the preparation method of the coated glass, a ZrO layer, a Cr layer or a CrNx layer and the like are introduced into the specific film layer position through the structural design of the low-radiation film, so that the low-radiation film has the advantages of neutral transmission color, high temperature resistance, good sun shading performance, good wear resistance, good oxidation resistance and the like, is suitable for preparing flat steel and bent steel coated glass, and can be used for preparing toughened three-silver coated glass.

Owner:东莞南玻工程玻璃有限公司 +1

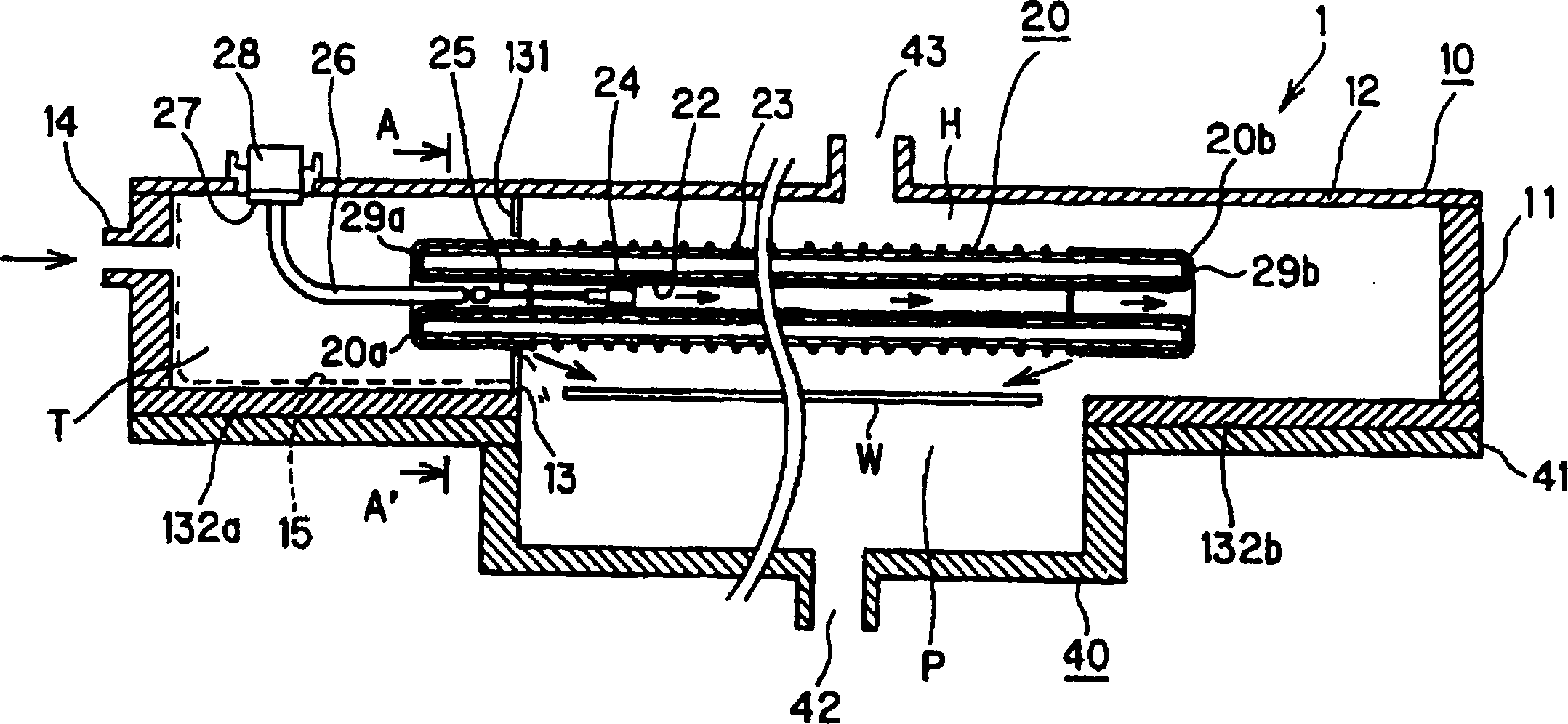

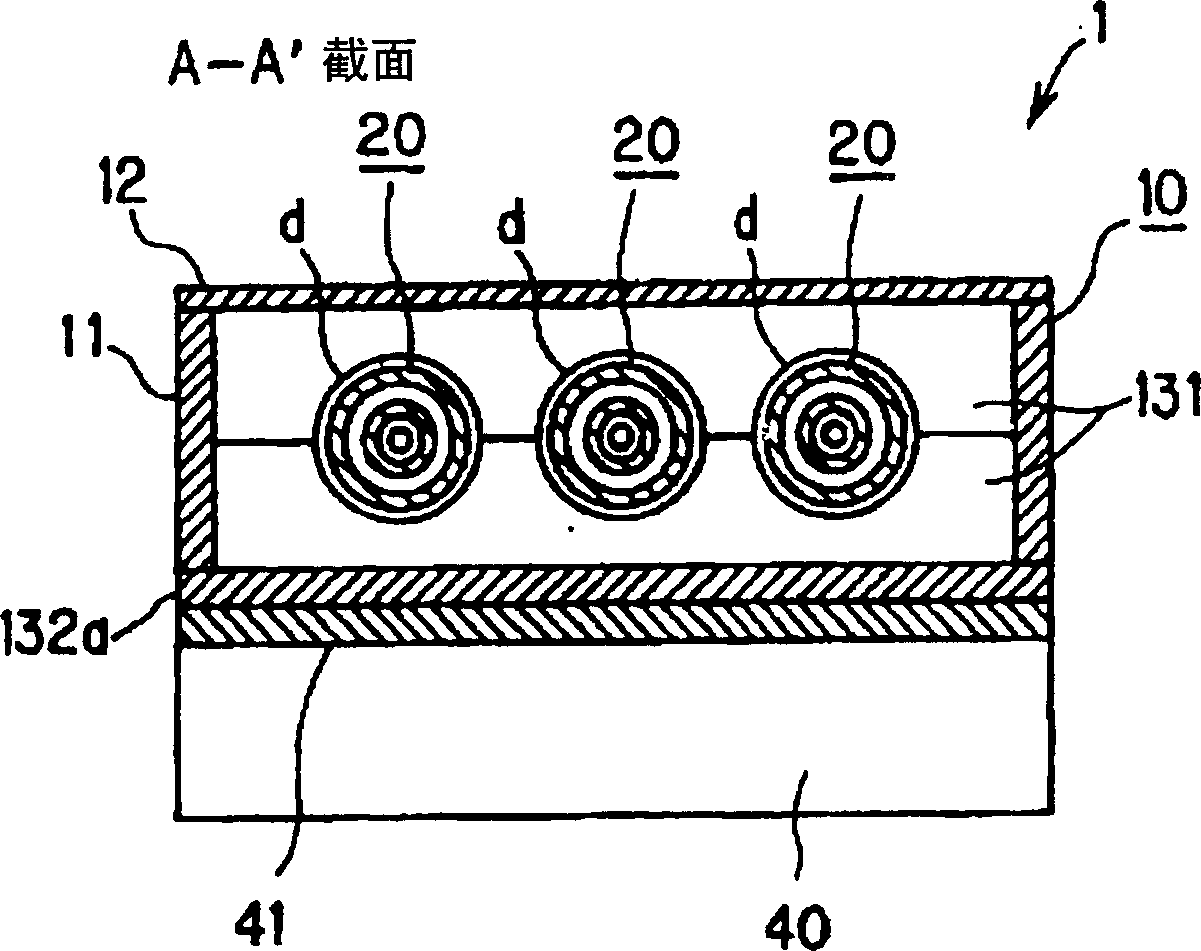

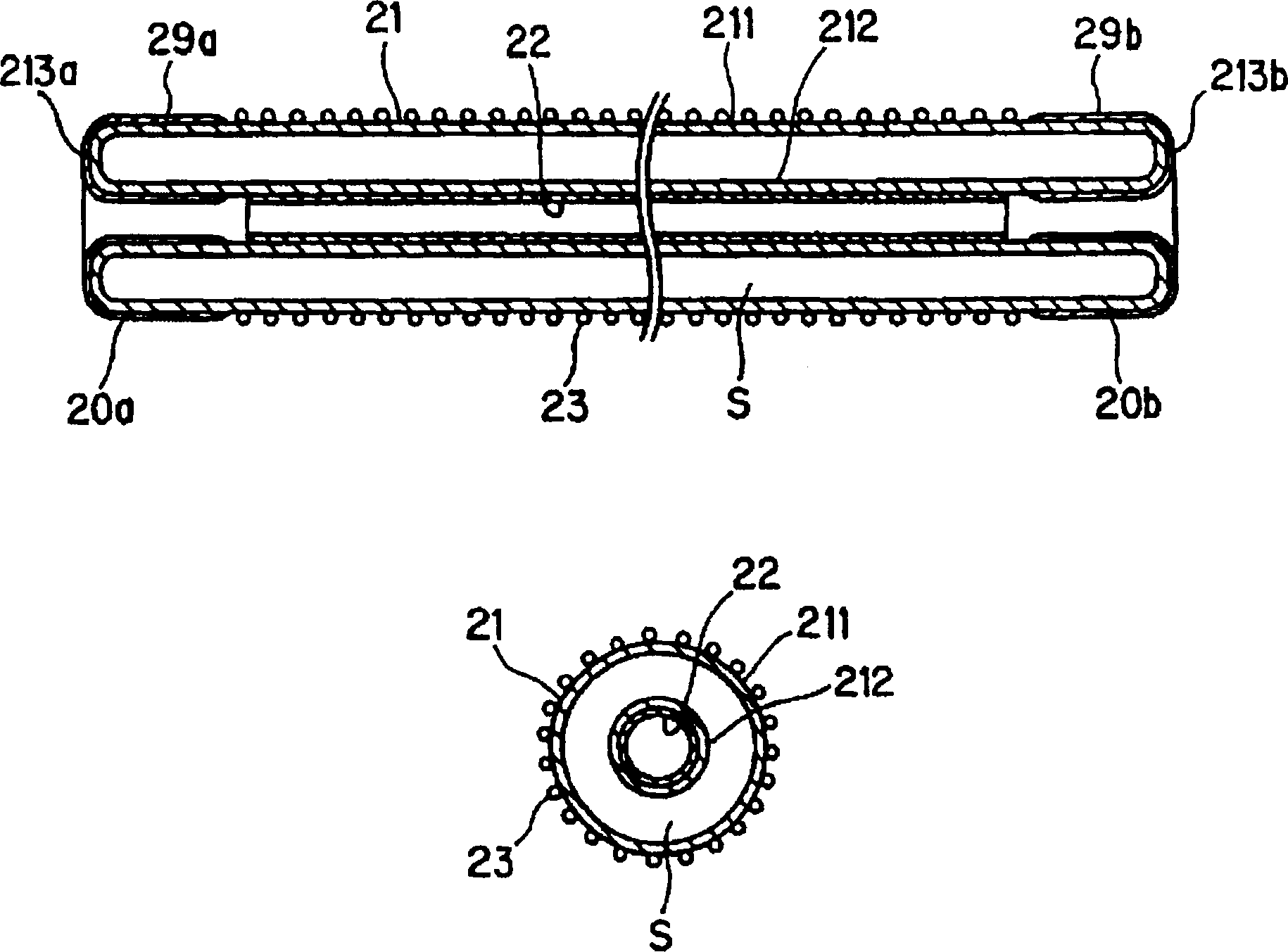

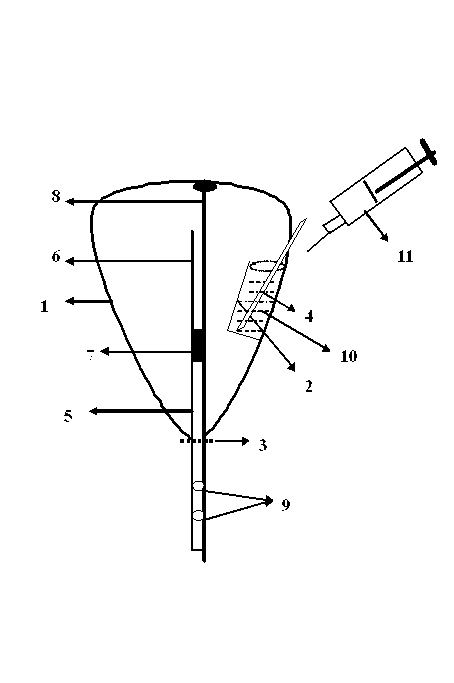

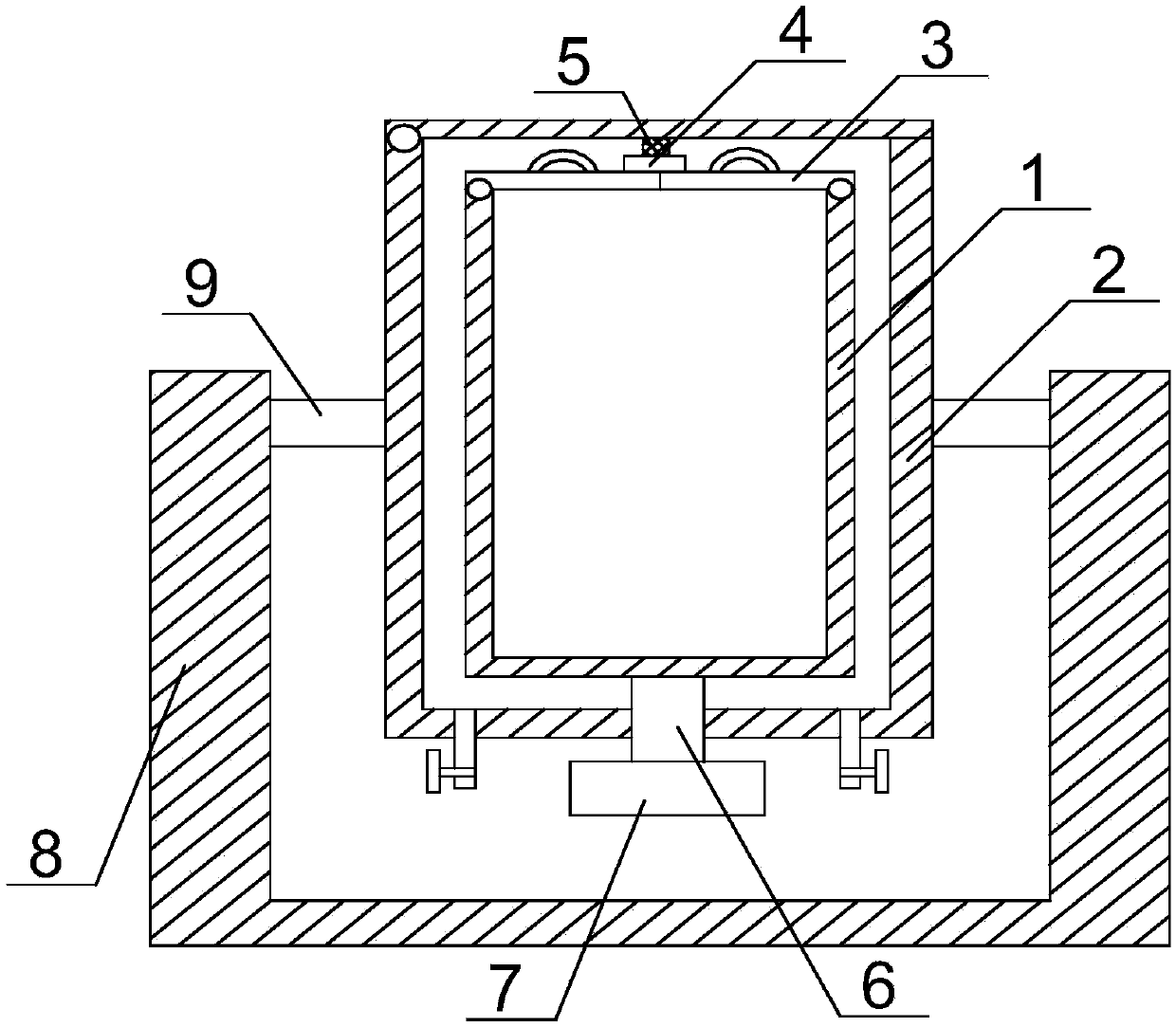

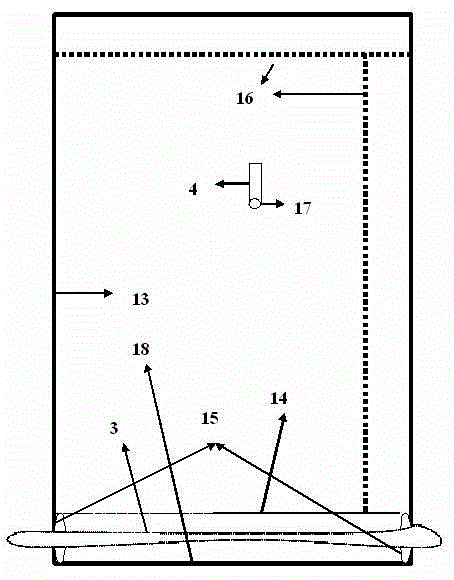

Quasi molecular lamp device

ActiveCN1783421ASimple structureLow costGaseous substancesGas discharge lamp detailsDielectricUltraviolet lights

The present invention provides an excimer lamp device, which simplifies the structure of the device by removing the light output window that divides the lampshade and the irradiated area, can realize cost reduction, and prevents the power supply components arranged near the end of the lamp from being exposed to active oxygen to prevent Oxidation, and can reduce the occurrence of deterioration and breakage of the part. An excimer lamp device is provided with an excimer lamp that emits ultraviolet light through the discharge of a dielectric, and a lampshade that accommodates the excimer lamp; an opening for taking out radiated light from the lamp is formed on the lampshade, through which the lampshade The internal space communicates with the internal space of the processing chamber for processing the object to be processed; it is characterized in that a power supply component is connected to at least one end of the above-mentioned excimer lamp to form a power supply joint; inside the lampshade, a partition is provided to form a power supply Part of the separation between the lamp end area of the junction and the interior space of the lampshade.

