Integral direct drive device of gantry crane

An all-in-one, door machine technology, applied in transportation and packaging, elevators in buildings, etc., can solve the problems of occupying space, complicated structure, difficult installation, debugging, maintenance, etc., to save system space, compact structure, installation and maintenance. Easy and fast debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

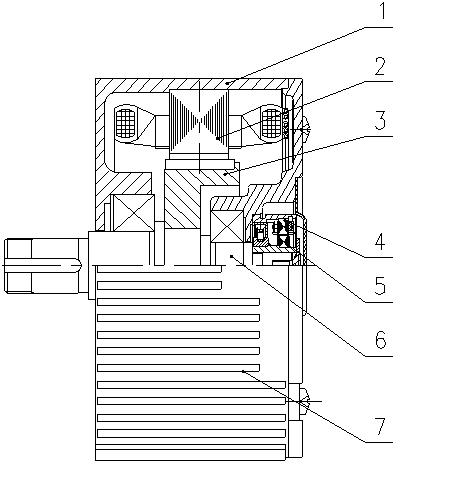

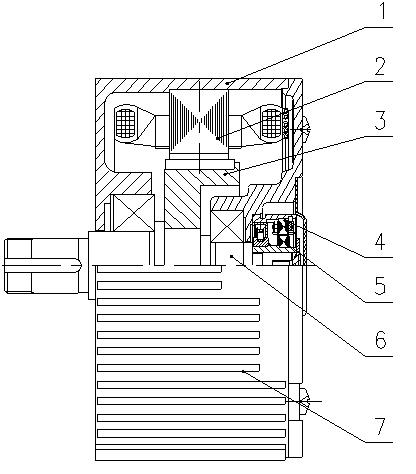

[0007] Such as figure 1 As shown, the present invention installs the rotor 3 of the permanent magnet direct drive motor and the rotor 5 of the signal detector on the rotating shaft 6 of the direct drive device in the housing 1 respectively, and the stator 2 of the permanent magnet direct drive motor and the stator 4 of the signal detector are respectively installed on the Inside the housing 1, the rotor 3 of the permanent magnet direct drive motor and the stator 2 of the permanent magnet direct drive motor cooperate with each other; the rotor 5 of the signal detector and the stator 4 of the signal detector cooperate with each other to form a rotary transformer. Radial cooling fins 7 are also integrated outside the housing 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com