Electrochromic glass with neutral tone and preparation method and application thereof

An electrochromic glass, neutral technology, used in nonlinear optics, instruments, optics, etc., can solve the problems of affecting the observation of the external natural environment, single color, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The present invention also provides a method for preparing an electrochromic glass with a more neutral color tone, which mainly includes: using the base glass layer as a substrate, sequentially plating a first conductive layer, a solar spectrum adjustment functional layer, a cation generating layer, an auxiliary Regulating functional layer, second conductive layer and outer protective layer.

[0067] In some embodiments, in the preparation method of the electrochromic glass with a more neutral color tone, the substrate glass layer used needs to be cleaned and dried before coating.

[0068] In some embodiments, the operation of plating the first conductive layer in the preparation method of the more neutral electrochromic glass includes: raising the temperature of the substrate to 280-550 degrees Celsius, using corresponding materials, In an atmosphere with a flow rate of 300sccm to 2000sccm and an oxygen flow rate of 5sccm to 2000sccm, the power is 10KW to 60KW, and the...

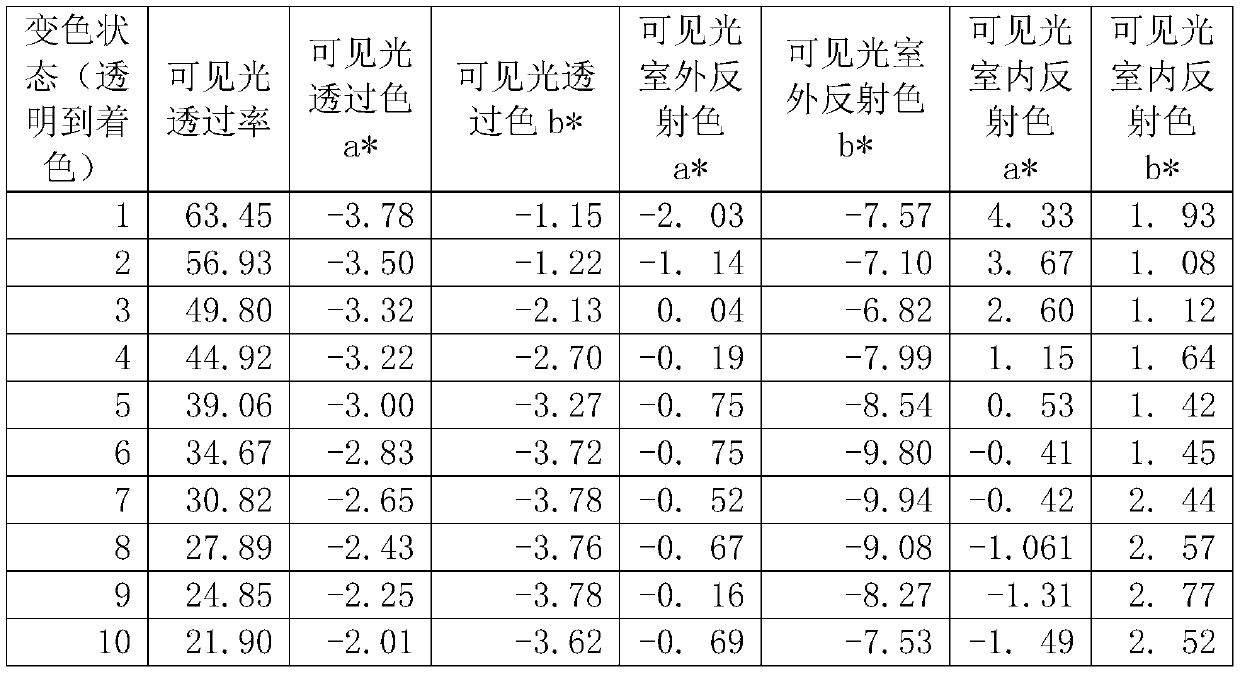

Embodiment 1

[0086] Embodiment 1 Electrochromic glass with more neutral color tone of the present invention and its preparation method

[0087] The more neutral electrochromic glass of this embodiment includes:

[0088] Substrate glass layer: 0.1mm thick fresh transparent float glass;

[0089] The first transparent conductive layer: a 1nm thick indium tin oxide (ITO) film layer;

[0090] Solar spectrum adjustment function layer: Si x Nb y N z and Zn m Nb n o k A film layer with a thickness of 0.1 microns combined at a mass ratio of 1:1; wherein the subscript content: x is 40%, y is 20%, z is 40%; m is 20%, n is 20%, and k is 60%;

[0091] Cation generation layer: 300nm thick lithium ion metal film layer;

[0092] Auxiliary adjustment function layer: Ni x1 Nb y1 N z1 and Ti m1 Nb n1 o k1 A film layer with a thickness of 500nm combined according to a mass ratio of 1:2; wherein the subscript content: x1 is 30%, y1 is 30%, z1 is 40%; m1 is 40%, n1 is 30%, and k1 is 30% %;

[0...

Embodiment 2

[0105] Example 2 Electrochromic glass with more neutral color tone of the present invention and its preparation method

[0106] The more neutral electrochromic glass of this embodiment includes:

[0107] Substrate glass layer: 0.1mm thick fresh transparent float glass;

[0108] The first transparent conductive layer: a 1nm thick indium tin oxide (ITO) film layer;

[0109] Solar spectrum adjustment function layer: Si x Nb y N z and Zn m Nb n o k A film layer with a thickness of 0.1 microns combined at a mass ratio of 1:1; wherein the subscript content: x is 40%, y is 20%, z is 40%; m is 20%, n is 20%, and k is 60%;

[0110] Cation generation layer: 300nm thick lithium ion metal film layer;

[0111] Auxiliary adjustment function layer: Ni x1 Nb y1 N z1 and Ti m1 Nb n1 o k1 A film layer with a thickness of 500nm combined according to a mass ratio of 1:2; wherein the subscript content: x1 is 30%, y1 is 30%, z1 is 40%; m1 is 40%, n1 is 30%, and k1 is 30% %;

[0112...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com