Preparation method of black extinction polyimide film

A technology for preparing matte polyimide and film, applied in the field of polyimide film manufacturing, can solve the problems of high production control precision requirements, uneven melting, complex manufacturing process, etc., to ensure the insulation performance and mechanical properties of the film. , The effect of enhancing tear resistance and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

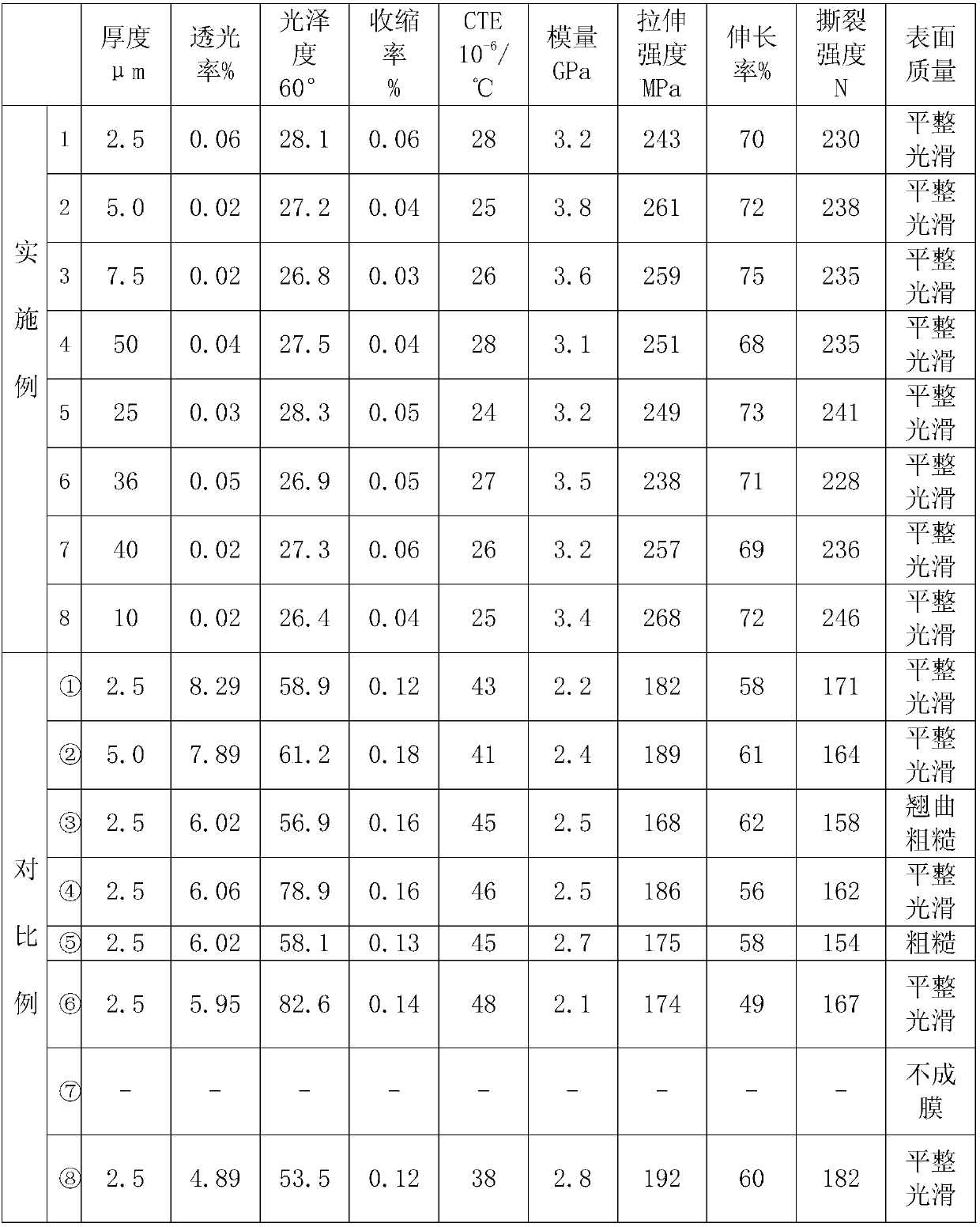

Examples

Embodiment 1

[0049] Ⅰ. Preparation of polyamic acid resin solution

[0050] In a nitrogen atmosphere, the temperature of the synthesis system is controlled to be 12°C, and 2.39 kg of aromatic diamine 4,4'-diaminodiphenyl ether (4,4 '-ODA) was stirred and dissolved. After 4,4'-ODA was completely dissolved, 2.61kg of aromatic dianhydride pyromellitic acid diacid (PMDA) was added at a constant speed in 8 times at a molar ratio of 1:1 to the aromatic diamine. , and stirred at 1200r / min, synthesized by polycondensation reaction for 12h to obtain a polyamic acid resin solution with a solid content of M=5kg, that is, a solid content ratio of 10wt%;

[0051] Ⅱ. Black slurry preparation

[0052] 20wt% of the solid content M in the polyamic acid resin solution gained by step 1 gets carbon black 1kg and adds solvent N, N'-dimethylacetamide (DMAC) 2.33kg and mixes and stirs to obtain carbon black content 30% Black slurry; the average particle size of carbon black in this example is 0.01 μm.

[0053...

Embodiment 2

[0065] Ⅰ. Preparation of polyamic acid resin solution

[0066] In a nitrogen atmosphere, the temperature of the synthesis system is controlled at 75°C, and 2.39kg of aromatic diamine 4,4'-diaminodiphenyl ether (4,4 '-ODA) was stirred and dissolved. After 4,4'-ODA was completely dissolved, 2.61kg of aromatic dianhydride pyromellitic acid diacid (PMDA) was added at a constant speed in 8 times at a molar ratio of 1:1 to the aromatic diamine. , and stirred at 1200r / min, synthesized by polycondensation reaction for 12h to obtain a polyamic acid resin solution with a solid content of M=5kg, that is, a solid content ratio of 10wt%;

[0067] Ⅱ. Black slurry preparation

[0068] According to the 20wt% of the solid content M in the polyamic acid resin solution gained in step I, get bone charcoal 1kg and add solvent N, N'-dimethylformamide (DMF) 4.56kg, mix and stir to obtain the black slurry of bone charcoal content 18%. Material; the average particle size of bone char in this example...

Embodiment 3

[0076] Ⅰ. Preparation of polyamic acid resin solution

[0077] In a nitrogen atmosphere, control the temperature of the synthesis system at 22°C, add 6.38kg of aromatic diamine 2,2'-bis(trifluoromethyl)benzidine to 37.5kg of N,N'-dialkylcarboxamide solvent and stir Dissolve, after it is completely dissolved, add 5.99 kg of aromatic dianhydride 3,3',4,4'-biphenyl tetracarboxylic acid dianhydride (BPDA ), and stirred at 1000r / min, synthesized by polycondensation reaction for 8h to obtain a polyamic acid resin solution with a solid content of M=12.4kg, that is, a solid content ratio of 25wt%;

[0078] Ⅱ. Black slurry preparation

[0079] According to the 16wt% of the solid content M in the polyamic acid resin solution gained in step 1, get iron black 2kg and add solvent N, mix and stir in 18kg of N'-dimethyl sulfoxide (DMSO) to obtain iron black content 10% black Slurry; the average particle size of iron black in this example is 0.8 μm.

[0080] The mixing and stirring after a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com