Owner:USHIO DENKI KK

Improved coating material for fabric coating finishing

InactiveCN105401432AAnti-agingImprove wrinkle resistanceLight resistant fibresMicrosphereAntioxidant

An improved coating material for fabric coating finishing is prepared from, by weight, 25-35 parts of a silicone acrylic emulsion, 12-16 parts of an adhesive, 2-5 parts of a phosphite antioxidant, 1.5-2.6 parts of nanometer calcium carbonate, 4-7 parts of aqueous latex, 0.3-0.6 parts of a dispersant, 15-35 parts of deionized water, 12-20 parts of butanetriol, 2-4.2 parts of an antiseptic, 6-12 parts of NTB emission powder, 5-8 parts of a fire retardant, 3-6 parts of nitrile butadiene rubber, 20-30 parts of PVC resin, 12-26 parts of hollow ceramic microspheres and 10-14 parts of EVA. The improved coating material for fabric coating finishing has the advantages of good ageing and crease resistance, realization of shading, radiation prevention and moisture permeation functions of fabrics, convenient construction and no pollution.

Owner:王丽萍

Aluminum foil package material, and preparation method and application of aluminum foil package material

InactiveCN108611015APuncture resistantHigh temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterPack material

The invention provides an aluminum foil package material. A polyester film in the aluminum foil package material serves as an outer layer of the aluminum foil package material and has the advantages of puncture resistance, high and low temperature resistance, and oil resistance, and good toughness, airtightness and fragrance protectiveness; aluminum foil has the advantages of moisture proofing, airtightness, light proofing, corrosion resistance, fragrance protectiveness, nontoxicity and no odor; a polyethylene film is low in moisture permeability and can exert a moisture-proof effect; a firstpolyurethane glue layer and