High-temperature-resistant weatherproof fireproof chlorinated polyvinyl chloride (CPVC) corrugated board with low heat conductivity, and preparation method of chlorinated polyvinyl chloride (CPVC) corrugated board

A technology of chlorinated polyvinyl chloride and low thermal conductivity, which is applied in the field of corrugated boards, can solve the problems of uneven stress distribution, high processing difficulty, and high molding difficulty, and achieve the effects of enhanced fluidity, reduced processing difficulty, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

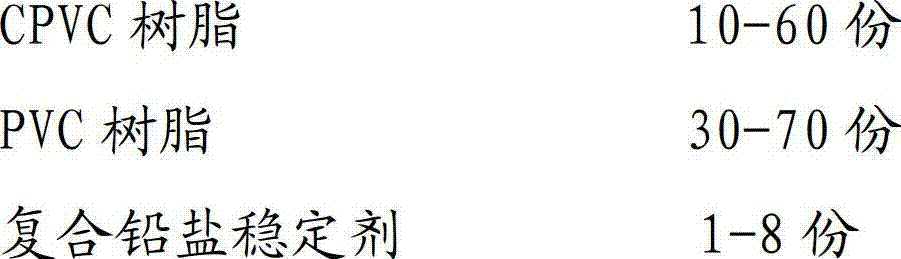

[0029] A chlorinated polyvinyl chloride corrugated board with high temperature resistance, weather resistance, fire prevention and low thermal conductivity, which is prepared from the following raw materials in parts by weight:

[0030]

[0031] Wherein, the anti-impact additive is a mixture of ACM and CPE; the processing aid is ACR; the filler is calcium carbonate; the lubricant is calcium stearate.

[0032] The preparation method is as follows:

[0033] (1) Thermally mix the raw materials, add the raw materials to a 1000r / min high-speed mixer and mix for 10 minutes or until the temperature reaches 115°C, then put the mixed materials into a 500r / min cold mixer with a cold water jacket, Fully cool down to 60°C;

[0034] (2) Release the mixed materials to the trough, spread them out and place them at room temperature for 20 hours;

[0035] (3) Put the placed material into the upper hopper of the extruder through the screw conveyor and enter the extrusion process. The barre...

Embodiment 2

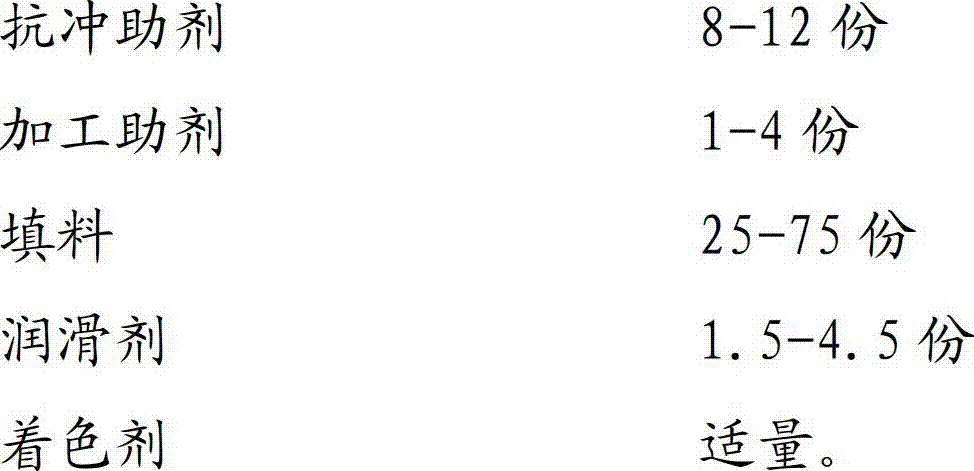

[0039] A chlorinated polyvinyl chloride corrugated board with high temperature resistance, weather resistance, fire prevention and low thermal conductivity, which is prepared from the following raw materials in parts by weight:

[0040]

[0041] Wherein, ACM is used as the anti-impact additive; ACR is used as the processing aid; calcium carbonate is used as the filler; OPE is used as the lubricant.

