Bearing assembly and disassembly tool

A technology for assembly and disassembly of tools, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of unreliable connection between the pulling claw and the bearing, the pulling claw is easy to break, and the pulling force of the pulling claw is inconsistent. The effect of slippage, strong pull plate and large pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

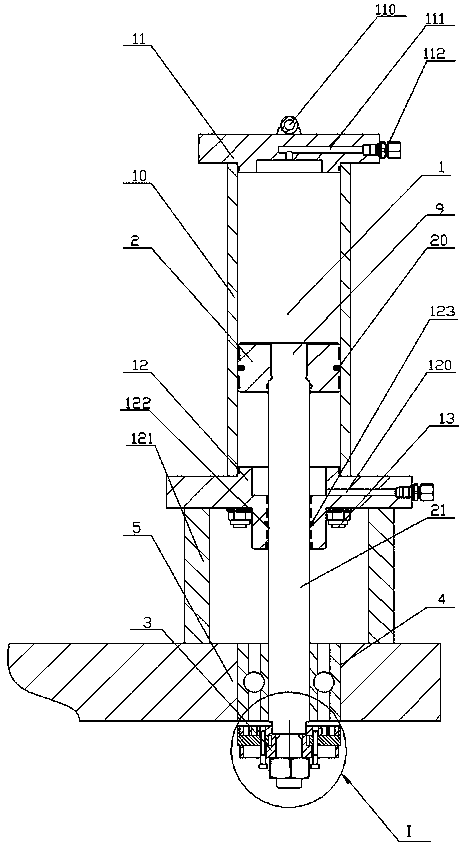

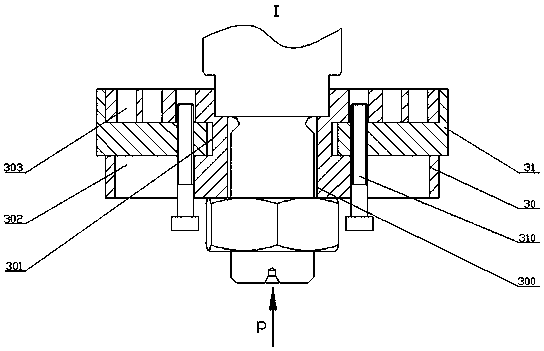

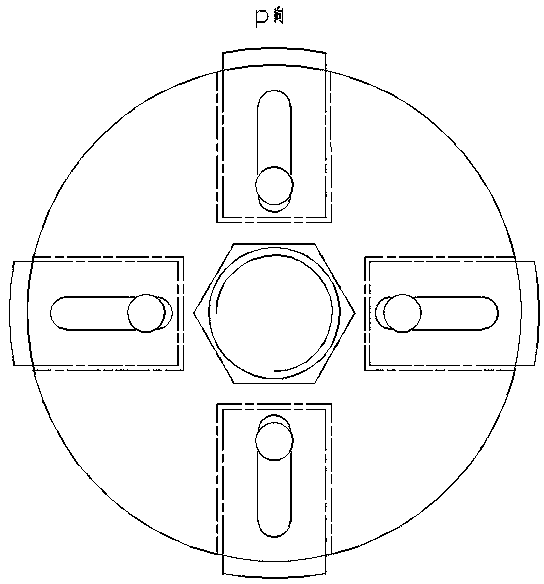

[0010] Such as figure 1 , figure 2 and image 3 As shown, the technical solution adopted in this specific embodiment is: a bearing assembly and disassembly tool, which is composed of an oil cylinder 1, a piston 2 and a pulling plate 3, and the oil cylinder 1 is composed of a cylinder body 10, an upper cover 11 and a lower cover 12 , the upper cover 11 is provided with earrings 110, the side is provided with an upper oil inlet 111, and the upper oil inlet 111 is equipped with an oil inlet joint 112; the side of the lower cover 12 is provided with a lower oil inlet 120, and the lower cover 12 is provided with There is a pillar 121, the center of the lower cover 12 is provided with a slotted through hole 122, and the through hole 122 is provided with a sealing ring 123 in the groove; the upper cover 11 and the lower cover 12 are connected and fixed to the cylinder body through a connecting rod 13 10 at the upper and lower ends, the piston 2 is provided with a sealing ring 20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com