a second polyurethane glue layer formed by polyurethane glue can exert adhesive effects on the polyester film and the aluminum foil that are arranged on the two sides of the first polyurethane glue layer, and the aluminum foil and the polyethylene film that are arranged on the two sides of the second polyurethane glue layer; a hot melt adhesive has strong viscosity; anda hot melt adhesive layer formed by the hot melt adhesive can ensure that the aluminum foil package material has good sealability and an unsealing pull force is not too large at the same time. In addition, expensive raw materials are not required for preparation of the aluminum foil package material, and the production cost is low.

Owner:温州市瑞欣印务包装有限公司

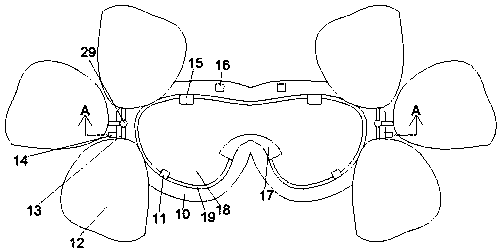

Riding glasses

InactiveCN110262075AWatch clearlyWith windshieldNon-optical adjunctsNon-optical partsUses eyeglassesDrive shaft

The invention discloses riding glasses. The glasses comprise a glasses frame. Storing grooves are bilaterally and symmetrically arranged in the glasses frame. Glasses color change mechanisms are arranged in the storing grooves. The glasses color change mechanisms comprise input shafts rotatably connected to rear end walls of the storing grooves. An upper side of each input shaft is provided with a transmission shaft and an output shaft which are rotatably connected to the rear end wall of each storing groove. The output shaft is located at a right side of the transmission shaft. The input shaft is fixedly provided with a rotation rod. An upper end surface of the rotation rod is fixedly provided with a first curved rod. The glasses have wind-proof, shading and dust-proof functions. When different weather is encountered, a color of eyeglasses can be changed to adapt to different weathers so as to obtain the best usage experience. During riding, wind generated by the riding can be used to cool and defog a contact area between the glasses and a user so that the user can see more clearly.

