Aircraft with centrifugal fan capable of vertically taking off and landing

A centrifugal fan and vertical take-off and landing technology, applied in the aviation field, can solve the problems of small living space for passengers, low reliability, and poor flight performance, and achieve the effects of convenient and flexible operation, simple and reliable structure, and stable airflow of working medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

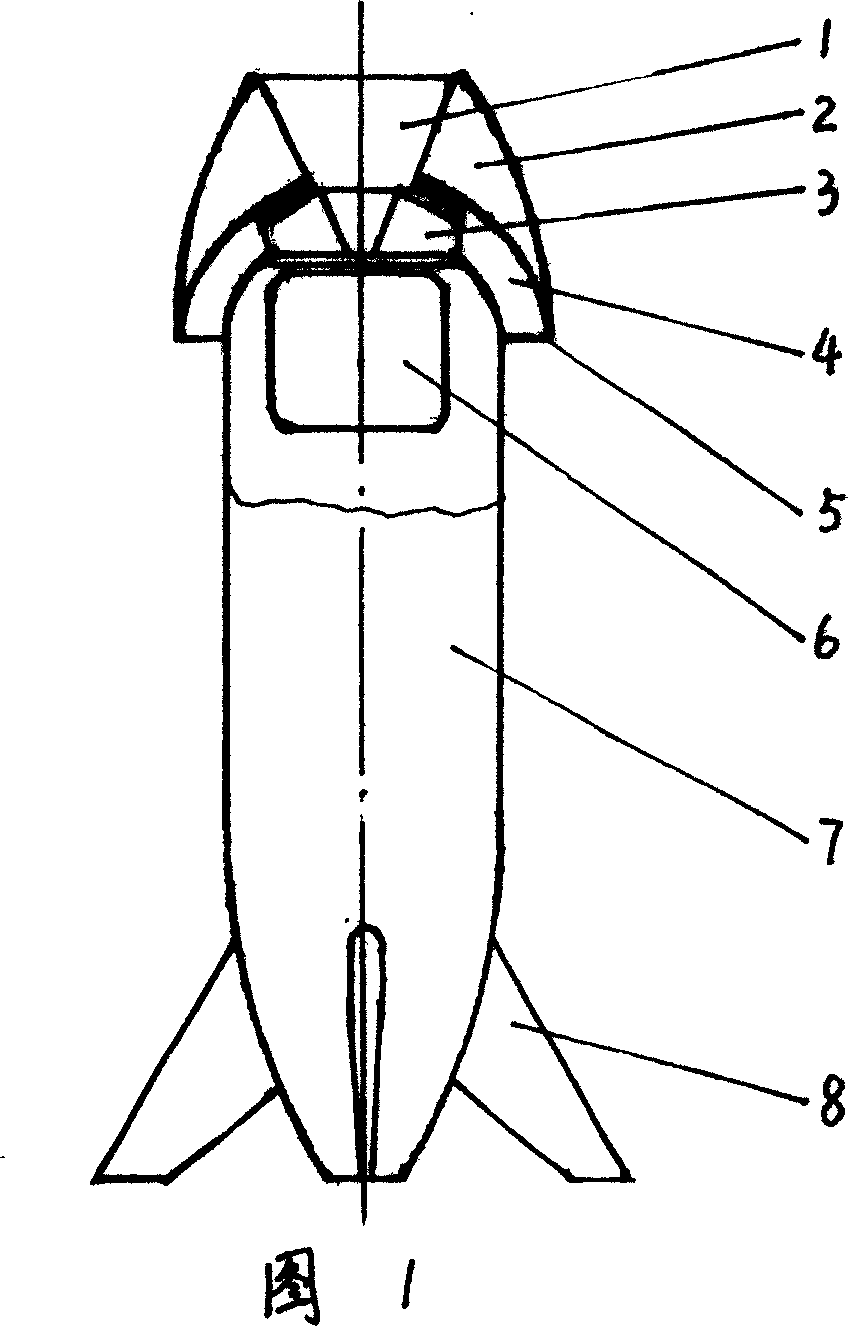

