Airing rack for textile processing and capable of improving airing efficiency of textiles

A technology for textiles and drying racks, applied in the field of textile processing, which can solve the problems of high cost and inability to change the drying position, and achieve the effect of improving the drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

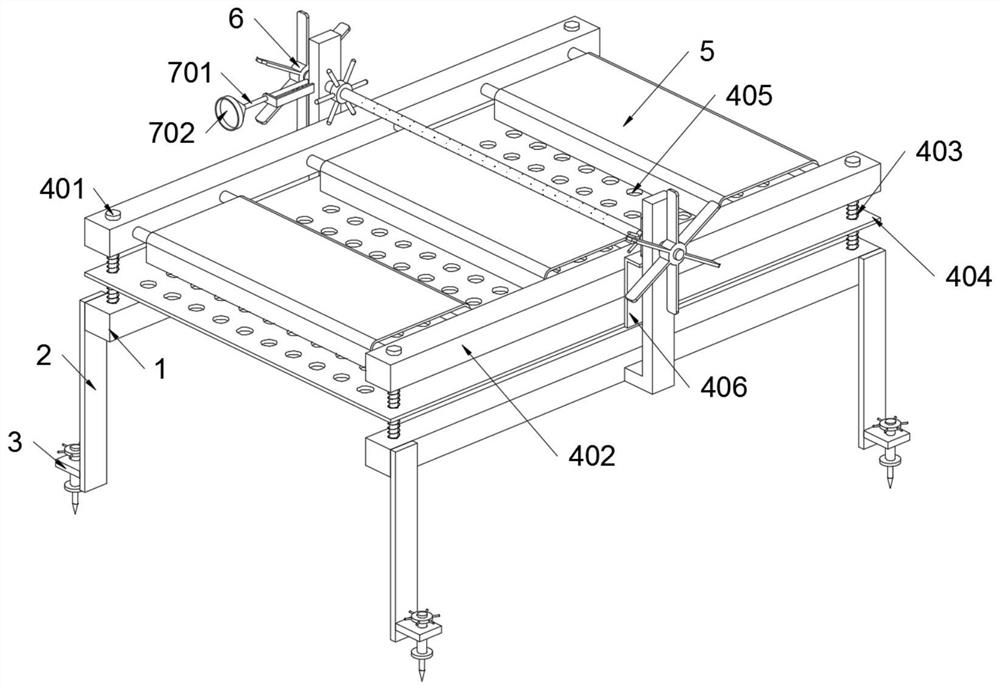

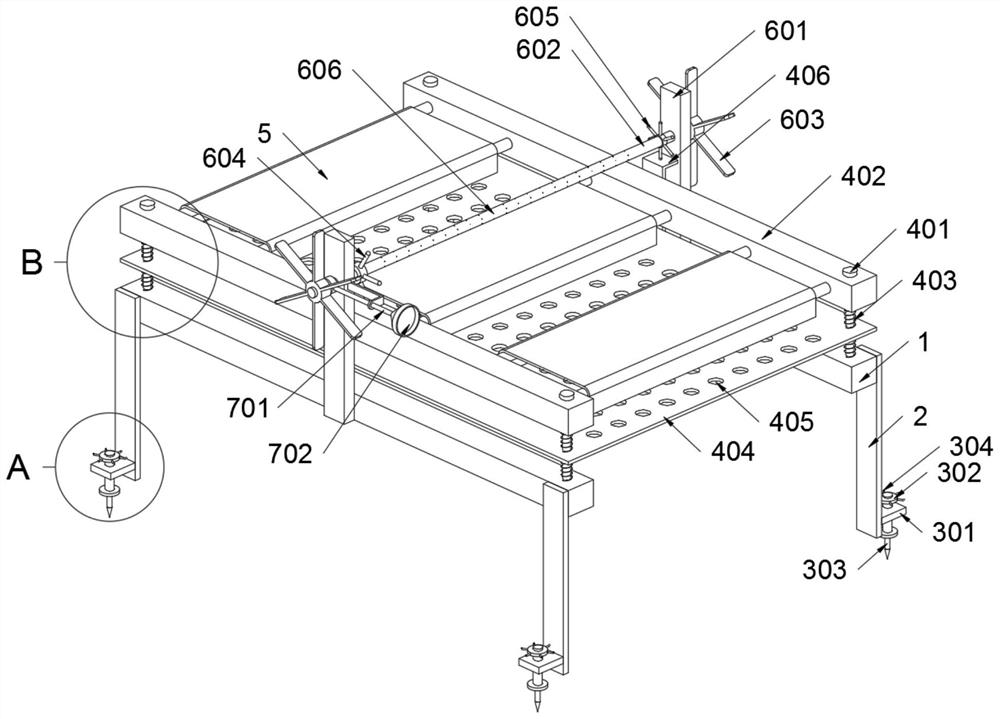

[0035]as attached figure 1 To attach Figure 8 Shown:

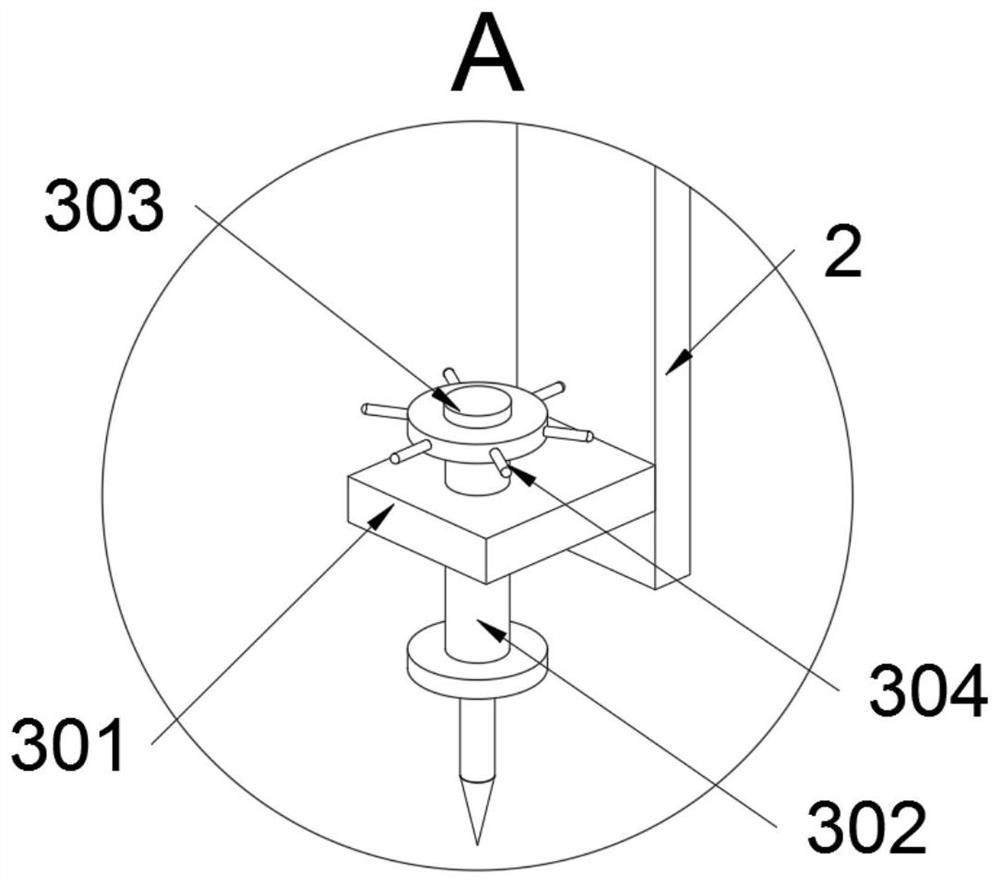

[0036] The present invention provides a drying rack for textile processing that improves the drying efficiency of textiles, comprising a rack body 1; four supporting legs 2 are welded on the rack body 1, and a fixing structure 3 is welded on each supporting leg 2 ; A drying structure 4 is installed on the frame body 1, and a cloth 5 is placed on the drying structure 4; a driving structure 6 is installed on the frame body 1, and an auxiliary structure 7 is installed on the driving structure 6; figure 2 , the driving structure 6 includes a rotating seat 601, a pipe body 602, blades 603 and a toggle lever A604, the rotating seat 601 is welded on the frame body 1, and the pipe body 602 is welded with blades 603; the pipe body 602 is welded in an annular array There is a toggle rod A604, and the head end of the toggle rod A604 is in elastic contact with the top surface of the drying rack 402; The continuous toggling struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com