Owner:济宁韩瑞眼镜有限公司

Plant grafting and seeding cap bag

InactiveCN103190323AWith humidificationWith obvious humidificationPlant protective coveringsRootstockSeedling

Owner:ANHUI SCI & TECH UNIV

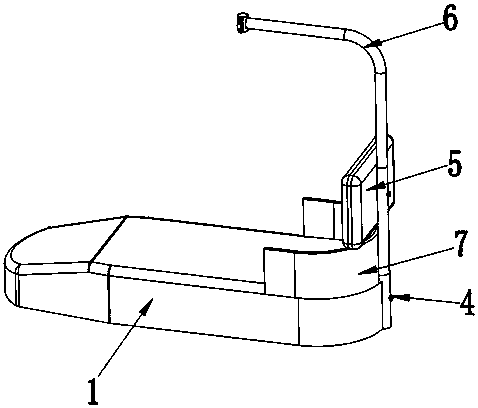

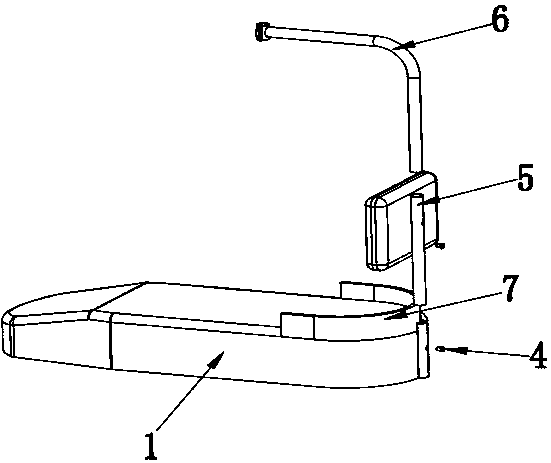

Laser cutting machine and processing method for processing automotive interior parts

ActiveCN106378537BStable supportImprove the state of stressVehicle componentsMetal working apparatusEngineeringLaser cutting

The invention discloses a laser cutting machine used for machining an automobile interior trim part. The cutting machine comprises a machine base, a supporting frame, an upper moving device, a cutting robot, a laser cutting enclosure device, a fixing device, a camera device and an electric control device; the supporting frame is mounted on the machine base, the upper moving device is supported above the machine base through the supporting frame, the upper moving device comprises a gear and rack transmission system driven by a stepping motor, the upper end of the cutting robot is connected with the lower end of the upper moving device, the fixing device is arranged on the machine base and close to the laser cutting enclosure device, the camera device is arranged on a cutting machine inlet and located on the upper portion of the supporting frame, and the electric control device is arranged outside the supporting frame; the laser cutting machine used for machining the automobile interior trim part can increase the cutting range, the laser cutting enclosure device and the cutting clamp fixing device are arranged, the influence on the surroundings is reduced, the fixing time of a cutting clamp is shortened, and the production efficiency is improved.

Owner:常州涵洋高分子材料科技有限公司

Tea package bag with multi-layer structure

InactiveCN102424175AImprove herbicidal activityBroad-spectrum sterilization and mildew removal abilitySynthetic resin layered productsBagsPolyesterPrinting ink

The invention discloses a tea packaging bag with a multi-layer structure. The tea packaging bag has a layered structure, and comprises an oriented polypropylene (OPP) film, a polyester (PET) laser film, an aluminum foil and a polyurethane (PE) film from outside to inside; and various layers are attached to one another to form the tea packaging bag. The tea packaging bag has the advantages of the OPP, PET, the aluminum foil and the PE, has a better sealing effect, and ensures a better tea preserving effect and long storage time; and printed ink hardly infiltrates the packaging bag, so that tea is more safe and sanitary.

Owner:南安市华辉包装有限公司

Replaceable double-layer shutters with anti-smog and noise reduction functions

InactiveCN103850634BWith shadingWith noise reductionDoor/window protective devicesActivated carbonEngineering

The invention relates to a replaceable dual-layer shutter with anti-haze and denoising functions. The replaceable dual-layer shutter with the anti-haze and denoising functions comprises a soundproof felt curtain piece, anion curtain pieces, sealing rubber, an aluminum alloy curtain fixing frame, curtain piece rotary shafts, pull ropes, replaceable activated carbon cloth, rotary gears and a soundproof curtain piece alloy outer frame. The replaceable dual-layer shutter with the anti-haze and denoising functions adopts the dual-layer structural mode with the two layers using different materials, such as the soundproof felt curtain piece and the anion curtain pieces and realizes the functions of anti-haze, denoising and the like by the fact that people select and use different curtains, so the life of people is more comfortable.