[0042] The preparation method is as follows:

[0043] (1) Thermally mix the raw materials, add the raw materials to a 1100r / min high-speed mixer and mix for 10 minutes, or mix until the temperature reaches 115°C, and then put the mixed materials into a 600r / min cold mixer with a cold water jacket , fully cool down to 65°C;

[0044] (2) Release the mixed materials to the trough, spread them out and place them at room temperature for 24 hours;

[0045] (3) Put the placed material into the upper hopper of the extruder through the screw conveyor and enter the extrusion process. T...

Embodiment 3

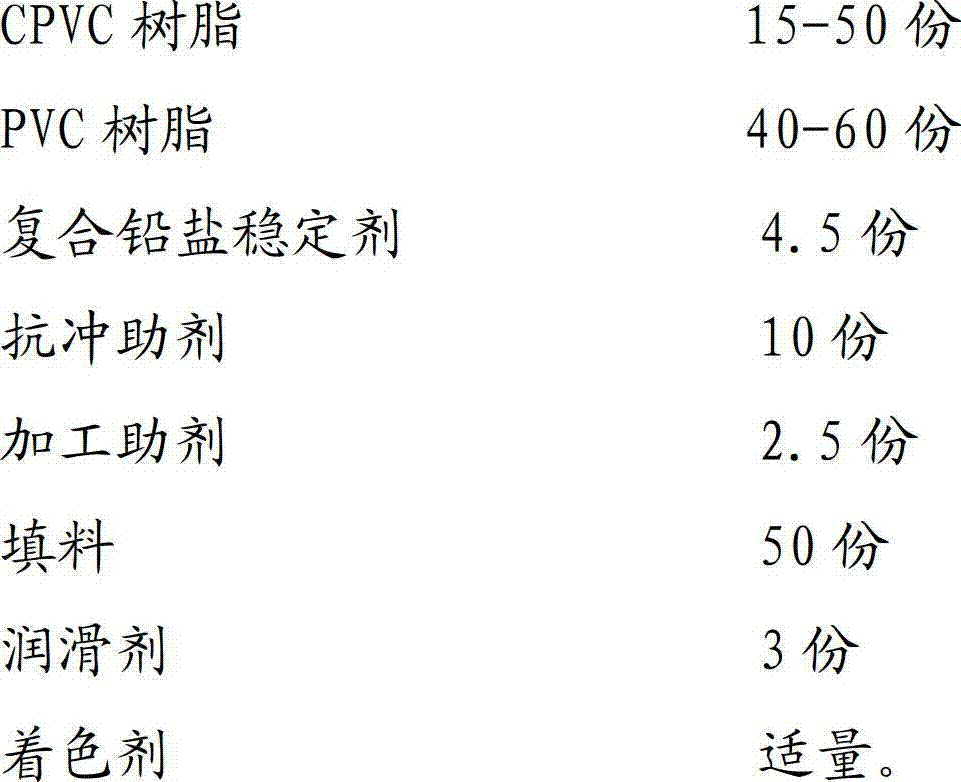

[0049] A chlorinated polyvinyl chloride corrugated board with high temperature resistance, weather resistance, fire prevention and low thermal conductivity is prepared from the following raw materials in parts by weight:

[0050]

[0051] Wherein, the anti-impact additive is CPE; the processing aid is ACR; the filler is calcium carbonate; and the lubricant is glyceryl stearate.

[0052] The preparation method is as follows:

[0053] (1) Thermally mix the raw materials, add the raw materials to a 1200r / min high-speed mixer and mix for 10 minutes, or mix until the temperature reaches 115°C, and then put the heated material into a 700r / min cold mixer with a cold water jacket , fully cool down to 65°C;

[0054] (2) Release the mixed materials to the trough, spread them out and place them at room temperature for 28 hours;

[0055] (3) Put the placed material into the upper hopper of the extruder through the screw conveyor and enter the extrusion process. The barrel of the extrud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com