A kind of convective heat sink and its manufacturing method

A heat sink and heat pipe technology, which is applied in the field of convection heat sink and its production, can solve the problem of large unit power load, etc., and achieve the effect of large power load, good density consistency, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

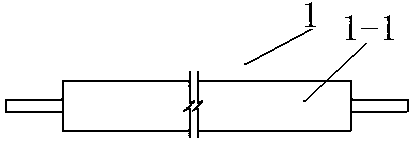

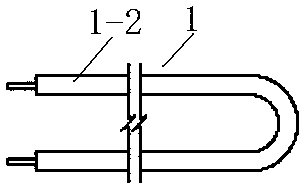

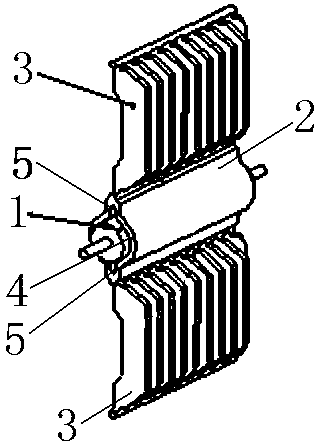

[0023] Refer to attached Figure 1~5 , a convection radiator includes a heat pipe 2, a heat sink 3 and an electric heating pipe 1. Heat pipe 2 is provided with electric heating pipe installation hole 4, heat pipe installation hole 4 is provided with shrinkage joint (groove) 5, electric heat pipe 1 is installed in electric heat pipe installation hole 4, and heat dissipation pipe 2 is equipped with heat sink 3 outside, heat sink 3 There are compensation shrinkage joints. The heat sink 3 adopts guide fins.

[0024] Radiating fins 3 are distributed symmetrically on the outside of the heat pipe 2 . See attached image 3 .

[0025] The heat sink 3 adopts the guide fins made up and down of the heat pipe. See attached image 3 .

[0026] Compensating shrinkage joints 6 are left in the longitudinal direction of the heat sink 3 . See attached Figure 4 .

[0027] The compensation shrinkage joint 6 is provided with openings, and the openings are in staggered directions, or in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com