Owner:BEIJING UNIV OF TECH

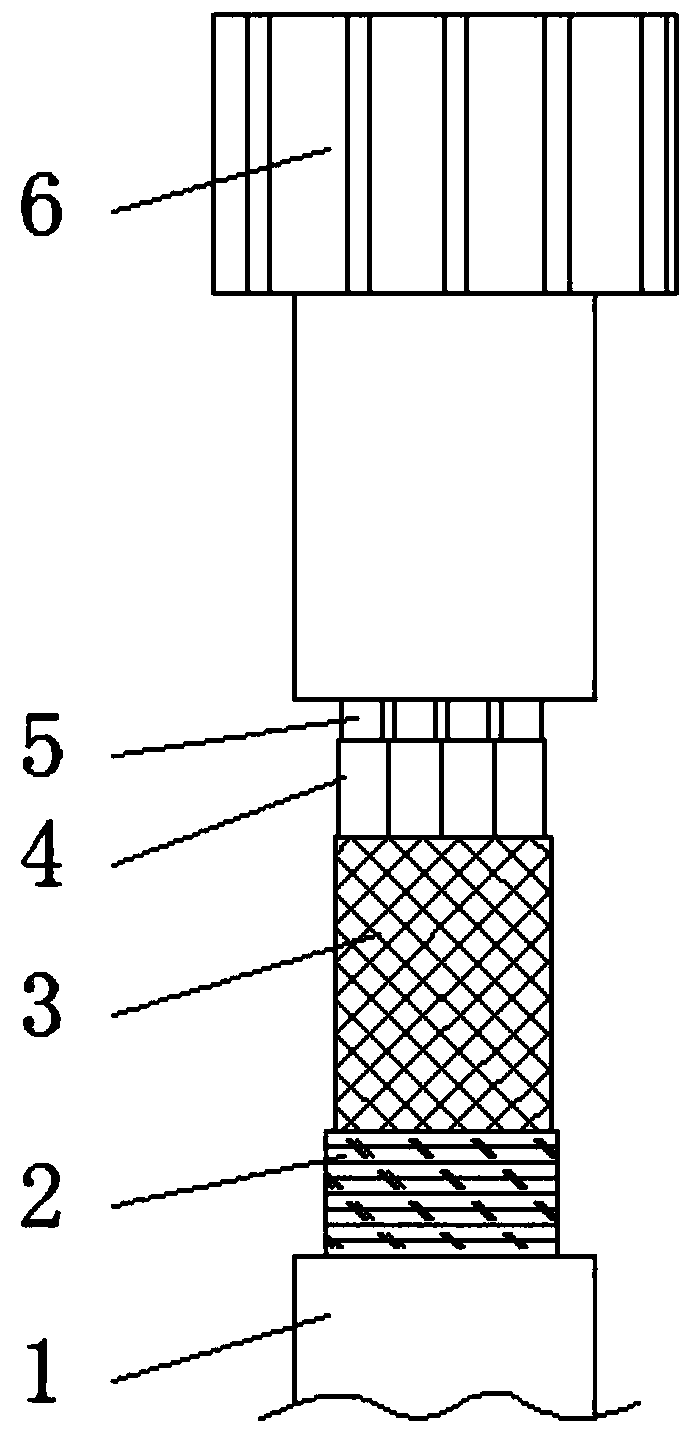

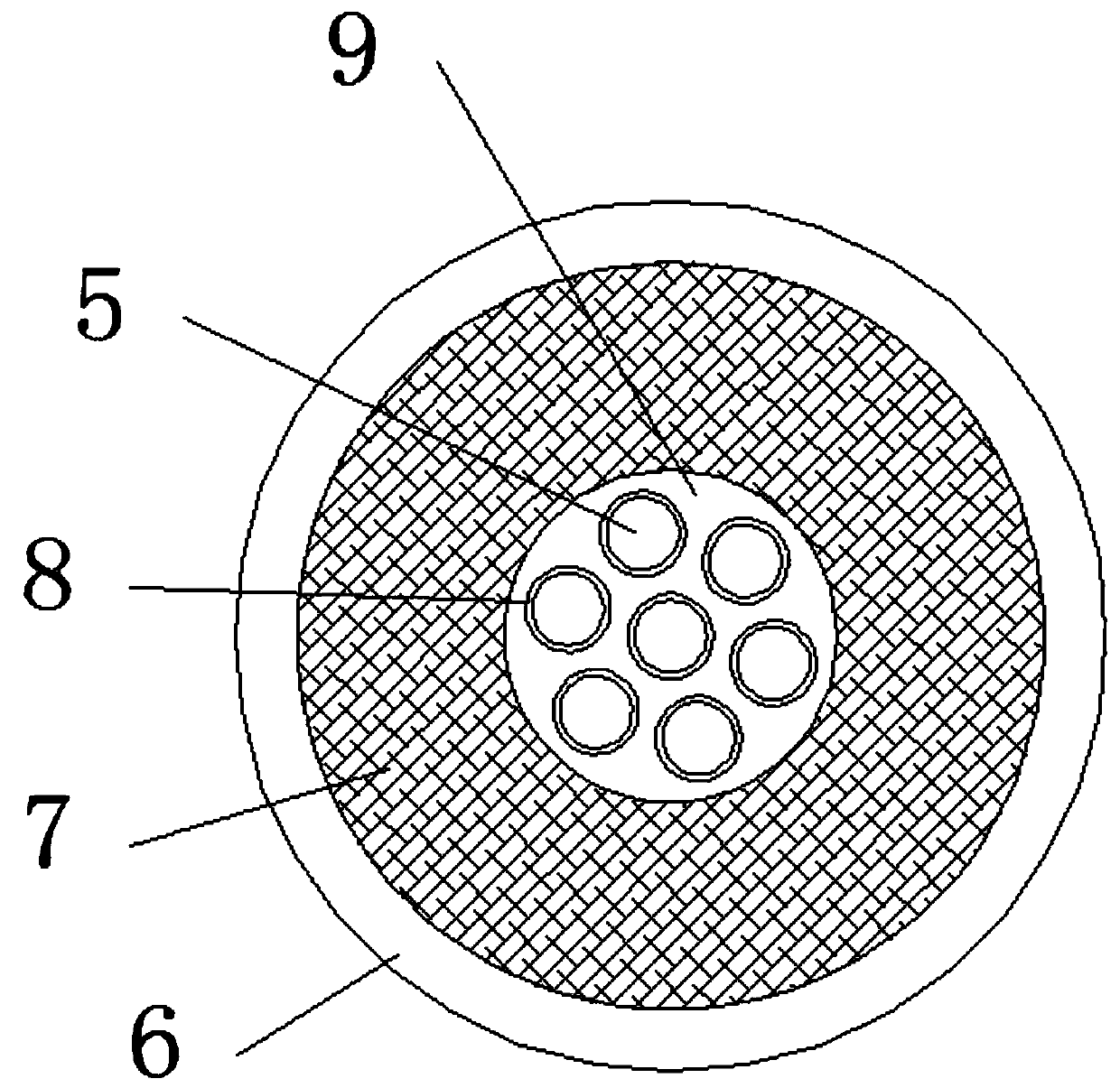

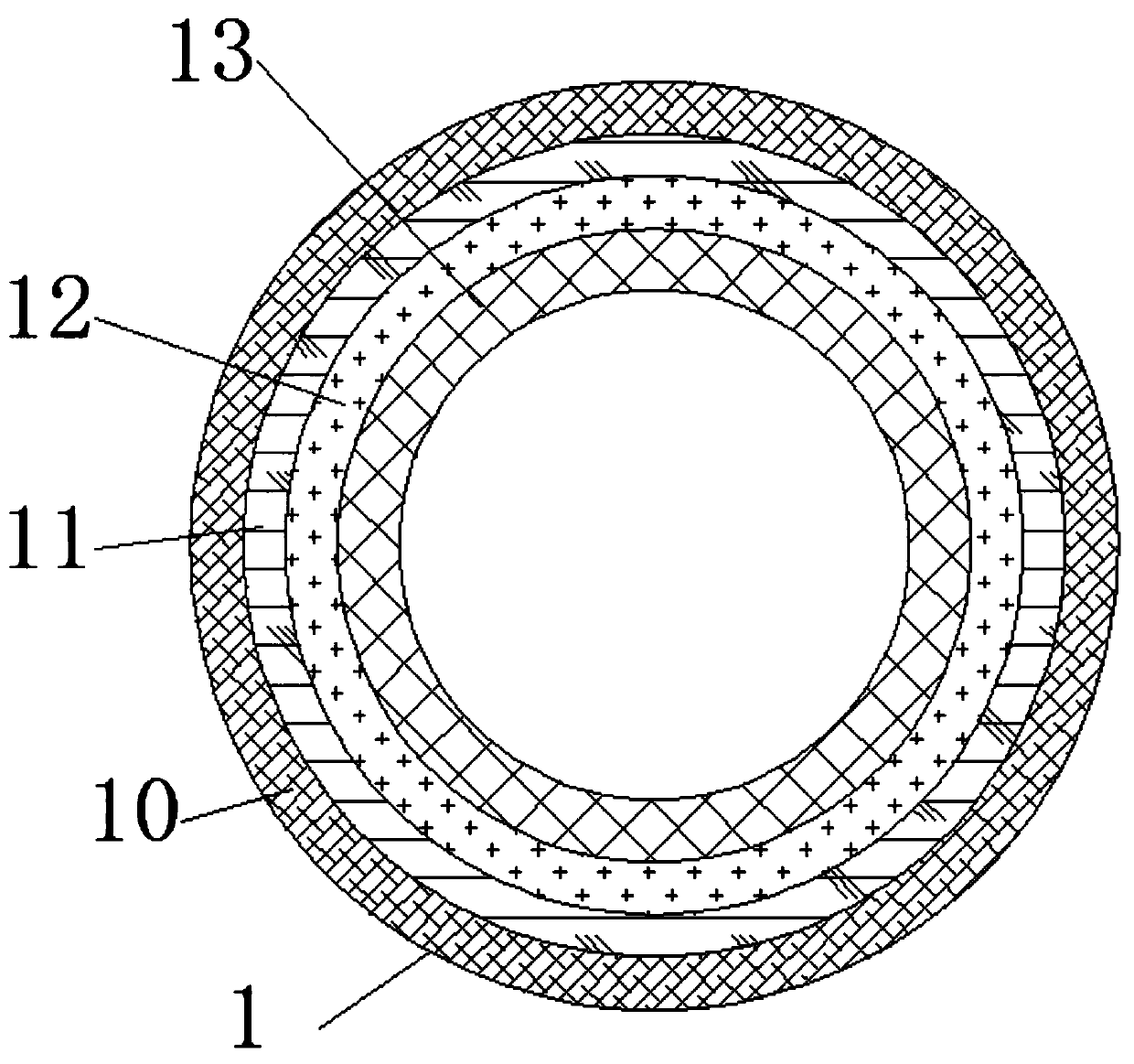

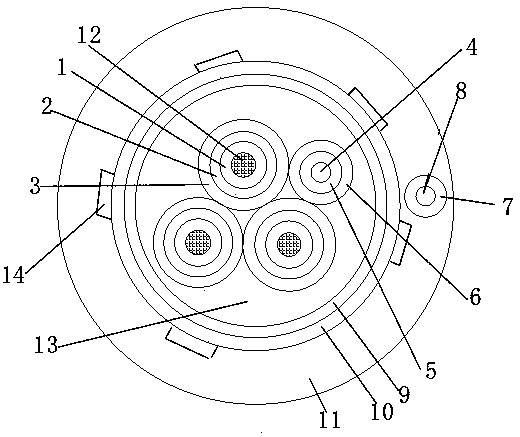

An environment-friendly communication cable for monitoring system

ActiveCN108847301BEasy to installFirmly connectedCommunication cablesInsulated cablesElectrical conductorUltraviolet

