Power apparatus for aircraft

A power device and aircraft technology, which is applied in the direction of driving multiple propellers, aircraft parts, transportation and packaging, etc., can solve the problems of low power factor, poor flight performance, and reduced reliability of axial fans, and achieve high performance Excellent, high power load, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

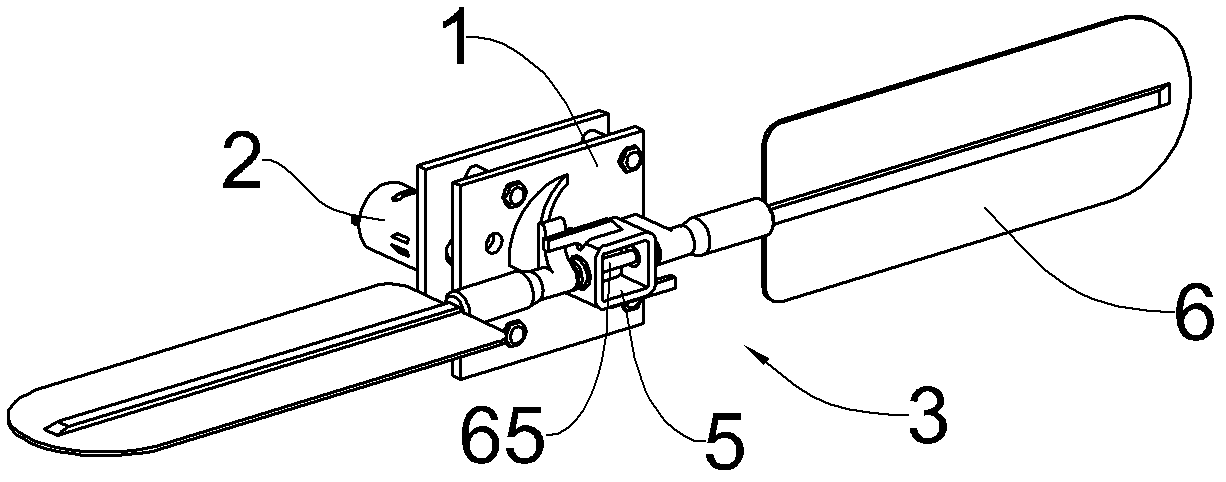

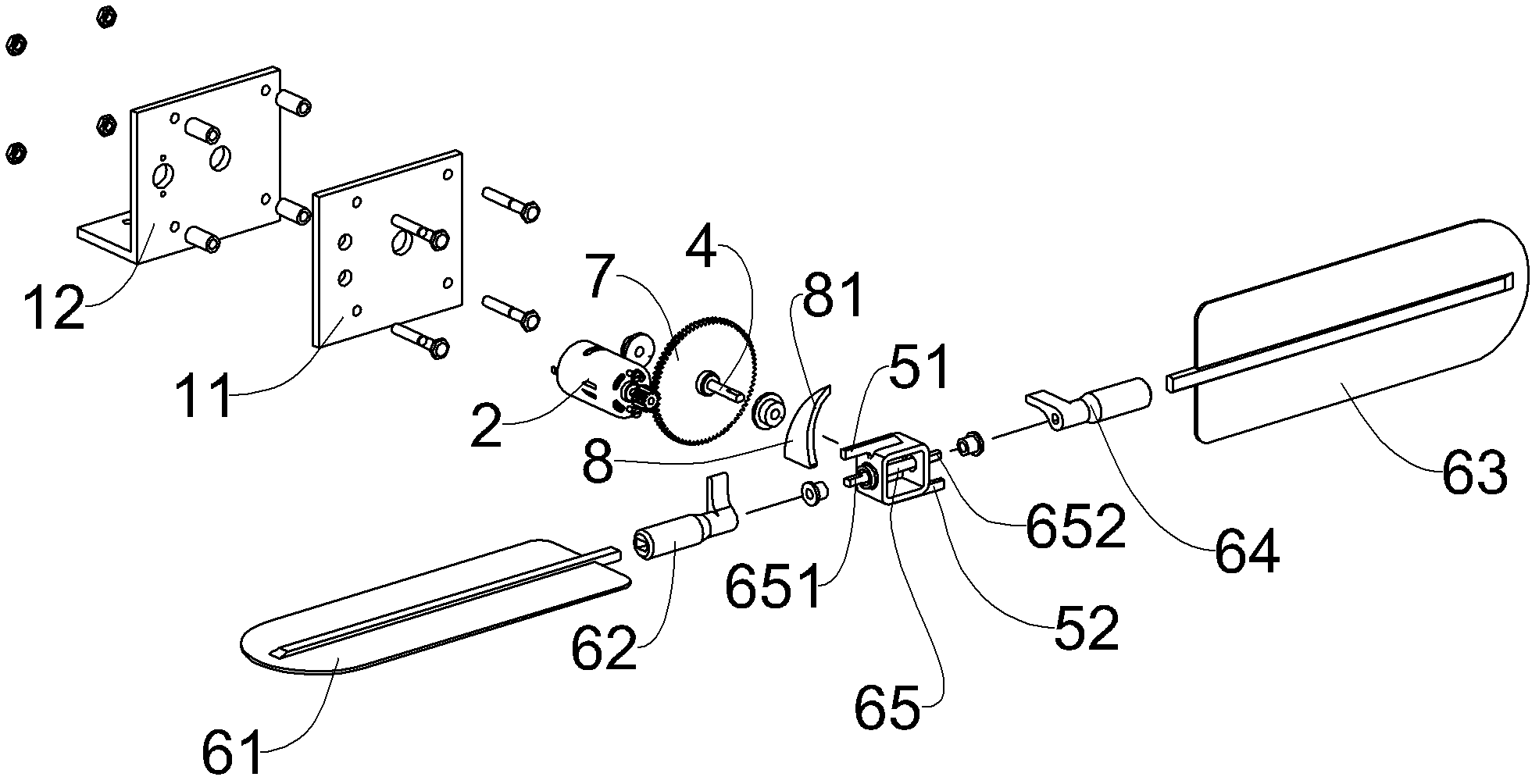

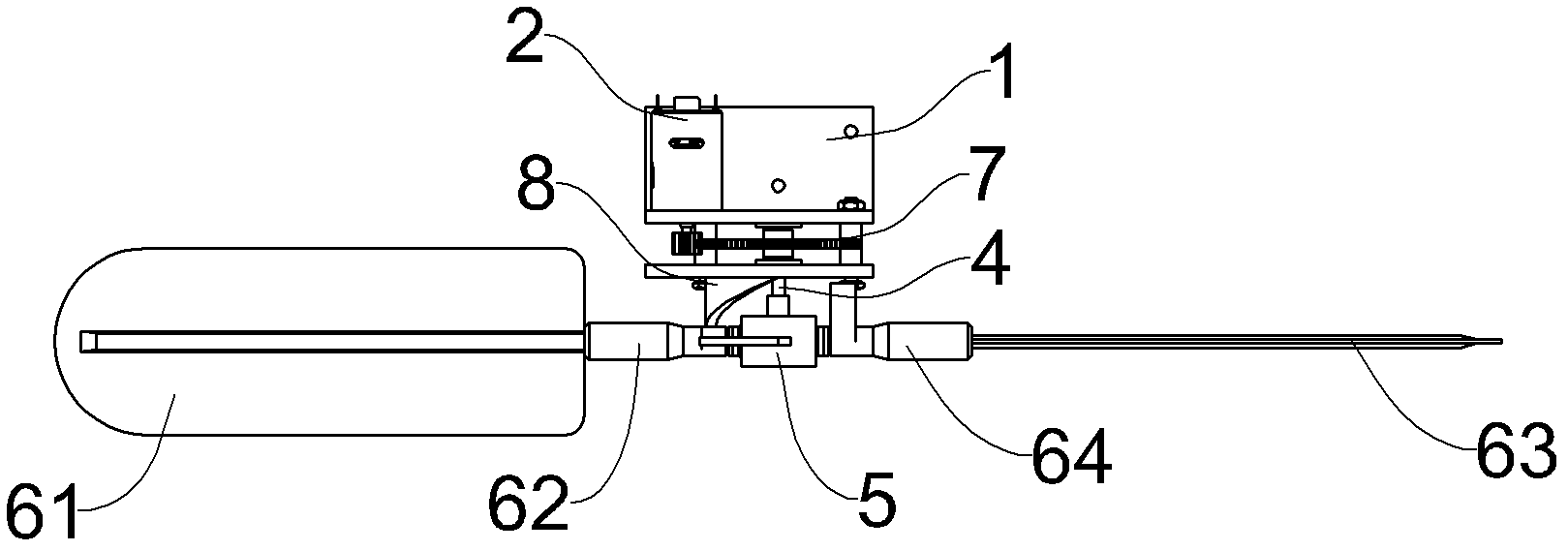

[0032] Figure 1 to Figure 4 A power device for an aircraft is shown, comprising a base 1, a motor 2 as a driving source, and a propeller 3 driven by the motor 2, and the propeller 3 includes a propeller shaft 4, a propeller hub 5 and a propeller The blade assembly 6, the motor 2 is connected with the propeller shaft 4 through the transmission gear set 7 to drive its rotation, the propeller shaft 4 and the blade assembly 6 are connected through the propeller hub 5, when the propeller shaft 4 rotates, its Drive the propeller hub 5 and the propeller assembly 6 to rotate around the axis of the propeller