Low-radiation film, coated glass and preparation method of coated glass

A low-emissivity film and coated glass technology, applied in glass manufacturing equipment, glass molding, glass tempering, etc., can solve problems such as difficulty in meeting application requirements, inability to achieve neutrality, naturalness, and large color changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

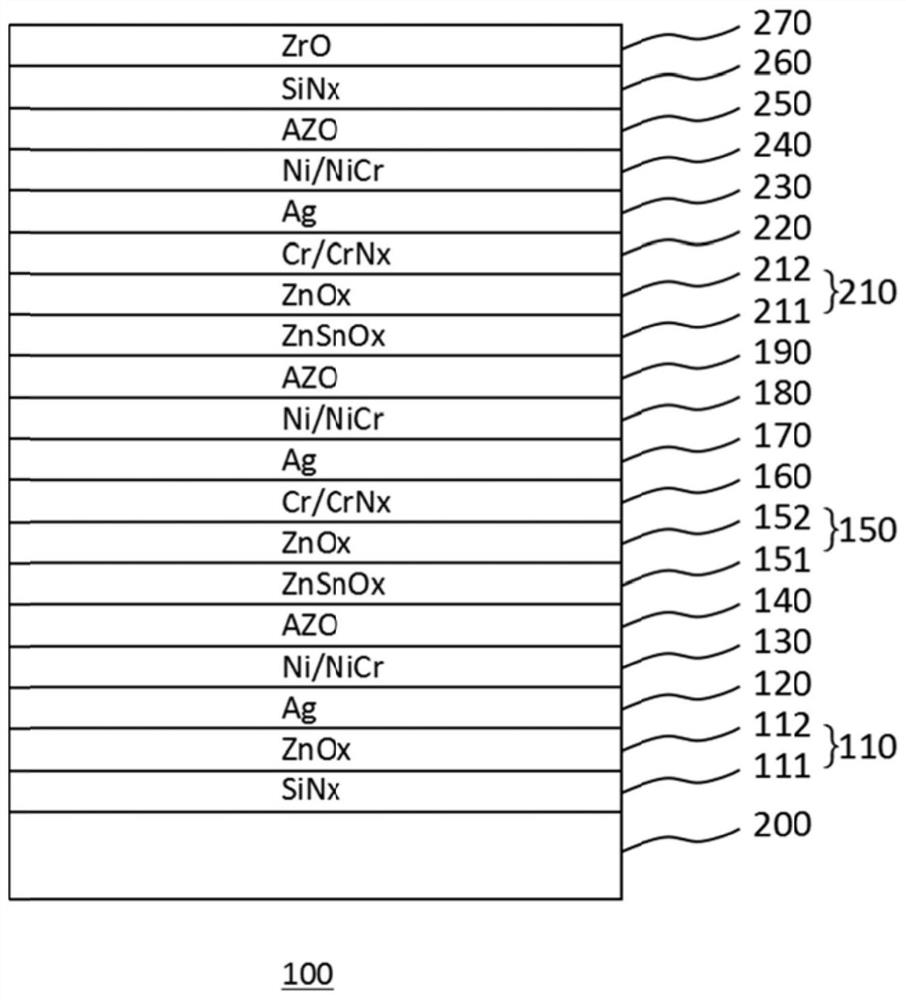

[0081] A kind of triple-silver laminated glass, comprising: the second glass substrate (6mm), PVB (1.52mm), the first glass substrate 200 (6mm), low-emissivity film 100 stacked in sequence, the low-emissivity film 100 includes stacked in sequence on the first SiN on the surface of the glass substrate opposite to PVB x (20~30nm), ZnO x (7~12nm), Ag(4~15nm), NiCr(0.5~3nm), AZO(5~10nm), ZnSnOx(40~60nm), ZnO x (7~12nm), CrN x (0.5~3nm), Ag(8~20nm), NiCr(0.5~3nm), AZO(5~10nm), ZnSnO x (50~70nm), ZnO x (7~12nm), CrN x (0.5~3nm), NiCr(0.5~5nm), Ag(10~20nm), AZO(5~10nm), SiN x (20~40nm), ZrO (3~15nm).

[0082] The preparation method of this triple silver laminated glass comprises:

[0083] (1) Coating: According to the structure of the above-mentioned low-emissivity film 100, corresponding film materials are plated sequentially on the first glass substrate 200, so that the above-mentioned low-emissivity film 100 is formed on one side surface of the first glass substrate, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com