The invention discloses an environmental protection communication cable for a monitoring system, which comprises a protective sleeve, a conductor and an inner sheath, wherein an insulating layer is mounted on the outer part of the conductor; the inner sheath is mounted on one side of the insulating layer; a metal-clad layer is mounted on the other side of the insulating layer; a filling layer is mounted inside the metal-clad layer; the metal-clad layer is connected with the protective sleeve through a shielding mesh; a flame-retardant base fabric layer is embedded inside the protective sleeve;an aluminum foil layer is mounted inside the flame-retardant base fabric layer; an anti-oxidation layer is mounted on the periphery of the protective sleeve; an anti-ultraviolet layer is mounted on one side of the anti-oxidation layer; a limiting stand is mounted on one end of the protective sleeve; and the limiting stand is embedded to the bottom of an installation member. The environmental protection communication cable for the monitoring system in the invention has anti-aging protection, fireproof and moisture proof performance and is convenient to install, thereby improving the safety ofuse.

Owner:安徽融商天下信息科技有限公司

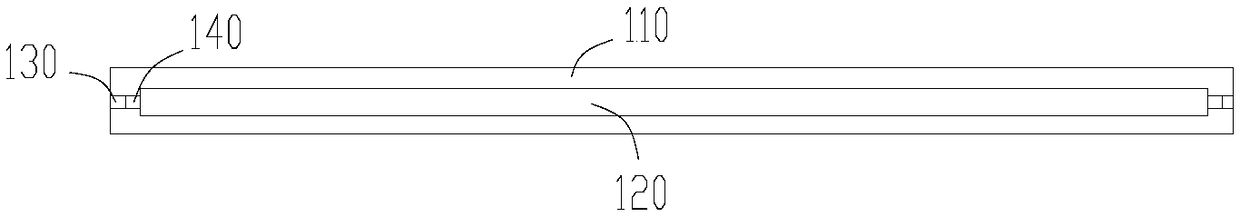

Temperature-measuring soft fire-proof water-blocking signal power cable

InactiveCN107945941AImprove shielding effectGood flexibilityPower cables with screens/conductive layersPower cables including optical transmission elementsWater blockTemperature monitoring

The invention discloses a temperature-measuring soft fire-proof water-blocking signal power cable comprising a cable core formed by twisting of three insulated wire cores and one optical fiber unit. The gap of the cable core is filled with a water-blocking cable paste; the outside of the cable core is extruded by an aluminum-plastic composite tape split screen; a steel-wire main shielding layer isbraided outside the aluminum-plastic composite tape split screen; an outer tooth-shaped water-blocking sheath is arranged outside the steel-wire main shielding layer; fireproof mud is arranged at thetooth form of the outer tooth-shaped water-blocking sheath; and a temperature monitoring wire core is arranged inside the outer sheath. According to the invention, the temperature monitoring wire core is arranged inside the outer sheath and thus the temperature change of the cable in use can be monitored; and an external monitoring device is connected by a monitoring cable to carry out alarming.

Owner:WUXI JIANGNAN CABLE

Combined sound insulation curtain

The invention provides a combined sound insulation curtain comprising at least one curtain unit. The at least one curtain unit comprises a curtain surface layer and a sound insulation layer, the curtain surface layer is provided with a receiving cavity and an opening communicating with the receiving cavity, the curtain surface layer is internally provided with a first connecting member, a second connecting member is disposed on the sound insulation layer, the sound insulation layer is located in the receiving cavity, and the sound insulation layer and the curtain surface layer are detachably connected to the second connecting member through the first connecting member. The combined sound insulation curtain has the functions of shading and decoration during use, also has the function of sound insulation, and can be disassembled before cleaning to facilitate cleaning.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

Glass fiber/PVC (polyvinyl chloride) composite membrane material and preparation method thereof

ActiveCN102555352BWith shadingWith heat insulation effectSynthetic resin layered productsLaminationFiberGlass fiber

Owner:NINGBO XIANFENG NEW MATERIAL

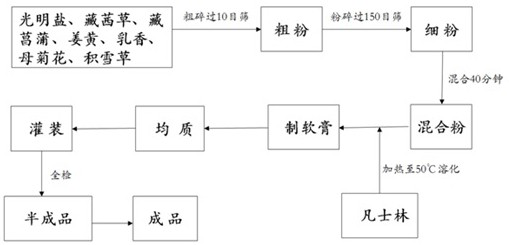

A kind of whitening cream of Tibetan medicine and preparation method thereof

ActiveCN113425654BRestore elasticityRestore lusterSievingCosmetic preparationsRough skinSkin elasticity

The invention discloses a Tibetan medicine whitening cream and a preparation method thereof. The Tibetan medicine whitening cream includes medicinal powder and a matrix, and the ratio of the medicinal powder to the matrix is 1:1-1.5; the medicinal powder includes bright salt, Tibetan madder, Tibetan Calamus, turmeric, frankincense, chamomile and centella asiatica, the mass ratio is 1:1:1:1:1:1:1; the base is vaseline; the preparation method of the Tibetan medicine whitening cream comprises the following steps , respectively coarsely crush and sieve bright salt, Tibetan madder, Tibetan calamus, turmeric and frankincense, crush and sieve, and mix to obtain a mixed medicinal powder; heat and melt the matrix, add it to the mixed medicinal powder to make an ointment; homogenize the ointment, After filling and full inspection, semi-finished products are formed, and semi-finished products are packaged into finished products. The Tibetan medicine whitening cream in the present invention has the effects of nourishing the skin, restoring skin elasticity and luster, improving dull and rough skin, whitening the skin, reducing pigmentation, and eliminating pregnancy spots and various stains. The dosage form is ointment, which is convenient to use ,Safe and effective.

Owner:桑德才让

Surface active agent solution packaging device capable of reducing loss

InactiveCN107804594AChange structureAvoid placingDomestic cooling apparatusLighting and heating apparatusBiochemical engineeringActive agent

The invention discloses a surface active agent solution packaging device capable of reducing loss. The surface active agent solution packaging device comprises a tank body. A sleeve is arranged on theouter portion of the tank body, the tank body is completely located in the sleeve, a space allowing water to circulate is arranged between the tank body and the sleeve, a sealing cover at the top ofthe tank body comprises two door planks which are mutually connected, and one sides of the two door planks are both hinged to the top of the tank body; the directions that the two door planks rotate on the tank body around the hinged end are opposite, a sealing pad is arranged between the sealing cover at the top of the tank body and an upper cover at the top of the sleeve, and the sealing pad ispasted to a connecting seam of the two door planks and seals the connecting seam; and the sealing pad is connected with the upper cover at the top of the sleeve through a vertically placed spring, andthe upper cover at the top of the sleeve is movably connected with the sleeve. According to the surface active agent solution packaging device capable of reducing the loss, condensate water or heat preservation water is poured into a space between the tank body and the sleeve to be used for adjusting the temperature of the environment where the tank body is located, so that a fluorine-containingsurface active agent is located in a best storage environment, and the quality guarantee period can be prolonged.