shaft 4 together. The base 1 is composed of a front base plate 11 and a rear base plate 12. The motor 2 is mounted on the rear side of the rear base plate 12. The transmission gear set 7 is located between the front base plate 11 and the rear base plate 12. The propeller shaft 4 passes through the front base plate 11.

[0033] The paddle assembly 6 includes a first blade 61, a fi...

Embodiment 2

[0038] Figure 10 and Figure 11 The power unit shown for the aircraft also includes a base 1, a motor 2 as a driving source, and a propeller 13 driven by the motor 2 to rotate. The propeller 13 includes a propeller shaft 14, a hub 15 and a "Four groups of paddle assemblies 161, 162, 163, 164 distributed in the shape of a font, the motor 2 is connected with the propeller shaft 14 through the transmission gear set 7 to drive its rotation, the propeller shaft 14 and the four groups of paddle assemblies 161, 162, 163 , 164 are connected by the propeller hub 15 , when the propeller shaft 14 rotates, it drives the propeller hub 15 and four sets of blade assemblies 161 , 162 , 163 , 164 to rotate around the axis of the propeller shaft 14 together. The base 1 is composed of a front base plate 11 and a rear base plate 12. The motor 2 is mounted on the rear side of the rear base plate 12. The transmission gear set 7 is located between the front base plate 11 and the rear base plate 12...

Embodiment 3

[0045] Such as Figure 14 to Figure 19 As shown, the power unit of this embodiment also includes a base 1, a motor 2, and a propeller 23 driven by the motor 2, which are similar to those shown in the first embodiment. In addition, this embodiment is also A volute 20 is added on the basis of the power device shown in Embodiment 1. The bottom of the volute 20 has an air outlet 201 , and the upper part has an air inlet 202 . The propeller 23 is arranged inside the volute 20 . When the propeller 23 rotates in the volute 20, an airflow is generated, and the volute 20 plays the role of guiding the airflow and concentrating it to be ejected from the air injection port 201. When the air injection port 201 sprays downward, a lift is generated, and when the air injection port 201 sprays air backward produce forward thrust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com