Pull disc

A technology of trays and pull rods, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of unreliable connection between the claw and the bearing, inconsistent pulling force of the claw, and easily damaged bearings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

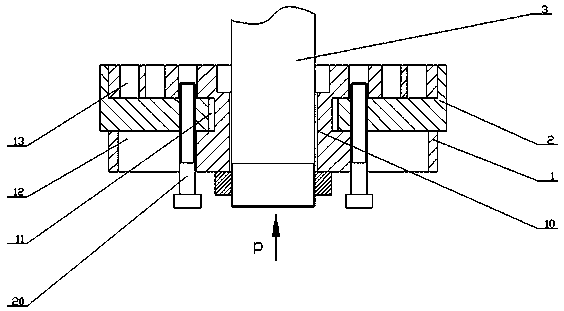

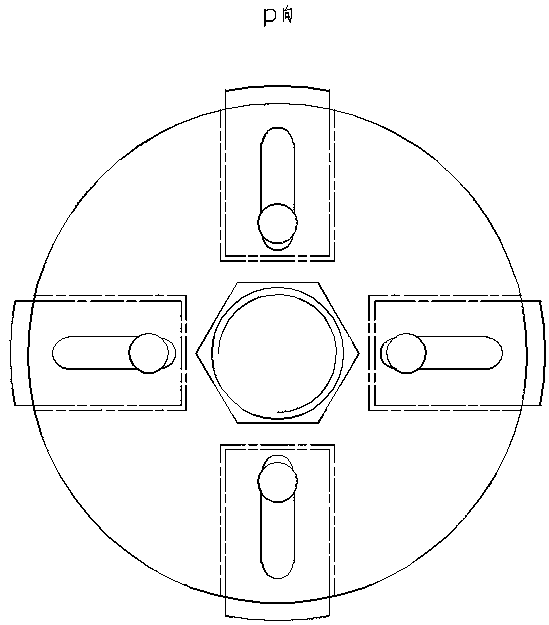

[0008] Such as figure 1 and figure 2 As shown, the technical solution adopted in this specific embodiment is: a pull plate, consisting of a tray 1 and a slider 2, the center of the tray 1 is provided with a through hole 10 connected to one end of the pull rod 3; the middle of the side of the tray 1 A plurality of chutes 11 extending horizontally to the center of the tray 1 are arranged at intervals along the circumference; a plurality of guide grooves 12 connected with the chutes 11 are arranged on the bottom of the tray 1; , and the positioning hole 13 corresponding to the guide groove 12, the slider 2 is set in the chute 11 of the tray 1, one end of the slider 2 is provided with a positioning pin 20, and one end of the positioning pin 20 can be inserted into the positioning hole on the tray 1 13, the other end of the positioning pin 20 stretches out of the guide groove 12 below the tray 1.

[0009] When assembling or disassembling the bearing, according to the diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com