Owner:成都凯米拉科技有限公司

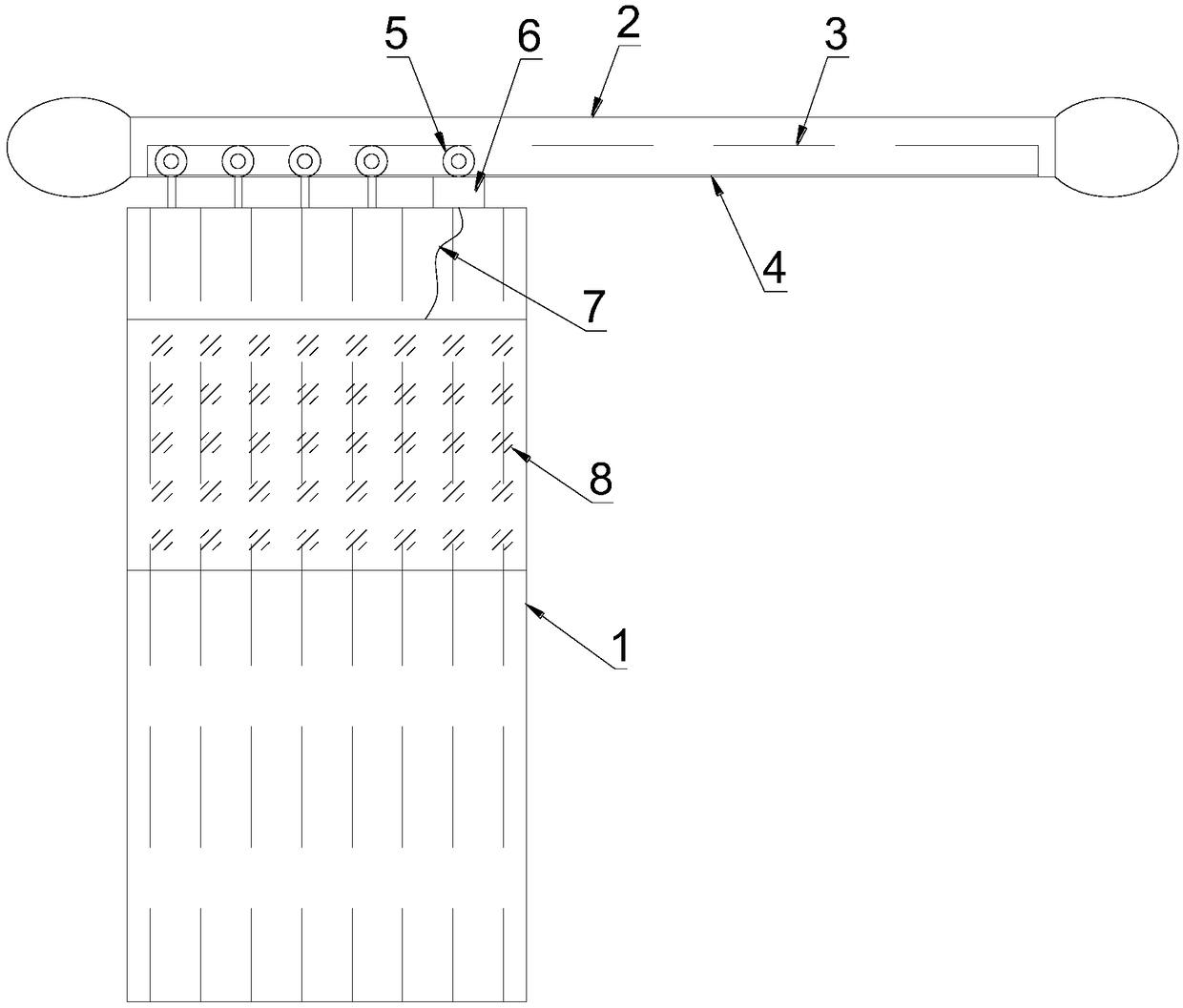

An electronic curtain with negative ion ventilation and heat insulation

ActiveCN109263222BBreathableWith heat insulationSynthetic resin layered productsAromatherapyElectrical battery

The invention discloses an electronic curtain with functions of negative ion release, ventilation and heat insulation, belongs to the technical field of electronic home, and solves the problem that anexisting curtain is poor in light shading, heat insulation and ventilation and cannot release negative ions. The electronic curtain is characterized by comprising a curtain body and a curtain hangingrod, wherein the bottom side of the inner portion of the curtain hanging rod is provided with a T-shaped sliding rail, the T-shaped sliding rail is internally provided with moving wheels, every two moving wheels are in one set and connected through a wheel shaft, a gear in the middle of the wheel shaft at the outermost side is meshed with a gear on a motor shaft of a motor, and a solar film battery is applied on the outer side of the curtain body; closing or opening of the curtain body is achieved and controlled remotely, the solar film battery supplies power for closing or opening of the curtain body, and no additional power is required, the energy is saved, the environment is protected, the curtain body is composed of a light-shielding layer, a heat-insulating layer, a PU hot-melt adhesive layer, an elastic mesh frame, a nanofiber braid layer and a gas permeable layer from the outside to the inside in sequence, and has the functions of light shielding, heat insulation, ventilation,negative ion release and aromatherapy.

Owner:SHENZHEN YUANCHAO IND CO LTD

Electronic curtain with functions of negative ion release, ventilation and heat insulation

ActiveCN109263222ABreathableWith heat insulationSynthetic resin layered productsThermal insulationMotor shaft

The invention discloses an electronic curtain with functions of negative ion release, ventilation and heat insulation, belongs to the technical field of electronic home, and solves the problem that anexisting curtain is poor in light shading, heat insulation and ventilation and cannot release negative ions. The electronic curtain is characterized by comprising a curtain body and a curtain hangingrod, wherein the bottom side of the inner portion of the curtain hanging rod is provided with a T-shaped sliding rail, the T-shaped sliding rail is internally provided with moving wheels, every two moving wheels are in one set and connected through a wheel shaft, a gear in the middle of the wheel shaft at the outermost side is meshed with a gear on a motor shaft of a motor, and a solar film battery is applied on the outer side of the curtain body; closing or opening of the curtain body is achieved and controlled remotely, the solar film battery supplies power for closing or opening of the curtain body, and no additional power is required, the energy is saved, the environment is protected, the curtain body is composed of a light-shielding layer, a heat-insulating layer, a PU hot-melt adhesive layer, an elastic mesh frame, a nanofiber braid layer and a gas permeable layer from the outside to the inside in sequence, and has the functions of light shielding, heat insulation, ventilation,negative ion release and aromatherapy.

