Surface active agent solution packaging device capable of reducing loss

A technology of surfactants and loss, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of short shelf life and short shelf life of fluorine-containing surfactants, so as to extend the shelf life, reduce the growth of bacteria, The effect of strengthening airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

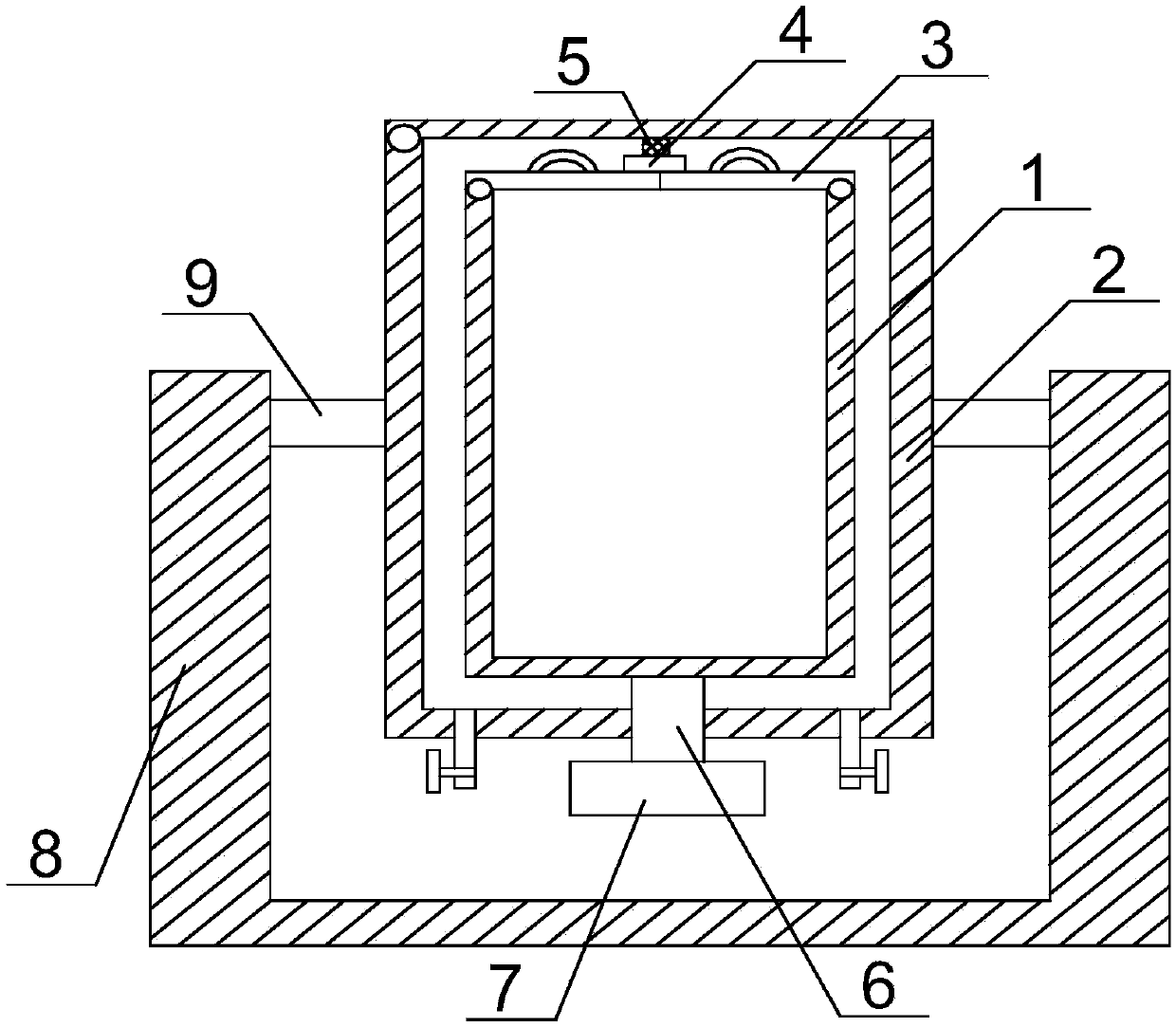

[0023] Such as figure 1 As shown, the surfactant solution packaging device for reducing loss of the present invention includes a tank body 1, the outside of the tank body 1 is provided with a sleeve 2, the tank body 1 is completely located inside the sleeve 2, and the tank body 1 and the sleeve There is a space for water supply and circulation between the two. The sealing cover on the top of the tank body 1 includes two interconnected door panels 3. One side of the two door panels 3 is hinged with the top of the tank body 1. The two door panels 3 are on the tank body 1. The direction of rotation around the hinged end is opposite, and a sealing gasket 4 is arranged between the top sealing cover of the tank body 1 and the upper cover on the top of the sleeve 2, and the sealing gasket 4 is pasted on the connecting seam of the two door panels 3 and the connection is made. Seam sealing, the gasket 4 is connected to the upper cover on the top of the sleeve 2 through the vertically p...

Embodiment 2

[0026] Based on Embodiment 1, a rotating shaft 6 is vertically inserted into the bottom of the sleeve 2, the rotating shaft 6 is rotationally connected with the sleeve 2, the upper end of the rotating shaft 6 is connected with the bottom of the tank body 1, and the lower end of the rotating shaft 6 is located outside the sleeve 2 and connected Limit plate 7. The rotating shaft 6 is screwed to the bottom of the sleeve 2 . The limiting plate is convenient for rotating the rotating shaft, and can also limit the stop position of the rotating shaft; the upward rotation of the rotating shaft can push the tank body upwards, which not only helps to take out the material from the tank body, but also helps the sealing gasket to be tightly connected with the tank body sealing cover.

Embodiment 3

[0028] Based on the above-mentioned embodiment, a groove 8 is provided on the outside of the sleeve 2 , and the sleeve 2 is located in the groove 8 , and a horizontal electric shaft 9 is connected between the two side walls of the groove 8 and the outer wall of the sleeve 2 .

[0029] The groove supports the sleeve, and the electric shaft can drive the sleeve and the tank to rotate in the vertical direction, which can effectively prevent the fluorine-containing surfactant from losing its activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com