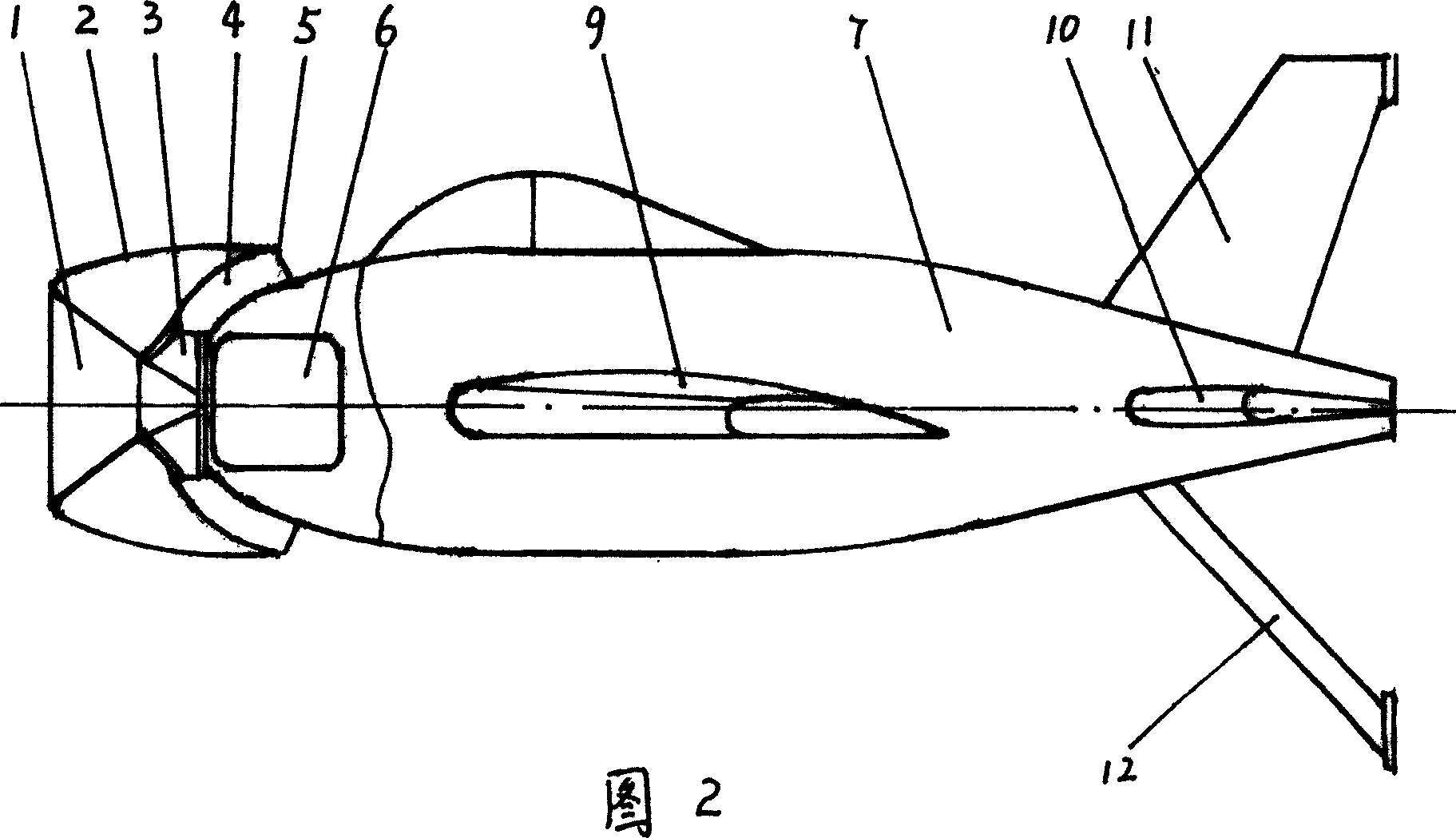

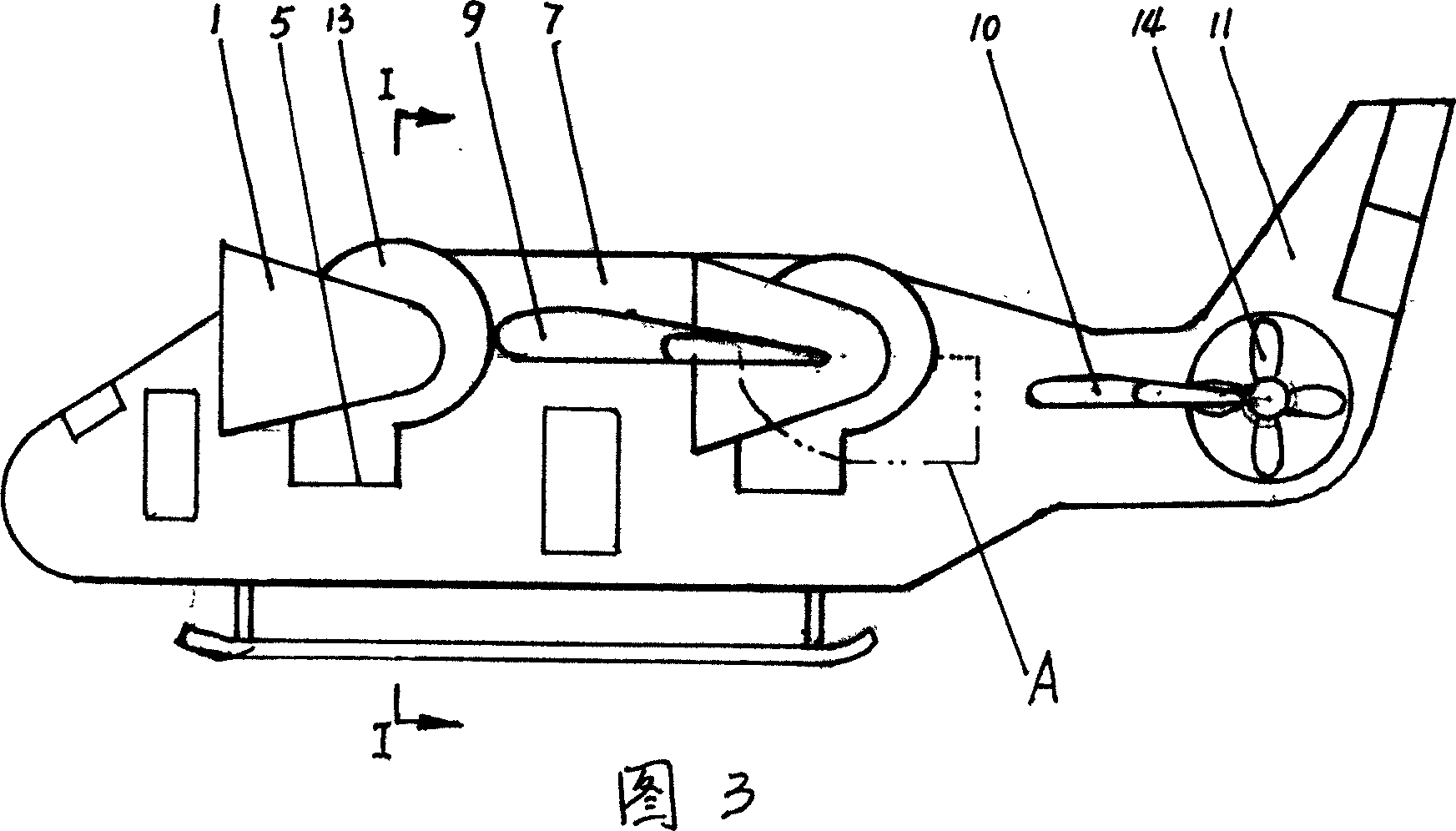

[0014] Among Fig. 1, the centrifugal fan 3 is located at the front of the fuselage, and the motor 6 is connected with the centrifugal fan 3 or connected with the motor through a transmission mechanism. In front of the centrifugal fan 3, an air inlet 1 and a fairing 2 are arranged, and the centrifugal fan The periphery of 3 is provided with air outlet 5 and wind deflector 4, and the rear of fuselage 7 is provided with empennage 8, and aircraft becomes vertical state after landing and take-off, when engine 6 drives centrifugal fan 3 to rotate, air can pass through Centrifugal fan 3 produces dynamic pressure energy and escapes into the atmosphere from the air outlet at a high speed, and produces a reaction force to make the aircraft rise. Manipulating the empennage 8 makes the aircraft tilt or become horizontal, and the aircraft can fly forward. The empennage 8 can be used as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com