Stretching resistance detection device of curtain wall embedded part used for anchor plate construction after embedded

A technology of detection devices and embedded parts, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that the test space cannot meet the requirements, do not have operability, hidden dangers of curtain wall safety, etc., to increase scientific demonstration Sexuality, avoiding bad hidden dangers, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

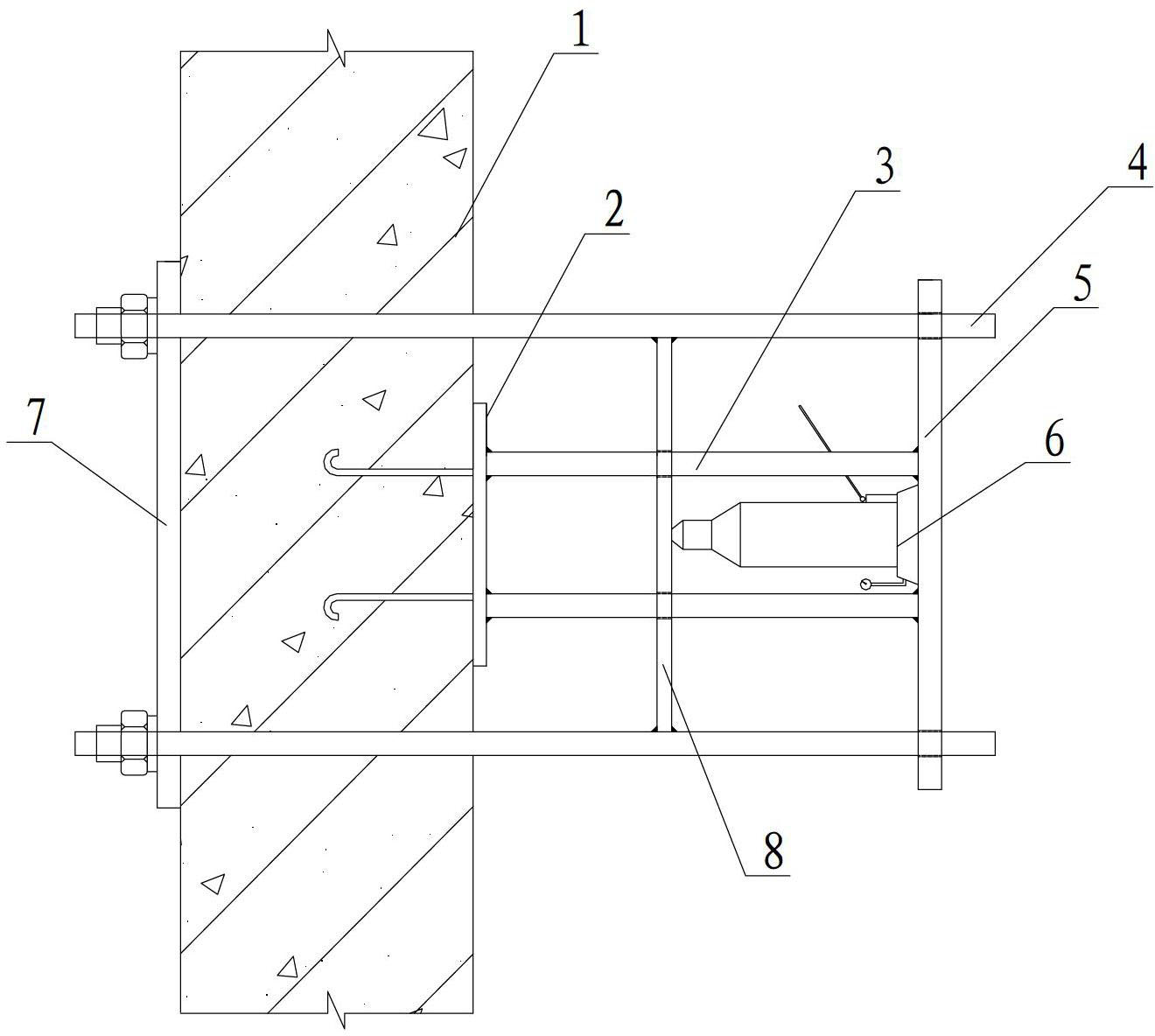

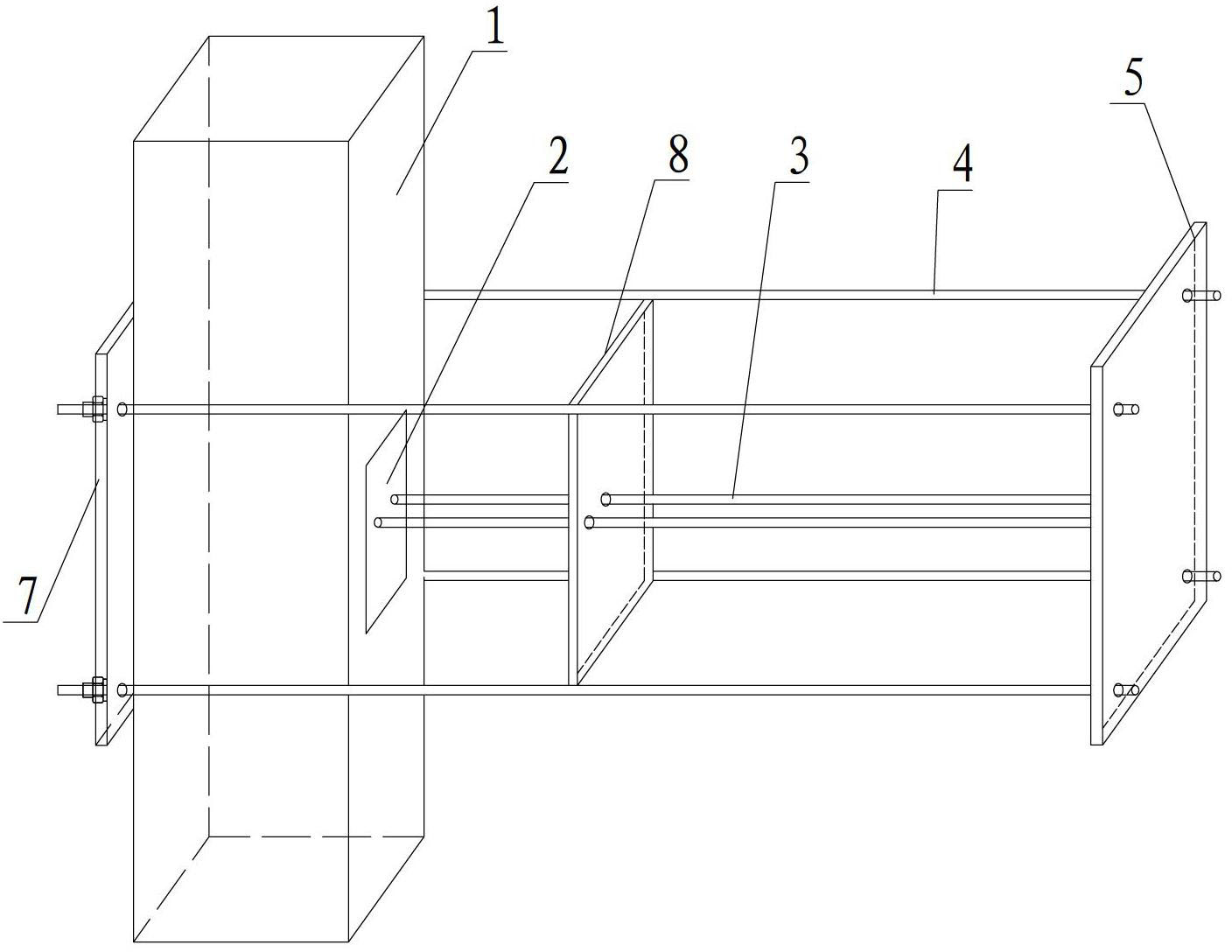

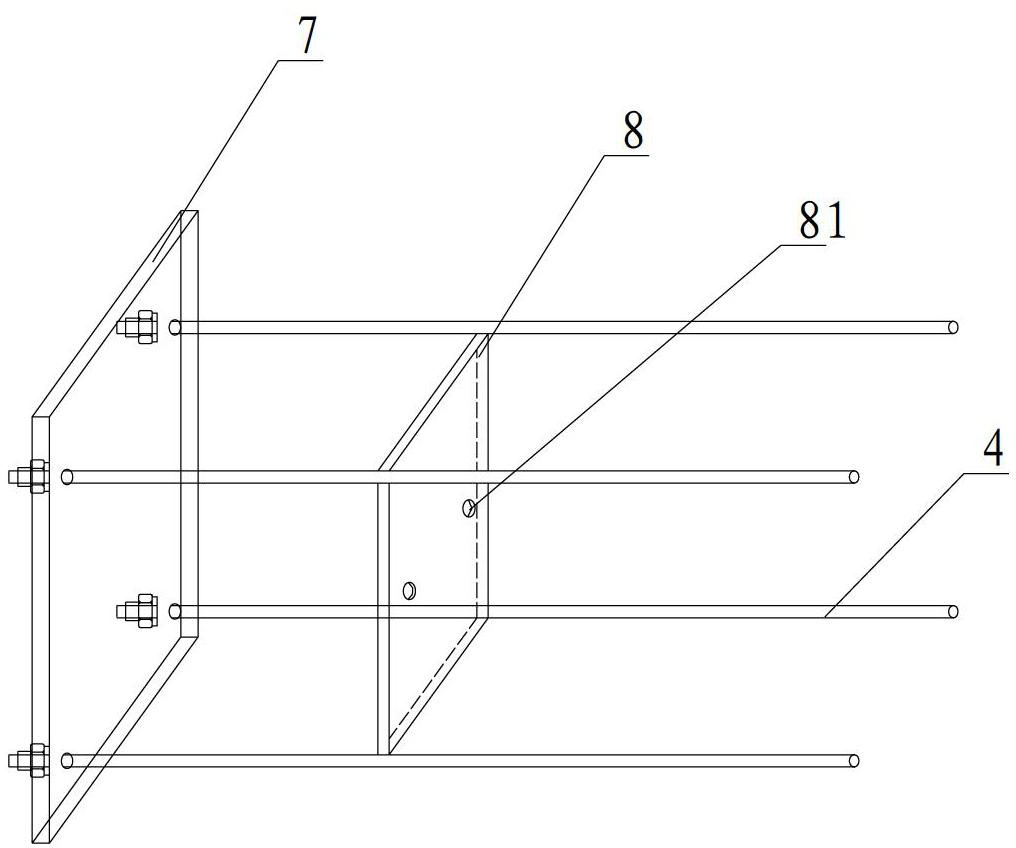

[0029] A tensile force detection device for embedded curtain wall embedded parts used for anchor plate structure. The detection device includes a fixed bracket attached to the outer surface of the main structure and a sliding bracket that is slidably mounted on the fixed bracket; the fixed bracket includes A pair of symmetrical rods vertically attached to the main structure, all rods are fixed to a connecting plate, the connecting plate is perpendicular to the rods, and a guide hole is provided in the middle; the sliding bracket includes sliding wear on all the rods The tie rod support plate far away from the end of the main structure, the tie rod support plate is parallel to the connecting plate, and the main structure is arranged on both sides of the connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com