Hardenable reaction resin system

a reaction resin and resin technology, applied in the direction of printed circuit, transportation and packaging, non-metallic protective coating application, etc., can solve the problems of inability to implement higher filler contents in systems, and achieve low linear shrinkage, low thermal expansion coefficient, and high elongation at rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A reaction resin system according to the present invention has three basic components: a resin component A, a filler B, and polymer particles C, which are dispersed in resin component A. In addition, at least one hardener D and commonly used additives are provided such as one or more antifoaming agents, sedimentation inhibitors, or adhesion promoters.

[0010] In general, it should be kept in mind that the reaction resin system must form a stable system before and during processing to prevent the components from separating. Thus, filler particles B and polymer particles C should form stable dispersions with resin component A, and, if there are more resin components A, resin components A should form stable solutions or emulsions among themselves. This stability must be ensured during both processing and hardening of the reaction resin system.

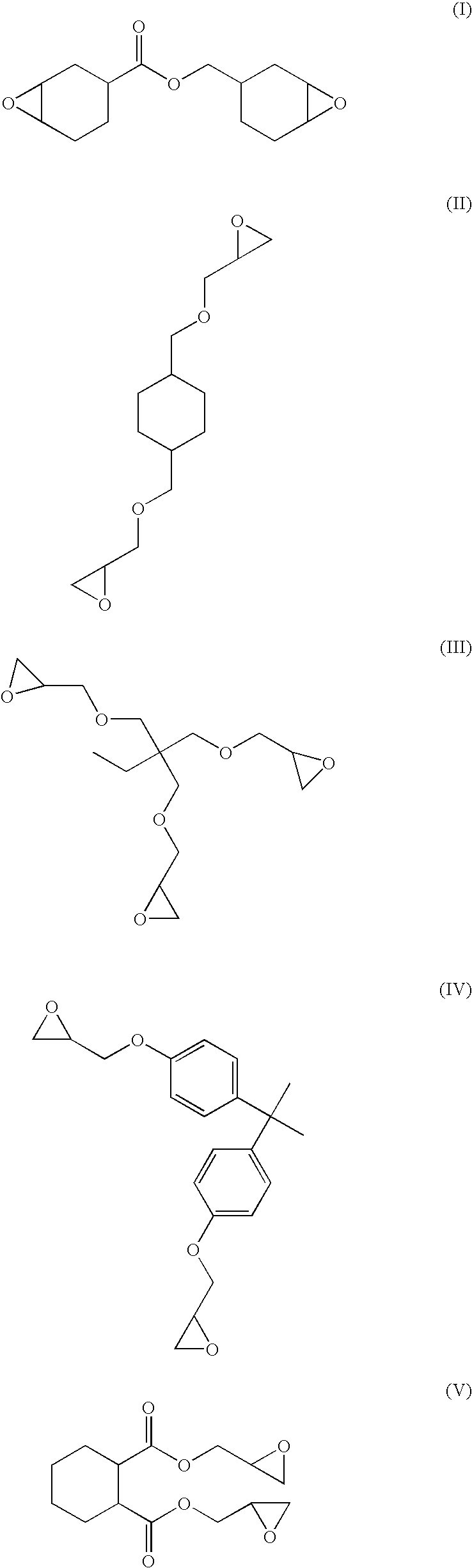

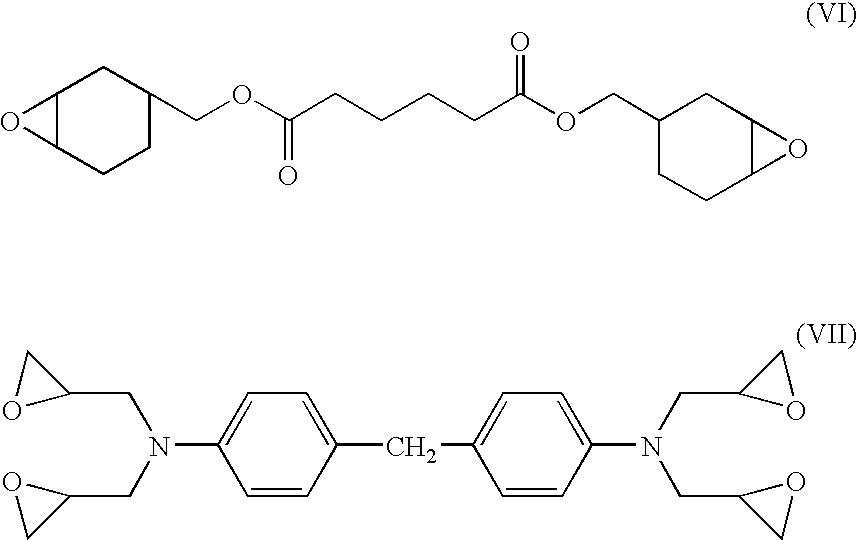

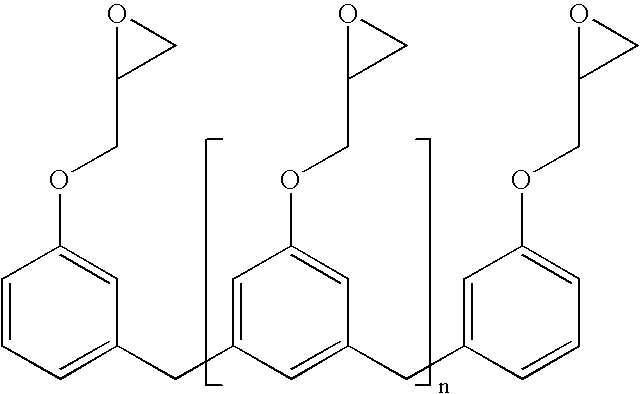

[0011] Basically a plurality of monomers, cross-linkable compounds, or mixtures of such compounds may be used as resin component A. Partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com