Owner:SHENZHEN YUANCHAO IND CO LTD

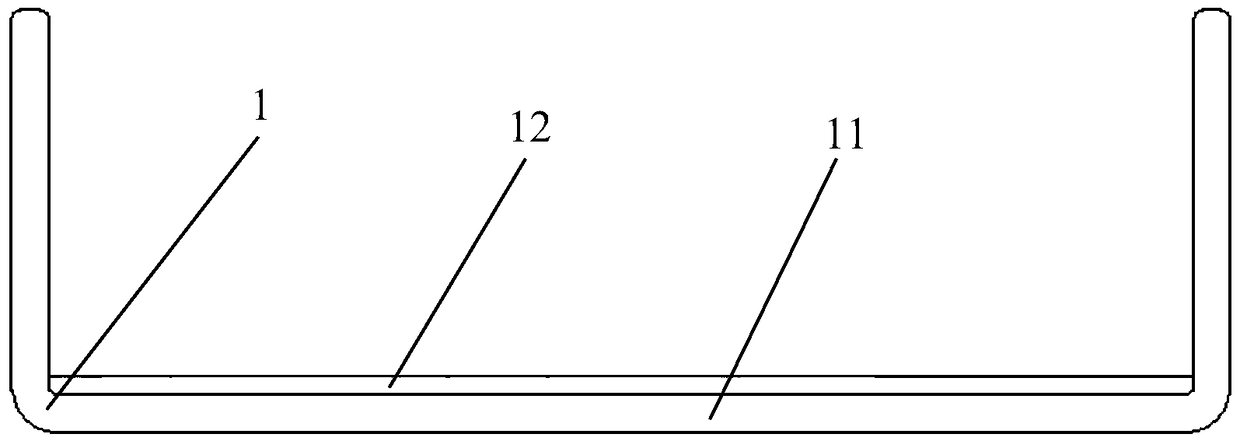

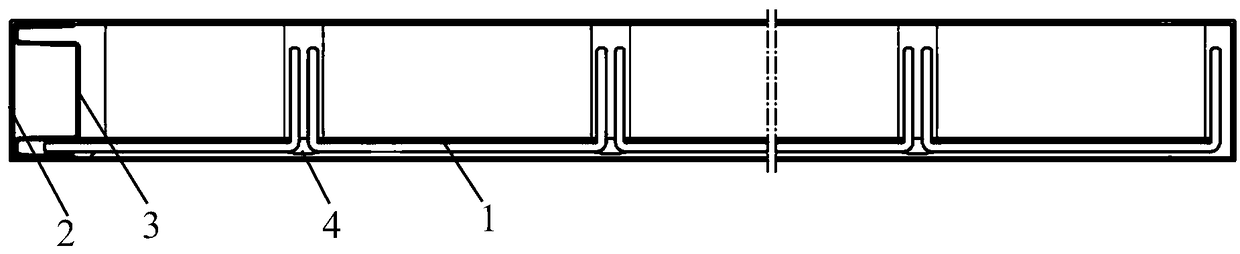

Manufacturing method and application of glazed tempered/semi-tempered U-shaped glass

The invention discloses a manufacturing method of glazed tempered / semi-tempered U-shaped glass. The manufacturing method comprises the following steps: selecting an inorganic glaze material and U-shaped glass with the thickness of 5 to 10mm; firstly, putting the inorganic glaze material and the U-shaped glass on a washing frame; dipping a washing solution by utilizing a sponge brush and uniformlywiping the surface of the U-shaped glass for 2 to 3min; then washing the surface of the glass by utilizing clean water until no dirt is retained on the surface of the U-shaped glass; drying the washedglass with hot air; when the U-shaped glass is dried, applying glaze as soon as possible; uniformly printing or spraying the inorganic glaze material on a web plate of the U-shaped glass; carrying out drying treatment after the inorganic glaze material is sprayed; drying for 4 to 10min in a temperature range of 650 to 750 DEG C, and stopping until the inorganic glaze material is completely dried,so as to obtain the U-shaped glass coated with the inorganic glaze material; cooling the U-shaped glass coated with the inorganic glaze material through industrial air cooling equipment, and coolingfor 5 to 10min to obtain the glazed tempered / semi-tempered U-shaped glass. The glazed tempered / semi-tempered U-shaped glass provided by the invention has abundant colors, is not easy to fade and has good light-shielding, heat-insulation, heat-preservation and energy-saving effects.

Owner:浙江祥捷绿建科技有限公司

Novel saddle

The invention discloses a novel saddle and belongs to the field of saddle cushions of motorbikes and electric vehicles. The novel saddle comprises a saddle cushion supporting rack, a high-density sponge cushion, composite aluminium foil, a movable children safety seat, a backrest and an umbrella fixing rack. The composite aluminium foil wraps the saddle cushion supporting rack and the sponge cushion, is flexible in texture, good in ductility, firm, durable and resistant to aging and can have a great heat insulation effect, and the situation can be avoided that the saddle cushion is too hot after being exposed under the sun for a long time in summer. The movable children safety seat brings convenience and relief to parents, the backrest can make a passenger feel comfortable and safe duringriding, the umbrella fixing rack can be used for fixing an umbrella to shield the sun and rainwater, and all the components can also be disassembled and assembled. The novel saddle is simple, practical and uniquely innovative and brings great convenience to living and travelling of common people.

Owner:NANNING FUJIU INFORMATION TECH

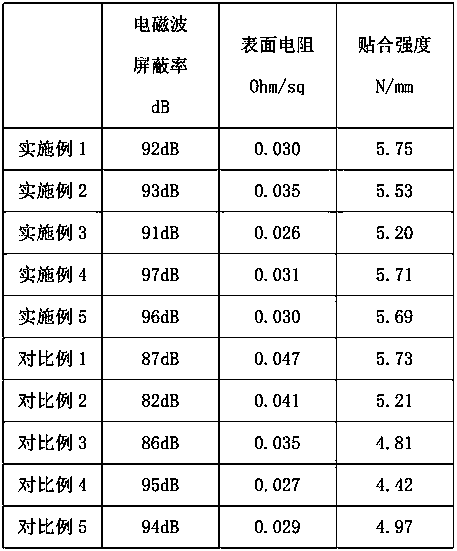

A kind of electromagnetic wave shielding film material and preparation method thereof

ActiveCN108718518BSolve post-soldering installation operationsAvoid installationMagnetic/electric field screeningEster polymer adhesivesPolymer scienceAnisotropic conductive adhesive

The invention provides an electromagnetic wave shielding film material, which is characterized in that a layer of frosted black resin of 5-6 microns is coated on one surface of copper foil, and an anisotropic conductive adhesive layer of 10-12 microns is coated on the other surface; a PET protective layer is added on the outer layer of the frosted black resin; and a layer of PET release film is added on the outer layer of the anisotropic conductive adhesive layer. The invention provides an electromagnetic wave shielding film material and a preparation method thereof; the light shielding property and the excellent electromagnetic wave shielding performance are achieved; and the ultra-thin structure of the material and the excellent bonding performance with various substrates are realized.

Owner:SHENZHEN LICHANGSHI ADHESIVE PROD

Using method of plant grafting and seeding cap bag

The invention discloses a using method of a plant grafting and seeding cap bag, and relates to the plant grafting technology. The scion protection is carried out by the plant grafting and seeding cap bag in a plant grafting process. The using method comprises five steps of grafting, lashing a support upright post, bagging, water-flooding and removing the bag. The using method has the characteristics that the plant grafting and seeding cap bag can humidify, keep warm, prevent wind, shield the light and prevent rain. A good small environment climate condition is created for plant grafting and seeding; generation of grafted seedling callus and coalescence of a wound are facilitated; and the survival rate and the quality of the grafted seeding can be greatly improved. The using method is simple in operation mode; a sunshade net is not needed to shade after grafting is finished; and the labor intensity and the grafting cost can be reduced.

Owner:ANHUI SCI & TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com